The global wood screw market is experiencing steady growth, driven by rising construction activities, increasing demand for sustainable building materials, and advancements in fastener technology. According to a report by Mordor Intelligence, the global wood screw market was valued at approximately USD 3.8 billion in 2023 and is projected to grow at a CAGR of over 5.2% from 2024 to 2029. This expansion is fueled by the growing preference for timber in residential and commercial construction, particularly in regions like North America and Europe, where renovation projects and new-build developments continue to rise. Additionally, innovations in coating technologies—such as galvanization and thermoplastic coatings—are enhancing corrosion resistance and load-bearing capacity, making modern wood anchor screws more reliable than ever.

As demand surges, manufacturers are investing in R&D to improve product performance, sustainability, and ease of installation. With increasing emphasis on structural integrity and energy-efficient building practices, the role of high-quality wood anchor screws has become more critical. In this competitive landscape, a select group of manufacturers has emerged as leaders, combining engineering precision, scalable production, and global distribution networks to meet evolving industry standards. This list highlights the top 8 wood anchor screw manufacturers shaping the market today, based on innovation, market presence, and product performance metrics.

Top 8 Wood Anchor Screw Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Star Drive Wood Screws – Screw Products, Inc.

Domain Est. 1999

Website: screw-products.com

Key Highlights: Screw Products Inc. specializes in star drive stainless steel and heat treated wood screws for decks, log homes, remodeling, kitchen cabinets, docks, ……

#2 Pro-Twist

Domain Est. 2003

Website: pro-twist.com

Key Highlights: Pro-Twist is an industry-leading manufacturer of professional-grade fasteners that are used for a wide variety of applications. Get started with us today!…

#3 Fastening Systems — Screws & Nails

Domain Est. 1995

Website: strongtie.com

Key Highlights: Information about our wide variety of nail types and screw styles designed for every project including our Strong-Drive® and Deck-Drive™ product lines….

#4 Fasteners

Domain Est. 1995

Website: hilti.com

Key Highlights: Shop all products · Mechanical anchors · Chemical anchors · Anchor rods & elements · Cast-in anchors · Cast-in anchor channels · Screws · Nails · Threaded studs & ……

#5 Specialty Fastening Solutions for the Commercial Construction …

Domain Est. 1996

Website: itwbuildex.com

Key Highlights: We manufacture self-drilling and tapping screws, anchors, toggles, and other fastening systems under the Teks, Sammys, Dec-King, EZ Ancor, and Rock-On-brands….

#6 SPAX US

Domain Est. 2004

Website: spax.us

Key Highlights: Our Engineered Screws & Fasteners are manufactured and rigorously tested right here in the heart of America. Rely on us to help you drive the highest quality….

#7 Metallics

Domain Est. 2004

Website: nsiindustries.com

Key Highlights: Metallics, a part of the NSI family, is more than just a supplier—we’re your source for innovative, reliable, high-quality fasteners and anchors….

#8 Sammys Anchors

Domain Est. 2018

Website: sammysanchors.com

Key Highlights: Sammys has revolutionized threaded rod hanging on jobsites across America saving countless hours in labor on Fire Sprinkler, Electrical, and HVAC projects….

Expert Sourcing Insights for Wood Anchor Screw

H2: Projected Market Trends for Wood Anchor Screws in 2026

The global wood anchor screw market is poised for significant evolution by 2026, driven by advancements in construction technologies, growing emphasis on sustainable building materials, and rising demand across residential, commercial, and industrial sectors. Key trends shaping the market landscape include:

-

Increased Demand in Residential Construction

With the ongoing global housing boom—particularly in emerging economies—wood anchor screws are experiencing heightened demand. Their use in timber framing, decking, and structural connections in wooden homes is expanding due to the material’s ease of installation and cost-efficiency compared to traditional fastening methods. -

Growth in Sustainable and Eco-Friendly Building Practices

As green building certifications (such as LEED and BREEAM) gain traction, there is a shift toward wood-based construction systems that are renewable and low-carbon. High-performance wood anchor screws compatible with engineered wood products (e.g., cross-laminated timber) are seeing increased adoption in low-carbon and modular construction projects. -

Technological Innovation and Product Differentiation

Manufacturers are investing in R&D to develop corrosion-resistant, high-tensile strength screws with improved thread designs for better grip and load distribution. Coatings such as zinc flake, hot-dip galvanization, and stainless steel variants are gaining popularity to extend service life in harsh environments. -

Expansion in DIY and Home Improvement Markets

The rise of the DIY culture, accelerated by online tutorials and home renovation platforms, is fueling retail sales of wood anchor screws. Consumer-friendly packaging, multi-purpose designs, and compatibility with cordless power tools are key drivers in this segment. -

Regional Market Shifts

North America and Europe remain dominant markets due to stringent building codes and widespread use of wood-frame construction. However, Asia-Pacific—especially China, India, and Southeast Asia—is expected to witness the highest growth rate, driven by rapid urbanization and infrastructure development. -

Supply Chain Optimization and Localized Production

In response to post-pandemic disruptions and rising logistics costs, companies are increasingly adopting regional manufacturing and inventory strategies. This localization trend enhances supply reliability and reduces lead times for construction projects. -

Integration with Digital Construction Tools

The growing use of Building Information Modeling (BIM) and prefabrication techniques is influencing screw specifications. Manufacturers are collaborating with design firms to provide precise fastener data in digital formats, supporting accuracy in automated assembly processes.

In conclusion, the wood anchor screw market in 2026 will be characterized by innovation, sustainability, and regional diversification. Companies that align with green building trends, invest in product performance, and adapt to evolving construction methodologies are likely to gain a competitive edge.

Common Pitfalls When Sourcing Wood Anchor Screws (Quality and Intellectual Property)

Sourcing wood anchor screws—especially for high-load or safety-critical applications—requires careful attention to both product quality and intellectual property (IP) considerations. Overlooking these aspects can lead to structural failures, legal disputes, and reputational damage. Below are key pitfalls to avoid:

Poor Material Quality and Manufacturing Standards

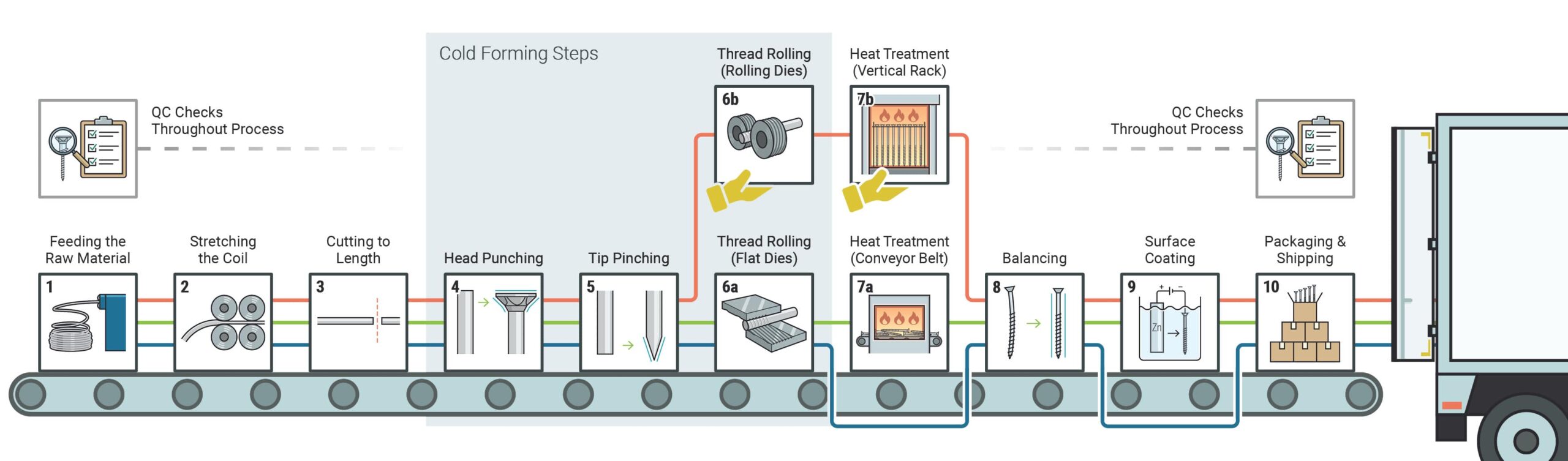

Low-cost suppliers may use substandard materials such as low-grade steel or improperly treated metals, leading to reduced tensile strength, corrosion resistance, and long-term durability. Inadequate manufacturing processes (e.g., poor thread rolling, inconsistent heat treatment) can compromise performance. Always verify material certifications (e.g., ASTM, ISO) and request test reports for load capacity and salt spray resistance.

Lack of Independent Testing and Certification

Many generic wood anchor screws lack third-party testing or compliance with recognized standards (e.g., ICC-ES, CE, ETA). Relying solely on supplier claims without certified performance data increases the risk of using underperforming products, especially in structural or seismic applications. Ensure products are tested and listed by accredited bodies.

Counterfeit or IP-Infringing Products

Popular wood anchor screw designs (e.g., patented helix geometry, tip design, or coating technology) are often copied without authorization. Sourcing counterfeit or IP-infringing screws not only violates intellectual property rights but also risks poor quality, as knock-offs typically don’t undergo the same R&D or quality control. This can expose your company to legal liability and damage customer trust.

Inadequate Traceability and Documentation

Without batch traceability, material certifications, and test reports, it becomes difficult to verify quality or respond to product failures. Suppliers who cannot provide full documentation may be sourcing from unverified or inconsistent manufacturing sources, increasing procurement risk.

Misrepresentation of Performance Claims

Some suppliers exaggerate load ratings, suitability for specific wood types, or environmental resistance (e.g., outdoor, marine, or ACQ-treated lumber applications). Always cross-check performance claims with independent data sheets and ensure compatibility with your project requirements.

Ignoring IP Clearance in Procurement Contracts

Failing to include IP indemnification clauses in supplier agreements leaves buyers exposed if the sourced screws infringe on third-party patents or trademarks. Ensure contracts require suppliers to warrant that products do not violate any IP rights and to assume liability if infringement occurs.

By addressing these pitfalls proactively—through due diligence, supplier vetting, and attention to both technical and legal details—buyers can ensure reliable performance and mitigate risks associated with quality and intellectual property when sourcing wood anchor screws.

Logistics & Compliance Guide for Wood Anchor Screw

Product Overview

Wood Anchor Screws are specialized fasteners designed for securing materials to wooden substrates. They feature self-tapping threads and a robust design to ensure strong holding power in softwood, hardwood, and engineered wood products. Common applications include construction, furniture assembly, and woodworking projects.

Packaging Specifications

- Standard Packaging: Screws are typically supplied in bulk (polybags, plastic pails) or pre-packed blister cards, depending on order volume and end-use requirements.

- Labeling: Each package must include product name, size (diameter x length), material (e.g., carbon steel, stainless steel), finish (e.g., zinc-plated), quantity, batch/lot number, and manufacturer details.

- Inner Packaging: Anti-corrosion paper or VCI (Vapor Corrosion Inhibitor) sachets recommended for metal components to prevent rust during transit.

Storage Conditions

- Store in a dry, temperature-controlled environment (10–30°C).

- Avoid direct exposure to moisture, humidity, and corrosive chemicals.

- Keep packages sealed until use to prevent contamination or oxidation.

- Stack pallets no higher than recommended to avoid crushing lower layers.

Transportation Requirements

- Mode of Transport: Suitable for road, rail, air, and sea freight. Use enclosed, non-vented containers to prevent moisture ingress.

- Palletization: Use standard EUR/ISO pallets. Secure packages with stretch wrap and corner boards. Max load height: 1.8 meters.

- Hazard Classification: Non-hazardous (UN3082, environmentally hazardous substance, liquid, n.o.s. does not apply). Classified as general cargo.

- Documentation: Include commercial invoice, packing list, and bill of lading/air waybill. For international shipments, provide HS Code (e.g., 7318.15 for screws of iron or steel).

Import/Export Compliance

- HS Code: 7318.15.00 (Screws, bolts, and nuts, of iron or steel) – verify local tariff database for country-specific subcodes.

- Customs Declarations: Accurate product description, country of origin, declared value, and quantity required.

- Country-Specific Regulations:

- USA (CBP): Comply with 19 U.S.C. 1304 (country of origin marking). Subject to anti-dumping duties if sourced from certain regions.

- EU: Must comply with REACH (Registration, Evaluation, Authorisation and Restriction of Chemicals) and RoHS if used in electrical/electronic applications. CE marking not required for standalone fasteners.

- UK: Follow UKCA marking guidelines where applicable; post-Brexit import rules apply.

- Canada: Complies with CCC (Canadian Customs Tariff), Schedule B: 7318.15.00. Bilingual labeling required.

Quality & Safety Standards

- Material Standards: Conform to ASTM A325, ISO 898-1 (for mechanical properties), or DIN 7996 (for wood screws).

- Testing Requirements: Periodic tensile strength, torque testing, and salt spray testing (per ASTM B117) for corrosion resistance.

- Certifications: Provide Material Test Reports (MTRs) and Certificate of Compliance (CoC) upon request.

Environmental & Sustainability Compliance

- Recyclability: Steel components are 100% recyclable. Packaging should use recyclable materials where possible.

- Waste Management: Follow local regulations for disposal of damaged or excess stock. Metal scrap to be recycled through certified facilities.

- Carbon Footprint: Optimize shipping routes and consolidate loads to reduce emissions. Consider carbon offset programs for high-volume shipments.

Documentation & Recordkeeping

- Retain shipping documents, CoC, test reports, and customs filings for a minimum of 5 years.

- Implement traceability systems using lot/batch numbers for full product lifecycle tracking.

- Digital records should be backed up and accessible for audits.

Emergency & Incident Response

- Spill/Leak Protocol: In case of bulk package damage, collect loose screws safely; no chemical hazard, but slip/trip risk exists.

- Contact Information: Provide 24/7 logistics and compliance support contact details with all shipments.

Contacts & Support

For logistics inquiries: [email protected] | +1 (555) 123-4567

For compliance support: [email protected] | +1 (555) 123-4568

In conclusion, sourcing wood anchor screws requires careful consideration of several key factors including material quality, screw size and type, intended application, and supplier reliability. Choosing the right wood anchor screw—whether for indoor furniture, outdoor structures, or heavy-duty construction—ensures durability, safety, and long-term performance. It is essential to evaluate suppliers based on their reputation, certifications, pricing, and ability to meet volume and delivery requirements. By prioritizing quality and compatibility with specific wood types and load requirements, businesses and individuals can make informed purchasing decisions that enhance structural integrity and minimize maintenance costs. Ultimately, a well-sourced wood anchor screw contributes significantly to the success and longevity of any woodworking or construction project.