The global slatwall panel market is experiencing robust growth, driven by rising demand for modular and customizable storage solutions across retail, residential, and commercial spaces. According to Grand View Research, the global wall panel market size was valued at USD 10.3 billion in 2022 and is expected to expand at a compound annual growth rate (CAGR) of 5.8% from 2023 to 2030. This growth is fueled by increasing urbanization, the expansion of e-commerce fulfillment centers, and a growing preference for space-efficient interior designs. Wood slatwall panels, in particular, are gaining traction due to their aesthetic appeal, durability, and versatility in applications ranging from garage organization to retail displays. As demand climbs, manufacturers are innovating with sustainable materials and advanced finishing techniques to meet evolving customer needs. In this competitive landscape, identifying leading wood slatwall panel producers becomes critical for contractors, retailers, and designers seeking high-performance, reliable solutions. Based on market presence, product quality, and innovation, here are the top 10 wood slatwall panel manufacturers shaping the industry.

Top 10 Wood Slatwall Panel Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Oak Acoustic Wood Slat

Domain Est. 2003

Website: feltright.com

Key Highlights: Designed as an elegant sound dampening solution. Absorbs 55% of the sound waves they come in contact with. Reduces excess noise and eliminates echo….

#2 Wind Mill Slatwall Products

Domain Est. 2004

Website: windmillslatwall.com

Key Highlights: Wind Mill Slatwall Products manufactures custom slatwall, retail display panels, fixtures and a vast array of wood component parts….

#3 Natural Acoustic Wood Slat Wall Panels

Domain Est. 2012

Website: msisurfaces.com

Key Highlights: Natural Acoustic Wood Slat Wall Panels feature a fluted beige wood design. These sound absording acoustic wall panels are ideal for home and office spaces….

#4 Wooden slat wall, wall panels & acoustic panels » WoodUpp

Domain Est. 2015

Website: woodupp.com

Key Highlights: WoodUpp is innovative do-it-yourself wood wall panels, wooden slatwall & acoustic panels, developed so you can mount a wooden wall easily….

#5 Slat Wall Panels

Domain Est. 2021

#6 Wooden Acoustic Slat Wall Panels

Domain Est. 2022

Website: akuwoodpanel.com

Key Highlights: Rating 4.9 (881) · $35 delivery · 30-day returnsReal wood veneer ✓3 sided design ✓Up to 85% sound absorption ✓Eco friendly ✓Easy to install ✓Acoustic slat wall panels for styl…

#7 PANELUX™

Domain Est. 2022

Website: panelux.ca

Key Highlights: PANELUX™ slat panels: acoustic architecture, refined. Bring warmth, rhythm, and sound control to your interiors with our signature acoustic wood slat panels….

#8 Wooden Slat Wall, Wood Veneer & Acoustic Panels

Domain Est. 2023

Website: woodsonpanels.com

Key Highlights: Free delivery over $450 30-day returns…

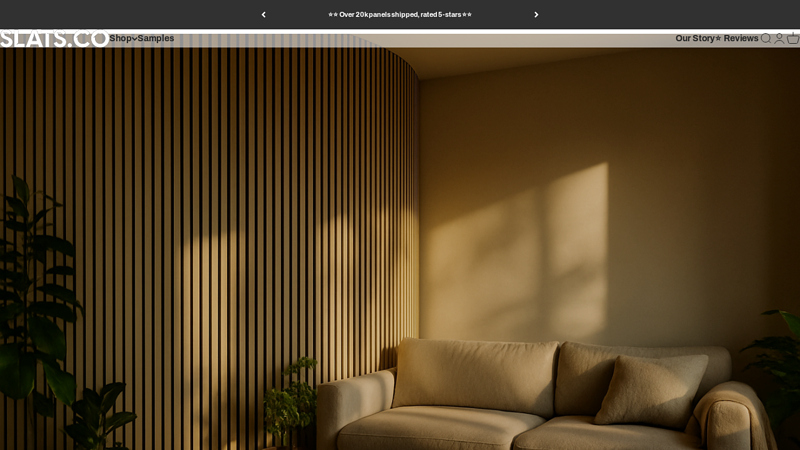

#9 Wood Slat Wall Panels for Modern Slatted Accent Walls & Interiors

Domain Est. 2023

Website: slats.co

Key Highlights: Elevate your surroundings with our functional yet stylish wooden acoustic panels, available in 10 different colors and wood finishes. Shop Acoustic Panels….

#10 Wood Wall Paneling

Domain Est. 2023

Expert Sourcing Insights for Wood Slatwall Panel

H2: 2026 Market Trends for Wood Slatwall Panels

The global market for wood slatwall panels is poised for significant evolution by 2026, driven by shifting consumer preferences, sustainability demands, and innovations in retail and commercial interior design. As businesses and homeowners increasingly prioritize modular, customizable, and aesthetically pleasing storage and display solutions, wood slatwall panels are emerging as a preferred choice across multiple sectors.

One of the most prominent trends shaping the 2026 market is the rising emphasis on sustainable and eco-friendly building materials. With growing awareness of deforestation and carbon footprints, manufacturers are responding by sourcing wood from certified sustainable forests (e.g., FSC or PEFC) and incorporating low-VOC finishes and adhesives. Bamboo and reclaimed wood variants are also gaining traction as eco-conscious alternatives, appealing to environmentally aware consumers and green-certified construction projects.

Another key driver is the expansion of the retail and e-commerce fulfillment sectors. As brick-and-mortar stores focus on enhancing in-store experiences and optimizing space utilization, wood slatwall panels offer a visually warm, flexible solution for product displays, signage, and modular shelving. Their adaptability allows for quick reconfiguration, making them ideal for pop-up shops and seasonal layouts. Similarly, small-to-mid-sized warehouses and fulfillment centers are adopting slatwall systems for lightweight inventory organization, combining functionality with a more professional appearance than traditional metal alternatives.

The residential and home improvement market is also fueling demand. The DIY (do-it-yourself) trend continues to grow, supported by online tutorials and home organization influencers. Wood slatwall panels are increasingly used in home offices, garages, closets, and hobby rooms due to their ease of installation and customizable configurations. Manufacturers are capitalizing on this by offering pre-finished panels, color-matching accessories, and integrated lighting options to enhance both utility and aesthetics.

Technological integration is another emerging trend. By 2026, smart slatwall systems—featuring embedded LED lighting, IoT-enabled inventory tracking, and modular power outlets—are expected to enter niche commercial markets. These innovations cater to high-end retail environments and tech-forward workspaces seeking seamless functionality.

Regionally, North America and Europe lead in adoption due to mature retail infrastructure and strong DIY cultures. However, the Asia-Pacific region is projected to experience the fastest growth, driven by urbanization, rising disposable incomes, and expanding retail and hospitality sectors in countries like China, India, and Southeast Asia.

In conclusion, the 2026 wood slatwall panel market will be characterized by sustainability, customization, and technological enhancement. As demand grows across retail, commercial, and residential applications, manufacturers who innovate in materials, design, and smart features will be well-positioned to capture market share in this dynamic and evolving landscape.

Common Pitfalls When Sourcing Wood Slatwall Panels (Quality, IP)

Sourcing wood slatwall panels for commercial or retail applications requires careful attention to both quality and intellectual property (IP) considerations. Overlooking these factors can lead to subpar installations, legal risks, or brand damage. Below are key pitfalls to avoid.

1. Prioritizing Cost Over Quality

One of the most common mistakes is selecting wood slatwall panels based solely on price. Low-cost options may use inferior wood species, inconsistent thicknesses, or poor surface finishes. These compromises result in:

– Warping or cracking over time

– Inconsistent appearance across panels

– Reduced durability under heavy use

Always request samples and evaluate:

– Wood species and grain consistency

– Sanding and finishing quality

– Moisture content and stability

2. Ignoring Moisture and Environmental Resistance

Wood slatwall panels exposed to high-humidity environments (e.g., retail stores, showrooms) can degrade if not properly treated. Panels lacking proper sealing or moisture-resistant finishes may swell, delaminate, or harbor mold.

Ensure the supplier specifies:

– Moisture-resistant coatings

– Suitability for indoor climate conditions

– Warranty covering environmental damage

3. Overlooking Intellectual Property (IP) and Design Rights

Many slatwall panel designs—especially those with unique profiles, patterns, or patented mounting systems—are protected by intellectual property rights. Sourcing generic or counterfeit versions may lead to:

– Legal action from original designers or manufacturers

– Infringement claims affecting your brand

– Forced removal and replacement of installed panels

Always:

– Verify that the supplier has rights to produce and sell the design

– Request documentation of IP clearance or licensing

– Avoid suppliers offering “look-alike” versions of branded products

4. Inconsistent Sourcing and Batch Variation

Wood is a natural material, and color/grain variation between production batches can be significant. If future orders don’t match prior shipments, your installation may look patchy or unprofessional.

To mitigate:

– Order all panels needed for a project at once

– Confirm batch consistency policies with the supplier

– Keep extra panels on hand for future repairs or expansions

5. Poor Tolerances and Installation Challenges

Low-quality slatwall panels often have inconsistent slot spacing, uneven edges, or inaccurate dimensions. This leads to:

– Misaligned accessories (shelves, hooks)

– Gaps or uneven mounting

– Increased labor time and frustration

Inspect sample panels for:

– Precision of slot cutting

– Straightness of edges

– Uniformity of thickness

6. Lack of Sustainability and Certification Transparency

Environmental and corporate responsibility concerns are growing. Sourcing wood from illegal or unsustainable sources can damage your brand and violate regulations.

Ensure suppliers provide:

– FSC or PEFC certification

– Clear documentation of wood origin

– Compliance with import regulations (e.g., Lacey Act in the U.S.)

7. Inadequate Supplier Due Diligence

Choosing a supplier without thorough vetting increases the risk of receiving substandard or non-compliant products.

Conduct due diligence by:

– Requesting references or case studies

– Reviewing manufacturing processes

– Confirming product warranties and return policies

Conclusion

Avoiding these pitfalls requires balancing cost with quality, verifying legal compliance, and working with reputable suppliers. Investing time upfront in proper sourcing protects your project’s integrity, reduces long-term costs, and safeguards your brand against IP and quality-related risks.

Logistics & Compliance Guide for Wood Slatwall Panels

Product Overview

Wood Slatwall Panels are engineered wood panels with horizontal grooves (slots) designed for versatile wall-mounted storage systems. Commonly used in retail, garages, workshops, and offices, these panels are typically made from medium-density fiberboard (MDF), plywood, or particleboard, often with a wood veneer or laminate finish.

Packaging & Handling

- Packaging: Panels should be securely packaged in stretch wrap or corrugated cardboard to prevent chipping, moisture exposure, and surface scratches.

- Stacking: Store panels flat on a level surface; avoid vertical storage to prevent warping. Maximum stack height should not exceed manufacturer recommendations (usually 30–40 panels).

- Handling: Use proper lifting techniques or mechanical aids (e.g., pallet jacks) to avoid strain or damage. Avoid dragging panels across surfaces.

- Edge Protection: Use edge protectors during transport to safeguard grooved edges.

Transportation Requirements

- Mode of Transport: Suitable for truck, rail, or ocean freight. Ensure proper securing to prevent movement during transit.

- Palletization: Panels should be unitized on standard 48″x40″ pallets with adequate strapping or banding.

- Moisture Protection: Use moisture-resistant wrapping or place desiccants in enclosed shipments, especially for international or long-haul transport.

- Temperature Control: Avoid extreme temperatures and high humidity to prevent warping or delamination.

Import/Export Compliance

- Harmonized System (HS) Code: Common HS code for wood slatwall panels is 4412.31 (Plywood) or 4410.11 (Particleboard), depending on core material. Confirm with local customs authority.

- Lacey Act (USA): Requires proof of legal sourcing of wood. Importers must declare species and country of harvest. Use of certified sustainable wood (e.g., FSC or PEFC) is recommended.

- Phytosanitary Certification: May be required for raw wood components; panels made from processed wood (e.g., MDF, plywood) often exempt but verify per destination country.

- ISPM 15 (International Standards for Phytosanitary Measures No. 15): Wooden pallets or dunnage must be heat-treated and marked with the official ISPM 15 stamp if used in international shipments.

Environmental & Safety Regulations

- Formaldehyde Emissions (CARB Phase 2 & EPA TSCA Title VI): Panels made from composite wood (MDF, particleboard) must comply with formaldehyde emission limits in the U.S. Ensure third-party certification (e.g., CARB-certified) when applicable.

- REACH & RoHS (EU): Confirm absence of restricted substances (e.g., heavy metals, certain flame retardants) in finishes or coatings.

- VOC Emissions: Low-VOC finishes may be required in regions with strict indoor air quality standards (e.g., California Section 01350).

Labeling & Documentation

- Product Labeling: Include product name, dimensions, material type, manufacturer, batch/lot number, and compliance markings (e.g., CARB, FSC).

- Safety Data Sheet (SDS): Required for composite wood products due to potential formaldehyde content.

- Customs Documentation: Prepare commercial invoice, packing list, bill of lading/airway bill, and any required certificates (e.g., Lacey Act declaration, phytosanitary, ISPM 15).

Storage & Warehouse Guidelines

- Environment: Store in a dry, well-ventilated area with stable temperature (15–25°C / 59–77°F) and humidity (35–65% RH).

- Floor Clearance: Elevate pallets at least 4 inches off the floor using wooden bearers to prevent moisture absorption.

- Inventory Rotation: Use FIFO (First In, First Out) method to reduce risk of aging or obsolescence.

End-of-Life & Sustainability

- Recyclability: MDF and particleboard panels may be recyclable in specialized facilities; consult local waste management.

- Disposal: Do not incinerate without proper emission controls due to potential formaldehyde release.

- Sustainability Claims: Only make environmental claims (e.g., “recyclable,” “sustainably sourced”) if backed by certification or verifiable data.

Summary

Proper logistics and compliance management for Wood Slatwall Panels ensures product integrity, regulatory adherence, and market access. Emphasize secure packaging, moisture protection, emission compliance, and accurate documentation throughout the supply chain. Partner with certified suppliers and stay updated on regional regulatory changes to mitigate risks.

In conclusion, sourcing wood slatwall panels requires a careful balance of quality, sustainability, cost, and supplier reliability. Evaluating suppliers based on material origin, manufacturing standards, and environmental certifications ensures both durability and eco-responsibility. Additionally, considering customization options, lead times, and logistical factors supports efficient integration into your project or retail display needs. By conducting thorough research and due diligence, businesses can secure high-quality wood slatwall panels that enhance aesthetics, functionality, and long-term value while aligning with ethical and operational goals.