The global wool grease market is experiencing steady growth, driven by rising demand for lanolin—a key derivative of wool grease—in the cosmetics, pharmaceutical, and industrial sectors. According to a 2023 report by Grand View Research, the global lanolin market was valued at USD 208.6 million and is expected to expand at a compound annual growth rate (CAGR) of 5.2% from 2023 to 2030. This growth is fueled by increasing consumer preference for natural, bio-based ingredients in personal care products and the expanding use of lanolin in medical applications such as wound healing and dermatological treatments. Additionally, Mordor Intelligence projects heightened activity in the wool processing sector, particularly in major wool-producing regions like Australia, New Zealand, and South America, further boosting raw wool grease supply. As downstream demand grows, a select group of manufacturers have emerged as leaders in wool grease refinement and distribution—driving innovation, ensuring sustainability, and shaping the future of this niche yet vital segment of the global oleochemical industry.

Top 9 Wool Grease Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 About Rolex Lanolin Products Ltd

Domain Est. 1997

Website: rolexlanolin.com

Key Highlights: Lanolin is a highly refined and purified natural grease that is extracted from Sheep’s Wool. The crude (or raw) grease is secreted from the sheep’s ……

#2 Wool grease: Composition and specification

Domain Est. 1998

Website: lanolin.com

Key Highlights: Wool grease is a complex mixture of esters, di-esters, and hydroxy esters resulting from the condensation of high molecular weight lanolin alcohols with lanolin ……

#3 Lanolene, Wool derived Lanolin, Natural Eco

Domain Est. 2000

Website: lanolene.com

Key Highlights: Lanolene is based on the South Coast of New South Wales, Australia. Producing high quality liquid lanolin protectants and lubricant products along with ……

#4 Wool Grease

Domain Est. 2005

Website: michellwool.com

Key Highlights: Michell supplies high-quality wool grease for lanolin production, lubricants, corrosion protection and more….

#5 Wool Grease

Domain Est. 2011

Website: modernwoollens.com

Key Highlights: Overview of Modern Woollens Wool Grease. Wool Grease is secreted by the sebaceous glands of sheep. It is a light brown semi-solid wax….

#6 About Us!

Domain Est. 2013

Website: woolwaxusa.com

Key Highlights: WoolWax Undercoating Formula is a lanolin based corrosion inhibitor developed solely to protect the undercarriages of automobiles and trucks….

#7 LanEsters

Domain Est. 2017

Website: lanesters.com

Key Highlights: Wool grease is a natural wax secreted by the sebaceous glands of sheep covering the wool fibres. It naturally protects the sheep’s skin and wool from ……

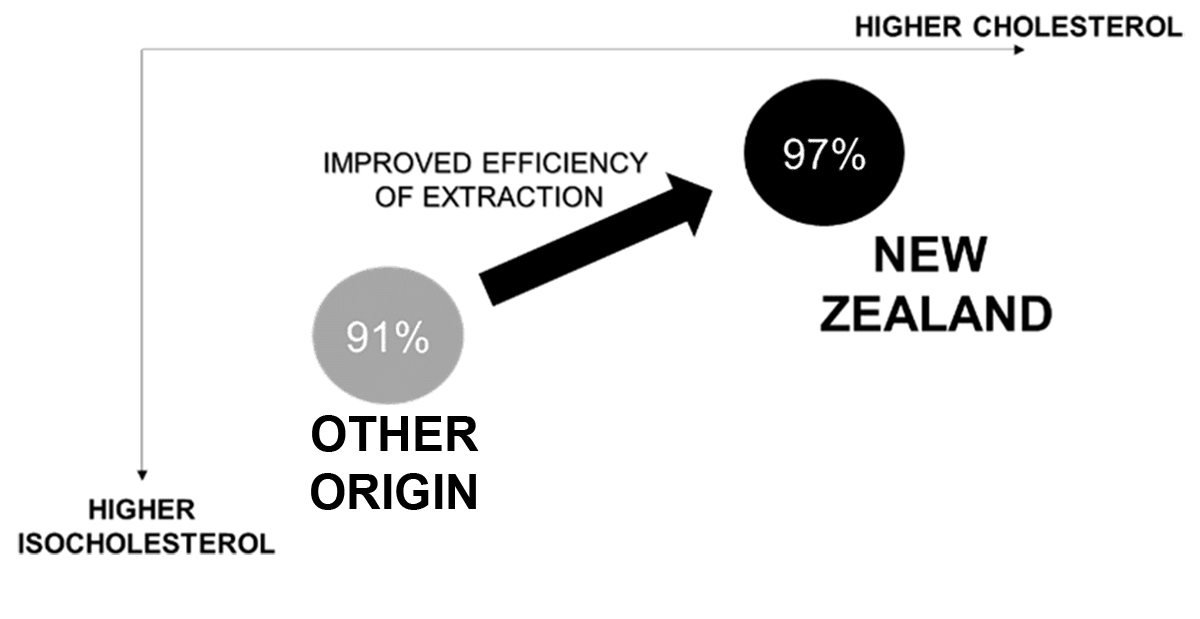

#8 High Cholesterol Wool Grease

Website: woolworks.co.nz

Key Highlights: New Zealand wool grease comes from healthy free range sheep. Our product has a high cholesterol content with low residual ash and water, and no additives….

#9 Prolan

Website: prolan.co.nz

Key Highlights: Our lanolin-based range of products are made from sheep wool grease, which is a sustainable resource. We have different blends available for any application ……

Expert Sourcing Insights for Wool Grease

H2: 2026 Market Trends for Wool Grease

The global wool grease market is anticipated to experience moderate but steady growth by 2026, driven by increasing demand for natural and sustainable raw materials across various industrial and consumer sectors. Wool grease, a byproduct of raw wool processing, serves as a primary source of lanolin—an essential ingredient in cosmetics, pharmaceuticals, and industrial lubricants. The following key trends are expected to shape the wool grease market in 2026:

-

Rising Demand in the Cosmetics and Personal Care Industry

Lanolin, derived from wool grease, continues to gain traction as a natural emollient and moisturizing agent in skincare and haircare products. With growing consumer preference for clean-label, biodegradable, and cruelty-free ingredients, manufacturers are increasingly turning to lanolin as an effective, renewable alternative to synthetic additives. This trend is expected to drive higher procurement of wool grease, particularly in regions with strong cosmetics industries such as North America, Europe, and parts of Asia-Pacific. -

Expansion of Pharmaceutical Applications

Lanolin’s bioactive properties, including wound-healing and skin-protective qualities, make it valuable in over-the-counter pharmaceuticals and medical ointments. By 2026, increased R&D investments in dermal delivery systems and antimicrobial formulations are likely to boost demand for high-purity lanolin, further stimulating the wool grease supply chain. -

Sustainability and Circular Economy Initiatives

As the textile and agricultural sectors emphasize circular economy models, wool grease is being repositioned as a high-value co-product rather than waste. Innovations in wool scouring and recovery technologies are improving extraction yields and purity, making wool grease a more attractive resource for green chemistry applications. Regulatory support for bio-based materials in the EU and North America is expected to incentivize investment in wool grease refinement. -

Geopolitical and Supply Chain Dynamics

Major wool-producing countries such as Australia, New Zealand, and Argentina remain dominant suppliers of raw wool grease. However, rising labor costs, climate variability affecting sheep farming, and export restrictions could impact supply stability. In response, some processors are establishing localized refining facilities to reduce dependence on long supply chains and respond faster to market demands. -

Price Volatility and Market Consolidation

Wool grease prices are expected to remain subject to fluctuations due to varying wool production cycles and demand from end-user industries. By 2026, increased consolidation among lanolin refiners and vertical integration of wool processing operations may lead to more stable pricing and improved quality control across the value chain. -

Technological Advancements in Processing

Emerging technologies such as supercritical fluid extraction and membrane filtration are enhancing the efficiency and sustainability of wool grease refining. These advancements allow for higher recovery of lanolin with lower environmental impact, supporting compliance with stricter environmental regulations and improving profit margins for producers.

In conclusion, the 2026 wool grease market will be characterized by growing demand from high-value industries, technological innovation, and sustainability-driven transformation. While challenges related to supply consistency and price volatility persist, strategic investments in processing and downstream applications are expected to strengthen the market’s resilience and long-term growth potential.

Common Pitfalls in Sourcing Wool Grease: Quality and Intellectual Property Concerns

Sourcing wool grease (also known as lanolin or wool wax) presents unique challenges, particularly concerning consistent quality and intellectual property (IP) protection. Overlooking these pitfalls can lead to supply disruptions, product failures, and legal vulnerabilities.

Quality Inconsistencies and Verification Challenges

Wool grease is a natural by-product of sheep wool processing, making its composition inherently variable. Key quality risks include:

– Batch-to-Batch Variability: Differences in sheep breed, diet, climate, and shearing season significantly affect lanolin composition, leading to inconsistent melting points, viscosity, and purity.

– Contamination Risks: Residual pesticides (e.g., organophosphates), dirt, vegetable matter, or microbial contamination from improper wool handling can compromise safety and efficacy, especially in pharmaceutical or cosmetic applications.

– Adulteration and Mislabeling: Some suppliers may dilute wool grease with cheaper oils or synthetic waxes, misrepresenting the product’s purity. Without rigorous third-party testing, such adulteration is difficult to detect.

– Inadequate Specifications: Relying solely on supplier-provided certificates of analysis (CoA) without independent verification or clear, measurable quality parameters (e.g., hydroxyl value, unsaponifiable matter, color) increases risk.

Mitigation Strategy: Establish strict quality specifications, require ISO-compliant testing (e.g., ISO 1875), and conduct regular audits and independent lab testing of incoming materials.

Intellectual Property Risks and Supply Chain Transparency

The processing and application of wool grease—especially in high-value sectors like cosmetics, pharmaceuticals, and specialty lubricants—often involve proprietary formulations and technologies, creating IP exposure:

– Reverse Engineering Vulnerabilities: If suppliers handle formulations or provide custom-processed lanolin, there is a risk of trade secret leakage, particularly in jurisdictions with weak IP enforcement.

– Lack of Process IP Protection: Advanced refining methods (e.g., molecular distillation, supercritical extraction) may be patented. Sourcing from unlicensed processors could expose buyers to infringement claims.

– Unclear Ownership in Joint Development: Collaborating with suppliers on product development without clear IP agreements can result in disputes over ownership of improvements or new formulations.

– Opaque Supply Chains: Multiple intermediaries between wool producers and final suppliers obscure traceability, increasing the risk of inadvertently sourcing from entities using infringing processes or unethical practices.

Mitigation Strategy: Conduct thorough due diligence on supplier IP compliance, use robust confidentiality agreements (NDAs), define IP ownership in contracts, and prioritize vertically integrated or certified suppliers with transparent sourcing and processing practices.

Addressing these quality and IP pitfalls is essential for ensuring supply reliability, regulatory compliance, and the protection of proprietary innovations when sourcing wool grease.

Logistics & Compliance Guide for Wool Grease

Overview of Wool Grease

Wool grease, commonly known as lanolin, is a natural wax secreted by sheep and extracted during the scouring of raw wool. It is widely used in cosmetics, pharmaceuticals, and industrial applications due to its emollient and water-repellent properties. Proper logistics and compliance are essential due to its classification as a non-hazardous but regulated organic substance under international trade and transportation standards.

Regulatory Classification

Wool grease is generally classified as a non-hazardous material under most international transport regulations. However, it may be subject to specific rules depending on the form (crude, refined, anhydrous) and the destination country. Key classifications include:

– UN Number: Typically not assigned for crude wool grease when transported in solid or semi-solid form.

– IMO/IMDG Code: Usually not regulated as dangerous goods under maritime transport when in non-liquid form.

– IATA: Not classified as a dangerous good for air transport if properly packaged and declared.

– Customs Tariff Codes: Varies by country; common HS Code: 1505.00 (Fats and oils of animal origin, including lanolin).

Packaging Requirements

Appropriate packaging ensures product integrity and regulatory compliance during transit:

– Use sealed, moisture-resistant containers (e.g., food-grade plastic drums, lined steel drums, or super sacks for bulk).

– Label all packages with product name, net weight, batch number, and supplier information.

– For international shipments, include bilingual labeling if required by the destination country.

– Protect from contamination, heat, and direct sunlight to prevent oxidation or degradation.

Storage Conditions

- Store in a cool, dry, and well-ventilated area.

- Ideal temperature range: 10°C to 25°C (50°F to 77°F).

- Avoid prolonged exposure to UV light and high humidity.

- Keep away from strong oxidizing agents and incompatible materials.

Transportation Guidelines

- Road: Use clean, covered vehicles. Prevent contamination from other cargo. Maintain documentation (e.g., waybill, certificate of analysis).

- Sea: Stow away from heat sources and incompatible goods. Ensure proper ventilation in containers to avoid condensation.

- Air: Comply with IATA guidelines. Provide a Material Safety Data Sheet (MSDS/SDS) upon request, even if not classified as hazardous.

- Documentation: Include commercial invoice, packing list, bill of lading/air waybill, and any required export declarations.

Import/Export Compliance

- Export Controls: Verify if export licenses are required (rare for wool grease, but possible in some jurisdictions).

- Import Regulations: Check destination country requirements (e.g., USDA, EU REACH, or TSCA in the US).

- Phytosanitary Certificates: Generally not required, as wool grease is processed and not considered a plant pest vector.

- Customs Declarations: Accurately classify under the appropriate HS code and declare value for duty assessment.

Environmental & Safety Considerations

- Wool grease is biodegradable and non-toxic but should not be released into waterways.

- Spill management: Absorb with inert material (e.g., sand, vermiculite) and dispose of according to local waste regulations.

- Personal protective equipment (PPE) such as gloves and safety glasses recommended during handling to avoid skin irritation in sensitive individuals.

Certification & Traceability

- Maintain batch traceability from wool source to final product.

- Provide Certificates of Analysis (CoA) confirming purity, moisture content, and absence of contaminants (e.g., pesticides, heavy metals).

- For cosmetic/pharmaceutical grades, ensure compliance with pharmacopeial standards (e.g., USP, Ph. Eur.).

Key Regulatory References

- GHS (Globally Harmonized System): May require SDS preparation depending on downstream use.

- REACH (EU): Registration may be required if imported in quantities over 1 tonne/year.

- FDA (USA): Regulated as a cosmetic ingredient; compliance with 21 CFR Part 700 required for final products.

- APEDA (India): Certification may be required for export from wool-producing regions.

Conclusion

Effective logistics and compliance for wool grease hinge on accurate classification, proper packaging, and adherence to international trade regulations. Maintaining detailed records, ensuring product quality, and staying updated on regulatory changes will support smooth global distribution and minimize compliance risks.

In conclusion, sourcing wool grease (also known as lanolin) requires a careful balance between quality, sustainability, and ethical considerations. As a valuable byproduct of the wool industry, wool grease offers numerous benefits in cosmetics, pharmaceuticals, and industrial applications due to its emollient and water-repellent properties. Effective sourcing involves establishing transparent supply chains, partnering with reputable wool producers and processors, and ensuring animal welfare and environmental standards are met. Additionally, advancements in processing and purification technologies enhance the quality and safety of sourced wool grease, meeting regulatory and consumer demands. Ultimately, responsible and efficient sourcing not only supports product performance and compliance but also aligns with growing market expectations for sustainable and ethically produced raw materials.