The global CNC machine market is experiencing robust growth, driven by increasing demand for precision manufacturing across industries such as woodworking, automotive, and furniture. According to Grand View Research, the global CNC machine market size was valued at USD 77.5 billion in 2022 and is expected to expand at a compound annual growth rate (CAGR) of 7.8% from 2023 to 2030. The rising adoption of automation and advancements in computer-aided design (CAD) and computer-aided manufacturing (CAM) technologies are key factors accelerating this growth. Within the woodworking sector, 4×8-foot CNC machines—known for their capacity to handle standard sheet sizes—have become essential tools for manufacturers seeking efficiency, repeatability, and high-quality output. As demand for customized wood products surges, particularly in cabinetry, signage, and modular furniture, the need for reliable and high-performance 4×8 wood CNC machines has never been greater. This report highlights the top 10 manufacturers leading innovation and market share in this dynamic segment, combining technical excellence, scalability, and proven performance to meet evolving industry needs.

Top 10 Wood Cnc Machine 4X8 Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

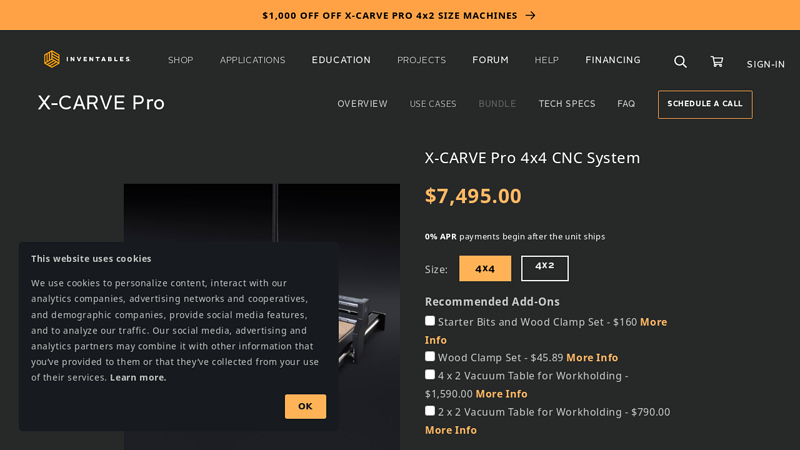

#1 X

Domain Est. 2001

Website: inventables.com

Key Highlights: In stock 2-day deliveryWith our tiling feature, you can cut full, 4×8 sheets on a 4×4 work area. Configure a full CNC Solution.You get the CNC machine and premium support. Recommen…

#2 CNC Routers

Domain Est. 2002

Website: shopsabre.com

Key Highlights: ShopSabre’s American-made CNC Routers feature cutting-edge technology and premium components, the kind typically only seen on much higher-priced machines….

#3 Stepcraft Inc.

Domain Est. 2014

Website: stepcraft.us

Key Highlights: Unlock endless possibilities with STEPCRAFT CNC machines, designed to handle aluminum, wood, plastic, and so much more….

#4 AXYZ CNC Routers

Domain Est. 1995

Website: axyz.com

Key Highlights: AXYZ delivers customizable CNC router systems for signage, woodworking, plating, plastics, metal fabrication and cladding. We help you automate better with ……

#5 4×8 cnc routers for sign making, wood, plastic, aluminum.

Domain Est. 2011

Website: veloxcnc.com

Key Highlights: VELOX CNC router cutting through .0625″ thick carbon fiber/fiber glass material. Using a custom size machine 74×14. This is similar to our 4×4 and 2×2 machines….

#6 Avid CNC

Domain Est. 2016

Website: avidcnc.com

Key Highlights: Our AVID CNC makes quick work of wood and especially aluminum to help us build projects faster, 100% in-house….

#7 Maslow CNC

Domain Est. 2016

Website: maslowcnc.com

Key Highlights: Bring big human scale things from the digital world into the physical world. Our goal is to make large format CNC routing accessible….

#8 CNC Machines

Domain Est. 2020

Website: phantomcncsystems.com

Key Highlights: From Startups to Scale-Ups — We’ve Got a Machine for That. COSMIC. The Cosmic is a robust single-tool CNC machine available in 4×4, 4×8, and 5×10 sizes….

#9 4×8 CNC Machines

Domain Est. 2024

#10 CATEKCNC

Domain Est. 2023

Website: catekcnc.com

Key Highlights: The standard basic 4×8 feet CNC wood router comes with a T-slot aluminum alloy workbench as standard and can be equipped with various functional kits for ……

Expert Sourcing Insights for Wood Cnc Machine 4X8

H2: Projected 2026 Market Trends for 4×8 Wood CNC Machines

The global market for 4×8 wood CNC machines is poised for significant transformation by 2026, driven by technological advancements, evolving consumer demands, and shifts in manufacturing practices. These computer-controlled routers, known for their versatility in cutting, carving, and shaping wood across a standard 4-foot by 8-foot sheet, are becoming increasingly central to industries ranging from cabinetry and furniture to architectural millwork and custom fabrication.

One of the dominant trends shaping the 2026 landscape is the integration of automation and smart technology. Manufacturers are increasingly embedding IoT (Internet of Things) capabilities into 4×8 CNC machines, enabling remote monitoring, predictive maintenance, and real-time performance analytics. This shift enhances operational efficiency, reduces downtime, and supports the growing trend of Industry 4.0 in woodworking operations.

Additionally, there is a rising demand for user-friendly software and intuitive interfaces. By 2026, expect broader adoption of cloud-based CAD/CAM platforms that allow seamless design transfer, collaborative workflows, and compatibility across devices. This lowers the entry barrier for small to medium-sized enterprises (SMEs) and hobbyists, expanding the consumer base.

Sustainability is another key driver influencing market dynamics. As environmental regulations tighten, manufacturers are investing in energy-efficient motors, dust collection systems, and machines designed for optimal material utilization. This not only reduces waste but also aligns with green building standards—an increasingly important factor for commercial buyers.

Geographically, North America and Europe remain strong markets due to established woodworking industries and high adoption of automation. However, rapid industrialization in Asia-Pacific—particularly in countries like India and Vietnam—is expected to fuel double-digit growth in CNC router demand. Localized production and cost-effective models tailored to regional needs will be critical for market penetration.

Lastly, customization and modularity are emerging as competitive differentiators. By 2026, many 4×8 wood CNC machines will offer modular upgrades—such as automated tool changers (ATC), vacuum hold-down systems, and multi-axis capabilities—allowing users to scale functionality based on project requirements without replacing entire systems.

In summary, the 2026 market for 4×8 wood CNC machines will be characterized by smarter, more efficient, and adaptable systems, catering to a diverse and increasingly tech-savvy user base across global markets.

Common Pitfalls When Sourcing a 4×8 Wood CNC Machine (Quality and IP Concerns)

Logistics & Compliance Guide for Wood CNC Machine (4×8)

Overview of the 4×8 Wood CNC Machine

A 4×8 wood CNC machine refers to a computer numerical control (CNC) router designed to cut, carve, and shape wood and similar materials on a worktable measuring 4 feet by 8 feet (approximately 1.22 x 2.44 meters). These machines are commonly used in woodworking shops, furniture manufacturing, cabinetry, and sign-making industries. Due to their size, weight, and technical nature, shipping and compliance procedures require careful planning.

Packaging and Crating Requirements

Proper packaging is essential to prevent damage during transit. The CNC machine must be securely mounted inside a custom wooden crate with reinforced corners and internal bracing. Use anti-vibration materials such as foam, rubber padding, or air-ride supports to protect sensitive components like the spindle, gantry, and control panel. All moving parts should be locked or immobilized, and electrical components must be shielded from moisture and dust. Clearly label the crate with “Fragile,” “This Side Up,” and handling instructions.

Shipping Method and Transportation Mode

Given the size and weight (typically 1,500–3,000 lbs or more), 4×8 CNC machines are generally shipped via freight—either Less-Than-Truckload (LTL) or full truckload (FTL). For international shipments, ocean freight (FCL or LCL) is standard. Coordinate with a freight carrier experienced in handling heavy machinery. Ensure the delivery vehicle is equipped with a lift gate or loading dock access at the destination. Notify the receiver in advance for scheduling and site preparation.

Import/Export Documentation

For international shipments, essential documentation includes:

– Commercial Invoice (detailing machine value, model, and specifications)

– Packing List (itemizing contents and crate dimensions)

– Bill of Lading (BOL)

– Certificate of Origin

– Import/Export Declaration

– Harmonized System (HS) Code: Typically 8465.95.00 for CNC routing machines (verify based on country-specific tariff schedules)

Ensure all documents are accurate to prevent customs delays.

Customs Clearance and Duties

The importing country will assess duties and taxes based on the declared value and HS code. Research duty rates in the destination country—some regions offer reduced tariffs for industrial machinery. Provide technical specifications to support correct classification. Be prepared for possible inspection by customs authorities. Use a licensed customs broker to facilitate clearance and ensure compliance with local trade regulations.

Electrical and Safety Compliance

Verify that the machine meets electrical standards of the destination country (e.g., voltage: 110V/220V, phase: single/three-phase). Include a NEMA-compliant plug for the U.S. or appropriate connector for other regions. The machine should comply with relevant safety standards such as:

– CE Marking (for European Union)

– UL/CSA Certification (for U.S. and Canada)

– ISO 13849 (safety of machinery)

Provide user manuals and safety documentation in the local language if required.

Environmental and Material Regulations

Ensure compliance with environmental regulations related to wood dust extraction and noise emissions. Some regions require dust collection systems to meet specific air quality standards (e.g., OSHA in the U.S.). Confirm that any lubricants or coolants used are non-toxic and compliant with local environmental laws.

Installation and Site Preparation

The receiving site must have:

– Adequate floor space (minimum 6×10 feet recommended for operation and access)

– Level, solid flooring capable of supporting the machine’s weight

– Proper electrical supply matching the machine’s requirements

– Ventilation or dust extraction system

Schedule a technician for installation and calibration, especially for precision work.

Warranty and After-Sales Support

Confirm warranty terms and availability of technical support in the destination country. Provide contact information for local service partners or authorized technicians. Include spare parts (e.g., bits, belts) and maintenance guides in the shipment if possible.

Conclusion

Shipping and deploying a 4×8 wood CNC machine involves careful attention to logistics, compliance, and safety. Proper documentation, secure packaging, and adherence to regional regulations ensure smooth delivery and operation. Partnering with experienced freight and customs professionals minimizes risks and supports long-term success.

Conclusion for Sourcing a 4×8 Wood CNC Machine

Sourcing a 4×8-foot CNC machine for woodworking is a significant investment that can greatly enhance productivity, precision, and design flexibility for woodworking operations. After evaluating key factors such as machine build quality, spindle power, controller systems, software compatibility, customer support, and budget, it is clear that the right machine depends on specific production needs, material types, and long-term goals.

Machined with large-format capabilities, a 4×8 CNC router allows for full-sheet processing of plywood, MDF, solid wood, and other materials, minimizing waste and maximizing efficiency. When sourcing, prioritize reputable manufacturers with proven track records, robust customer service, and accessible spare parts. Additionally, consider features like vacuum tables, auto-tool changers, and integrated dust collection to further optimize performance.

In conclusion, selecting the ideal 4×8 wood CNC machine requires a balanced assessment of technical specifications, operational requirements, and total cost of ownership. With the right machine in place, businesses can achieve higher throughput, improved accuracy, and greater creativity in custom woodworking projects—ultimately delivering a strong return on investment and a competitive edge in the market.