The global patch panel market, a critical component of structured cabling systems in data centers and enterprise networks, is witnessing robust growth driven by rising data traffic, digital transformation initiatives, and the expansion of cloud infrastructure. According to a report by Mordor Intelligence, the global network patch panel market was valued at USD 1.72 billion in 2023 and is projected to reach USD 2.81 billion by 2029, growing at a CAGR of approximately 8.5% during the forecast period. Similarly, Grand View Research projects strong momentum in the broader data center infrastructure market, citing increasing demand for high-density, reliable connectivity solutions—particularly in high-performance environments requiring XLR and other professional-grade patching systems. As industries from broadcasting to live events prioritize audio fidelity and signal integrity, manufacturers of XLR patch panels are at the forefront of innovation, balancing durability, scalability, and electromagnetic interference resistance. The following list highlights the top 9 XLR patch panel manufacturers shaping this evolving landscape through technical excellence and market responsiveness.

Top 9 Xlr Patch Panel Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

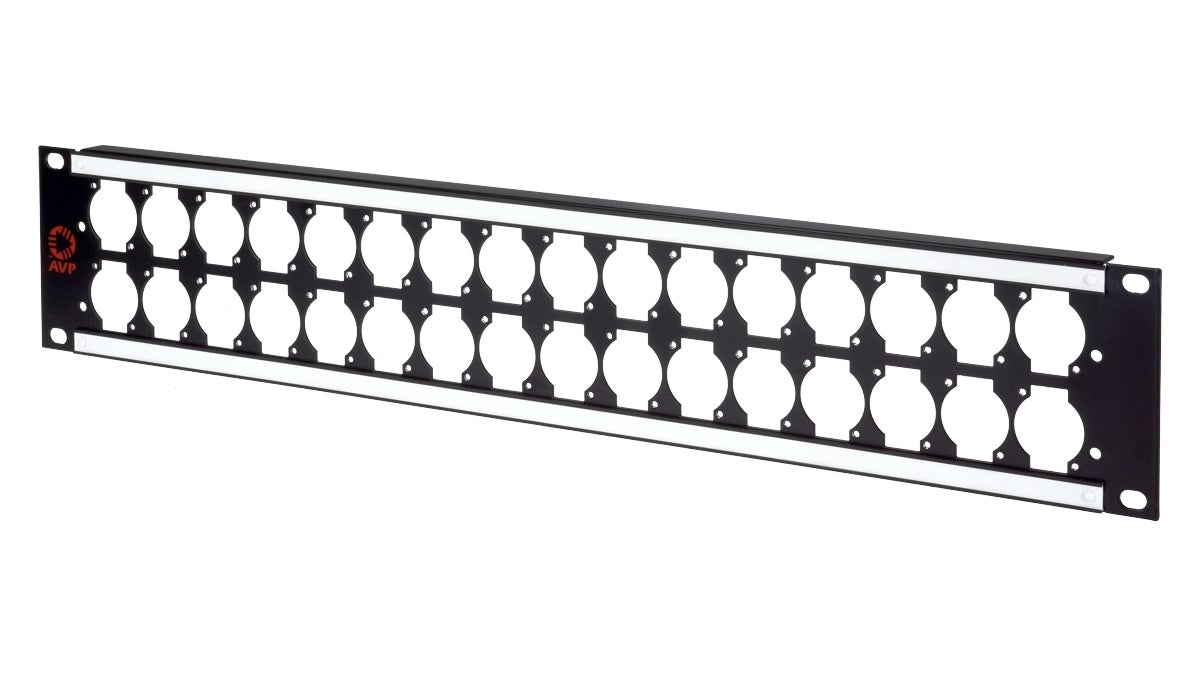

#1 AVP Broadcast: AVP

Domain Est. 2012 | Founded: 1985

Website: avpbroadcast.com

Key Highlights: Free delivery over $199AVP Broadcast, founded in 1985, is a manufacturer of commercial broadcast, telecom, and satellite equipment, including the design and manufacturing of audio,…

#2 Audio

Domain Est. 1995

Website: bittree.com

Key Highlights: Bittree’s Audio Patchbays are available in TT (Bantam), 1/4″ (Long-Frame), E3, XLR, and have been developed specifically for today’s audio environment….

#3 Where to Buy XLR Patch Panel

Domain Est. 1995

#4 XLR patch panels

Domain Est. 1996

Website: canford.co.uk

Key Highlights: CANARE UNIFIED SERIES FLUSH MOUNT CONNECTORS | XLR TERMINATION PANELS – Flat and Angled, Canford and Neutrik XLR connectors….

#5 XLR Passthrough Panels

Domain Est. 1996

Website: switchcraft.com

Key Highlights: PT Series Audio Pass-Through I/O Panels are a perfect solution for anyone requiring front-of-rack access to their I/O’s in any permanent or mobile studio ……

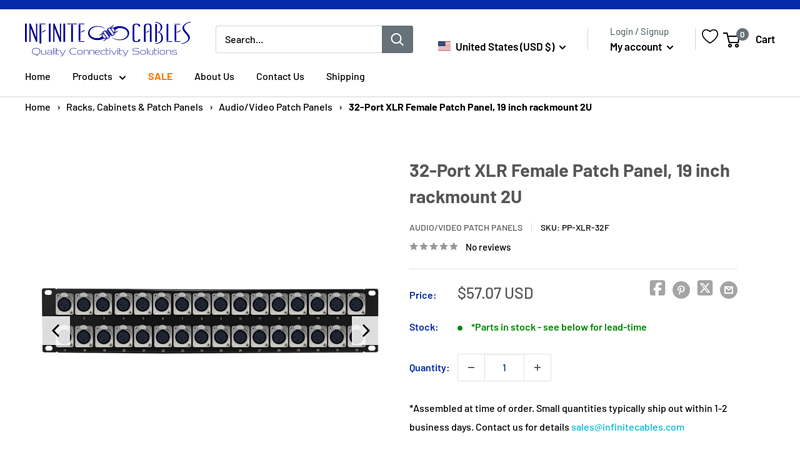

#6 32

Domain Est. 2002

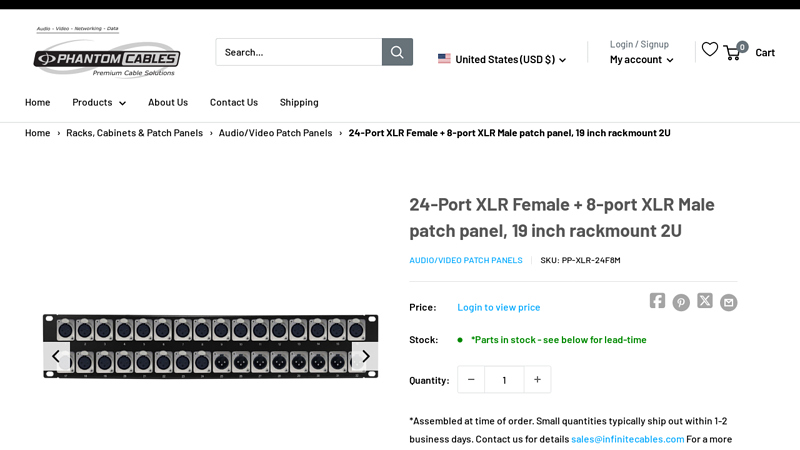

#7 24

Domain Est. 2004

Website: us.phantomcables.com

Key Highlights: This 24 port XLR patch bay has eight XLR male and twenty four locking XLR female connectors on the front and solder connectors on the back….

#8 XLR Patch Panels

Domain Est. 2013

Website: patchpanelsxlr.com

Key Highlights: XLR Patch Panels – 3 Pin Bulkhead Adapters. These are long – you need a minimum 5″ of depth behind your panel in order to plug cables in to the rear side….

#9 Patch Panels

Domain Est. 2000

Website: btpa.com

Key Highlights: Manufacturer. Best-Tronics Mfg., Inc. (1). Category. Un-Wired Panels (1). Price … MIC/XLR · MIC Patch Cables – Small Diameter · Panel “Whip” Assemblies ……

Expert Sourcing Insights for Xlr Patch Panel

2026 Market Trends for XLR Patch Panels

The XLR patch panel market in 2026 is poised for steady, specialized growth, driven by continued demand in professional audio sectors despite broader technological shifts. Here’s an analysis of key trends shaping the market:

Stable Demand in Core Professional Applications

XLR patch panels remain indispensable in live sound, broadcast studios, recording facilities, and fixed installations where reliability, balanced audio transmission, and noise rejection are critical. The enduring need for high-fidelity analog audio connections in theaters, houses of worship, and post-production environments ensures consistent demand. As live events rebound and media production expands globally, infrastructure relying on XLR connectivity will sustain the relevance of patch panels for routing and signal management.

Integration with Hybrid Analog-Digital Systems

While digital audio networking (e.g., Dante, AVB, AES67) grows, many environments adopt hybrid architectures. XLR patch panels are increasingly used at the edge of these systems—connecting legacy analog gear to digital cores or providing breakout points for stage boxes and I/O racks. This integration fosters demand for patch panels with enhanced labeling, modular configurations, and compatibility with both XLR and other connector types (e.g., TRS, terminal blocks), allowing seamless adaptation in mixed-signal environments.

Focus on Build Quality, Reliability, and Serviceability

In mission-critical applications, durability and long-term performance are paramount. Manufacturers are emphasizing rugged metal housings, gold-plated contacts, and tool-less access to terminals to reduce maintenance time. The trend favors panels with superior shielding and grounding to minimize interference—especially important in high-density installations. Serviceability and ease of reconfiguration are becoming key differentiators in competitive bidding for large-scale installations.

Niche Innovation Amidst Mature Technology

As a mature technology, XLR patch panels see incremental rather than revolutionary innovation. However, trends include improved labeling systems (laser-etched, color-coded), compact high-density designs for space-constrained racks, and eco-conscious manufacturing. Some vendors offer customizable configurations, allowing integrators to tailor panel layouts to specific project needs, enhancing value in complex installations.

Regional and Sector-Specific Growth

Growth is strongest in emerging markets investing in broadcast infrastructure, live entertainment venues, and education facilities. Additionally, the expansion of podcast studios and hybrid workspaces with professional audio requirements presents a niche growth segment. However, market expansion is tempered by the gradual shift toward wireless and networked audio in some consumer and semi-professional applications.

In conclusion, the XLR patch panel market in 2026 will remain resilient, anchored in professional audio’s reliance on trusted analog infrastructure. While not experiencing explosive growth, it will evolve through integration with digital systems, enhanced design, and specialization—securing its role as a foundational component in high-quality audio signal routing.

Common Pitfalls When Sourcing an XLR Patch Panel (Quality, IP)

Sourcing an XLR patch panel—especially one designed for professional audio environments—requires careful consideration of both build quality and Ingress Protection (IP) rating. Overlooking key factors can lead to performance issues, reliability problems, and costly replacements. Below are common pitfalls to avoid:

Overlooking Build Quality and Materials

One of the most frequent mistakes is choosing a patch panel based solely on price without evaluating the quality of materials and construction. Low-cost panels often use substandard metals for XLR connectors, thin chassis, and poor solder joints, leading to signal degradation, intermittent connections, or physical failure over time. Always verify that connectors are made from durable materials (e.g., nickel or brass with gold plating), and that the panel housing is robust—ideally steel or aluminum.

Ignoring IP Rating for Environmental Suitability

Many buyers assume all patch panels are suitable for any environment, but IP ratings are critical for installations exposed to dust or moisture. For outdoor or industrial settings, selecting a panel without an appropriate IP rating (e.g., IP54 or higher) can result in corrosion, short circuits, or complete failure. Ensure the IP rating matches the installation environment—indoor studio setups may only need basic protection, while outdoor or stage environments demand sealed enclosures.

Assuming All XLR Panels Support Balanced Audio Properly

Not all patch panels preserve balanced audio integrity. Poor internal wiring, lack of proper shielding, or ground loop issues can introduce noise and degrade audio quality. Verify that the panel is designed specifically for balanced audio signals and includes features like isolated grounds or star-quad wiring to maintain signal fidelity.

Neglecting Connector Density and Spacing

High-density panels may seem efficient, but tight spacing can make cabling difficult and increase the risk of accidental disconnection or connector damage. Ensure there’s adequate space between XLR jacks for standard connectors and frequent patching, especially in live sound or broadcast applications where reliability under pressure is essential.

Failing to Verify Mounting and Installation Compatibility

Some patch panels are designed for specific rack configurations or wall mounts. Buyers often overlook depth, rack unit (U) size, or rear clearance, leading to installation challenges. Confirm the panel’s dimensions and mounting requirements fit your intended setup—especially in space-constrained or permanent installations.

Disregarding Manufacturer Reputation and Support

Choosing an unknown or uncertified brand can lead to inconsistent quality and lack of technical support. Reputable manufacturers typically provide detailed specifications, durability testing data, and warranties. Research brand reliability and read user reviews to avoid sourcing from vendors with a history of defective products.

By avoiding these common pitfalls, you can select an XLR patch panel that ensures long-term reliability, optimal audio performance, and suitability for your specific environment. Always prioritize quality construction, appropriate IP protection, and application-specific design.

Logistics & Compliance Guide for XLR Patch Panel

This guide outlines key logistics considerations and compliance requirements for the handling, transportation, installation, and use of XLR patch panels in professional audio environments.

Product Identification & Specifications

Ensure all units match the specified model number, channel count (e.g., 8, 16, 24 ports), connector type (3-pin or 5-pin XLR), and mounting configuration (19-inch rack, wall-mount, etc.). Verify packaging includes manufacturer labels with part number, serial number (if applicable), and country of origin.

Packaging & Handling

Use original manufacturer packaging or equivalent protective materials (foam inserts, sturdy boxes) to prevent physical damage during transit. Handle units with care to avoid bending pins or damaging chassis. Store in a dry, temperature-controlled environment away from dust and moisture when not in use.

Shipping & Transportation

Ship via approved freight carriers experienced in handling sensitive audio equipment. Clearly label packages as “Fragile” and “This Side Up.” For international shipments, ensure compliance with Incoterms (e.g., FOB, DDP) and provide detailed commercial invoices, packing lists, and material safety data sheets (MSDS) if required.

Import/Export Compliance

Confirm that the XLR patch panel meets destination country regulations. Check for applicable Harmonized System (HS) codes (e.g., 8536.69 for electrical connectors). Ensure compliance with customs requirements, including CE marking for Europe, UKCA for the United Kingdom, and FCC regulations for the United States, where applicable.

Electrical & Safety Standards

Verify that the product complies with relevant safety standards such as IEC 60601 (for medical environments, if applicable), IEC 60950-1 (information technology equipment safety), or IEC 62368-1 (audio/video, information and communication technology equipment). Grounding and insulation must meet local electrical codes.

RoHS & Environmental Compliance

Confirm that the XLR patch panel is RoHS (Restriction of Hazardous Substances) compliant, particularly for sales within the European Union. Components must not contain restricted substances such as lead, mercury, cadmium, or certain flame retardants above allowable limits. Dispose of packaging and defective units according to local e-waste regulations.

Installation & Use Requirements

Install in accordance with manufacturer instructions and local building/electrical codes. Ensure proper cable management and ventilation to prevent overheating. Only qualified personnel should perform installation in permanent or commercial audio installations.

Documentation & Traceability

Maintain records of purchase orders, compliance certificates (CE, RoHS, FCC), and shipping documentation. Register products with the manufacturer if required for warranty or service purposes.

Warranty & Support

Adhere to the manufacturer’s warranty terms, which may be voided by improper handling, modifications, or use outside specified environmental conditions. Contact authorized service providers for repairs or compliance-related inquiries.

For the most accurate and up-to-date compliance details, refer to the manufacturer’s official documentation and consult with local regulatory authorities when deploying XLR patch panels in critical or regulated environments.

Conclusion for Sourcing XLR Patch Panel:

Sourcing an XLR patch panel requires careful consideration of audio quality, durability, connectivity needs, and compatibility with existing equipment. After evaluating various options, the ideal solution should offer reliable gold-plated connectors, robust metal or rugged plastic housing, and clean signal transmission to minimize interference in professional audio environments. Whether choosing a pre-wired, custom-configured, or modular patch panel, it is essential to prioritize build quality and manufacturer reputation. Additionally, considering future scalability, ease of installation, and cable management will ensure long-term functionality in studios, live sound setups, or broadcast facilities. Ultimately, investing in a high-quality XLR patch panel enhances system organization, signal integrity, and overall operational efficiency, making it a critical component in any professional audio infrastructure.