The global conveyor systems market is experiencing robust growth, driven by increasing automation across manufacturing, warehousing, and distribution sectors. According to Grand View Research, the global conveyor systems market size was valued at USD 5.8 billion in 2022 and is projected to expand at a compound annual growth rate (CAGR) of 5.3% from 2023 to 2030. This growth is fueled by rising demand for efficient material handling solutions, labor cost reduction, and the expansion of e-commerce fulfillment centers. As industries continue to prioritize operational efficiency and throughput optimization, the need for reliable item conveyor manufacturers has never been more critical. In this landscape, selecting the right manufacturer can significantly impact productivity, system reliability, and long-term cost savings. Based on performance, innovation, and market presence, the following eight manufacturers have emerged as leaders in providing item conveyor solutions tailored to diverse industrial applications.

Top 8 You’Re Going To Need An Item Conveyor Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 QC Conveyors

Domain Est. 2013

Website: qcconveyors.com

Key Highlights: QC Conveyors is a trusted conveyor manufacturer providing custom systems for industrial and automation applications. Fast lead times and expert support….

#2 Belt Conveyor Systems

Domain Est. 1998

Website: ultimationinc.com

Key Highlights: Ultimation is one of the top conveyor belt manufacturers. Our simple and versatile belt conveyor systems use two or more pulleys to drive looped belts….

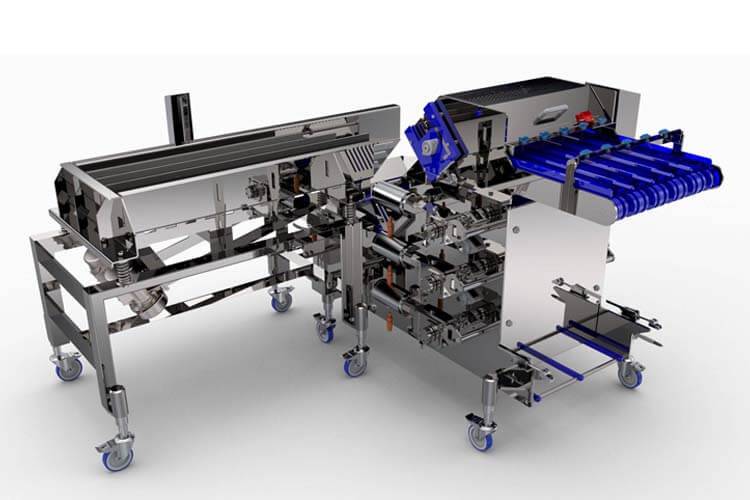

#3 Conveyor Manufacturer in USA

Domain Est. 1998

Website: 4smartmove.com

Key Highlights: We are a conveyor systems manufacturer with the engineering expertise to build a custom system which will automate your work flow….

#4 Industrial Conveyors

Domain Est. 2016

Website: vention.io

Key Highlights: Vention’s conveyor system is comprised of modular parts that snap together, allowing you to assemble a complete conveyor system in just four to eight hours….

#5 Conovey

Domain Est. 2016

Website: conovey.com

Key Highlights: We manufacture only the highest quality conveyors, vibratory feeders, merging and sorting systems, metal detectors and checkweighers, carton erectors, case ……

#6 Span Tech Conveyors

Domain Est. 2017

Website: spantechconveyors.com

Key Highlights: Explore Span Tech’s custom conveyors for packaging, food, pharma, and more—built for efficiency, flexibility, and increased productivity….

#7 Conveyor Manufacturers

Website: conveyorcompanies.com

Key Highlights: Quickly locate the leading conveyor manufacturers and suppliers in the USA whose knowledgeable staffs offer fast shipping and detailed specifications at ……

#8 White Conveyors

Domain Est. 1998

Website: white-conveyors.com

Key Highlights: White offers a full line of standard and custom conveying solutions that are designed to deliver relentless performance with minimal maintenance. With more than ……

Expert Sourcing Insights for You’Re Going To Need An Item Conveyor

2026 Market Trends for Item Conveyors: Navigating the Future of Material Handling

As we approach 2026, the global item conveyor market is poised for significant transformation, driven by technological advancements, evolving consumer demands, and a heightened focus on operational efficiency. Understanding these key trends is crucial for businesses investing in or relying on conveyor systems.

H2: Accelerated Automation and Integration with Advanced Technologies

By 2026, automation will be the cornerstone of conveyor system adoption. Businesses across e-commerce fulfillment, manufacturing, and logistics will increasingly deploy conveyors not as standalone machines, but as integral components of highly automated ecosystems. The integration of conveyors with robotics (AGVs/AMRs), sophisticated Warehouse Management Systems (WMS), and Enterprise Resource Planning (ERP) platforms will enable seamless, data-driven material flow. Real-time tracking, dynamic routing, and predictive maintenance will become standard expectations, minimizing downtime and maximizing throughput. Investment in conveyors with built-in sensors and IoT connectivity will surge, allowing for remote monitoring and optimization.

H2: Surge in E-Commerce and Omnichannel Fulfillment Driving Demand

The relentless growth of e-commerce, particularly same-day and next-day delivery expectations, will be a primary growth engine for the conveyor market in 2026. Fulfillment centers will require highly flexible, high-speed conveyor solutions capable of handling diverse item sizes, weights, and packaging types with minimal manual intervention. Sortation systems, cross-belt conveyors, and automated induction stations will see widespread deployment to accelerate order processing and reduce errors. Furthermore, the rise of omnichannel retail (integrating online, in-store, and curbside pickup) will necessitate conveyors that can efficiently route goods within distribution centers and stores, supporting complex fulfillment workflows.

H2: Emphasis on Flexibility, Scalability, and Modular Design

Static, rigid conveyor layouts will become increasingly obsolete. The 2026 market will prioritize flexible and modular conveyor systems that can be easily reconfigured, expanded, or repurposed to adapt to changing product lines, seasonal demand fluctuations, or new facility layouts. Plug-and-play components, lightweight materials, and standardized interfaces will be key selling points. This trend is fueled by the need for resilience in supply chains and the desire to future-proof investments. Companies will favor solutions that allow for incremental scaling rather than complete overhauls.

H2: Focus on Sustainability and Energy Efficiency

Sustainability mandates and rising energy costs will push conveyor manufacturers and users towards greener solutions by 2026. Demand will grow for conveyors featuring energy-efficient motors (like brushless DC), regenerative braking systems that capture energy during deceleration, and designs that minimize friction and power consumption. The use of recycled and recyclable materials in conveyor construction will become more common. Lifecycle assessments will play a larger role in procurement decisions, favoring systems with lower environmental impact and longer operational lifespans.

H2: Increased Adoption of AI and Predictive Analytics

Artificial Intelligence (AI) and machine learning will move beyond pilot projects to become embedded in conveyor system management by 2026. AI algorithms will analyze vast amounts of operational data from sensors to optimize routing in real-time, predict bottlenecks before they occur, and schedule maintenance proactively based on actual wear and usage patterns (predictive maintenance). This will lead to significant improvements in overall equipment effectiveness (OEE), reduced maintenance costs, and extended conveyor lifespans. AI will also enhance quality control by identifying anomalies in item flow or potential damage points.

These converging trends point towards a 2026 conveyor market characterized by intelligent, connected, flexible, and sustainable systems that are fundamental to achieving the speed, efficiency, and resilience required in modern industrial and logistics operations.

Common Pitfalls When Sourcing You’re Going to Need an Item Conveyor (Quality, IP)

Sourcing a conveyor system—especially one critical to operations like “You’re Going to Need an Item Conveyor”—involves numerous technical and logistical considerations. Overlooking key factors can lead to performance issues, safety risks, or costly downtime. Below are common pitfalls related to quality and Ingress Protection (IP) ratings that buyers should avoid.

Pitfall 1: Prioritizing Cost Over Quality

Opting for the lowest-cost conveyor often results in subpar materials, poor construction, and shorter service life. Low-quality components may fail under continuous operation, leading to frequent maintenance and replacement costs that outweigh initial savings.

Pitfall 2: Ignoring IP Rating Requirements

The Ingress Protection (IP) rating defines a system’s resistance to dust and moisture. A common mistake is selecting a conveyor with an insufficient IP rating for the operating environment. For example:

– Using an IP54-rated conveyor in a washdown environment requiring IP69K can lead to motor failure or electrical hazards.

– In dusty environments, failing to specify at least IP65 can result in internal component contamination and mechanical failure.

Pitfall 3: Assuming Standard Ratings Fit All Environments

Not all facilities have the same environmental demands. A conveyor suitable for a dry warehouse may not perform in a food processing plant with high humidity and sanitation requirements. Always match the IP rating—and material quality (e.g., stainless steel vs. carbon steel)—to the specific operational conditions.

Pitfall 4: Overlooking Certification and Compliance

Reputable conveyors should meet industry standards (e.g., CE, UL, IP certifications). Sourcing from suppliers who cannot provide documentation raises red flags about quality control and regulatory compliance, increasing liability risks.

Pitfall 5: Inadequate Supplier Vetting

Failing to assess a supplier’s track record, manufacturing processes, and after-sales support can lead to receiving poorly built or incorrectly specified equipment. Always request references, case studies, and test reports—especially for IP claims.

Pitfall 6: Misunderstanding IP Code Structure

Many buyers misinterpret IP ratings. Remember:

– The first digit = solid particle protection (e.g., dust).

– The second digit = liquid ingress protection (e.g., water jets).

Choosing a conveyor without understanding these distinctions can result in insufficient environmental protection.

Pitfall 7: Neglecting Long-Term Maintenance Needs

High-quality conveyors with appropriate IP ratings are designed for durability and easier maintenance. Low-quality alternatives may be cheaper upfront but often require more frequent servicing, part replacements, and downtime—increasing total cost of ownership.

Conclusion

To avoid these pitfalls, prioritize quality materials, verify IP ratings for your specific use case, and partner with trusted suppliers who provide full transparency and certification. Investing in the right conveyor from the start ensures reliability, safety, and operational efficiency.

Logistics & Compliance Guide for You’re Going to Need an Item Conveyor

When implementing an item conveyor system in your facility, careful attention must be paid to logistics planning and regulatory compliance to ensure safety, efficiency, and legal adherence. This guide outlines key considerations for successful deployment.

System Design and Integration

Ensure the conveyor system is designed to integrate seamlessly with existing workflows, material handling equipment, and facility layout. Conduct a site assessment to verify clearances, load capacities, and power requirements. Collaborate with engineering and operations teams to map material flow and avoid bottlenecks.

Regulatory Compliance

Adhere to local, national, and international safety and operational standards. Key regulations include:

- OSHA (Occupational Safety and Health Administration) – Ensure guarding, emergency stops, lockout/tagout (LOTO) procedures, and worker training meet OSHA 29 CFR 1910 standards.

- ANSI/ASME B20.1 – Follow safety standards for conveyors and related equipment, including guarding, warning signs, and control systems.

- CE Marking (EU) – For operations in Europe, ensure compliance with the Machinery Directive (2006/42/EC), including risk assessments and technical documentation.

- Electrical Codes (e.g., NEC, IEC) – Verify electrical components comply with applicable codes for wiring, grounding, and explosion-proofing (if needed).

Installation and Commissioning

Use certified technicians for installation. Conduct pre-commissioning inspections, including alignment checks, motor calibration, and sensor testing. Perform a full system test under load conditions and document results for compliance records.

Worker Training and Safety Protocols

Provide comprehensive training for all personnel interacting with the conveyor. Training must cover safe operation, emergency procedures, and hazard recognition. Maintain training logs and update protocols as system configurations change.

Maintenance and Documentation

Establish a preventive maintenance schedule based on manufacturer guidelines. Keep detailed logs of inspections, repairs, and component replacements. Retain technical manuals, compliance certificates, and risk assessments on file for audits.

Environmental and Accessibility Considerations

Ensure the conveyor system accounts for environmental factors such as temperature, humidity, and dust. Where applicable, comply with ADA or local accessibility standards for work zones adjacent to conveyor paths.

Supply Chain and Spare Parts Logistics

Secure a reliable supply chain for critical spare parts to minimize downtime. Maintain an inventory of high-failure components such as bearings, belts, and sensors. Map lead times and identify backup suppliers.

By following this guide, you can ensure your item conveyor system is safely installed, legally compliant, and efficiently integrated into your operational logistics.

In conclusion, for efficient and effective sourcing, you’re going to need an item conveyor to streamline the movement of goods, reduce manual labor, minimize handling errors, and ensure a consistent flow of materials throughout the production or distribution process. Investing in the right conveyor system will enhance operational efficiency, support scalability, and contribute to long-term cost savings.