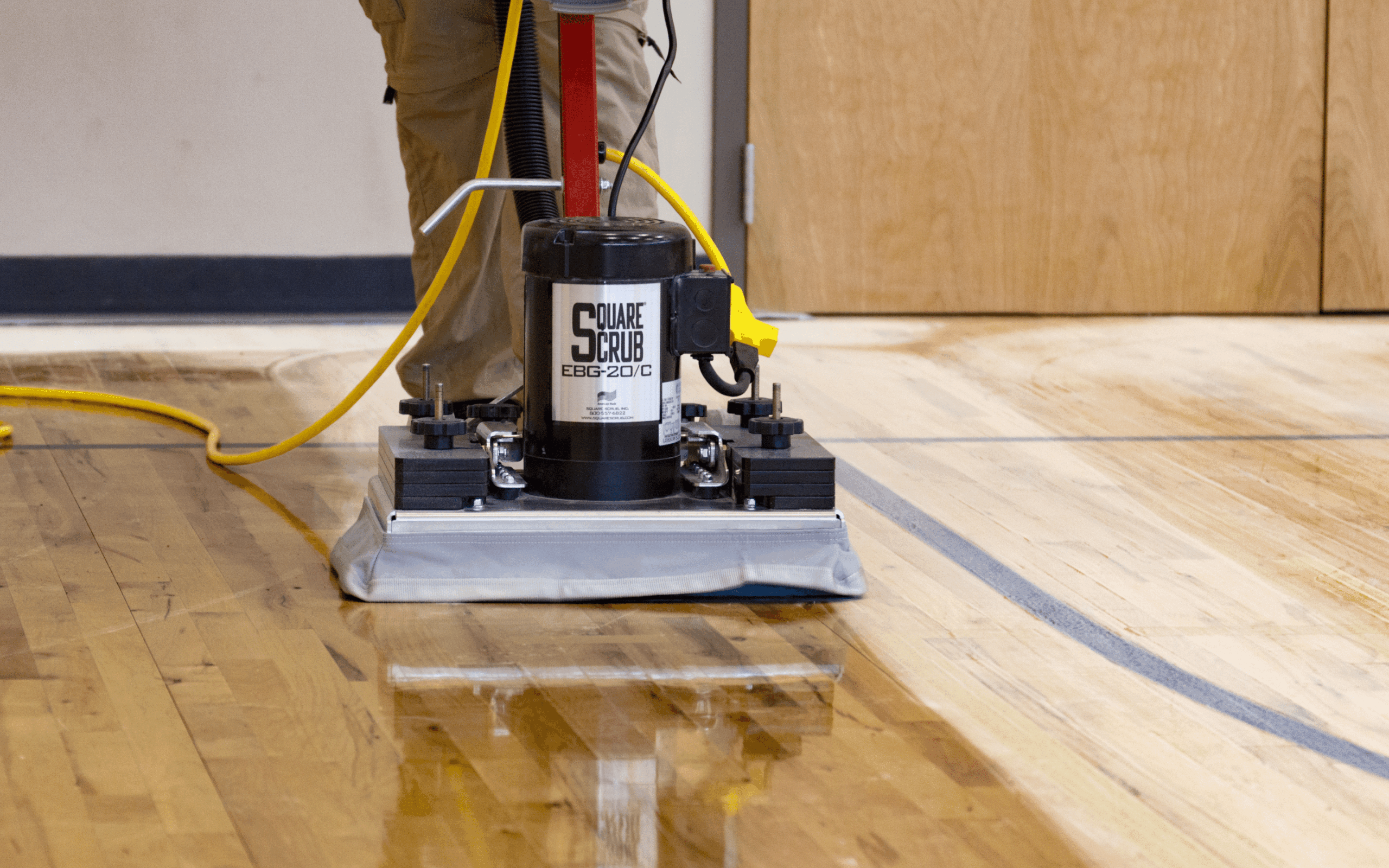

The global floor care equipment market is experiencing robust growth, driven by increasing demand for high-performance cleaning and maintenance solutions across residential, commercial, and industrial sectors. According to a 2023 report by Mordor Intelligence, the global floor scrubber and polisher market is projected to grow at a CAGR of approximately 6.8% from 2023 to 2028, fueled by rising hygiene standards and urbanization. Similarly, Grand View Research estimates that the broader commercial cleaning equipment market—encompassing floor polishing systems—was valued at over USD 15 billion in 2022 and is expected to expand at a CAGR of 7.2% through 2030. Wood floor polishing machines, in particular, are witnessing heightened adoption due to the growing preference for hardwood flooring in premium residential and hospitality spaces. As sustainability and efficiency become key purchasing drivers, leading manufacturers are investing in advanced, eco-friendly, and low-noise polishing technologies. In this evolving landscape, a select group of global manufacturers are setting industry benchmarks through innovation, durability, and performance—making them the top contenders in the wood floor polishing machine market.

Top 10 Wood Floor Polishing Machine Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Clarke

Domain Est. 1997

Website: nilfisk.com

Key Highlights: Created by inventor and tinkerer Alex A. Clarke in 1916, the Clarke Company began with a better, faster sanding machine for restoring wood bar tops and school ……

#2 Clarke®Floor Scrubbers & Accessories

Domain Est. 1998 | Founded: 1916

Website: floorscrubbers.com

Key Highlights: 30-day returnsClarke has been manufacturing equipment since 1916. It started with a sanding machine for restoring wood bar tops and school desks….

#3 Commercial Floor Machines

Domain Est. 1998

Website: americhem.net

Key Highlights: ➜ Ideal for cleaning, buffing, polishing, sanding, stripping, and coating removal. These versatile machines tackle a variety of cleaning and buffing tasks….

#4 HUMMEL

Domain Est. 1999

Website: laegler.com

Key Highlights: The HUMMEL belt sander is mainly used for sanding wooden floors. It enables precise and economical sanding of both small and large surfaces….

#5 Lägler Floor Sanding Machines and Accessories

Domain Est. 2001

Website: khr-online.com

Key Highlights: Lägler offers the most comprehensive and highest quality range of machines for the professional sanding of wooden floors and the preparation of subfloors….

#6 Essex Silver

Domain Est. 2002 | Founded: 1958

Website: essexsilverline.com

Key Highlights: Essex Silver Line has been manufacturing the world’s finest floor sanders since 1958. Why are our machines the best? One reason: they work. All Silver-line ……

#7 Floor Machines for Professionals

Domain Est. 2002

Website: mastercraftusa.com

Key Highlights: 3–7 day deliveryExplore Mastercraft®’s premium floor machines designed for professional cleaning. Shop now for quality equipment that transforms your floor care!…

#8 Corded Floor Machines

Domain Est. 2011

Website: pioneereclipse.com

Key Highlights: Our corded electric rotary machines provide versatile function and efficiency for smaller spaces and spot repairs. Our auto scrubber comes standard with ……

#9 Floor Grinders

Domain Est. 2018

Website: hypergrinder.com

Key Highlights: HG HYPER GRINDER is the benchmark in grinding and polishing equipment, including grinders/polishers, dust extractors, diamond tools and much more….

#10 Clean&Robot Solutions Business

Website: amano.co.jp

Key Highlights: Clean&Robot Solutions Business provides commercial-use robotic cleaning machines, floor cleaners, polishers, and other cleaning equipment, ……

Expert Sourcing Insights for Wood Floor Polishing Machine

H2: 2026 Market Trends for Wood Floor Polishing Machines

The global market for wood floor polishing machines is poised for significant transformation by 2026, driven by technological innovation, evolving consumer preferences, and a growing emphasis on sustainability. Below is an analysis of key trends expected to shape the industry in the coming years:

1. Increased Demand for Eco-Friendly and Low-Dust Solutions

Environmental awareness is reshaping the flooring maintenance sector. By 2026, there will be heightened demand for wood floor polishing machines equipped with advanced dust-containment systems and energy-efficient motors. Manufacturers are increasingly adopting eco-conscious materials and designs to comply with global green building standards such as LEED and BREEAM, especially in commercial and residential renovation projects.

2. Rise of Smart and Automated Machines

Integration of smart technology is a dominant trend. By 2026, expect widespread adoption of IoT-enabled wood floor polishing machines that offer real-time performance monitoring, predictive maintenance alerts, and remote control via mobile apps. Autonomous or semi-autonomous floor polishers—featuring AI-driven navigation and adaptive polishing algorithms—will gain traction in large-scale facilities such as hotels, offices, and retail spaces, reducing labor costs and improving consistency.

3. Expansion in Residential and DIY Markets

While commercial applications remain strong, the residential segment is growing rapidly. Homeowners are investing more in hardwood floor maintenance due to rising property values and a DIY culture empowered by online tutorials. Lightweight, user-friendly polishing machines with ergonomic designs and simplified controls will dominate this space, supported by e-commerce platforms and rental services.

4. Growth in Emerging Markets

Asia-Pacific, Latin America, and parts of Africa are expected to witness robust market expansion by 2026. Urbanization, rising disposable incomes, and the proliferation of modern construction projects are fueling demand for professional floor care equipment. Local manufacturing and partnerships with international brands will help meet regional needs while reducing costs.

5. Emphasis on Multi-Functionality and Durability

Consumers and professionals alike are seeking versatile machines capable of sanding, buffing, polishing, and cleaning in a single unit. By 2026, manufacturers will focus on modular designs and interchangeable pads/tools to enhance machine utility. Additionally, product durability and lower total cost of ownership will be key selling points, influencing procurement decisions in both rental and owned equipment markets.

6. Impact of Labor Shortages and Service Models

Labor shortages in the construction and maintenance sectors are accelerating the shift toward automated solutions. Alongside machine sales, service-based models—such as equipment-as-a-service (EaaS) and on-demand floor polishing—will gain momentum, especially in commercial facilities aiming to optimize operational efficiency.

Conclusion

By 2026, the wood floor polishing machine market will be defined by innovation, sustainability, and smart integration. Companies that prioritize R&D, adapt to regional market dynamics, and embrace digital transformation will be best positioned to lead in this evolving landscape.

Common Pitfalls When Sourcing a Wood Floor Polishing Machine (Quality and IP)

Sourcing a wood floor polishing machine involves more than just finding the lowest price. Overlooking critical aspects such as quality and intellectual property (IP) can lead to costly mistakes, operational disruptions, and legal risks. Below are key pitfalls to avoid:

Poor Build Quality and Durability

Many budget machines use substandard materials and components, leading to frequent breakdowns, inconsistent polishing results, and higher long-term maintenance costs. Look for machines with robust housings, high-quality motors, and durable polishing pads. Always request product certifications (e.g., CE, ISO) and ask for references or third-party test reports to verify durability claims.

Inadequate Performance for Specific Applications

Not all wood floor polishers are created equal. Some models may lack the variable speed control, weight distribution, or pad compatibility required for different wood types or finishes. Using an unsuitable machine can damage floor surfaces or leave streaks and swirl marks. Ensure the machine specifications match your project requirements—commercial vs. residential, hardwood vs. engineered wood, etc.

Insufficient After-Sales Support and Spare Parts Availability

Low-cost suppliers, especially overseas manufacturers, may offer limited technical support, training, or spare parts. This can result in extended downtime when repairs are needed. Confirm the supplier’s service network, warranty terms, and availability of replacement parts before purchasing.

Ignoring Intellectual Property (IP) Risks

Purchasing machines that infringe on patents or trademarks can expose your business to legal action. Some suppliers replicate branded designs without authorization, offering “compatible” or “generic” models that violate IP rights. Always verify that the machine does not copy patented technology or logos, and request documentation proving IP compliance from the supplier.

Lack of Safety and Compliance Certifications

Non-compliant machines may not meet regional safety standards (e.g., OSHA in the U.S., CE in Europe), posing risks to operators and liability to your business. Machines without proper electrical safety, dust extraction, or emergency stop features can lead to accidents and regulatory fines. Insist on up-to-date compliance certifications relevant to your market.

Hidden Costs from Low-Quality Imports

While initially cheaper, imported machines may incur unexpected costs due to shipping delays, import duties, or the need for modifications to meet local standards. Additionally, poor quality control can result in high defect rates, returns, and customer dissatisfaction. Evaluate total cost of ownership, not just the upfront price.

Overlooking User Training and Ergonomics

A poorly designed machine can cause operator fatigue, reduce efficiency, and increase the risk of injury. Check for ergonomic handles, adjustable height settings, and intuitive controls. Also, confirm whether the supplier offers operator training—essential for achieving consistent results and prolonging machine life.

By carefully assessing quality standards and IP compliance during sourcing, you can avoid these common pitfalls and invest in a reliable, legally sound wood floor polishing machine that delivers long-term value.

Logistics & Compliance Guide for Wood Floor Polishing Machine

Product Classification and HS Code

Wood floor polishing machines are typically classified under Harmonized System (HS) codes related to machinery for working wood or floor treatment equipment. A common classification is 8467.21.00 (Machines for working wood, corks, or similar using a rotating spindle – sanding machines). Confirm the exact HS code with your customs broker or national tariff schedule, as variations may apply based on design and function.

Import/Export Regulations

Compliance with international trade regulations is essential. Key considerations include:

– Export Controls: Verify if the machine contains components subject to export restrictions (e.g., high-power motors or specialized electronics).

– Import Duties and Taxes: Research duty rates, VAT, or GST applicable in the destination country. Use the confirmed HS code to determine tariffs.

– Trade Agreements: Check for preferential treatment under free trade agreements (e.g., USMCA, CPTPP, EU agreements) that may reduce or eliminate duties.

Packaging and Shipping Requirements

Proper packaging ensures safe transit and compliance with carrier standards:

– Use robust wooden or corrugated crates to protect the machine from impact, moisture, and vibration.

– Secure all moving parts and include anti-rust treatment for metal components.

– Label packages with handling instructions (e.g., “Fragile,” “This Side Up”) and include barcodes or RFID tags if required.

– Comply with International Safe Transit Association (ISTA) standards for transport packaging.

Documentation for Customs Clearance

Accurate documentation is critical for smooth customs processing. Required documents typically include:

– Commercial Invoice (detailing value, quantity, and terms of sale)

– Packing List (itemizing contents per package)

– Bill of Lading or Air Waybill

– Certificate of Origin (to claim tariff preferences if applicable)

– Import/Export License (if required by country)

– Product Compliance Certificates (e.g., CE, UKCA, EAC – see below)

Electrical and Safety Compliance

Ensure the machine meets electrical and safety standards in the destination market:

– CE Marking (EU): Required under the Machinery Directive (2006/42/EC) and Low Voltage Directive (2014/35/EU). Includes conformity assessment and technical file preparation.

– UKCA Marking (UK): Mandatory for sales in Great Britain; requirements mirror CE but apply post-Brexit.

– UL/CSA Certification (USA/Canada): Recommended or required for electrical safety; check with OSHA and local authorities.

– EAC Certification (Eurasian Economic Union): Needed for Russia, Kazakhstan, and other EAEU countries under TR CU 010/2011 (Machinery Safety) and TR CU 004/2011 (Low Voltage).

Environmental and Noise Regulations

Wood floor polishing machines may be subject to environmental and noise standards:

– EU Ecodesign Directive (2009/125/EC): May apply to energy-related products; verify if applicable.

– Noise Emission Standards: Comply with directives such as EU 2000/14/EC for outdoor equipment noise. Include noise level data in technical documentation.

– RoHS Compliance (EU/UK/China): Ensure electrical components are free from restricted hazardous substances (e.g., lead, cadmium).

Battery and Motor Considerations

If the machine includes a battery or high-power motor:

– Lithium batteries must comply with UN 38.3 testing and be shipped according to IATA Dangerous Goods Regulations (Class 9) if transported by air.

– Include Safety Data Sheets (SDS) and proper labeling for battery-powered models.

– Confirm motor voltage and frequency compatibility with the destination’s electrical grid (e.g., 110V/60Hz for North America, 230V/50Hz for Europe).

After-Sales and Warranty Compliance

- Provide multilingual user manuals and safety instructions compliant with local language requirements.

- Establish a service and spare parts network or partner with local distributors.

- Adhere to local consumer protection laws regarding warranty duration, service response times, and product liability.

Summary and Recommendations

To ensure successful global distribution of wood floor polishing machines:

– Verify HS code and customs requirements early in the process.

– Obtain all necessary safety and environmental certifications before shipping.

– Partner with experienced freight forwarders and customs brokers familiar with machinery imports.

– Maintain thorough documentation for audits and regulatory inspections.

Consult local authorities and legal experts in target markets to address region-specific compliance obligations.

In conclusion, sourcing a wood floor polishing machine requires careful consideration of several key factors, including the type and condition of flooring, machine performance and durability, ease of use, maintenance requirements, and budget constraints. It is essential to evaluate both commercial-grade and residential-grade equipment based on intended usage frequency and desired finish quality. Additionally, researching reputable suppliers, comparing features across models, and reading user reviews can significantly influence the decision-making process. Renting versus purchasing should also be assessed depending on project scale and long-term needs. Ultimately, selecting the right wood floor polishing machine ensures efficient operation, professional results, and extended lifespan of the flooring, leading to satisfied clients and cost-effective maintenance over time.