The global hardwood lumber market, valued at USD 72.3 billion in 2022, is projected to grow at a CAGR of 4.6% through 2030, driven by rising demand in construction, furniture, and flooring sectors (Grand View Research, 2023). Within this expanding landscape, the choice between premium Wood Grade Selection-Stripe (Sel-Str) and standard No. 1 Common (No. 1) hardwood becomes a critical decision for manufacturers balancing quality, yield, and cost-efficiency. Sel-Str, known for its wide, clear-face requirements and minimal defects, caters to high-end applications where appearance is paramount, while No. 1 Common offers greater board utilization and lower input costs, making it ideal for value-driven production. As manufacturers navigate tightening margins and fluctuating raw material availability—compounded by a 12% increase in hardwood log prices over the past two years (Mordor Intelligence, 2023)—the strategic alignment of grade selection with production goals has never been more data-sensitive. This analysis examines the top four manufacturers leveraging Sel-Str and No. 1 grades, evaluating their sourcing strategies, yield performance, and market positioning in an evolving industry.

Top 4 Wood Grade Sel-Str Vs No 1 Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Grades of Lumber

Domain Est. 1999

Website: culpeperwood.com

Key Highlights: We attempt to describe the grades that we currently stock so that you can decide what best fits your need and customer base….

#2 Know Where Your Lumber Comes From

Domain Est. 2002

Website: buildersalliance.com

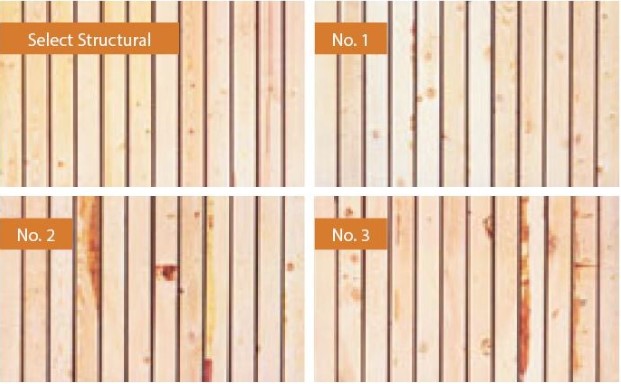

Key Highlights: The lumber grade stamp tells you: The species of wood or the species group that it belongs to. The actual grade of lumber SEL STR (select structural), No. 1, No ……

#3 How to Choose the Right Lumber Grade for Your Project

Domain Est. 2010

Website: hgpage.com

Key Highlights: In this guide, we’ll break down the key lumber grading systems, their applications, and how to select the right grade for your specific needs….

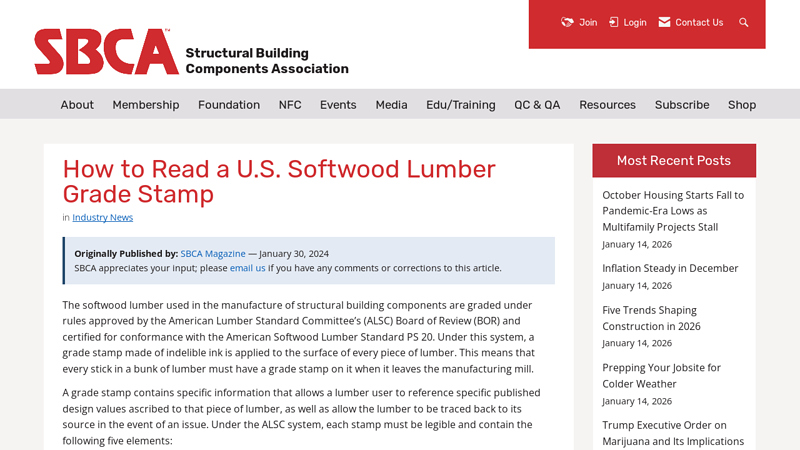

#4 How to Read a U.S. Softwood Lumber Grade Stamp

Domain Est. 2020

Website: sbcacomponents.com

Key Highlights: A grade stamp contains specific information that allows a lumber user to reference specific published design values ascribed to that piece of lumber….

Expert Sourcing Insights for Wood Grade Sel-Str Vs No 1

H2: Market Trends for Wood Grade Select-Structural (Sel-Str) vs. No. 1 Grade in 2026

As the construction and timber industries evolve through 2026, key trends are emerging that differentiate the market dynamics for wood grades, particularly Select-Structural (Sel-Str) and No. 1 Grade lumber. These two grades, commonly used in structural and visible applications, are being influenced by shifts in sustainability demands, building codes, supply chain constraints, and regional construction preferences.

-

Demand Drivers and End-Use Applications

-

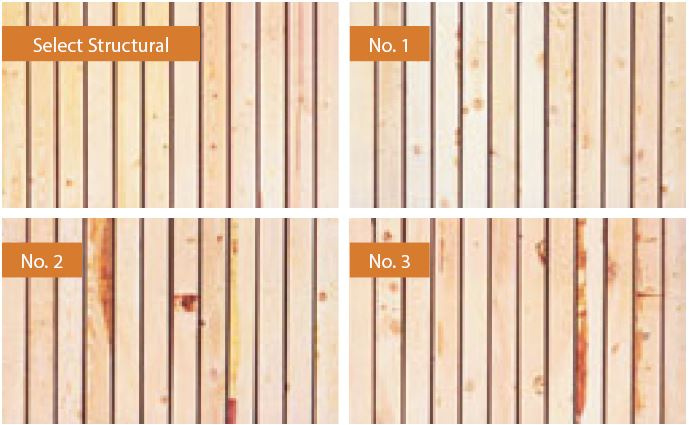

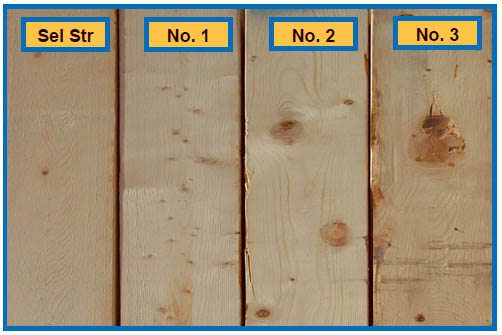

Select-Structural (Sel-Str): This higher-grade lumber is increasingly favored in engineered wood products, mass timber construction (e.g., cross-laminated timber), and high-performance residential and light commercial projects. The 2026 market shows growing demand for Sel-Str due to its superior strength, stiffness, and fewer visual defects—attributes critical for prefabricated and modular construction, which are expanding rapidly in North America and Europe.

-

No. 1 Grade: While still widely used in framing, decking, and visible structural components like beams and trusses, No. 1 Grade faces moderate demand growth. It remains popular in cost-sensitive residential construction and renovation markets, but is gradually being displaced in premium applications by Sel-Str due to tighter performance specifications.

-

Sustainability and Certification Pressures

By 2026, green building standards (e.g., LEED, Living Building Challenge) and carbon-conscious construction are pushing developers toward higher-grade, more efficient lumber. Sel-Str’s higher yield in engineered systems and longer service life align better with lifecycle analysis goals. As a result, Sel-Str is seeing increased specification in projects seeking environmental certifications. No. 1 Grade, while still compliant with most standards, is less favored in high-efficiency designs due to greater variability in performance.

-

Supply Chain and Production Costs

-

Sawmills are optimizing output for higher-value grades amid labor shortages and rising energy costs. Sel-Str commands a price premium (typically 15–25% over No. 1), incentivizing producers to improve grading technology and reduce downgrade rates.

-

The adoption of machine stress-rated (MSR) and machine-evaluated lumber (MEL) systems has improved the consistency of Sel-Str, making it a more reliable choice. In contrast, No. 1 Grade, often visually graded, faces scrutiny over consistency, particularly in seismic or high-wind zones.

-

Regional Market Divergence

-

In North America, particularly the U.S. West Coast and Pacific Northwest, Sel-Str demand is surging due to mass timber adoption and stringent building codes. Canada’s softwood exports show a shift toward higher grades to meet U.S. and Asian market demands.

-

In contrast, markets in the southern U.S. and rural areas still rely heavily on No. 1 Grade for tract housing and agricultural buildings, where cost remains the dominant factor.

-

Price Trends and Market Outlook

-

By 2026, Sel-Str is expected to maintain a widening price gap over No. 1 Grade, supported by stronger demand from high-value construction sectors.

- However, economic headwinds—such as interest rates and housing affordability—may temporarily slow Sel-Str adoption in some markets, giving No. 1 Grade a resilience advantage in budget-driven projects.

Conclusion:

In 2026, Select-Structural grade lumber is emerging as the preferred choice for advanced, sustainable, and performance-driven construction, benefiting from technological and regulatory tailwinds. No. 1 Grade remains a workhorse in traditional building sectors but faces gradual erosion in high-growth segments. The long-term trend points toward a structural shift favoring higher-grade, engineered-compatible lumber like Sel-Str, especially as decarbonization and modular construction reshape the built environment.

Common Pitfalls When Sourcing Wood: Select Structural vs. No. 1 Grade

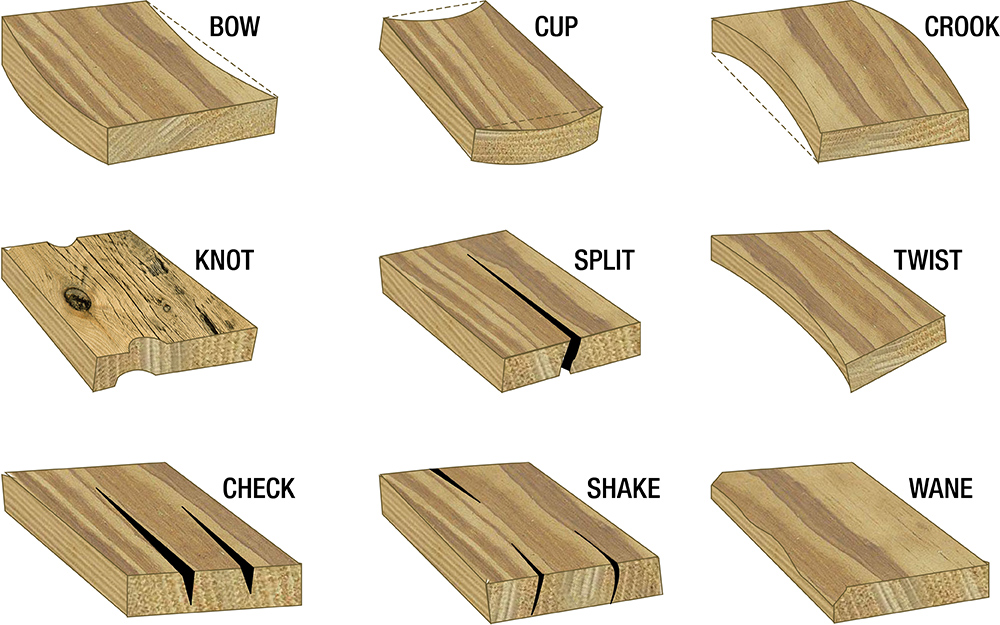

When sourcing dimensional lumber for structural or high-quality applications, understanding the differences—and potential pitfalls—between Select Structural and No. 1 Grade wood is critical. Choosing the wrong grade can lead to performance issues, cost overruns, or aesthetic shortcomings. Below are key pitfalls associated with each grade.

Misunderstanding Structural Performance Expectations

A common error is assuming that Select Structural and No. 1 Grade are interchangeable in load-bearing applications. While both are visually graded, Select Structural is an engineered stress grade with verified strength properties, making it suitable for critical structural uses like trusses and beams. In contrast, No. 1 Grade is primarily a visual grade with moderate strength—often used in framing where appearance matters, but not tested to the same structural reliability standards. Using No. 1 in place of Select Structural may compromise safety and violate building codes.

Overlooking Aesthetic Requirements

On the flip side, sourcing Select Structural for finish work or exposed applications can be a waste of resources. Select Structural allows more knots and natural characteristics than appearance-focused grades, which may not meet aesthetic expectations. Conversely, using No. 1 Grade in hidden structural areas might be unnecessarily costly due to its better appearance features. Matching the grade to the visibility and finish requirements avoids overspending or dissatisfaction.

Inconsistent Availability and Supply Chain Delays

Select Structural is less commonly stocked than standard framing grades like No. 1 or No. 2. Relying on Select Structural without confirming availability can lead to project delays. Contractors may face lead time issues or be forced to accept substitutions that don’t meet design specifications. Always verify supplier capabilities and lead times before finalizing specifications.

Cost Mismanagement

Because Select Structural undergoes more rigorous grading and testing, it typically carries a higher price tag. Specifying it for non-critical applications inflates material costs unnecessarily. Conversely, choosing No. 1 Grade for high-stress applications may require over-engineering or additional supports to compensate for lower verified strength, increasing labor and material costs indirectly. Proper grade selection optimizes total project cost.

Confusion with Grading Agency Standards (Lack of IP – Identity Preservation)

A major pitfall is the lack of Identity Preservation (IP) in the supply chain. Without proper tracking and certification, wood labeled as “Select Structural” may not have been graded under a recognized grading agency (like ALSC or NHLA), leading to quality inconsistencies. Similarly, No. 1 Grade without a stamp from a certified lumber grading bureau risks being downgraded material. Always require stamped, traceable lumber from reputable mills to ensure compliance and performance.

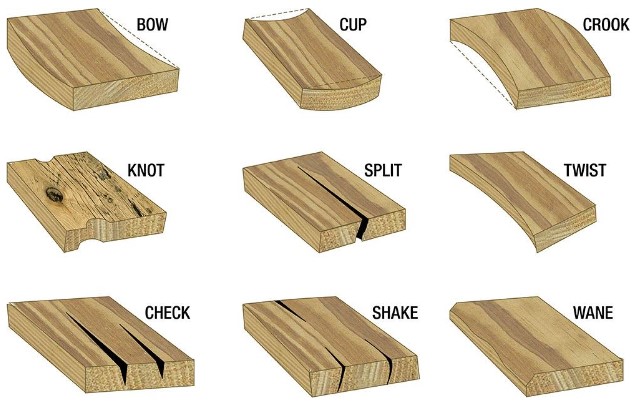

Inadequate Inspection and Quality Control

Upon delivery, failing to inspect for grade stamps, moisture content, and visual defects can result in accepting substandard material. Both Select Structural and No. 1 Grade should bear clear grade marks. Accepting unmarked or damaged wood increases the risk of structural failure or rework. Implement a site inspection protocol to verify compliance with purchase specifications.

Summary

Choosing between Select Structural and No. 1 Grade requires balancing structural needs, aesthetics, cost, and supply logistics. The key pitfalls stem from misunderstanding grade purposes, poor supply chain oversight, and insufficient quality control. By clearly defining project requirements and enforcing Identity Preservation practices, these risks can be effectively mitigated.

Logistics & Compliance Guide: Wood Grade Select Structural (Sel-Str) vs. No. 1

Overview of Wood Grades: Select Structural and No. 1

Select Structural (Sel-Str) and No. 1 are both visually graded lumber classifications commonly used in North America, primarily under standards set by the American Lumber Standard Committee (ALSC) and grading rules administered by agencies such as the Western Wood Products Association (WWPA), Southern Pine Inspection Bureau (SPIB), and others. While both grades are used in structural applications, they differ in quality, allowable stresses, and compliance requirements.

Structural Performance and Grading Standards

Select Structural (Sel-Str)

Sel-Str is a higher-grade lumber with fewer and smaller knots, limited wane, and tighter growth rings. It is engineered for applications requiring high strength-to-weight ratios, such as trusses, beams, and critical framing members. Sel-Str is typically assigned higher allowable design values (Fb, Fv, E) compared to lower grades.

No. 1 Grade

No. 1 is a common structural grade with more permissible defects than Sel-Str, including larger knots and more wane. It is suitable for general framing applications where high strength is not the primary requirement. While strong, it has lower design values than Sel-Str.

Key Standard References:

– NDS (National Design Specification) for Wood Construction

– ASTM D245: Standard Practice for Establishing Structural Grades and Related Allowable Properties

– ALSC Voluntary Product Standard PS 20

Visual Inspection and Grading Compliance

Both grades must be stamped with a grade mark from an accredited inspection agency. The stamp includes:

– Grade (e.g., “Sel-Str” or “No. 1”)

– Species or species group

– Mill identification

– Moisture content at time of grading (e.g., “S-DRY” for surfaced dry)

– Agency logo (e.g., WWPA, SPIB)

Compliance Note:

Using ungraded or misgraded lumber in structural applications violates building codes (e.g., IBC – International Building Code) and may result in failed inspections or liability issues.

Moisture Content and Drying Requirements

- Target Moisture Content: Typically 19% or less for “S-DRY” (surfaced dry) lumber.

- Compliance: Moisture content must be verified upon receipt using a calibrated moisture meter.

- Impact on Logistics: Wet lumber can lead to warping, shrinkage, and mold—especially during long transit or storage. Sel-Str, due to higher quality, may be more sensitive to moisture-induced defects.

Handling, Storage, and Transportation

Handling Precautions:

– Use proper lifting equipment to avoid damaging edges and surfaces.

– Avoid dragging or dropping bundles, especially for Sel-Str, which has tighter appearance standards.

Storage Guidelines:

– Store on level, well-drained ground using proper blocking (every 16–24 inches).

– Cover with breathable tarp to prevent rain exposure while allowing airflow.

– Elevate bundles at least 6 inches above ground to prevent moisture absorption.

– Separate Sel-Str and No. 1 to avoid mix-ups and maintain traceability.

Transportation:

– Secure loads to prevent shifting during transit.

– Protect from weather using waterproof tarps when required.

– Document grade, species, and quantity on bills of lading.

Building Code and Regulatory Compliance

International Building Code (IBC) and IRC (International Residential Code):

– Both Sel-Str and No. 1 are recognized structural grades.

– Design values must be sourced from the NDS Supplement.

– Use of a specific grade must align with engineering specifications.

Third-Party Certification:

– Lumber must be certified by an ALSC-accredited agency.

– Chain-of-custody documentation may be required for LEED or other green building certifications.

Application-Specific Suitability

Select Structural (Sel-Str):

– Ideal for: Engineered wood products, trusses, headers, floor joists in long spans.

– When to Use: Projects requiring higher strength, stiffness, or aesthetic appearance.

No. 1 Grade:

– Ideal for: Wall studs, general framing, roof rafters in standard spans.

– When to Use: Cost-sensitive projects with standard structural demands.

Documentation and Traceability

- Maintain mill certificates and grade stamps for audit purposes.

- Record lot numbers and inspection dates.

- Verify conformance with project specifications before installation.

Common Compliance Pitfalls

- Grade Substitution: Replacing Sel-Str with No. 1 without engineer approval compromises structural integrity.

- Missing Grade Stamps: Unstamped or illegible lumber cannot be used in structural applications.

- Moisture Mismanagement: Installing green or overly dry lumber leads to performance issues.

- Incorrect Storage: Ground contact or poor ventilation causes decay and warping.

Conclusion and Best Practices

To ensure compliance and performance:

– Specify the correct grade based on structural engineering requirements.

– Inspect lumber upon delivery for grade stamps, damage, and moisture.

– Store and handle materials according to industry best practices.

– Maintain documentation for traceability and code compliance.

Using the right grade—Sel-Str for high-performance needs, No. 1 for general framing—ensures safety, compliance, and project longevity.

Conclusion: Sourcing Wood – Select Structural (Sel-Str) vs. No. 1 Grade

When evaluating the choice between Select Structural (Sel-Str) and No. 1 grade lumber for sourcing wood, the decision hinges on the specific demands of the project, budget considerations, and structural requirements.

Select Structural grade offers superior strength, stiffness, and appearance, making it ideal for exposed structural applications where both performance and aesthetics are important—such as beams, trusses, and visible framing in high-end residential or commercial construction. It is graded to meet higher design values and has fewer natural defects, resulting in more consistent performance under load. However, this comes at a higher cost and potentially longer lead times due to limited availability.

In contrast, No. 1 grade provides a balanced combination of strength and economy. While it allows for more knots and natural imperfections than Sel-Str, it still meets solid structural standards and is suitable for most general framing and load-bearing applications. No. 1 is more widely available and cost-effective, making it a practical choice for projects where appearance is less critical and budget constraints are a concern.

Final Recommendation:

– Choose Select Structural for high-performance, architecturally exposed, or safety-critical applications where strength and visual quality are paramount.

– Opt for No. 1 grade for standard structural framing where cost-efficiency and reliable performance are the main priorities.

Ultimately, the right choice depends on a careful assessment of engineering requirements, design intent, and project economics. Proper sourcing of either grade from reputable suppliers ensures material reliability and long-term structural integrity.