The global woven polypropylene (PP) bag market is experiencing robust growth, driven by rising demand across agriculture, construction, food packaging, and logistics sectors. According to a 2023 report by Mordor Intelligence, the market was valued at USD 11.8 billion in 2022 and is projected to grow at a CAGR of over 5.2% from 2023 to 2028. This expansion is fueled by the material’s durability, cost-effectiveness, and increasing preference for reusable packaging solutions amid growing environmental awareness. Grand View Research further supports this trajectory, noting that Asia Pacific dominates both production and consumption due to industrialization and expanding agrochemical industries in countries like India and China. As demand escalates, manufacturers are investing in automation, sustainable practices, and innovative designs to meet evolving regulatory and customer standards. Against this backdrop, identifying the top woven PP bag manufacturers becomes essential for businesses seeking reliable, scalable, and quality-driven supply partners.

Top 10 Woven Bag Pp Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 PP Woven Sack Production Line

Domain Est. 2003

Website: phyllis.com.tw

Key Highlights: The new generation of woven sack conversion line for bottom-sewn sacks is suitable for coated and uncoated woven fabric, BOPP film laminated fabric….

#2 Lincon Polymers

Domain Est. 2004

Website: linconpolymers.com

Key Highlights: Lincon Polymers is a leading PP woven bags manufacturers and exporters worldwide. The woven polypropylene we offer are suitable for all kinds of packaging ……

#3 Plastic Bags Manufacturers

Domain Est. 2006

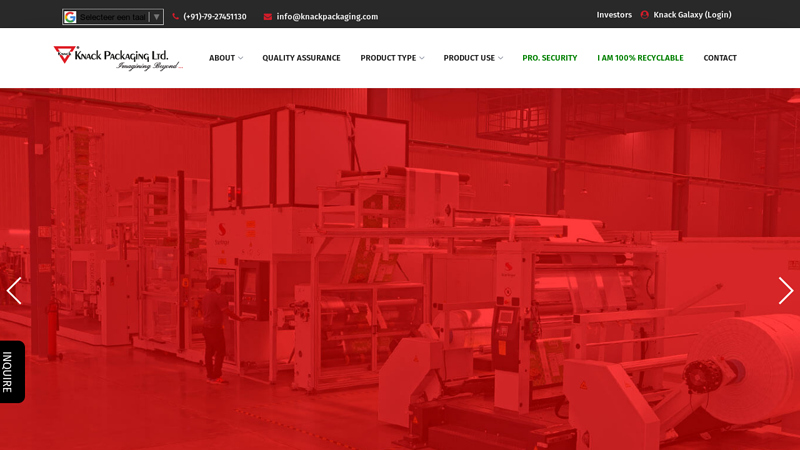

Website: knackpackaging.com

Key Highlights: Knack Packaging is the largest manufacturer and exporter of PPE / PP Woven Fabrics & Bags / Printed and Laminated Woven PP Bags. (PLWPP)…

#4 Cady Bag Company

Domain Est. 2006

Website: cadybag.com

Key Highlights: Cady Bag company is a manufacturer of polypropylene woven bags and fabrics. Products include mesh bags, specialty bags, and geotextile fabrics for niche ……

#5 Sah Polymers

Domain Est. 2010

Website: sahpolymers.com

Key Highlights: Sah Polymers Limited is the leading PP woven bags manufacturer in India from the last 25 years. We manufacture & export PP woven fabric bags. Enquire Today!…

#6 C.P. PACKAGING

Domain Est. 2010

Website: cpwovenbag.com

Key Highlights: We are a manufacturer of high quality woven bag With over 40 years’ experience and being the largest manufacturer PP woven bag in South East Asia combined ……

#7 Leading PP Woven Bags Manufacturer & Supplier

Domain Est. 2011

Website: alliancepolysacks.com

Key Highlights: Alliance Polysacks Pvt. Ltd. is leading PP woven bags manufacturer with a capacity of producing over 30 million bags per month….

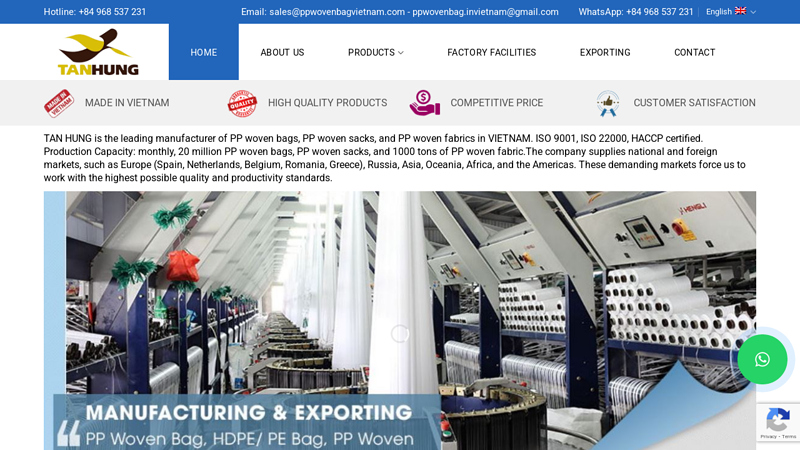

#8 Manufacturer of PP Woven Bag, PP Woven Fabric

Domain Est. 2017

Website: ppwovenbagvietnam.com

Key Highlights: TAN HUNG is the leading manufacturer of PP woven bags, PP woven sacks, and PP woven fabrics in VIETNAM. ISO 9001, ISO 22000, HACCP certified….

#9 Govardhan Polyplast Pvt Ltd (GPPL)

Domain Est. 2018

Website: govardhanpolyplast.com

Key Highlights: We are one of the pre-eminent manufacturer & exporter of HDPE/ PP Woven Fabric , HDPE / PP Woven Sack & Bags , Multicolour Printed BOPP Laminated Bags / Sack & ……

#10 PP Woven Bag

Domain Est. 2007

Website: anitaplastics.com

Key Highlights: Anita Plastic’s PP woven bag is crafted from high-quality polypropylene/HDPE raw material. These pp bags are not just sturdy but also lightweight….

Expert Sourcing Insights for Woven Bag Pp

H2: Market Trends for Woven PP Bags in 2026

The global woven polypropylene (PP) bag market is expected to undergo significant transformation by 2026, driven by evolving consumer preferences, regulatory pressures, technological advancements, and sustainability initiatives. As industries seek cost-effective, durable, and eco-conscious packaging solutions, woven PP bags remain a key player in sectors such as agriculture, construction, food & beverage, and retail. Below is an analysis of the key market trends shaping the woven PP bag industry in 2026:

1. Rising Demand for Sustainable Packaging Solutions

With increasing environmental awareness and government regulations targeting single-use plastics, manufacturers are innovating to make woven PP bags more sustainable. By 2026, the market will see a surge in recyclable, reusable, and biodegradable PP blends. Many companies are investing in closed-loop recycling systems and incorporating post-consumer recycled (PCR) content into woven bags to reduce carbon footprint and meet ESG (Environmental, Social, and Governance) goals.

2. Growth in Agrochemical and Food Packaging Sectors

The agricultural sector remains a major consumer of woven PP bags, especially for packaging fertilizers, grains, and animal feed. In developing economies, rising agricultural output and government support for modern farming practices are boosting demand. Additionally, food safety regulations are encouraging the use of food-grade woven PP bags with laminated or coated interiors, ensuring longer shelf life and contamination protection.

3. Expansion in Emerging Markets

Asia-Pacific, particularly India, China, and Southeast Asia, continues to dominate the woven PP bag market in 2026. Rapid urbanization, industrial growth, and increasing investments in infrastructure and retail are driving demand. Africa and Latin America are also emerging as high-potential markets due to growing populations, expanding agricultural activities, and improved supply chain logistics.

4. Technological Advancements in Manufacturing

Automation and digital printing technologies are revolutionizing woven PP bag production. By 2026, manufacturers are increasingly adopting high-speed weaving, ultrasonic sealing, and flexographic printing to improve efficiency, reduce waste, and offer customized branding options. Smart manufacturing (Industry 4.0) integration allows real-time monitoring, predictive maintenance, and better quality control.

5. Shift Toward Premium and Branded Packaging

Brands are leveraging woven PP bags as marketing tools, opting for high-quality, aesthetically appealing designs with vivid graphics and enhanced durability. The trend toward premiumization is especially evident in the retail and fashion sectors, where reusable woven PP tote bags are marketed as eco-friendly alternatives to traditional shopping bags.

6. Regulatory Pressures and Material Innovation

Governments worldwide are implementing stricter regulations on plastic usage, pushing manufacturers to develop thinner yet stronger PP fabrics and explore hybrid materials. Innovations such as oxo-degradable and compostable PP variants are gaining traction, although concerns over microplastics are steering the industry toward genuinely recyclable solutions.

7. E-commerce and Logistics Influence

The booming e-commerce sector demands durable and lightweight packaging. Woven PP bags are increasingly used for shipping bulk goods, industrial components, and textiles due to their high tensile strength and moisture resistance. In 2026, expect increased adoption in last-mile delivery systems, especially for heavy or irregularly shaped items.

In conclusion, the woven PP bag market in 2026 is poised for sustained growth, underpinned by innovation, sustainability, and regional economic development. While environmental challenges persist, the industry’s adaptability and focus on circular economy principles position woven PP bags as a resilient and evolving packaging solution across global markets.

Common Pitfalls Sourcing Woven PP Bags (Quality, IP)

Sourcing woven polypropylene (PP) bags can be cost-effective, but overlooking key quality and intellectual property (IP) risks can lead to significant problems. Here are common pitfalls to avoid:

Inadequate Quality Control Standards

One of the most frequent issues is failing to establish or enforce clear quality specifications. Buyers may accept samples without rigorous testing, leading to inconsistencies in fabric weight, stitching strength, or print accuracy in bulk production. Without defined standards for tear resistance, UV protection, or load capacity, delivered bags may fail under real-world conditions, damaging brand reputation.

Poor Material Composition and Durability

Not all polypropylene is created equal. Suppliers may use recycled or substandard resin to cut costs, resulting in brittle fabric, inconsistent texture, or reduced lifespan. Bags may degrade quickly when exposed to sunlight or heavy use. Always verify the resin type (e.g., virgin vs. recycled PP) and request material certifications to ensure durability and safety, especially for food-grade or outdoor applications.

Inconsistent Printing and Branding

Woven PP bags often serve as marketing tools, making print quality critical. Pitfalls include color mismatches, misaligned logos, or low-resolution graphics due to poor printing techniques (e.g., flexographic vs. rotogravure). Without approved print proofs and Pantone color matching, branding may appear unprofessional or inconsistent across batches.

Weak Stitching and Construction

Even with strong fabric, poor craftsmanship can lead to failure. Look out for uneven stitching, skipped stitches, or inadequate seam allowances. Handles and stress points must be reinforced—especially for heavy-duty bags. Conduct load testing during quality inspections to verify structural integrity.

Lack of Intellectual Property Protection

When providing custom designs, logos, or unique bag structures, failing to secure IP rights is a major risk. Suppliers in some regions may reproduce or sell your designs to competitors without legal repercussions. Always use Non-Disclosure Agreements (NDAs) and include IP ownership clauses in manufacturing contracts to retain full rights to your designs.

Insufficient Compliance and Certification Checks

Depending on the end-use, woven PP bags may need to meet regulatory standards (e.g., FDA for food contact, REACH for chemicals in the EU). Overlooking compliance can result in shipment rejections or legal penalties. Confirm that materials are non-toxic, lead-free, and meet relevant environmental and safety regulations.

Overlooking Sustainability Claims

Many buyers seek eco-friendly options, but “recyclable” or “biodegradable” claims can be misleading. Some PP bags contain additives that hinder recycling or degrade poorly. Scrutinize certifications like ISO 14001 or third-party eco-labels, and request documentation to validate sustainability claims and avoid greenwashing.

Failure to Audit Suppliers

Relying solely on samples or supplier promises without on-site audits increases risk. Unannounced factory visits or third-party inspections help verify production capabilities, ethical labor practices, and quality control processes. Skipping this step may result in supply chain disruptions or reputational damage due to unethical manufacturing.

Logistics & Compliance Guide for Woven PP Bags

Overview of Woven PP Bags

Woven polypropylene (PP) bags are durable, lightweight, and widely used for packaging bulk commodities such as agricultural products, construction materials, chemicals, and foodstuffs. Their strength, resistance to moisture, and recyclability make them a popular choice in global supply chains. However, transporting and distributing woven PP bags requires careful attention to logistics planning and compliance with international and local regulations.

Material Specifications and Standards

Woven PP bags must meet specific quality and safety standards depending on their intended use. Common standards include:

– ISO 2730: Specifies requirements for woven PP sacks used in general packaging.

– ASTM D3951: Covers commercial packaging standards, including material durability and labeling.

– FDA Compliance: Required if bags are used for food-grade packaging (e.g., grains, sugar, flour).

– REACH & RoHS: Ensure the material is free from restricted hazardous substances, especially for shipments to the EU.

Manufacturers should provide certification of compliance with relevant standards to ensure regulatory acceptance.

Packaging and Unit Load Optimization

To maximize transport efficiency and minimize damage:

– Stackability: Woven PP bags should be uniformly sized and firmly sealed to allow stable stacking.

– Palletization: Use standardized pallets (e.g., EUR/EPAL or ISO pallets) and secure bags with stretch wrap or strapping.

– Load Securing: Prevent shifting during transit by using dunnage, load locks, or airbags in containers or trucks.

– Moisture Protection: Though PP is moisture-resistant, use moisture barriers or desiccants if transporting hygroscopic goods.

Transportation Modes and Considerations

Road Transport

Ideal for regional distribution. Ensure:

– Proper tarping or enclosed trailers to protect from weather.

– Compliance with weight limits and axle load regulations per country.

Sea Freight

Common for international shipments:

– Use dry, ventilated containers to prevent condensation.

– Fumigation certificates may be required based on destination country regulations (e.g., AQIS in Australia).

– Avoid moisture traps by placing bags on wooden pallets, not directly on container floors.

Rail and Air Freight

Rail is cost-effective for long overland routes; air freight is suitable for urgent, high-value shipments but limited by cost and weight.

Import and Export Compliance

Documentation Requirements

Ensure all shipments include:

– Commercial Invoice

– Packing List

– Bill of Lading or Air Waybill

– Certificate of Origin

– Material Safety Data Sheet (MSDS), if carrying hazardous materials

– Phytosanitary Certificate (if used for agricultural products)

Customs Classification

Woven PP bags typically fall under HS Code 6305.33 (Sacks and bags, of polypropylene strip or the like). Confirm classification with local customs authorities to ensure correct tariffs and duty rates.

Country-Specific Regulations

- USA: Complies with FDA and CPSC guidelines if used for consumer products.

- EU: Requires CE marking for certain applications and compliance with packaging waste directives (e.g., Producer Responsibility).

- GCC Countries: May require SASO certification and adherence to local standardization bodies.

- China: Needs CIQ inspection and customs clearance documentation.

Environmental and Sustainability Compliance

- Recyclability: Woven PP is recyclable (Resin ID Code 5). Encourage end-user recycling and provide disposal instructions.

- Packaging Waste Directives: In the EU and other regions, producers may be subject to Extended Producer Responsibility (EPR) schemes. Register with national compliance schemes if applicable.

- Carbon Footprint: Optimize logistics routes and use eco-friendly inks and additives to support sustainability goals.

Quality Control and Handling Procedures

- Pre-Shipment Inspection: Verify bag strength (e.g., drop tests, tensile strength) and print accuracy.

- Storage Conditions: Store in cool, dry areas away from direct sunlight to prevent UV degradation.

- Handling: Use mechanical equipment (forklifts, conveyors) to reduce manual labor and prevent tears or contamination.

Risk Management and Contingency Planning

- Insurance: Cover goods for loss, damage, or delay during transit. Specify coverage for environmental exposure or contamination.

- Supplier Audits: Regularly audit manufacturers for consistency in quality and compliance.

- Labeling Accuracy: Include handling instructions (e.g., “Do Not Stack Above X Layers”, “Keep Dry”) in local languages at destination.

Conclusion

Efficient logistics and strict compliance are essential for the successful global distribution of woven PP bags. By adhering to international standards, optimizing packaging and transport, and maintaining thorough documentation, businesses can ensure product integrity, regulatory acceptance, and customer satisfaction. Regular updates to compliance protocols and logistics strategies will help adapt to evolving regulations and market demands.

In conclusion, sourcing woven polypropylene (PP) bags presents a cost-effective, durable, and sustainable packaging solution for a wide range of industries. Their strength, reusability, and resistance to moisture make them ideal for both retail and industrial applications. When sourcing, it is essential to consider factors such as material quality, customization options, supplier reliability, and environmental impact. By partnering with reputable manufacturers and prioritizing eco-friendly production practices, businesses can leverage the benefits of woven PP bags while meeting sustainability goals and customer expectations. Overall, woven PP bags offer a practical and responsible choice in the evolving landscape of packaging solutions.