The global zinc roofing market is experiencing steady growth, driven by rising demand for durable, sustainable, and aesthetically pleasing building materials. According to Mordor Intelligence, the global zinc market is projected to grow at a CAGR of over 3.8% from 2024 to 2029, with construction emerging as a key end-use sector. Zinc’s natural corrosion resistance, low maintenance requirements, and 100% recyclability make it a preferred choice for roofing applications, especially in commercial and high-end residential projects. Within this segment, zinc stripping—for ridge, hip, and edge detailing—plays a critical role in weatherproofing and architectural finish. With increasing urbanization and stricter building energy codes across Europe and North America, demand for high-performance zinc roofing components continues to rise. This report identifies the top 10 manufacturers leading innovation, quality, and market share in zinc stripping for roofs, based on production capacity, geographic reach, product performance, and sustainability practices.

Top 10 Zinc Stripping For Roofs Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Zinc Strip

Domain Est. 2019

Website: artazn.com

Key Highlights: We are the largest zinc strip producer in North America and have in-house capabilities for melting, alloying, casting, rolling, slitting, and plating operations ……

#2 Durable Industrial Finishing Company

Website: difco.us.com

Key Highlights: Zinc plating provides an attractive finish to metal surfaces while increasing corrosion and oxidation resistance. DIFCO provides zinc plating in a variety of ……

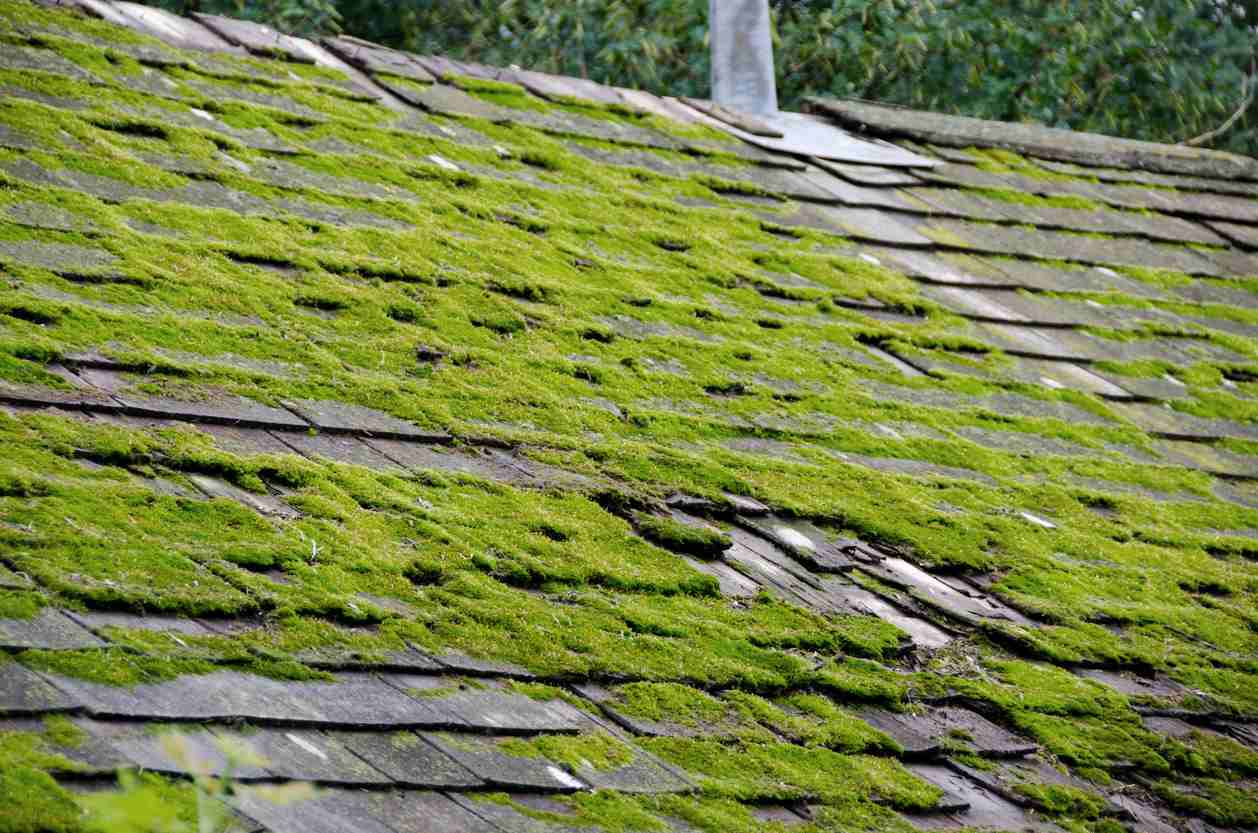

#3 Master Flow® Zinc Moss & Mildew Preventer

Domain Est. 1996

Website: gaf.com

Key Highlights: The zinc strip does not kill moss or mildew but helps inhibit their growth to help reduce the need for roof related to moss and mildew….

#4 Algae & Moss Prevention and Cleaning for Asphalt Roofing Systems

Domain Est. 1996

Website: asphaltroofing.org

Key Highlights: Adding zinc or copper strips to an existing roof is not recommended since this will require either applying the strips with exposed nails ……

#5 Goodbye Moss Zinc Strip

Domain Est. 1997

Website: menzies-metal.com

Key Highlights: Rating 5.0 (5) Size 2 2/3″ x 50′ (68mm x 15.24m)). Includes nails. Additional Information: Roof zinc strip to help prevent moss growth which can shorten shingle life….

#6 AZZ

Domain Est. 1997

Website: azz.com

Key Highlights: We are North America’s leading independent provider of hot-dip galvanizing and coil coating services. At AZZ, we provide sustainable, unmatched metal coating ……

#7 A durable zinc roofing

Domain Est. 1999

Website: nedzink.com

Key Highlights: Titanium zinc is flexible and suitable for any type of roofing ✔️ Maintenance-free and up to 100 years of life ✔️ Request a FREE sample now….

#8 Zinc Metallic® Coil, Flats, Metal Roofing

Domain Est. 2015

Website: westernstatesmetalroofing.com

Key Highlights: Zinc Metallic is a pre-painted metal that is designed to look like a weathered zinc or an old galvanized roof. This color has an aged metallic finish….

#9 Zinc strip

Website: grillo.de

Key Highlights: Customized zinc strip: Individually developed zinc strip with high flexibility, precise processing & a wide range of applications ▷ Find out more now!…

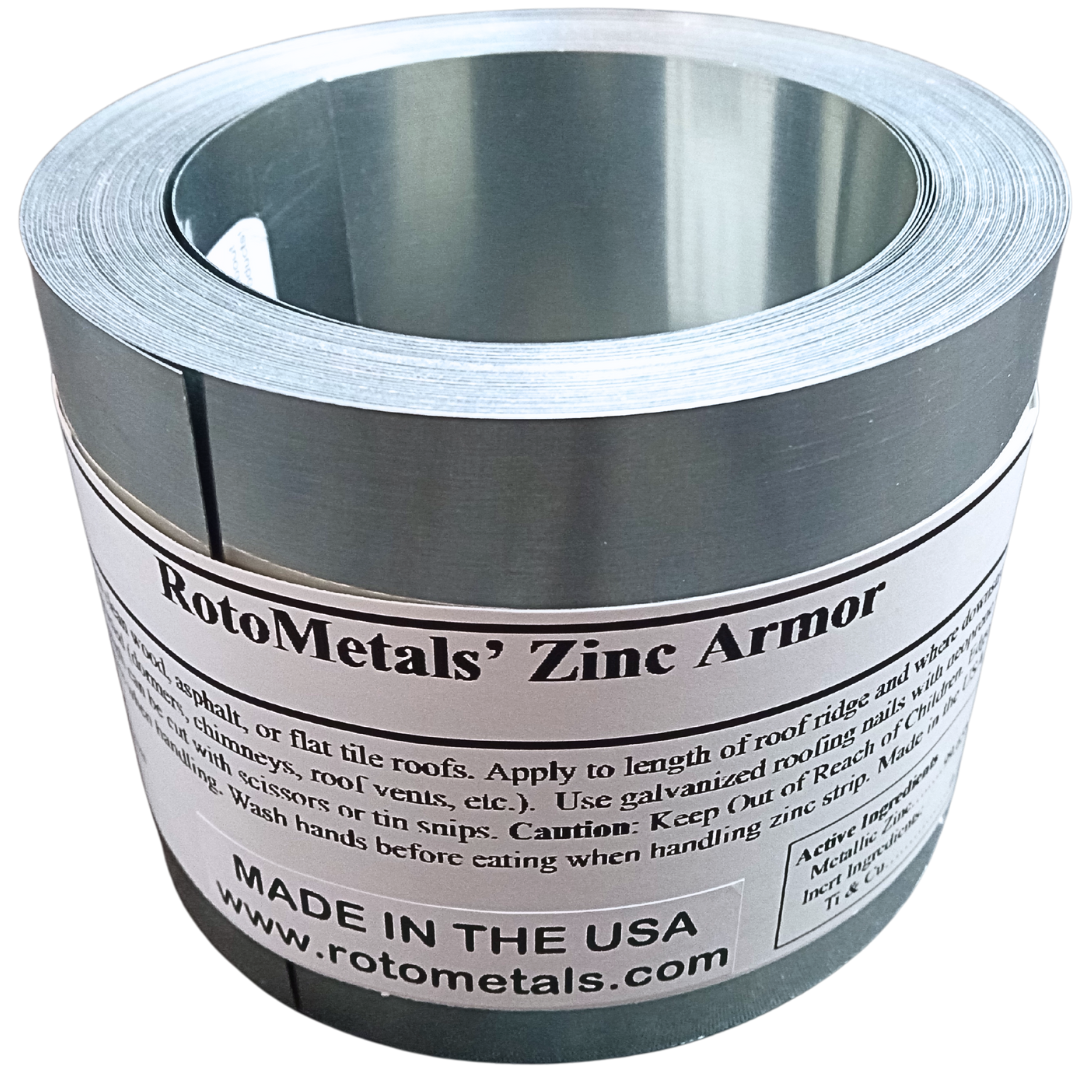

#10 Zinc Strip

Domain Est. 1996

Website: doitbest.com

Key Highlights: Explore a wide selection of premium Zinc Strip at Do it Best, including Z-Stop. ✓ Same day pick-up or home delivery….

Expert Sourcing Insights for Zinc Stripping For Roofs

H2: 2026 Market Trends for Zinc Stripping for Roofs

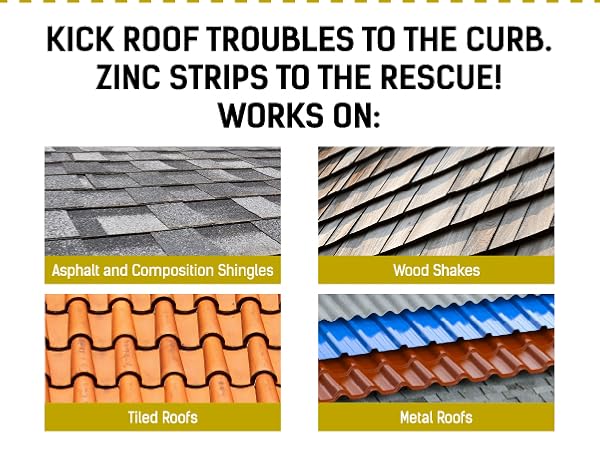

The global market for zinc stripping in roofing applications is poised for notable transformation by 2026, driven by increasing demand for sustainable building materials, advancements in architectural design, and growing focus on building longevity and weather resistance. Zinc stripping—used primarily for flashings, edging, and expansion joints on roofs—plays a critical role in ensuring water tightness and structural integrity, particularly in high-end residential, commercial, and heritage restoration projects.

One of the key drivers shaping the 2026 market landscape is the rising emphasis on green construction and energy-efficient buildings. Zinc, being 100% recyclable and requiring minimal maintenance over its lifespan (often exceeding 80–100 years), aligns perfectly with sustainability goals. As governments and private developers adopt stricter environmental regulations and pursue green certifications (such as LEED or BREEAM), the use of zinc in roofing components is expected to grow significantly.

Technological improvements in pre-weathered and coated zinc strips are also influencing market trends. By 2026, manufacturers are anticipated to offer more customized zinc solutions with enhanced corrosion resistance, improved formability, and aesthetic versatility. These innovations cater to architects seeking modern, minimalist designs with clean lines and long-term visual consistency.

Geographically, Europe remains the largest market for zinc roofing products due to its long-standing tradition in zinc usage and strong architectural heritage. However, North America and parts of Asia-Pacific (notably Japan and Australia) are witnessing accelerated adoption, fueled by urban redevelopment and high-performance building standards.

Additionally, supply chain dynamics and raw material costs will impact the 2026 market. Fluctuations in zinc prices, influenced by global mining output and industrial demand from sectors like automotive and construction, may affect affordability. However, increased regional production and recycling infrastructure are expected to mitigate some volatility.

In summary, by 2026, the zinc stripping for roofs market will be characterized by innovation, sustainability, and expanding geographic reach. Stakeholders—from manufacturers to architects—will increasingly prioritize durability, environmental performance, and design flexibility, solidifying zinc’s role as a premium material in modern roofing systems.

Common Pitfalls When Sourcing Zinc Stripping for Roofs (Quality & Intellectual Property)

Sourcing zinc stripping for roofing projects requires careful attention to both material quality and intellectual property considerations. Overlooking these aspects can lead to performance failures, legal risks, and reputational damage. Below are key pitfalls to avoid:

Poor Material Quality and Specifications

One of the most frequent issues in sourcing zinc stripping is the procurement of substandard material. Buyers may encounter zinc that does not meet required thickness, alloy composition, or surface finish standards. Off-spec zinc can corrode prematurely, warp under thermal stress, or fail to integrate properly with other roofing components. Always verify compliance with international standards such as EN 988 or ASTM B867, and request mill test certificates to confirm material properties.

Lack of Traceability and Certification

Reputable zinc suppliers provide full traceability, including batch numbers and certification of origin. Sourcing from suppliers who cannot offer documentation increases the risk of receiving recycled or reprocessed material that lacks performance guarantees. Without proper certification, it becomes difficult to validate claims about corrosion resistance, longevity, and suitability for architectural use.

Intellectual Property Infringement

Many premium zinc products—such as those from established brands like VMZINC, Rheinzink, or EQUITONE—are protected by trademarks, patents, or design rights. A common pitfall is sourcing look-alike or counterfeit materials that mimic the appearance of branded zinc but infringe on intellectual property. Using such materials can expose architects, contractors, and building owners to legal action, project delays, and costly replacements.

Misrepresentation of Finish and Aging Characteristics

Zinc develops a protective patina over time, and high-quality products are designed to age uniformly. Inferior zinc stripping may exhibit inconsistent coloring, staining, or premature degradation due to improper alloying or surface treatment. Suppliers may misrepresent the finish (e.g., pre-weathered, matte, or anthracite) without delivering the expected aesthetic or functional performance.

Inadequate Supplier Vetting

Choosing suppliers based solely on price or availability—especially from unfamiliar or offshore sources—can result in unreliable delivery, poor customer support, and lack of technical guidance. It’s essential to vet suppliers for industry experience, client references, and adherence to ethical manufacturing practices to ensure long-term project success.

Overlooking Environmental and Compliance Standards

Some zinc products may not comply with environmental regulations such as REACH or RoHS, particularly if sourced from regions with lax oversight. This can lead to compliance issues in projects requiring sustainable certifications (e.g., LEED, BREEAM). Ensure that the zinc stripping is produced responsibly and meets all relevant environmental and health standards.

By addressing these pitfalls proactively—through rigorous supplier evaluation, verification of certifications, and respect for intellectual property—stakeholders can ensure the durability, legality, and aesthetic integrity of zinc roof installations.

Logistics & Compliance Guide for Zinc Stripping for Roofs

Transportation and Handling

Zinc stripping must be transported and handled with care to prevent damage and ensure safety. Use padded, non-abrasive materials when loading and unloading to avoid scratches or deformation. Secure strips in bundles with protective spacers during transit to prevent movement and surface wear. Transport in covered vehicles to shield from moisture and contaminants. Always handle with clean gloves to minimize oxidation and oil transfer from skin.

Storage Requirements

Store zinc strips in a dry, well-ventilated indoor environment, preferably off the ground on wooden pallets or racks. Keep materials wrapped in original protective packaging until ready for installation. Avoid stacking heavy materials on top of zinc bundles to prevent warping. Maintain separation from dissimilar metals (e.g., copper, aluminum) to avoid galvanic corrosion. Monitor humidity levels to reduce the risk of surface tarnishing or white rust formation.

Installation Compliance Standards

Installation of zinc strips must adhere to manufacturer specifications and regional building codes. Follow proper fastening techniques using compatible, non-corrosive fasteners (e.g., stainless steel). Ensure adequate overlap and spacing between strips as per design guidelines to accommodate thermal expansion. Install in accordance with local wind uplift and weather resistance standards (e.g., ASTM E1592, IBC Chapter 15). Flashing and edge details must comply with roofing system requirements to maintain watertight integrity.

Environmental and Safety Regulations

Comply with environmental regulations regarding zinc runoff, especially in areas with sensitive water systems. Install gutter and downspout filters where required to minimize zinc particle discharge. Follow OSHA safety standards during handling and installation—use fall protection, cut-resistant gloves, and eye protection when working with metal tools. Recycle zinc waste and offcuts through certified metal recyclers to meet environmental sustainability goals.

Documentation and Certification

Maintain records of material certifications, including mill test reports confirming zinc composition (e.g., EN 988, ASTM B929). Keep copies of product warranties, installation manuals, and compliance declarations. Submit required documentation to building inspectors or certification bodies as part of project closeout. Ensure contractors are trained and certified by the zinc product manufacturer, where applicable, to validate warranty coverage.

Conclusion: Sourcing Zinc Stripping for Roofs

In conclusion, sourcing zinc stripping for roofing applications requires a careful balance between quality, durability, cost, and supplier reliability. Zinc stripping offers superior corrosion resistance, longevity, and an aesthetically pleasing natural patina, making it an excellent choice for high-performance roof detailing—especially in flashing, edging, and expansion joints. When sourcing, it is essential to select materials that meet recognized industry standards (such as EN 988 or ASTM B867) to ensure purity and performance.

Prioritizing reputable suppliers with experience in architectural metals ensures consistent product quality and technical support. Factors such as lead times, sustainability practices (including recyclability and low environmental impact), and compliance with local building codes should also influence the decision-making process. While the initial cost of zinc may be higher than alternatives like aluminum or galvanized steel, its long service life and low maintenance reduce lifecycle costs significantly.

Ultimately, investing in high-quality zinc stripping from trusted sources enhances the durability and aesthetic integrity of roofing systems, contributing to sustainable and resilient building solutions. Proper sourcing today supports long-term building performance and client satisfaction.