The global wood branding stamp market is experiencing steady growth, driven by increasing demand for traceability, quality assurance, and brand identity in the forestry, woodworking, and construction sectors. According to Grand View Research, the global wood marking and identification market was valued at approximately USD 2.1 billion in 2023 and is projected to expand at a CAGR of 5.8% through 2030. This growth is fueled by stricter regulatory requirements for timber sourcing, rising adoption of sustainable forestry practices, and the need for permanent, tamper-proof identification in supply chains. As demand for precision and durability in wood branding solutions rises, manufacturers are innovating with advanced materials, ergonomic designs, and customizable stamping technologies. In this evolving landscape, identifying reliable and high-performance wood branding stamp manufacturers has become critical for businesses aiming to maintain compliance, enhance branding, and streamline operations. Below are the top 10 manufacturers leading the industry through quality, innovation, and customer-centric solutions.

Top 10 Wood Branding Stamp Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

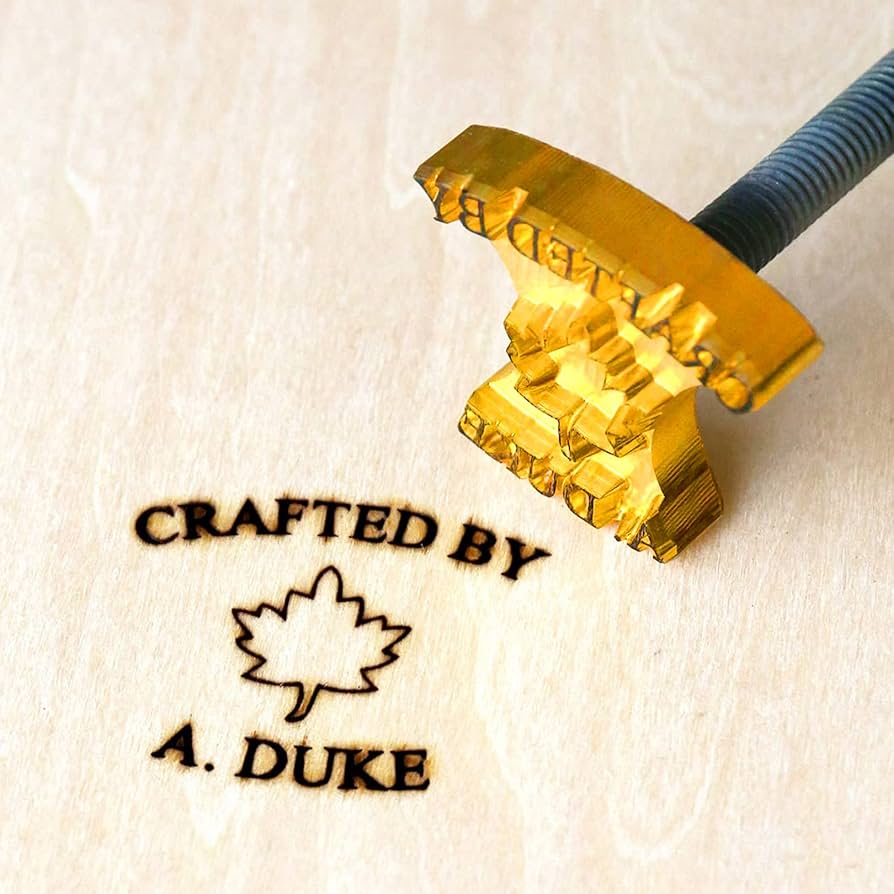

#1 Custom Fire Heated Wood Branding Irons

Domain Est. 1999

Website: lhbrandingirons.com

Key Highlights: In stock Rating 5.0 (2) Great for business logos, wedding ceremonies, and personalized gifts or décor. These brands are made of mild steel (stainless steel optional) with 34″ han…

#2 Wood Rubber Stamp

Domain Est. 1999

Website: thestampmaker.com

Key Highlights: All wood handle stamps ship in one business day! Easily design and purchase a classic wood handle rubber stamp here….

#3 Custom Electric Branding Iron

Domain Est. 1999

#4 Custom Leather Stamp, Branding Iron & Die Cut

Domain Est. 2012

Website: lwleathers.com

Key Highlights: We supply custom leather stamp, branding iron & steel rule die cut. Products include custom leather stamping machines, electric wood branding iron, ……

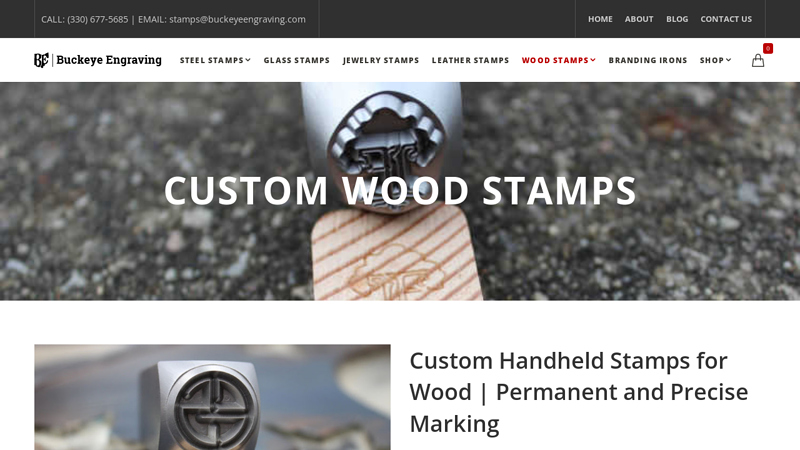

#5 Custom Wood Stamps

Domain Est. 2015

Website: buckeyeengraving.com

Key Highlights: Custom wood stamps and brands by Buckeye Engraving enable you to leave your makers mark on end and face grain. Free Quotes. Made in USA….

#6 Custom Branding Iron for Wood

Domain Est. 2016

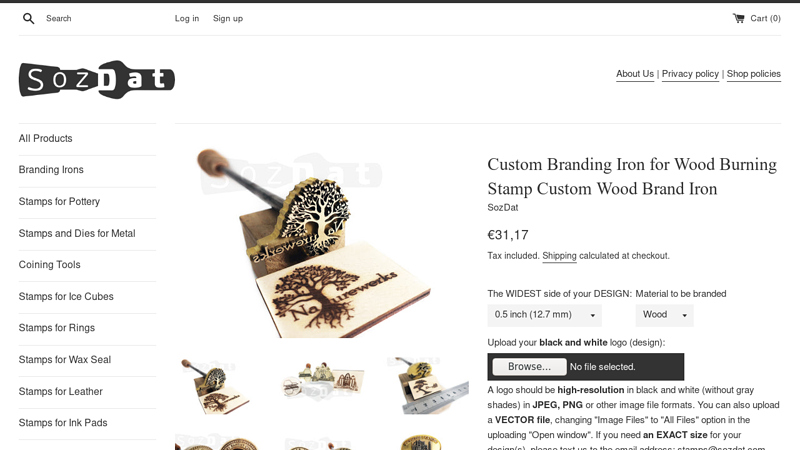

#7 Custom Branding Iron for Wood Burning Stamp Custom …

Domain Est. 2016

#8 Custom Wood Branding Iron with Personalised Logo

Domain Est. 2017

#9 Custom Branding Iron for Wood, Leather & Crafting

Domain Est. 2018

Website: solisdepot.com

Key Highlights: Rating 4.4 (90) Dec 18, 2025 · Introducing the Custom Branding Iron for Wood, Leather & Crafting by Arokimi – the ultimate tool for creators and artisans alike….

#10 Custom Wood and Leather Branding Iron

Domain Est. 2018

Website: bullets-n-broadheads.com

Key Highlights: This personalised logo maker allows you to engrave your unique designs onto a variety of materials, including wood, leather, plastic, and paper, ……

Expert Sourcing Insights for Wood Branding Stamp

2026 Market Trends for Wood Branding Stamps

The wood branding stamp market is poised for notable evolution by 2026, driven by technological advancements, shifting consumer preferences, and expanding applications across industries. This analysis outlines the key trends expected to shape the market landscape in the coming years.

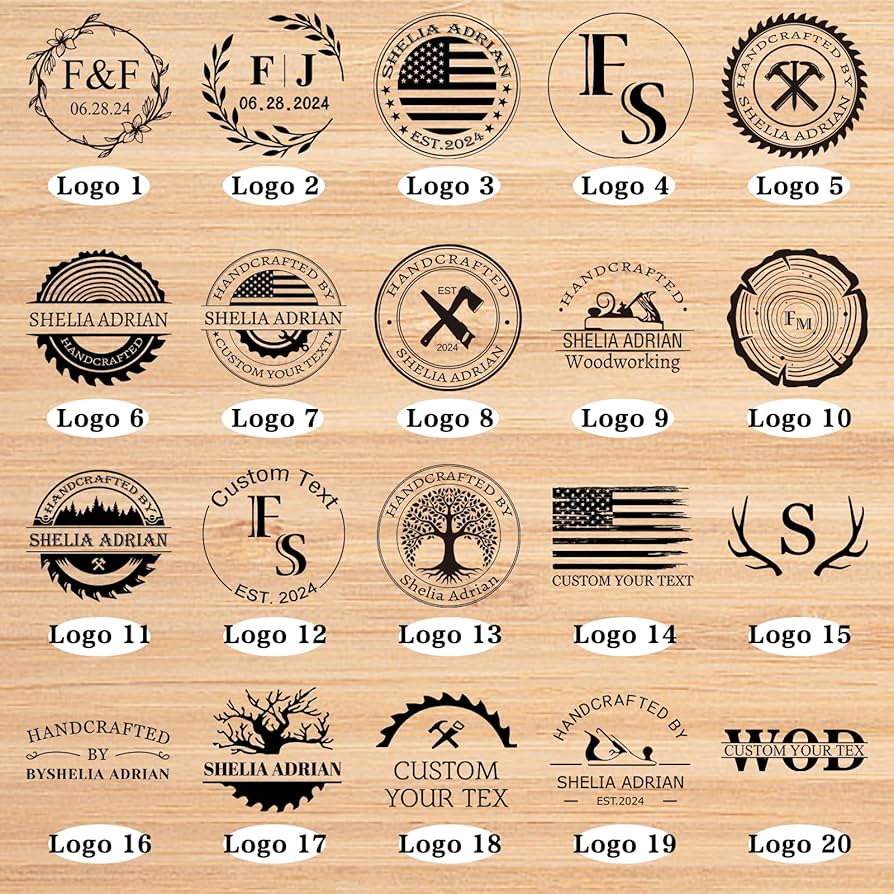

Growing Demand in Craftsmanship and Artisanal Goods

A continued rise in consumer preference for handmade, authentic, and personalized wood products is fueling demand for branding stamps. Artisans, woodworkers, and small-batch furniture makers increasingly use branding stamps to add unique logos, signatures, or decorative elements, enhancing brand identity and perceived value. This trend is amplified by e-commerce platforms like Etsy and social media marketing, where branded items stand out in a crowded marketplace.

Integration of Digital Design and Customization

By 2026, digital design tools and online configurators will dominate the branding stamp ordering process. Customers will expect real-time previews, 3D visualizations, and seamless integration with CAD software. The ability to upload logos or create custom designs online, combined with fast turnaround times for laser-cut or CNC-machined stamps, will become a standard offering among leading suppliers.

Expansion in Industrial and Commercial Applications

Beyond artisanal use, wood branding stamps are gaining traction in industrial settings such as lumber yards, timber processing, and furniture manufacturing. These applications require durable, high-precision stamps for traceability, quality control, and inventory management. Automated stamping systems integrated into production lines are expected to grow, particularly in regions with strict timber certification and sustainability regulations.

Adoption of Eco-Friendly and Durable Materials

Sustainability concerns will influence both stamp production and usage. Manufacturers will increasingly use recycled metals for stamp heads and eco-conscious packaging. Additionally, durable, long-lasting stamp materials like hardened steel will be preferred over disposable alternatives, aligning with broader industry trends toward reducing waste and improving lifecycle efficiency.

Technological Advancements in Heating and Application Methods

Electric and induction-heated branding systems will gain popularity due to their precision, energy efficiency, and reduced fire risk compared to traditional open-flame methods. Portable, battery-operated branding irons with digital temperature controls will become more common, offering greater flexibility for field use and on-site branding in construction or forestry applications.

Regional Market Growth and E-Commerce Penetration

Emerging markets in Asia-Pacific and Latin America will see increased adoption of wood branding stamps, driven by growth in woodworking industries and export-oriented furniture manufacturing. Simultaneously, global e-commerce platforms will make high-quality branding tools more accessible to small businesses and hobbyists, reducing entry barriers and democratizing brand expression in woodcraft.

Rising Importance of Brand Protection and Traceability

As counterfeit wood products and illegal logging remain concerns, branding stamps will play a critical role in product authentication and chain-of-custody tracking. Custom serial-numbered or QR-code-integrated branding solutions may emerge, allowing consumers and regulators to verify origin and sustainability credentials through mobile scanning.

In summary, the 2026 wood branding stamp market will be characterized by innovation, personalization, and sustainability. Companies that invest in digital customization, durable technology, and eco-conscious practices are likely to lead in this evolving and increasingly competitive space.

Common Pitfalls When Sourcing Wood Branding Stamps (Quality, IP)

Sourcing wood branding stamps—especially for commercial or branded use—comes with several potential pitfalls related to quality and intellectual property (IP). Being aware of these can help avoid costly mistakes, legal issues, and subpar results.

Poor Material and Craftsmanship

One of the most common quality pitfalls is receiving a stamp made from low-grade materials or with poor craftsmanship. Inexpensive stamps may use soft metals that warp or degrade quickly under high heat, leading to blurry or inconsistent branding. Look for stamps made from durable metals like brass, steel, or copper, which withstand repeated heating and maintain sharp detail over time.

Inconsistent Heat Distribution

A poorly designed or manufactured branding iron may heat unevenly, resulting in partial or patchy burns. This is often due to inadequate heating elements or poor thermal conductivity in the metal. Ensure the supplier provides specifications on heat distribution and, if possible, test a sample before placing a large order.

Lack of Customization Accuracy

When ordering custom designs, discrepancies between the submitted artwork and the final product are common. Misaligned text, distorted logos, or incorrect sizing can occur if the manufacturer doesn’t follow precise specifications. Always request a proof or digital mockup before production and clarify tolerances for detail and size.

Intellectual Property Infringement

Using logos, trademarks, or copyrighted designs without proper authorization is a serious IP risk. Even if a supplier agrees to produce a stamp with a well-known logo, you could face legal action from the brand owner. Always confirm you have the rights to reproduce any design, especially if it includes registered trademarks or artistic works.

Unauthorized Use of Brand Names or Logos

Sourcing a stamp that replicates another company’s branding—even unintentionally—can lead to cease-and-desist letters or lawsuits. Avoid using fonts, symbols, or layouts that closely mimic established brands unless you have explicit licensing permission.

Supplier Reliability and Transparency

Some suppliers, especially those found on open marketplaces, may lack transparency about their manufacturing process or materials used. They might also subcontract work without quality control, increasing the risk of defects. Vet suppliers thoroughly, request references, and consider visiting facilities if sourcing in bulk.

Inadequate Testing and Safety Standards

Low-quality branding irons may lack safety features or fail to meet electrical and temperature safety standards, especially plug-in models. This poses risks to users and can result in product liability issues. Ensure the supplier complies with relevant safety certifications (e.g., CE, UL) where applicable.

By addressing these pitfalls early—focusing on material quality, design accuracy, and IP compliance—you can source a durable, effective, and legally sound wood branding stamp that meets your needs.

Logistics & Compliance Guide for Wood Branding Stamps

Overview of Wood Branding Stamp Applications

Wood branding stamps are widely used across industries such as forestry, construction, furniture manufacturing, and export packaging to mark ownership, grade, species, or certification details on wooden materials. Proper logistics and compliance ensure these stamps meet regulatory, safety, and quality standards.

Regulatory Compliance Requirements

Wood branding stamps may be subject to regional and international regulations, particularly when used in exported goods or certified timber. Key compliance considerations include:

– ISPM 15 Compliance: For wood packaging material (e.g., pallets, crates), stamps must include an official ISPM 15 mark indicating heat treatment or fumigation. Unauthorized use or misapplication can lead to shipment rejection.

– Country-Specific Standards: Some countries require specific stamp content or formats (e.g., USDA for U.S. timber, PEFC/FSC for sustainable forestry). Verify local requirements before stamping.

– Traceability: Stamps must enable traceability of origin, treatment, and manufacturer as required by authorities or certification bodies.

Material Safety and Environmental Regulations

- Ink and Heating Elements: If electric or gas-powered branding tools are used, ensure compliance with local environmental and workplace safety regulations (e.g., OSHA, REACH, RoHS).

- Combustion Byproducts: Open-flame branding may generate smoke or emissions; operate in well-ventilated areas or use approved industrial exhaust systems to meet air quality standards.

Import and Export Considerations

- Customs Documentation: When shipping stamped wood products internationally, ensure all branding aligns with declared specifications. Mismatched branding can trigger customs inspections or delays.

- Labeling Accuracy: Confirm that stamps reflect correct species, grade, treatment method, and certification code to avoid false labeling penalties.

- Export Licensing: Certain wood species (e.g., protected or CITES-listed) require special permits. Branding must not misrepresent protected status.

Handling and Storage Logistics

- Stamp Tool Maintenance: Store branding irons in dry, secure locations to prevent rust or damage. Regularly inspect for wear that could affect stamp clarity.

- Temperature Management: Electric branding tools require safe storage away from moisture and extreme temperatures. Follow manufacturer guidelines for battery or power unit storage.

- Inventory Control: Track usage of stamps, especially for certified or regulated wood, to maintain audit-ready records.

Transportation of Branding Equipment

- Safe Packaging: When shipping branding irons or portable units, use heat-resistant and impact-protected packaging to prevent accidents or damage.

- Hazardous Materials: If using propane or other flammable fuels, comply with IATA/IMDG regulations for transporting hazardous goods.

- Battery-Powered Devices: Lithium-ion batteries in electric stamp tools must comply with UN38.3 testing and proper labeling during air transport.

Quality Assurance and Recordkeeping

- Stamp Legibility: Regularly verify that stamps produce clear, permanent marks that meet industry standards (e.g., ASTM D1945 for lumber stamps).

- Audit Readiness: Maintain logs of stamp usage, maintenance, and calibration. Retain records for traceability during compliance audits.

- Training and Certification: Ensure operators are trained in proper stamping techniques and regulatory requirements to minimize errors.

Penalties for Non-Compliance

Failure to follow logistics and compliance guidelines may result in:

– Rejection of shipments at borders

– Fines or legal action for false labeling

– Loss of certification (e.g., FSC, PEFC)

– Safety incidents due to improper equipment use

Adhering to this guide ensures operational efficiency, legal conformity, and market access for wood products bearing branding stamps.

Conclusion for Sourcing a Wood Branding Stamp:

Sourcing a wood branding stamp requires careful consideration of quality, customization, material durability, and supplier reliability. After evaluating various suppliers and options, it is evident that investing in a high-quality, well-crafted branding iron—preferably made from durable steel and customized to reflect your brand identity—ensures consistent, professional results. Whether sourcing locally or from specialized online manufacturers, it’s important to prioritize precision in design, efficient heating methods (manual, electric, or gas), and ethical production practices. A well-sourced wood branding stamp not only enhances product presentation and authenticity but also strengthens brand recognition and customer trust. Ultimately, choosing the right supplier and stamp design contributes significantly to the long-term success and professionalism of your woodworking or craft-based business.