The global ornamental metal products market, driven by rising demand for architectural aesthetics and durable security solutions, is projected to grow at a CAGR of 5.8% from 2023 to 2030, according to Grand View Research. With wrought iron gates remaining a preferred choice for residential and commercial properties, particularly in North America and Europe, manufacturers are increasingly focused on innovative and visually striking designs to differentiate their offerings. As urbanization and infrastructure development continue to surge—compounded by a growing emphasis on curb appeal and property security—the demand for premium wrought iron gate patterns has reached new heights. Leveraging data from Mordor Intelligence, which forecasts steady growth in the global metal fabrication market through 2028, it’s evident that design innovation is a key competitive lever for gate manufacturers. In response to these shifts, we’ve analyzed industry trends, customer preferences, and manufacturing feasibility to identify the top 10 wrought iron patterns that are shaping the market today—from classic scrollwork to modern geometric motifs—delivering both aesthetic impact and structural resilience.

Top 10 Wrought Iron Patterns For Gates Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

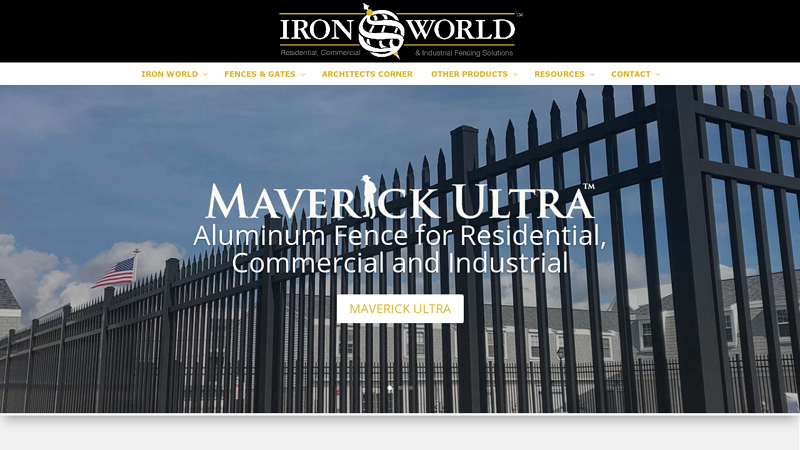

#1 Iron World Fencing

Domain Est. 2005

Website: ironworldfencing.com

Key Highlights: The fastest-growing manufacturer and distributor of decorative and ornamental iron fencing, aluminum fencing, chain link, slide, and swing gates nationwide….

#2 Los Angeles Iron

Domain Est. 2011

Website: losangelesiron.com

Key Highlights: We specialize in custom made wrought iron gates, wrought iron fence designs, wrought iron railings and much more for the greater Los Angeles area!Missing: patterns manufacturer…

#3 The Wrought Iron Factory

Website: wroughtironfactory.com.au

Key Highlights: The Wrought Iron Factory crafts premium wrought iron gates, doors, balustrades & panels with timeless style and durability. Enhance your property contact ……

#4 We Produce Quality, Wrought Iron Gates

Domain Est. 2001

Website: bejargate.com

Key Highlights: Wrought iron gates offer great ornamental traits. They are worked to give them an aesthetic appeal to make them look wonderful and elegant….

#5 Custom Wrought Iron Gates

Domain Est. 2004

Website: westcoastgate.com

Key Highlights: Whether you want bold, intricate patterns or understated elegance, a custom wrought iron gate transforms a basic entryway into a memorable feature….

#6 Anderson Ironworks

Domain Est. 2013

Website: andersonironworks.com

Key Highlights: Anderson Ironworks designs and fabricates custom wrought iron driveway gates and garden gates. From the curb, your gate is the first thing guests will see….

#7 Iron Gates

Domain Est. 2014

Website: preciseirondoors.com

Key Highlights: We have years of experience designing, manufacturing, and servicing wrought iron gates, and it truly shows in the beauty and craftsmanship of our work….

#8 Wrought Iron Railings, Balusters, Panels & More

Domain Est. 2021

Website: gonzatogroup.us

Key Highlights: $37 delivery 18-day returnsAs you explore these iron offerings, you will notice some truly original ideas in ornamental iron design. These stunning designs are perfect for iron gat…

#9

Domain Est. 2022

Website: davidiron.com

Key Highlights: We offer a wide range of fencing options including wrought iron, ornamental iron, security fences, and custom-designed gates. Each one is built for durability ……

#10 Unique Wrought Iron – Wrought Iron Gates

Website: uniquewroughtiron.com.au

Key Highlights: Unique Wrought Iron offers premium manufactured wrought iron gates, security doors, railings, and much more, all designed by our expert makers….

Expert Sourcing Insights for Wrought Iron Patterns For Gates

H2: 2026 Market Trends for Wrought Iron Patterns For Gates

The market for wrought iron patterns for gates in 2026 is poised for evolution, driven by shifting consumer preferences, technological advancements, and sustainability concerns. While maintaining its classic appeal, the sector is adapting to modern demands, resulting in several key trends shaping its trajectory.

1. Resurgence of Customization and Artisan Craftsmanship:

Despite mass production capabilities, demand for bespoke and hand-crafted wrought iron patterns is rising. Homeowners and commercial developers are increasingly seeking unique, personalized designs that reflect individual style or brand identity. In 2026, expect a premium on artisanal work featuring intricate scrollwork, nature-inspired motifs (floral, vine, and geometric patterns), and fusion designs blending traditional wrought iron with modern materials like powder-coated steel or integrated lighting. Customization will be facilitated by digital design tools, allowing clients to visualize and modify patterns before fabrication.

2. Integration of Smart Technology:

The convergence of security and aesthetics will drive the integration of smart features into wrought iron gates. While the ironwork itself remains traditional, 2026 will see more patterns designed to accommodate or complement smart components—such as hidden cameras, biometric access controls, Wi-Fi-enabled intercoms, and automated opening systems. Designers will craft patterns that allow seamless embedding of technology without compromising visual elegance.

3. Sustainability and Eco-Conscious Materials:

Environmental awareness is influencing material choices. While traditional wrought iron is durable and recyclable, the industry is shifting toward more sustainable practices. In 2026, manufacturers will emphasize the use of recycled iron and low-impact powder coatings with high UV and corrosion resistance. Additionally, digital pattern libraries and 3D modeling will reduce material waste by optimizing cutting and fabrication processes.

4. Modern Minimalism Meets Classic Craft:

Aesthetic preferences are leaning toward cleaner lines and minimalist designs, even within wrought iron. Expect popular 2026 patterns to include geometric grids, horizontal bars, and asymmetrical compositions that offer security without visual heaviness. These modern styles often incorporate subtle wrought iron detailing—such as forged accents or hand-twisted bars—creating a hybrid look that appeals to contemporary tastes while preserving craftsmanship.

5. Regional and Cultural Influences on Design:

Global design trends will increasingly influence wrought iron patterns. Mediterranean, Moroccan, and Asian-inspired motifs are gaining popularity in Western markets, while North American and European classical styles retain strong appeal in luxury developments. In 2026, pattern libraries will reflect greater cultural diversity, catering to international clientele and bespoke architectural projects.

6. E-Commerce and Digital Pattern Marketplaces:

The procurement of wrought iron patterns is becoming more digitized. Online platforms offering downloadable or customizable gate pattern templates—compatible with CNC cutting and CAD software—are expanding. This trend enables small workshops and DIY enthusiasts to access professional-grade designs, democratizing access to intricate wrought iron aesthetics and stimulating market growth.

In summary, the 2026 market for wrought iron patterns for gates will balance tradition with innovation. Demand will center on personalized, sustainable, and technologically enhanced designs that merge artistry with functionality, positioning wrought iron as a timeless yet forward-looking choice in architectural metalwork.

Common Pitfalls When Sourcing Wrought Iron Patterns for Gates

Quality Inconsistencies

One of the most frequent challenges when sourcing wrought iron patterns for gates is inconsistent quality. Many manufacturers—especially those overseas—may use substandard materials or employ poor welding and finishing techniques. Look out for thin metal gauges, uneven forging, rust-prone finishes, or weak joinery that can compromise both aesthetics and durability. Without rigorous quality control, even visually appealing patterns may degrade quickly when exposed to weather.

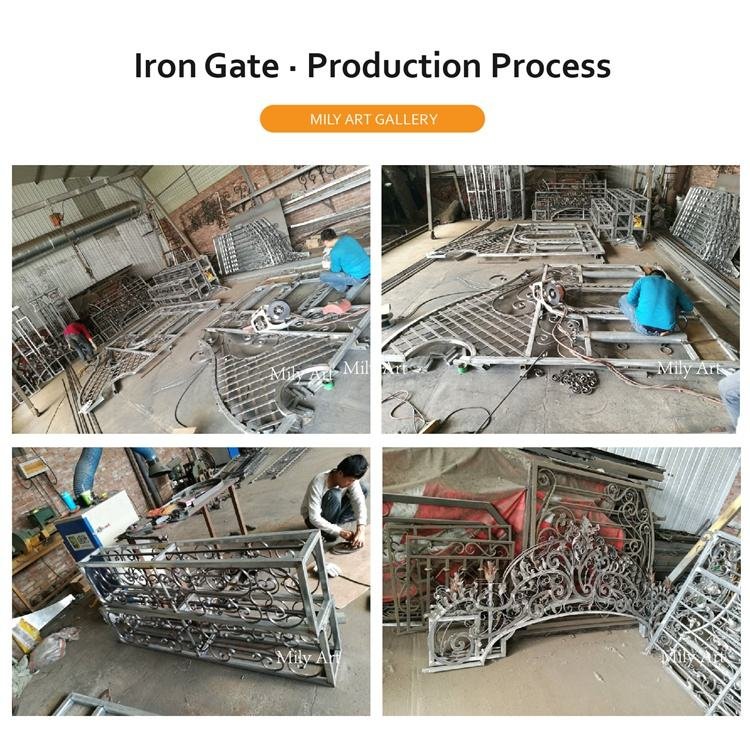

Lack of Skilled Craftsmanship

Authentic wrought iron work requires skilled artisans who understand traditional forging techniques. When sourcing from mass producers or low-cost suppliers, craftsmanship is often sacrificed for speed and volume. This can result in pattern inaccuracies, lack of fine detail, or mechanical-looking designs that lack the elegance of hand-forged ironwork. Always verify the maker’s expertise and request samples or site visits if possible.

Intellectual Property (IP) Infringement

Many wrought iron gate patterns are original designs protected by intellectual property rights. A common pitfall is unintentionally sourcing or replicating designs that are copyrighted or trademarked. Some suppliers may offer “inspired by” versions that closely mimic patented patterns, exposing buyers to legal risk. Always ensure that the supplier owns the rights to the design or has proper licensing, especially for custom or high-profile architectural projects.

Poor Design Documentation and Reproducibility

Wrought iron patterns often rely on detailed templates or CAD drawings for accurate replication. Inadequate or missing documentation can lead to inconsistencies when reproducing gates across multiple units or future replacements. Suppliers may not provide technical drawings or material specifications, making long-term maintenance or matching extensions difficult.

Misalignment Between Design and Structural Integrity

Intricate patterns may look impressive on paper but fail in real-world applications if not engineered for structural support. Overly decorative elements without adequate bracing can lead to warping, sagging, or failure over time—especially in large gates. Ensure that aesthetic patterns are backed by sound structural design, particularly for driveways or high-traffic areas.

Hidden Costs and Long Lead Times

Custom wrought iron patterns often come with underestimated costs and extended production timelines. Complex designs require more labor, specialized tools, and finishing processes. Buyers may face unexpected charges for modifications, shipping, or installation preparation. Always request a detailed quote and timeline upfront to avoid budget overruns.

Inadequate Finishing and Weather Resistance

Even the finest pattern can be ruined by poor finishing. Some suppliers apply cheap powder coating or paint that chips or fades quickly. Authentic wrought iron should be properly treated—hot-dip galvanized or sealed with durable finishes—to resist corrosion. Confirm the finishing process and warranty to ensure longevity.

Conclusion

To avoid these pitfalls, work with reputable, transparent suppliers who prioritize craftsmanship, provide IP-compliant designs, and offer comprehensive documentation and warranties. Investing time in due diligence ensures beautiful, durable, and legally secure wrought iron gates.

Logistics & Compliance Guide for Wrought Iron Patterns For Gates

Overview

Wrought iron patterns for gates are decorative and structural metal components used in architectural applications such as residential, commercial, and industrial properties. Proper logistics and compliance management ensure safe transportation, regulatory adherence, and customer satisfaction. This guide outlines key considerations for shipping, handling, and complying with international and domestic standards.

Classification & Harmonized System (HS) Code

Correct classification is crucial for customs clearance and duty assessment.

– Recommended HS Code: 7308.90 (Other structures and parts of structures, of iron or steel)

Note: Final classification may vary by country; verify with local customs authorities.

– Include detailed product descriptions (e.g., “hand-forged wrought iron gate patterns, decorative metalwork”) to prevent misclassification.

Packaging & Handling

Secure packaging prevents damage during transit.

– Use wooden crates or reinforced cardboard with internal bracing to protect intricate designs.

– Wrap individual components in anti-corrosive VCI (Vapor Corrosion Inhibitor) paper to prevent rust.

– Label packages with “Fragile,” “This Side Up,” and “Protect from Moisture.”

– For large or custom patterns, disassemble components where possible and include assembly instructions.

Transportation & Shipping

Choose appropriate transport methods based on size, weight, and destination.

– Domestic Shipments: Use freight carriers specializing in oversized or fragile goods. Palletize and secure with straps.

– International Shipments:

– Air freight for urgent, small-batch orders.

– Ocean freight for bulk shipments; use containerized shipping with moisture barriers.

– Ensure compliance with International Maritime Dangerous Goods (IMDG) Code if coatings or treatments involve hazardous materials.

Import/Export Compliance

Follow regulations to avoid delays or penalties.

– Export Documentation: Commercial invoice, packing list, bill of lading/air waybill, certificate of origin.

– Import Requirements: Verify destination country’s import duties, quotas, and product standards (e.g., CE marking in the EU, ANSI/AISC in the U.S.).

– Restricted Materials: Confirm wrought iron does not contain regulated substances (e.g., lead-based paints) under REACH (EU) or TSCA (U.S.).

Product Standards & Certifications

Ensure designs meet structural and safety requirements.

– Structural Integrity: Comply with local building codes (e.g., International Building Code – IBC).

– Finish & Coating: Powder-coated or galvanized finishes should meet ASTM B117 (salt spray resistance) and ISO 12944 (corrosion protection).

– Testing Documentation: Provide material test reports (MTRs) upon request, especially for architectural or public installations.

Environmental & Safety Regulations

Adhere to environmental standards in production and shipping.

– VOC Emissions: Use low-VOC coatings to comply with EPA (U.S.) or EU Directive 2004/42/EC.

– Waste Management: Recycle metal scraps in accordance with local environmental laws.

– Worker Safety: Follow OSHA (U.S.) or equivalent standards during manufacturing and packaging.

Customs Clearance Tips

Facilitate fast processing at borders.

– Provide accurate weight, dimensions, and material composition.

– Declare the value correctly to avoid under/over-valuation penalties.

– Use a licensed customs broker for complex international shipments.

After-Sales Support & Warranty Compliance

Maintain compliance post-delivery.

– Include installation guidelines and maintenance instructions.

– Offer corrosion warranties (e.g., 5–10 years) and document terms per consumer protection laws (e.g., Magnuson-Moss Warranty Act in the U.S.).

Conclusion

Effective logistics and compliance for wrought iron gate patterns require attention to classification, packaging, regulations, and customer requirements. By following this guide, manufacturers and distributors can ensure timely delivery, regulatory adherence, and long-term product performance.

In conclusion, sourcing wrought iron patterns for gates requires a careful balance between aesthetic appeal, structural integrity, and budget considerations. By exploring diverse sources—such as local blacksmiths, online marketplaces, architectural salvage yards, and custom fabrication shops—you can find unique or traditional designs that meet both functional and decorative needs. It’s important to verify the quality of materials, assess craftsmanship, and ensure compatibility with your property’s style and security requirements. Custom designs offer greater personalization, while pre-existing patterns can provide cost-effective and time-saving solutions. Ultimately, investing in well-sourced wrought iron patterns not only enhances the visual appeal of your entrance but also adds long-term value and durability to your property.