The global demand for security solutions in residential and commercial buildings has driven significant growth in the window safety products market, with wrought iron window bars emerging as a preferred choice due to their durability, strength, and aesthetic versatility. According to Grand View Research, the global home security market was valued at USD 53.7 billion in 2022 and is expected to expand at a compound annual growth rate (CAGR) of 9.6% from 2023 to 2030, driven by rising concerns over property safety and technological integration in security infrastructure. Mordor Intelligence further highlights that increased urbanization and residential construction, particularly in North America and Europe, are key growth catalysts for metal-based security products like wrought iron bars. As demand climbs, manufacturers are enhancing production efficiency, investing in powder-coated finishes for weather resistance, and offering customizable designs to align with architectural trends. In this competitive landscape, the top 10 wrought iron window bars manufacturers distinguish themselves through innovation, material quality, and expansive distribution networks—setting industry benchmarks in both performance and design.

Top 10 Wrought Iron Window Bars Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Kaufman

Domain Est. 2004 | Founded: 1907

Website: kaufmaniron.com

Key Highlights: A custom manufacturer of all types of ornamental iron works and window security gates. Since 1907 our family has been serving the NY metropolitan area….

#2 CRL

Domain Est. 1995

Website: crlaurence.com

Key Highlights: The leading full-service provider of architectural metals, glass fittings & professional-grade glazing supplies. Shop CRL’s architectural hardware today….

#3 Charter Manufacturing

Domain Est. 1997

Website: chartermfg.com

Key Highlights: We are a privately held family of market leading metals manufacturing businesses. Customer intimacy, employee engagement and continuous improvement drive our ……

#4 Custom Window Guards

Domain Est. 1999

Website: newmanironworks.com

Key Highlights: Discover our made-to-order window guards in various colors and metals. Enhance both beauty and security of your home. Order your custom window guards today!…

#5 Window Guards

Domain Est. 2000

Website: artistryofiron.com

Key Highlights: We are your ornamental iron security specialists! Have a project for us? Call us today at (505) 293-5061 to schedule your Free Onsite Estimate….

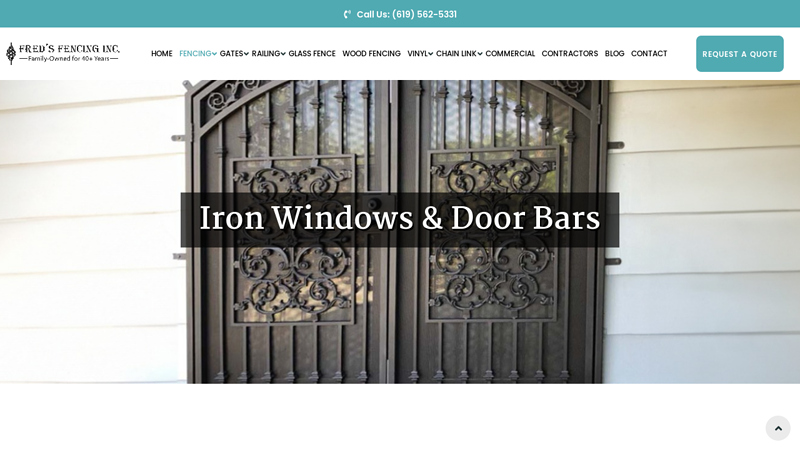

#6 Iron Window & Door Bars

Domain Est. 2003

Website: fredsfencing.com

Key Highlights: Protect your home with durable iron window & door bars from Fred’s Fencing. Enhance security & style with custom designs. Get a free quote today!…

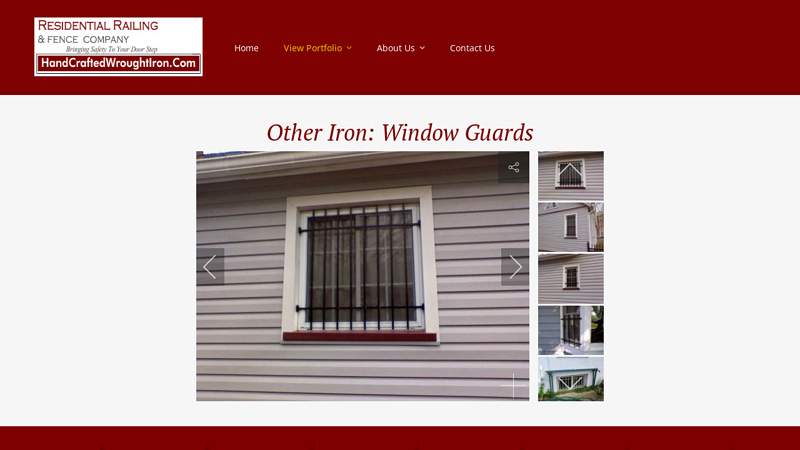

#7 Iron Window Guards

Domain Est. 2009

Website: handcraftedwroughtiron.com

Key Highlights: Iron window guards offer protection with elegance….

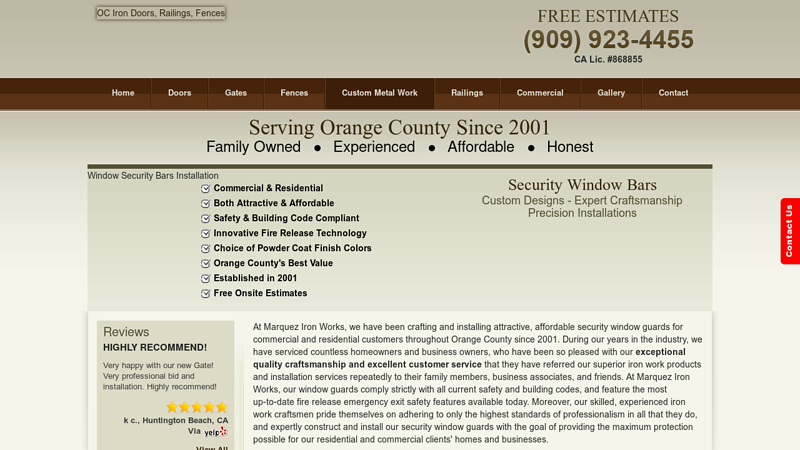

#8 Wrought Iron Security Window Bars

Domain Est. 2013 | Founded: 2001

Website: marquezironworks.com

Key Highlights: Marquez Iron Works – since 2001, Orange County, CA’s best value for custom wrought iron security window bars. Safety & building code compliant; fire-release ……

#9 Central States

Domain Est. 2020

Website: centralstatesco.com

Key Highlights: Central States is a 100% employee owned company who manufactures high quality metal roof, siding, and packages for buildings of all kinds….

#10 burglar

Domain Est. 2001

Website: bestmadewroughtiron.com

Key Highlights: Best Made Enterprises, Inc. will fabricate the highest quality wrought iron product at a competitive price with unsurpassed customer service….

Expert Sourcing Insights for Wrought Iron Window Bars

2026 Market Trends for Wrought Iron Window Bars

Rising Demand for Home Security Solutions

In 2026, the market for wrought iron window bars is expected to grow significantly, driven by increasing concerns about home security and property crime. As urbanization continues and residential areas expand into higher-risk zones, homeowners and property managers are prioritizing physical security measures. Wrought iron window bars remain a trusted, durable solution due to their strength and resistance to forced entry. The integration of these bars with modern alarm systems and surveillance is further enhancing their appeal, positioning them as both a functional and aesthetic security upgrade.

Shift Toward Decorative and Custom Designs

Consumers in 2026 are increasingly viewing window bars not just as security devices but as architectural enhancements. The demand for custom, ornamental wrought iron designs—featuring scrollwork, floral patterns, and artistic finishes—is rising, especially in historic districts and luxury housing markets. Homeowners are opting for powder-coated finishes in colors like matte black, bronze, and charcoal gray to match modern exteriors. This trend reflects a broader market shift toward products that combine safety with curb appeal.

Regulatory Influence and Safety Compliance

Building codes and fire safety regulations are shaping the design and installation of wrought iron window bars. In 2026, there is greater emphasis on removable or quick-release mechanisms that meet emergency egress requirements. Municipalities across North America and Europe are updating codes to balance security with life safety, leading manufacturers to innovate with easy-to-open interior releases that comply with fire department standards. This regulatory environment is driving product evolution and increasing the adoption of compliant models.

Growth in Retrofit and Renovation Markets

The home renovation sector is a key driver for wrought iron window bars in 2026. Aging housing stock in regions like the U.S. Sun Belt and Southern Europe is fueling demand for security upgrades during remodels. Contractors and DIY consumers are seeking durable, low-maintenance options, and wrought iron—known for its longevity and resistance to weathering—fits this need. Online retailers and home improvement stores report increased sales of pre-fabricated kits and installation guides, supporting broader market accessibility.

Sustainability and Material Sourcing

Environmental awareness is influencing material choices in construction. Wrought iron, being 100% recyclable and often made from recycled steel, aligns with green building initiatives. In 2026, manufacturers are promoting the sustainability of wrought iron products, emphasizing long lifespans and minimal environmental impact compared to plastic or aluminum alternatives. This eco-friendly positioning is resonating with environmentally conscious consumers and contributing to market growth.

Regional Market Variations

Demand for wrought iron window bars varies significantly by region in 2026. Latin America and parts of Southeast Asia show strong growth due to high crime rates and limited access to advanced electronic security. In contrast, Western Europe and North America are seeing steady but selective demand, primarily in urban centers and high-value neighborhoods. Emerging markets in Africa are also beginning to adopt wrought iron bars as middle-class homeowners seek affordable security solutions.

Technological Integration and Smart Features

A notable trend in 2026 is the integration of smart technology with traditional wrought iron bars. Some manufacturers are embedding sensors or connecting bars to smart home systems, enabling alerts when bars are tampered with or doors/windows are breached. While the core structure remains wrought iron, these hybrid solutions cater to tech-savvy consumers who want layered security without sacrificing aesthetics.

Conclusion

The 2026 market for wrought iron window bars is characterized by a blend of tradition and innovation. While rooted in proven physical security, the product category is evolving to meet modern demands for design, safety compliance, sustainability, and smart functionality. As homeowners continue to prioritize protection without compromising style, wrought iron window bars are poised for sustained relevance and growth in the global residential security market.

Common Pitfalls When Sourcing Wrought Iron Window Bars (Quality and Intellectual Property)

Sourcing wrought iron window bars involves more than just finding a supplier with the lowest price. Overlooking key aspects related to quality and intellectual property (IP) can lead to costly mistakes, safety risks, and legal complications. Here are the most common pitfalls to avoid:

Quality-Related Pitfalls

Using Inferior Materials

Many suppliers advertise “wrought iron” but actually use mild steel or low-grade alloys that corrode quickly and lack structural integrity. True wrought iron is rare and expensive; most modern “wrought iron” bars are actually forged or fabricated steel. However, even steel bars vary widely in quality—look for high-carbon or reinforced steel with proper anti-corrosion treatments like hot-dip galvanizing or powder coating.

Inconsistent Craftsmanship and Welding

Poorly welded joints, uneven spacing, or misaligned bars compromise both security and aesthetics. Hand-forged pieces may have charm, but inconsistent forging can create weak points. Always inspect samples for smooth welds, uniform finishes, and structural soundness.

Lack of Compliance with Building or Safety Codes

Some window bars do not meet local fire safety regulations, particularly regarding emergency egress. Installing non-compliant bars can lead to fines or liability in emergencies. Ensure the product includes quick-release mechanisms where required and meets local building codes.

Inadequate Protective Coatings

Even high-quality steel will rust without proper finishing. Suppliers may skimp on coatings or use thin paint that chips easily. Demand details about the finishing process—hot-dip galvanization followed by powder coating offers the best protection, especially in humid or coastal areas.

Insufficient Load Testing or Engineering Validation

Not all suppliers provide data on the strength or load-bearing capacity of their bars. Without proper engineering certification, bars may fail under stress (e.g., attempted break-ins or structural movement). Request performance data or third-party testing reports.

Intellectual Property (IP)-Related Pitfalls

Unintentional Replication of Protected Designs

Many wrought iron window bar designs—especially intricate, ornamental patterns—are protected by design patents or copyrights. Sourcing from manufacturers who copy branded or artistic designs can expose your project or business to infringement claims, even if you were unaware.

Sourcing from Suppliers with Questionable IP Practices

Some overseas or low-cost manufacturers routinely produce counterfeit or knock-off designs. Using their products may implicate you in IP violations. Always vet suppliers for original design capabilities or licensing agreements.

Lack of Design Ownership or Customization Rights

If you commission a custom design, ensure the contract specifies that you own the rights or have a license to use it. Otherwise, the supplier may reuse or resell your design, diluting exclusivity and potentially violating IP agreements.

Failure to Document IP Clearances

Keep records of design approvals, supplier warranties, and any IP disclaimers. In the event of a dispute, documented due diligence can protect your organization from liability.

By carefully evaluating both the material quality and intellectual property integrity of wrought iron window bars, buyers can avoid safety hazards, legal risks, and reputational damage. Always request samples, verify certifications, and consult legal counsel when dealing with custom or proprietary designs.

Logistics & Compliance Guide for Wrought Iron Window Bars

Product Classification & Tariff Codes

Wrought iron window bars typically fall under specific Harmonized System (HS) codes, which are crucial for international shipping and customs clearance. Common classifications include:

- HS Code 7308.90: Other construction structures and parts of structures, of iron or steel. This is the most frequently used code for wrought iron window bars.

- HS Code 7326.20: Other articles of iron or steel, grilles and gates.

Accurate classification ensures proper duty assessment and compliance with import/export regulations. Verify the exact code with your customs broker, as it may vary by country and product specifications (e.g., coated vs. uncoated, assembled vs. components).

Material & Manufacturing Standards

Wrought iron window bars must comply with relevant material and safety standards, especially if used in residential or commercial buildings:

- ASTM A36 / A500: Standard specifications for structural steel used in construction.

- Local Building Codes: Many jurisdictions require window bars to include quick-release mechanisms for emergency egress. For example:

- International Building Code (IBC) and International Residential Code (IRC): Mandate that window guards have an operable release device accessible from inside, allowing escape during fires or emergencies.

- NFPA 101 (Life Safety Code): Requires that any window barrier not impede emergency escape or rescue.

Ensure that all products are manufactured with compliant locking mechanisms and clearly labeled for emergency use.

Packaging & Shipping Considerations

Due to their weight and rigid structure, proper packaging is essential to prevent damage during transit:

- Secure Crating: Use wooden crates or heavy-duty pallets with corner protectors and strapping.

- Weather Protection: Wrap in moisture-resistant materials (e.g., plastic shrink wrap) to prevent rust during sea or outdoor transport.

- Labeling: Include clear labels indicating:

- Product name and SKU

- Weight and dimensions

- “Fragile” and “This Side Up” if applicable

- Compliance markings (e.g., “Meets IBC Egress Requirements”)

Import/Export Documentation

For international trade, ensure the following documents are prepared:

- Commercial Invoice: Detailing product description, quantity, value, and HS code.

- Packing List: Itemizing contents per package, weights, and dimensions.

- Bill of Lading (BOL) or Air Waybill (AWB): For freight tracking.

- Certificate of Origin: Required by some countries for tariff determination.

- Customs Declaration Forms: Country-specific (e.g., CBP Form 7501 in the U.S.).

Regulatory Compliance

Consider the following regulatory aspects depending on destination:

- U.S. Consumer Product Safety Commission (CPSC): While not directly regulating window bars, compliance with fire safety and egress codes is enforced at the state and municipal levels.

- European Union: May require CE marking if the product is part of a safety system, depending on national regulations.

- RoHS Compliance: Not typically applicable to structural iron products, but confirm if coatings or finishes contain restricted substances.

Installation & End-User Compliance

Provide end users with installation guidelines that emphasize compliance:

- Include instructions for installing quick-release mechanisms.

- Advise on proper anchoring into structural framing (not just drywall or siding).

- Recommend professional installation for commercial or multi-family buildings.

Environmental & Disposal Regulations

- Recyclability: Wrought iron is 100% recyclable. Inform customers of proper disposal or recycling options.

- Coatings and Finishes: If bars are powder-coated or painted, ensure compliance with VOC (volatile organic compound) regulations during manufacturing.

Summary

To ensure smooth logistics and full compliance for wrought iron window bars:

– Classify under the correct HS code.

– Adhere to building and fire safety codes, especially egress requirements.

– Package securely for transit.

– Prepare complete documentation for customs.

– Educate customers on compliant installation and emergency use.

Always consult with legal and customs experts in your target market to ensure alignment with local regulations.

In conclusion, sourcing wrought iron window bars requires careful consideration of quality, durability, security needs, and aesthetic appeal. While authentic wrought iron is less common today and often replaced by modern mild steel alternatives, it remains a preferred choice for its strength, malleability, and classic appearance. When sourcing, it is essential to evaluate reputable suppliers or custom metal fabricators, verify material specifications, and ensure compliance with local safety and building codes. Additionally, customization options, finish coatings for rust resistance, and professional installation play a vital role in maximizing both security and visual integration with the property. By prioritizing craftsmanship and reliable sourcing channels, homeowners and contractors can secure long-lasting, stylish, and effective window protection.