The global wood coatings market is experiencing steady growth, driven by rising demand for sustainable finishes and increasing investments in residential and commercial construction. According to a report by Mordor Intelligence, the wood coatings market was valued at USD 9.47 billion in 2023 and is projected to grow at a CAGR of over 5.2% from 2024 to 2029. This growth is fueled by advancements in eco-friendly formulations—particularly water-based and low-VOC paints—and a growing consumer preference for aesthetically enhanced wood surfaces in furniture, flooring, and cabinetry. As sustainability regulations tighten and innovation accelerates, paint manufacturers are focusing on durable, UV-resistant, and quick-drying wood color solutions. In this competitive landscape, ten companies have emerged as leaders, combining technological expertise, broad product portfolios, and global reach to set the standard in wood color paint manufacturing.

Top 10 Wood Color Paint Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Dunn

Domain Est. 1999

Website: dunnedwards.com

Key Highlights: Dunn-Edwards has been the leading paint manufacturer in the Southwestern United States. We are committed to providing the superior products and services….

#2 Pittsburgh Paints Co.

Domain Est. 2024

Website: pittsburghpaintsco.com

Key Highlights: The Pittsburgh Paints Company is a leading producer of interior and exterior paints, stains, caulks, repair products, adhesives, and sealants for homeowners ……

#3 Dutch Boy Paints

Domain Est. 1995

Website: dutchboy.com

Key Highlights: Transform your home with Dutch Boy paints. Find color collections, painting advice and all the inspiration you need to create a beautiful home….

#4 Benjamin Moore Paints & Exterior Stains

Domain Est. 1996

Website: benjaminmoore.com

Key Highlights: $5 deliveryExplore Benjamin Moore’s premium paint colors and products for your next interior or exterior project….

#5 Sherwin

Domain Est. 1998

Website: sherwin-williams.com

Key Highlights: Discover the possibilities of Sherwin-Williams® paint with over 1700 paint colors. Get paint color tips, project ideas & product advice for DIY and Pros….

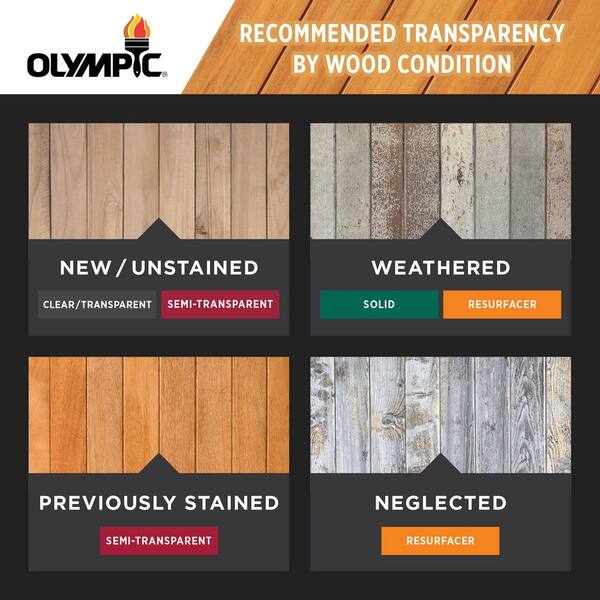

#6 Olympic Exterior Wood Stains

Domain Est. 1998

Website: olympic.com

Key Highlights: Whether its a patio, pergola, living room floor or piano bench – Olympic ® has the right wood stains & deck stains for your project….

#7 Wood Coatings Milesi, a leader in coating since 1947

Domain Est. 1999

Website: milesi.com

Key Highlights: Milesi is a brand of the multinational IVM Group, one of the largest and most important in Europe and around the world, specializing in wood coatings and ……

#8 Paint Solutions Specially Formulated for the Pro

Domain Est. 2004

Website: ppgpaints.com

Key Highlights: PPG provides high-quality paint products, color services, and support to professional painters, contractors, designers, architects, and specifiers….

#9 Mas Paints

Domain Est. 2011

Website: mas-paints.com

Key Highlights: MAS is a leading Italian brand of high quality wood paints, wood top coatings, special effect wood paints and dyes, and decorative textured paints and ……

#10 Lenmar Wood Finishes & Stains

Domain Est. 2018

Website: lenmarwoodfinishes.com

Key Highlights: Lenmar offers a robust portfolio of high-quality wood coatings solutions for various wood finishing applications including real wood flooring….

Expert Sourcing Insights for Wood Color Paint

2026 Market Trends for Wood Color Paint

The global wood color paint market is poised for significant transformation by 2026, driven by evolving consumer preferences, sustainability mandates, technological innovation, and shifts in construction and furniture industries. This analysis explores the key trends shaping the market under relevant H2 subheadings.

Growing Demand for Eco-Friendly and Low-VOC Formulations

Environmental consciousness is a dominant force in the paint and coatings industry. By 2026, demand for wood color paints with low or zero volatile organic compounds (VOCs) is expected to surge. Consumers and regulatory bodies alike are prioritizing indoor air quality and environmental safety. Water-based wood stains and eco-certified finishes (such as Green Seal, Cradle to Cradle, or EU Ecolabel) will gain market share over solvent-based alternatives. Manufacturers are investing heavily in bio-based resins and natural pigments to meet this demand, particularly in North America and Europe.

Rise of Natural and Authentic Wood Aesthetics

Interior design trends continue to favor natural materials and organic textures. By 2026, wood color paints that enhance or mimic the grain and warmth of real wood—such as whitewashed oak, walnut tones, and driftwood grays—will remain highly popular. Consumers are seeking finishes that offer the look of solid wood at a lower cost and with greater durability. Transparent and semi-transparent wood stains that preserve the wood’s natural character will see increased adoption in both residential and commercial spaces.

Expansion in the DIY and Home Renovation Sector

The do-it-yourself (DIY) home improvement market is growing rapidly, supported by online tutorials, accessible tools, and consumer desire for personalized spaces. Wood color paints tailored for easy application—such as wipe-on stains, gel formulations, and spray-on finishes—will be in high demand. Brands that offer user-friendly products with quick drying times and minimal prep requirements will capture significant market share, especially among younger homeowners and urban renovators.

Technological Advancements in Durability and Protection

Innovation in wood paint chemistry will focus on enhancing performance. By 2026, expect widespread availability of wood color paints with advanced UV resistance, moisture protection, and anti-fungal properties. These formulations are critical for both interior and exterior applications, especially in regions with extreme climates. Nanotechnology and self-healing coatings may begin entering premium segments, offering longer-lasting finishes with reduced maintenance.

Influence of Smart Homes and Integrated Design

As smart homes become mainstream, interior finishes—including wood color paints—will need to complement high-tech environments. Neutral and warm wood tones that blend seamlessly with smart lighting, minimalist furnishings, and modern materials (like metal and glass) will dominate. Customizable color-matching services and augmented reality (AR) apps allowing consumers to visualize wood finishes in their space will become standard offerings by paint brands.

Regional Market Dynamics

Growth will vary by region. North America and Europe will lead in sustainable and premium wood finishes due to strict regulations and high consumer awareness. The Asia-Pacific region, particularly China and India, will experience strong growth driven by urbanization, rising disposable incomes, and expanding construction sectors. Latin America and the Middle East will see moderate growth, with increasing interest in imported and high-performance wood coatings.

Competitive Landscape and Brand Differentiation

By 2026, competition among paint manufacturers will center on sustainability credentials, product innovation, and digital customer engagement. Major players like Sherwin-Williams, PPG, AkzoNobel, and Asian Paints are expected to expand their eco-friendly wood finish lines and invest in R&D. Smaller, niche brands focusing on artisanal, non-toxic, or regionally sourced wood paints may gain traction in premium and specialty markets.

Conclusion

The 2026 wood color paint market will be defined by sustainability, authenticity, ease of use, and technological performance. Companies that align with these trends—offering safe, durable, and aesthetically pleasing wood finishes—will be best positioned for growth in a competitive and environmentally conscious marketplace.

Common Pitfalls When Sourcing Wood Color Paint (Quality and Intellectual Property)

Sourcing wood color paint that meets both quality expectations and respects intellectual property (IP) rights involves several potential pitfalls. Being aware of these challenges can help ensure a reliable supply chain and protect your business legally and reputationally.

Inconsistent or Substandard Paint Quality

One of the most frequent issues is receiving paint that fails to meet performance or aesthetic standards. This includes color variation between batches, poor coverage, inadequate adhesion to wood substrates, or lack of durability against UV exposure, moisture, and wear. Low-quality binders, fillers, or pigments can result in premature fading, chipping, or peeling—especially critical in exterior wood applications.

Lack of Color Accuracy and Batch-to-Batch Consistency

Wood color paints often require precise matching to natural wood tones (e.g., walnut, oak, teak). Suppliers may not have robust color-matching processes or quality control, leading to deviations that impact product uniformity. Without standardized spectrophotometric measurement and batch documentation, reproducing the same shade over time becomes difficult, particularly when sourcing from multiple vendors or regions.

Misrepresentation of Product Composition and Performance Claims

Some suppliers may exaggerate or falsify technical specifications, such as VOC content, water resistance, or UV stability. Paints may be labeled as “eco-friendly” or “low-VOC” without proper certification. This not only affects performance but can also lead to compliance issues with environmental regulations like REACH or EPA standards.

Intellectual Property Infringement Risks

Using or sourcing paint formulations that replicate branded or patented colors (e.g., proprietary shades owned by well-known paint manufacturers) without authorization poses serious IP risks. Even if the paint is custom-formulated, similarities in color names, packaging, or technical data sheets can lead to trademark or design patent disputes. Buyers may unknowingly distribute products that infringe on protected formulations or color systems.

Use of Counterfeit or Unlicensed Formulations

In some markets, especially where oversight is limited, suppliers may offer counterfeit versions of branded wood color paints. These products often mimic the appearance and labeling of authentic brands but use inferior or unauthorized formulations. Sourcing such paints exposes companies to legal liability, quality failures, and damage to brand reputation.

Inadequate Documentation and Traceability

A lack of transparency in sourcing—such as missing material safety data sheets (MSDS), certificates of conformance, or formulation disclosures—can hinder quality assurance and regulatory compliance. Without proper documentation, it’s difficult to verify claims about ingredients, sustainable sourcing, or IP legitimacy, increasing supply chain risks.

Failure to Secure IP Rights in Custom Formulations

When developing custom wood color paints, businesses may assume ownership of the formulation, but without clear contractual agreements, the supplier or third-party lab may retain IP rights. This can limit exclusivity, prevent replication, or lead to the same formula being sold to competitors.

By addressing these pitfalls proactively—through due diligence, supplier audits, technical validation, and legal review—companies can ensure they source high-quality, compliant, and legally secure wood color paint solutions.

Logistics & Compliance Guide for Wood Color Paint

This guide outlines the key logistics and compliance considerations for the safe and legal handling, transportation, storage, and disposal of Wood Color Paint, a typically solvent-based or water-based coating used for coloring and protecting wood surfaces.

Regulatory Classification & Documentation

Wood Color Paint is generally classified as a hazardous material due to flammability (if solvent-based), potential health hazards (e.g., respiratory irritants, harmful if swallowed), and environmental concerns. Proper classification under GHS (Globally Harmonized System) and transportation regulations (e.g., DOT in the U.S., ADR in Europe) is essential. Ensure Safety Data Sheets (SDS) are up to date (version compliant with local regulations) and available to all handlers, emergency responders, and transporters. Shipments must be accompanied by accurate shipping papers indicating proper shipping names, UN numbers (e.g., UN1263 for flammable liquid, n.o.s.), hazard classes (e.g., Class 3 Flammable Liquid), and packing groups.

Packaging & Labeling Requirements

Use only UN-certified, leak-proof containers suitable for paint products. For transport, ensure packaging meets performance standards for the hazard class (e.g., IBCs, drums, pails). Each package must display correct GHS labels including hazard pictograms (e.g., flame, health hazard), signal words (e.g., “Danger”), hazard statements, and precautionary statements. Transport labels must align with regulatory requirements (e.g., diamond-shaped hazard labels for Class 3). Inner containers should be secured within outer packaging to prevent movement and damage. Avoid overfilling to allow for thermal expansion.

Storage Conditions & Handling Procedures

Store Wood Color Paint in a well-ventilated, cool, dry area away from direct sunlight, heat sources, and ignition sources. Maintain temperatures within manufacturer specifications (typically 50–80°F / 10–27°C). Flammable paints must be stored in approved flammable storage cabinets or dedicated hazardous storage areas compliant with fire codes (e.g., NFPA 30). Segregate from incompatible materials such as oxidizers and strong acids. Implement good housekeeping practices and prohibit smoking or open flames in storage areas. Use appropriate PPE (gloves, goggles, respirators if needed) during handling to prevent skin contact, inhalation, or ingestion.

Transportation Guidelines

Transport only in vehicles equipped with spill containment and fire extinguishers. Secure loads to prevent shifting during transit. Drivers must be trained in hazardous materials handling (e.g., DOT HAZMAT training) and carry required documentation (SDS, shipping papers, emergency response info). Follow route restrictions for hazardous cargo where applicable. Avoid extreme temperatures during transport. For international shipments, comply with IMDG (sea), IATA (air), or ADR (road in Europe) regulations as appropriate. Air transport of solvent-based paints is often restricted or prohibited.

Environmental & Disposal Compliance

Prevent releases into soil, waterways, or sewers. Implement spill prevention and response plans, including use of absorbents and containment. Used paint, empty containers, and cleanup materials are often regulated as hazardous waste. Follow local, state, and federal waste disposal regulations (e.g., RCRA in the U.S.). Empty containers must be properly drained and managed according to jurisdictional rules—many require triple-rinsing or professional cleaning before recycling or disposal. Never pour paint down drains or into the environment.

Emergency Response & Reporting

Ensure spill kits and fire suppression equipment are readily available. Train personnel in emergency procedures, including evacuation, spill containment, and first aid (e.g., eye flush stations). In case of fire, use extinguishing agents suitable for flammable liquids (e.g., CO2, dry chemical, foam). Report significant spills, fires, or exposures to relevant authorities as required by law (e.g., National Response Center in the U.S.). Maintain incident logs and conduct post-incident reviews to improve safety protocols.

Recordkeeping & Audits

Maintain records of SDS, training certifications, shipping documents, waste manifests, spill reports, and inspection logs for the duration required by regulation (typically 3–5 years). Conduct regular internal audits to verify compliance with safety, environmental, and transportation regulations. Update procedures and training as regulations or formulations change.

In conclusion, sourcing the right wood color paint requires careful consideration of several key factors, including the type of wood, desired finish (e.g., matte, satin, glossy), durability requirements, and environmental impact. Opting for high-quality, compatible paint that enhances the natural grain while providing long-term protection ensures both aesthetic appeal and functional performance. Whether for interior or exterior use, selecting low-VOC or eco-friendly options supports sustainability without compromising on color accuracy or coverage. Ultimately, proper research, sample testing, and sourcing from reputable suppliers will lead to a successful and satisfying wood finishing project.