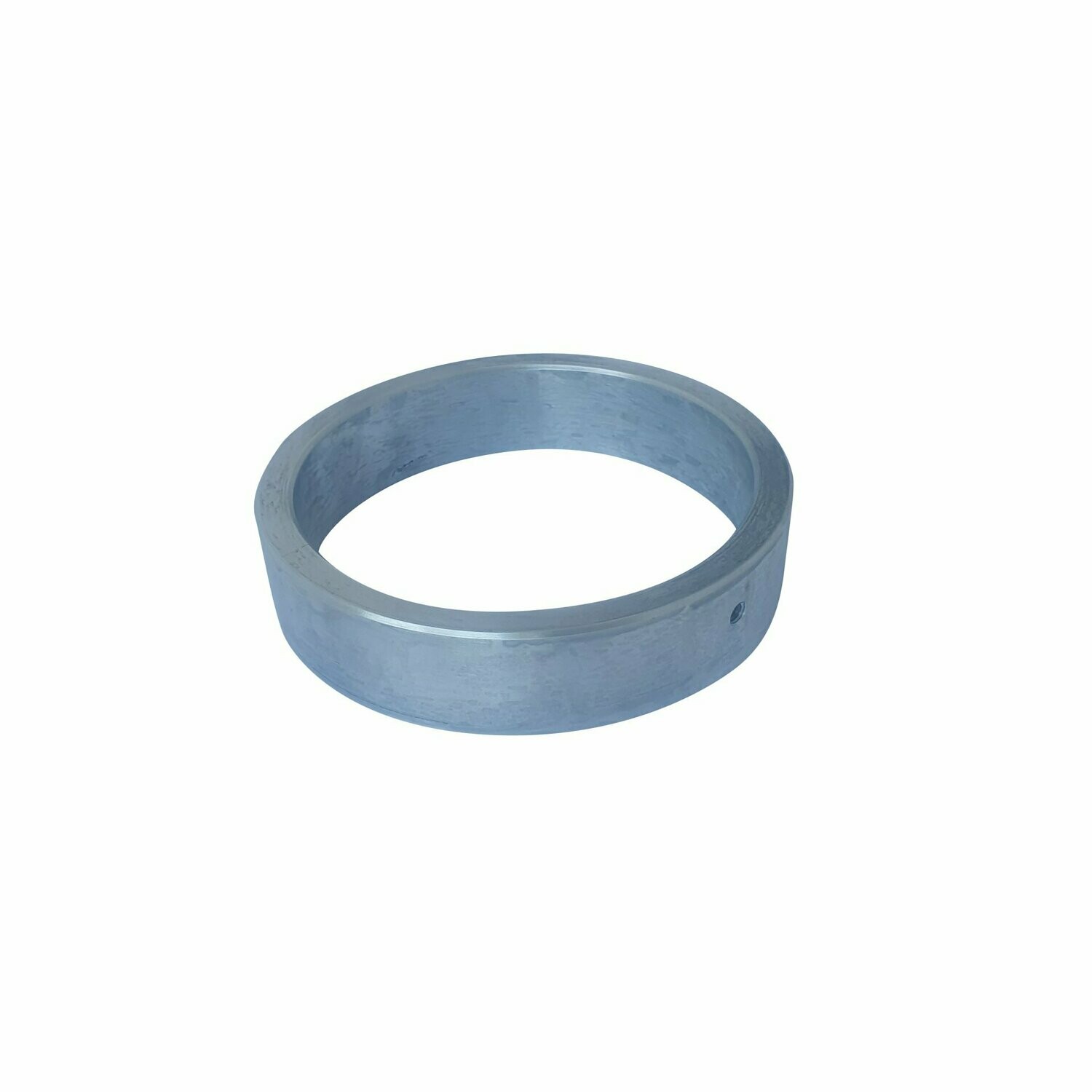

The global zinc ring market is experiencing steady growth, driven by increasing demand across industrial, construction, and consumer electronics sectors. According to a 2023 report by Mordor Intelligence, the global zinc die-casting market—which includes critical components like zinc rings—is projected to grow at a CAGR of over 5.8% from 2023 to 2028. This expansion is fueled by zinc’s superior corrosion resistance, cost-effectiveness, and excellent casting precision, making it ideal for high-performance applications. Additionally, rising infrastructure development in emerging economies and the push for lightweight, durable materials in manufacturing are amplifying demand. As the market becomes more competitive, identifying leading manufacturers who deliver quality, scalability, and innovation is crucial for procurement leaders and supply chain strategists. Based on production capacity, global reach, certifications, and market reputation, here are the top 10 zinc ring manufacturers shaping the industry landscape.

Top 10 Zinc Ring Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Fei Hong Five Metals Wares Co., Ltd.

Domain Est. 2003

Website: shishifeihong.com

Key Highlights: Fei Hong is one of the world’s leading manufacturers of zinc alloy products, offering a great range of zinc alloy parts, souvenirs, and corporate gifts….

#2 Zinc Rings Manufacturer

Domain Est. 2022

Website: attelements.com

Key Highlights: ATT is a professional supplier of zinc rings, and we also produce flakes, balls, ingots, balls, flakes, powders, rods, wires, sputtering targets, and many other ……

#3 O

Domain Est. 1998

Website: zoronmfg.com

Key Highlights: 3–4 day delivery 30-day returnsBrowse O-Rings, Steel, Stainless, Zinc, Brass in the Zoron Manufacturing, Inc. catalog including Item #,Price,Item Name,A – Inside Diameter,B – Wire …

#4 Zamak and Zinc Alloys

Domain Est. 2020

Website: zamak.us

Key Highlights: Zamak Manufacturer & Zinc Supplier. We import zinc ingot and produce every kind of zinc alloys with requested quality….

#5 Coating Cast Zinc Jewelry

Domain Est. 1997

Website: pfonline.com

Key Highlights: We have been producing plated zinc die castings for 50 years and have been successfully applying clear e-coat to them for 12 years. We apply ……

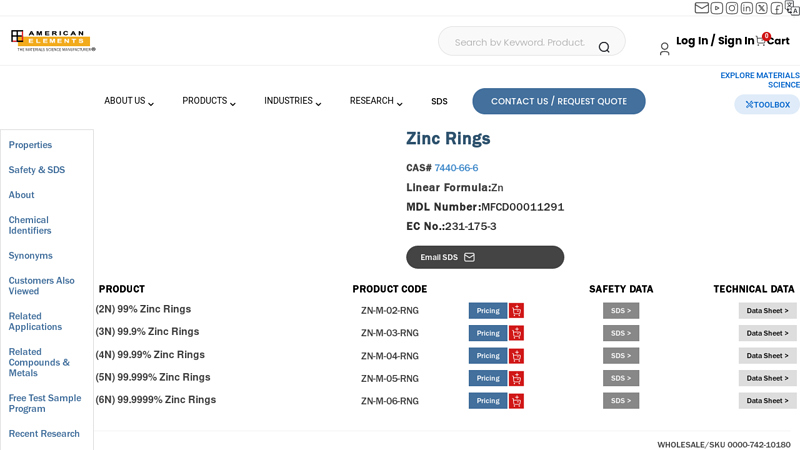

#6 Zinc Rings

Domain Est. 1998

Website: americanelements.com

Key Highlights: American Elements specializes in producing high purity uniform shaped Zinc rings. American Elements offers custom rings with annealed or hard tempers….

#7 Replacement Zinc Anode ring for pump inlet anode (JT70/JT90)

Domain Est. 2010

Website: jetthruster.com

Key Highlights: In stockReplacement Zinc Anode Ring for pump inlet anode JT70/JT90 Use the WS-CP-051-00 Replacement Zinc Anode ring, if the anode present into the WS-CP-050-00 is worn ……

#8 Zinc Products Supplier

Domain Est. 2013

Website: samaterials.com

Key Highlights: Zinc is a lustrous, brittle, silvery-white metal. It is fairly reactive that will be oxidized or reacts with other non-metals….

#9 ZINC

Domain Est. 2016

Website: chakradhari.com

Key Highlights: Zinc Ring. Sort By, Price (Low < High), Price (High > Low), Name (A – Z), Name (Z – A), Date (Old < New), Date (New > Old)….

#10 ZnC

Website: znc.com.de

Key Highlights: Find nearby zinc casting companies with ZnC listing. Find zinc alloys casting companies. Zinc die casting, sand casting, spin casting and more….

Expert Sourcing Insights for Zinc Ring

H2: Market Trends for Zinc Ring in 2026

The global market for zinc rings is poised for notable transformation by 2026, driven by shifts in consumer preferences, advancements in materials science, and growing sustainability concerns. Zinc, particularly in the form of zinc alloys such as zinc-copper-tin (commonly known as Zamak), has long been used in fashion jewelry due to its low cost, malleability, and ability to capture fine detail. As we approach 2026, several key trends are shaping the zinc ring segment:

-

Rise of Sustainable and Ethical Fashion Jewelry

Consumers are increasingly demanding transparency in sourcing and manufacturing. In response, manufacturers of zinc rings are adopting eco-friendly production methods, including closed-loop recycling of zinc alloys and reduced energy consumption in die-casting processes. Brands are also highlighting recyclability and low environmental impact as key selling points, aligning with broader ESG (Environmental, Social, and Governance) trends. -

Growth in Affordable Fashion and Fast Jewelry

Zinc rings continue to dominate the affordable fashion jewelry market due to their cost-effective production. With the rise of e-commerce platforms and direct-to-consumer (DTC) brands, zinc-based rings are being marketed as trendy, seasonal accessories. The fast jewelry model—akin to fast fashion—relies on quick turnaround times and low material costs, making zinc an ideal material. -

Innovation in Coatings and Durability

One of the traditional drawbacks of zinc alloy rings has been susceptibility to tarnishing and skin reactions due to nickel content. By 2026, advancements in protective coatings—such as PVD (Physical Vapor Deposition) and hypoallergenic plating—are enhancing the longevity and wearability of zinc rings. These improvements are expanding their appeal beyond fast fashion into more premium accessory segments. -

Customization and Personalization

Digital manufacturing technologies, including 3D printing and automated casting, are enabling mass customization. Consumers can now design personalized zinc rings online with custom engravings, shapes, and finishes. This trend is particularly strong among younger demographics who value individuality and self-expression. -

Regional Market Expansion

While North America and Europe remain significant markets, Asia-Pacific—especially India, China, and Southeast Asia—is witnessing rapid growth in demand for fashion jewelry. Rising disposable incomes, urbanization, and social media influence are driving demand for trendy, low-cost accessories like zinc rings. -

Competition from Alternative Materials

Despite its advantages, zinc faces competition from alternative base metals like stainless steel and titanium, which offer greater durability and hypoallergenic properties. However, zinc maintains a competitive edge in intricate design capabilities and lower production costs, ensuring its continued relevance.

Conclusion:

By 2026, the zinc ring market will be characterized by innovation, sustainability, and digital integration. While challenges around material perception and durability persist, ongoing technological and design advancements are positioning zinc rings as a versatile and eco-conscious choice in the global fashion jewelry landscape.

Common Pitfalls Sourcing Zinc Rings (Quality, IP)

Sourcing zinc rings—often used in decorative, costume, or low-cost fashion jewelry—can present several challenges, particularly concerning material quality and intellectual property (IP) risks. Being aware of these pitfalls is crucial for brands, retailers, and manufacturers to avoid reputational damage, legal issues, and customer dissatisfaction.

Poor Material Quality and Durability

One of the most frequent issues when sourcing zinc rings is inconsistent or substandard material quality. Zinc alloys (like Zamak) are popular due to their low cost and ease of casting, but they are prone to brittleness, corrosion, and skin reactions if not properly finished.

- Zinc Purity and Alloy Composition: Low-cost suppliers may use impure zinc or incorrect alloy ratios (e.g., too much lead or cadmium), leading to weak rings that break easily or pose health hazards.

- Inadequate Plating or Coating: Many zinc rings are plated with silver, gold, or other metals. Thin or poorly bonded plating wears off quickly, exposing the base metal and causing discoloration or skin irritation.

- Lack of Quality Control: Without strict manufacturing oversight, rings may have casting defects such as bubbles, cracks, or uneven surfaces.

Mitigation: Require material certifications (e.g., RoHS, REACH), conduct third-party testing, and insist on detailed specifications for alloy composition and plating thickness (e.g., minimum 2–3 microns for durable electroplating).

Skin Safety and Regulatory Compliance

Zinc rings that contain restricted substances or lack proper protective coatings can violate health and safety regulations.

- Nickel and Lead Content: Even in zinc alloys, nickel (a common allergen) or lead (a toxic heavy metal) may be present above legal limits, especially in non-compliant factories.

- Failure to Meet Regional Standards: Different markets (e.g., EU, USA, Canada) have strict limits on heavy metals in consumer products. Non-compliant rings risk being rejected at customs or recalled.

Mitigation: Specify compliance with local regulations (e.g., EU Nickel Directive, CPSIA in the U.S.) and require test reports from accredited labs (e.g., SGS, Intertek) before shipment.

Intellectual Property (IP) Infringement Risks

Sourcing from regions with weak IP enforcement increases the risk of unintentionally distributing counterfeit or infringing designs.

- Design Copying: Many suppliers, especially in high-volume manufacturing hubs, may replicate popular branded or artistic ring designs without authorization.

- Trademark and Copyright Violations: Rings featuring logos, symbols, or distinctive shapes from well-known brands (e.g., luxury brands, pop culture icons) can expose buyers to legal liability.

- Lack of IP Warranty: Suppliers may disclaim responsibility for IP issues, leaving the buyer liable for infringement claims.

Mitigation:

– Obtain written IP indemnification from suppliers.

– Use original designs or license third-party designs legally.

– Conduct design clearance searches before production.

– Audit suppliers for IP compliance practices.

Misrepresentation of Materials and Origin

Some suppliers may falsely advertise zinc rings as made from higher-value materials (e.g., “solid silver” or “sterling”) or misrepresent the country of origin to bypass tariffs or appeal to consumers.

- False Labeling: Calling a zinc-based ring “silver-tone” is acceptable, but labeling it as “sterling silver” when it’s not is deceptive and illegal.

- Country-of-Origin Fraud: Mislabeling the source to avoid import restrictions or duties can lead to customs penalties.

Mitigation: Include material authenticity clauses in contracts, verify claims with lab testing, and use supply chain transparency tools.

Conclusion

Sourcing zinc rings affordably doesn’t have to come at the cost of quality or legal safety. By focusing on verified material standards, regulatory compliance, and strong IP protections, buyers can avoid common pitfalls and deliver safe, reliable, and legitimate products to market. Always prioritize due diligence, supplier vetting, and independent quality assurance throughout the sourcing process.

Logistics & Compliance Guide for Zinc Ring

Product Classification and Regulatory Overview

Zinc Ring, as a product containing zinc, may be subject to various international and domestic regulations depending on its form (e.g., dietary supplement, industrial component, or consumer good), intended use, and composition. Accurate classification under relevant trade and safety regulations is essential for smooth logistics and compliance.

HS Code and Customs Classification

Determine the appropriate Harmonized System (HS) code for Zinc Ring based on its primary material and function. Possible classifications may fall under:

– 7904.00 – Zinc powders and flakes

– 7907.00 – Other articles of zinc

– 8517.81 – If incorporated into electronic devices

Consult local customs authorities or a licensed customs broker to confirm the correct HS code, as misclassification can lead to delays, fines, or shipment rejection.

Import and Export Controls

Zinc and zinc-containing products may be subject to export controls in certain jurisdictions, particularly if destined for restricted countries or end-uses. Verify compliance with:

– U.S. Export Administration Regulations (EAR)

– Wassenaar Arrangement (if applicable to dual-use technologies)

– REACH and RoHS in the European Union for chemical safety and hazardous substance restrictions

Packaging and Labeling Requirements

Ensure packaging complies with international shipping standards and includes:

– Product name: “Zinc Ring”

– Material composition (e.g., 99.9% pure zinc)

– Net weight and dimensions

– Manufacturer/importer contact information

– Applicable hazard symbols if zinc dust is present (zinc may be irritating to eyes and respiratory system)

– Compliance markings (e.g., CE, UKCA, or FDA as applicable)

Transportation and Shipping

Zinc Ring shipments must comply with transportation safety standards:

– IMDG Code for sea freight

– IATA Dangerous Goods Regulations – generally not classified as dangerous unless in powder form and in large quantities

– ADR for road transport in Europe

Use moisture-resistant packaging to prevent oxidation during transit. Avoid exposure to acids or corrosive substances.

Environmental and Safety Compliance

Zinc is a regulated substance under environmental protection laws:

– Comply with EPA regulations in the U.S. regarding zinc discharge and handling

– Follow GHS (Globally Harmonized System) for safety data sheets (SDS)

– Maintain SDS for Zinc Ring, especially if sold as raw material or industrial component

Documentation Requirements

Prepare and retain the following documents for each shipment:

– Commercial invoice

– Packing list

– Bill of lading or air waybill

– Certificate of Origin

– Safety Data Sheet (SDS)

– Export license (if required)

Quality Assurance and Traceability

Implement quality control measures to ensure zinc purity and product consistency. Maintain batch records and traceability logs to support compliance audits and product recalls if necessary.

Storage and Handling Guidelines

Store Zinc Ring in a cool, dry place away from moisture, acids, and oxidizing agents. Use appropriate personal protective equipment (PPE) when handling bulk quantities to avoid inhalation of zinc dust.

Jurisdiction-Specific Compliance

- United States: FDA oversight if marketed as a dietary supplement; OSHA guidelines for workplace safety

- European Union: REACH registration for zinc substances; compliance with CLP Regulation for labeling

- China: CCC certification may be required depending on application; adhere to AQSIQ import standards

Ensure all partners (suppliers, freight forwarders, distributors) are aware of and adhere to these compliance requirements to minimize risks and ensure seamless logistics operations.

Conclusion for Sourcing Zinc Rings:

After evaluating various factors such as cost, availability, quality, durability, and supplier reliability, sourcing zinc rings presents a cost-effective and practical solution for applications where lightweight strength, corrosion resistance (with proper plating or coating), and aesthetic appeal are required. Zinc alloy rings, particularly those made from Zamak, offer excellent castability and fine detail, making them ideal for fashion jewelry, industrial components, and commemorative items.

While pure zinc is not typically used for rings due to its brittleness, zinc-based alloys provide a favorable balance of mechanical properties and manufacturability. Key considerations when sourcing include selecting reputable suppliers who adhere to quality standards (e.g., RoHS compliance), ensuring consistent alloy composition, and verifying surface finishing processes to enhance durability and appearance.

In conclusion, zinc alloy rings are a viable and economical choice for bulk production and diverse applications, provided that sourcing strategies prioritize material quality, supplier credibility, and end-use requirements. With proper design and finishing, zinc rings can meet both functional and aesthetic expectations in a competitive market.