The global drilling rig market is experiencing robust growth, driven by rising demand for energy resources, increasing infrastructure development, and advancements in drilling technologies. According to a report by Mordor Intelligence, the global drilling rig market was valued at USD 9.4 billion in 2023 and is projected to grow at a CAGR of over 5.8% from 2024 to 2029. This expansion is further supported by growing investments in oil & gas exploration and the renewable energy sector, particularly in geothermal projects. As a leading player in the construction and heavy machinery space, XCMG has strengthened its footprint in the drilling rig segment, with several key manufacturers and affiliates specializing in high-performance rotary and foundation drilling equipment. The following list highlights the top six XCMG-affiliated or XCMG-recognized drilling rig manufacturers that are shaping the industry through innovation, technological integration, and scalable solutions—contributing significantly to XCMG’s rising market share in both domestic and international markets.

Top 6 Xcmg Drilling Rig Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Horizontal Drilling Rig, XCMG Horizontal Directional Drilling

Domain Est. 2019

Website: xcmghddrig.com

Key Highlights: Wuhan Yichao Technology Equipment Co., Ltd. is a professional supplier of horizontal directional drilling rigs. We are XCMG authorized distributor and has ……

#2 XCMG XR360 Rotary Drill Rig Price, Specs, Info

Domain Est. 2018

Website: product.global-ce.com

Key Highlights: XCMG Factory Xr360 Rotary Drill Machine Hydraulic Piling Drilling Rigs Price ; Warranty:: 1 Year ; Certification:: CE, RoHS, ISO 9001:2008 ; Condition:: New ; Drill ……

#3 XCMG

Domain Est. 2023

Website: xcmgglobal.com

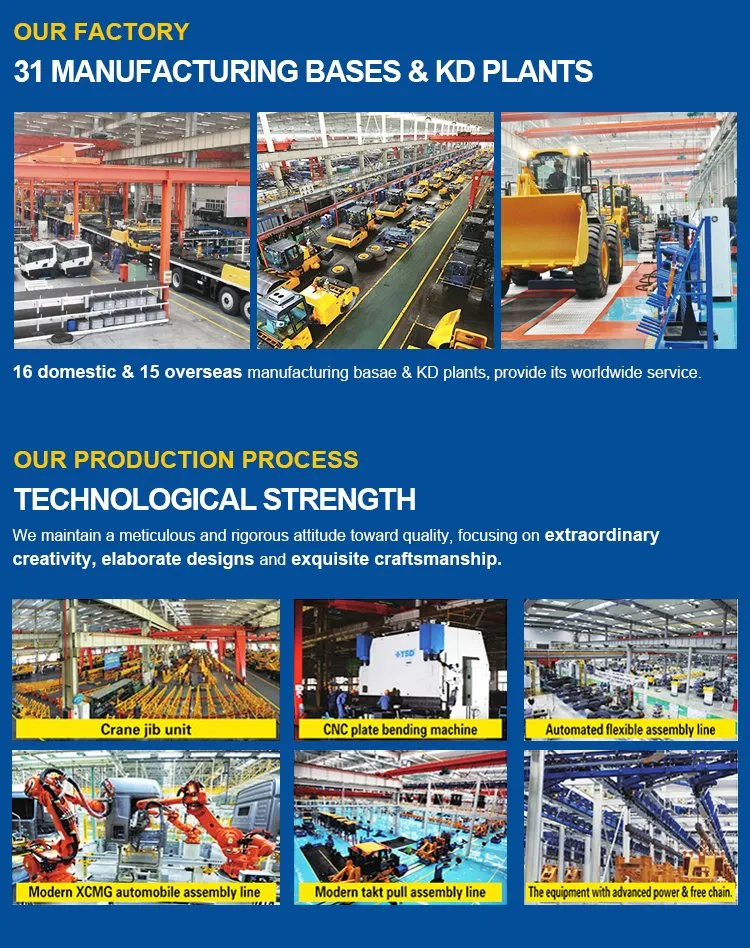

Key Highlights: XCMG is a top heavy machinery manufacturer in China. XCMG has the most complete construction equipment for sale such as excavators, loaders, road machinery, ……

#4 XCMG 2000m Depth XSC20/1000 China Trailer Mounted Water …

Domain Est. 2023

Website: machine.xcmg-generator.com

Key Highlights: XCMG Manufacturers 300m Small Truck Mounted Water Well Drilling Rig price. $30000.00-$50000.00. Self-support · XCMG Manufacturer Trailer Mounted Water Well ……

#5 Drilling Rigs – XCMG

Domain Est. 2018

Website: buyxcmg.com

Key Highlights: We are the leaders in the construction and building industries. We are world wide. We never give up on the new challenges. Get in touch now!…

#6 Rotary Drilling Rig

Domain Est. 2023 | Founded: 2017

Website: export-xcmg.com

Key Highlights: We was established in 2017 in Jinan, China. We are professional supplier for Chinese brand construction machinery, XCMG and Sany products….

Expert Sourcing Insights for Xcmg Drilling Rig

H2: Market Trends for XCMG Drilling Rigs in 2026

By 2026, the market for XCMG drilling rigs is poised to experience significant transformation driven by technological advancements, evolving infrastructure demands, and global sustainability initiatives. As one of China’s leading construction machinery manufacturers, XCMG is strategically positioned to capitalize on several key trends shaping the drilling equipment sector during the second half of the decade.

1. Infrastructure Expansion and Urbanization

Global infrastructure development—particularly in emerging markets across Southeast Asia, Africa, and Latin America—continues to drive demand for reliable and efficient drilling equipment. National infrastructure projects, including high-speed rail, urban transit systems, and renewable energy installations, require deep foundation and geotechnical solutions where XCMG drilling rigs excel. China’s ongoing “dual circulation” strategy and Belt and Road Initiative (BRI) will further boost export opportunities for XCMG, especially for mid-sized rotary drilling rigs suited for diverse geological conditions.

2. Electrification and Green Technology Adoption

Environmental regulations and carbon neutrality goals are accelerating the shift toward electric and hybrid construction machinery. By 2026, XCMG is expected to expand its portfolio of electric-powered drilling rigs, building on existing models like the XSL22 series. These rigs offer lower operating costs, reduced noise, and zero emissions—making them ideal for urban construction sites with strict environmental standards. Government incentives in Europe and China for green equipment adoption will further stimulate demand.

3. Smart Construction and Digital Integration

The integration of IoT, AI, and real-time data analytics into drilling operations is becoming standard. XCMG’s investment in smart construction ecosystems—such as its “Cloud Platform” for remote monitoring and predictive maintenance—will enhance rig performance, uptime, and operational safety. By 2026, customers will increasingly favor rigs equipped with automated drilling systems, GPS-guided positioning, and telematics, improving precision and reducing labor costs.

4. Aftermarket and Service Expansion

As the installed base of XCMG drilling rigs grows globally, demand for spare parts, maintenance services, and operator training will surge. XCMG is likely to strengthen its global service network and digital support platforms, offering subscription-based service models and remote diagnostics. This shift toward service-led revenue streams will improve customer retention and lifecycle value.

5. Competitive Landscape and Market Differentiation

While competing with global brands like Liebherr, Soilmec, and Casagrande, XCMG’s competitive advantage lies in cost-performance ratio, rapid customization, and strong supply chain resilience. By 2026, XCMG is expected to target niche applications such as offshore wind foundation drilling and mining exploration, where its larger rotary rigs (e.g., XR series) can leverage high torque and deep drilling capabilities.

Conclusion

The 2026 market for XCMG drilling rigs reflects a convergence of infrastructure demand, technological innovation, and sustainability imperatives. With strategic investments in electrification, digitalization, and global service infrastructure, XCMG is well-positioned to solidify its presence as a top-tier global provider of drilling solutions—balancing affordability with advanced performance in a rapidly evolving construction landscape.

Common Pitfalls When Sourcing XCMG Drilling Rigs: Quality and Intellectual Property Concerns

Logistics & Compliance Guide for XCMG Drilling Rig

This guide outlines the key logistical and compliance considerations involved in transporting and operating XCMG drilling rigs across various regions. Proper planning ensures timely delivery, regulatory adherence, and operational safety.

Transportation Planning

- Route Survey: Conduct a detailed route assessment to evaluate road conditions, bridge load limits, turning radii, and overhead clearance. Use GPS route planning tools and consult local authorities when necessary.

- Permits & Escorts: Secure oversize/overweight transport permits from relevant transportation departments. Arrange for pilot cars or police escorts if required by route or jurisdiction.

- Disassembly Requirements: Determine if disassembly (e.g., mast lowering, counterweight removal, track retraction) is needed to meet transport dimensions. Follow XCMG’s disassembly procedures in the operator manual.

- Loading & Securing: Use appropriate heavy-duty trailers (e.g., multi-axle lowboys). Secure the rig with rated chains, binders, and blocking to prevent movement during transit. Comply with FMCSA (U.S.) or equivalent national securing standards.

Export & Import Compliance

- Documentation: Prepare complete export documentation, including commercial invoice, packing list, bill of lading, certificate of origin, and equipment conformity certificates (e.g., CE, CCC).

- Customs Clearance: Provide HS code for XCMG drilling rigs (typically 8430.41 or 8430.49 depending on configuration) to facilitate customs classification. Ensure all import duties, taxes, and local regulations are met.

- Sanitary & Phytosanitary (SPS) Measures: Comply with soil and debris removal requirements to prevent cross-border contamination. Provide cleaning certificates if mandated.

- Trade Sanctions & Restrictions: Verify destination country is not under international trade sanctions. Confirm XCMG has export authorization for specific models and regions.

Regulatory & Safety Standards

- CE Marking (EU): Ensure the rig complies with EU Machinery Directive 2006/42/EC, electromagnetic compatibility (EMC), and noise emission standards. Retain the EC Declaration of Conformity.

- CCC Certification (China): For domestic use or re-export, verify the rig holds valid China Compulsory Certification (CCC) as required by Chinese regulations.

- OSHA & Local Workplace Safety (U.S./Global): Adhere to OSHA 29 CFR 1926 Subpart P (excavations) and equipment-specific standards. Implement site-specific safety plans, including fall protection and hazard communication.

- Environmental Regulations: Follow local emissions standards (e.g., EPA Tier 4 Final, EU Stage V). Manage fluid containment and noise levels per site requirements.

On-Site Setup & Operation Compliance

- Installation & Commissioning: Perform setup per XCMG guidelines. Conduct pre-operational checks on hydraulics, structural integrity, and safety systems.

- Operator Certification: Ensure operators are trained and certified per local regulations (e.g., NCCCO in the U.S., CPCS in the UK) and XCMG training programs.

- Inspection & Maintenance: Adhere to scheduled maintenance and inspection logs per XCMG service manual. Maintain records for regulatory audits.

- Permitting for Drilling Activities: Obtain necessary drilling permits from environmental or geological authorities, especially in protected areas or water-sensitive zones.

Return & Decommissioning Logistics

- Equipment Retrieval: Plan reverse logistics with the same attention to permits, route, and securing requirements.

- Export/Import Compliance for Return Shipments: Comply with re-import regulations, including customs declarations and depreciation reporting.

- Decommissioning & Disposal: Follow environmental guidelines for decommissioning. Recycle fluids and components per local waste management laws.

Adherence to this guide ensures efficient, legal, and safe handling of XCMG drilling rigs throughout their deployment cycle. Always consult XCMG’s official technical and compliance documentation for model-specific details.

Conclusion for Sourcing an XCMG Drilling Rig:

Sourcing an XCMG drilling rig presents a strategic and cost-effective solution for projects requiring reliable, high-performance foundation drilling equipment. As one of the leading global manufacturers in construction machinery, XCMG offers a wide range of drilling rigs that combine advanced technology, durability, and competitive pricing. Their strong reputation, extensive service network, and continuous innovation make them a trusted partner in infrastructure development across diverse markets.

Purchasing an XCMG drilling rig provides access to robust engineering, fuel efficiency, and modern automation features that enhance productivity and reduce operational downtime. Additionally, the availability of local dealer support and spare parts significantly improves maintenance efficiency and long-term usability.

Overall, sourcing an XCMG drilling rig represents a balanced investment—delivering high value, proven performance, and scalability for present and future drilling operations. With proper due diligence on model selection, warranty terms, and after-sales support, XCMG stands out as a reliable and forward-thinking choice in the heavy equipment market.