The global wire mesh market is experiencing robust expansion, driven by rising demand across construction, industrial filtration, and architectural design sectors. According to Grand View Research, the global metal mesh market was valued at USD 5.87 billion in 2022 and is projected to grow at a compound annual growth rate (CAGR) of 5.3% from 2023 to 2030. This growth is fueled by increased infrastructure development and a surge in creative applications such as wire sculpting and decorative architecture. As demand for high-quality, malleable mesh materials rises, manufacturers are innovating to meet the precise requirements of sculptors, designers, and fabricators. In this evolving landscape, a select group of wire mesh producers stands out for their material consistency, tensile strength, and aesthetic versatility—key factors in wire sculpting applications. Based on market presence, production capacity, and material innovation, the following list highlights the top 10 wire sculpting mesh manufacturers shaping the industry in 2024.

Top 10 Wire Sculpting Mesh Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Ferrier Wire

Domain Est. 1998

Website: ferrierwire.com

Key Highlights: Ferrier Wire supplies woven & welded mesh, perforated and expanded metal in Toronto for the architecture and industrial sectors. Call today!…

#2 Cambridge Architectural

Domain Est. 2005

Website: cambridgearchitectural.com

Key Highlights: Cambridge Architectural evolved from a world-renowned American industrial wire belt manufacturer with a century of successful engineered solutions….

#3 Precision Screen Manufacturing

Domain Est. 2008

Website: psm-mfg.com

Key Highlights: Leading manufacturer of industrial wire mesh products including woven wire mesh, welded wire, perforated metal, and grating solutions….

#4 ACS Industries

Domain Est. 1997

Website: acsindustries.com

Key Highlights: We are the only company to offer all the preferred filter media of knitted wire mesh, woven wire mesh, micro expanded metal, and sintered wound-wire….

#5 GKDMETALFABRICS

Domain Est. 2000

Website: gkdmetalfabrics.com

Key Highlights: GKD Metal Fabrics is the leading supplier of custom-woven architectural wire mesh and designs for various architectural applications. Contact us today….

#6 Activ

Domain Est. 1997

Website: sandtastik.com

Key Highlights: 9-day delivery 30-day returnsActiva Activ-Wire Mesh. Perfect armature or structural support for modeling sculptures. Flexible art and craft aluminum weave sheet material….

#7 Activ

Domain Est. 1999

#8 Fratelli Mariani & MARIANItech®

Domain Est. 2002 | Founded: 1929

Website: fratellimariani.com

Key Highlights: Wire Mesh and Expanded Metal for Industry and Architecture since 1929. The tradition of weaving meets the skills of wire processing. From Cormano, Italy….

#9 Mesh for crafts, modelling and sculptures

Domain Est. 2014

Website: expandedmetalcompany.com

Key Highlights: We manufacture a range of aluminium foil mesh products, which can also be used in sculpture and artworks, as they can be easily folded, wrapped or compressed ……

#10 The Best Wire Mesh for Sculpting and Art Installations

Domain Est. 2007

Website: themeshcompany.com

Key Highlights: Discover how to choose the best wire mesh for sculpting, from fine detailing to large installations. Explore top materials at The Mesh Company today!…

Expert Sourcing Insights for Wire Sculpting Mesh

2026 Market Trends for Wire Sculpting Mesh

Rising Demand in Architectural and Interior Design

By 2026, wire sculpting mesh is expected to see heightened adoption in architectural facades, interior partitions, and artistic installations. The growing emphasis on sustainable, lightweight, and customizable building materials will drive architects and designers toward wire mesh solutions. Its ability to diffuse light, provide ventilation, and serve as a dynamic visual element aligns with contemporary design preferences for biophilic and open-space environments.

Expansion in Art and Public Installations

The public art and urban development sectors are projected to increase their use of wire sculpting mesh due to its versatility and durability. Artists and municipalities are leveraging the material for large-scale outdoor sculptures, which resist corrosion and withstand environmental stress. By 2026, collaborations between municipalities and artists are expected to rise, especially in smart city initiatives that integrate aesthetic elements with functional urban infrastructure.

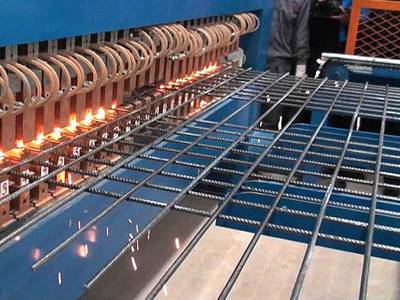

Technological Advancements in Manufacturing

Advances in CNC wire bending and 3D modeling software are enabling more intricate and precise wire mesh designs. By 2026, the integration of AI-assisted design tools and automation in production will reduce lead times and costs, making custom wire sculpting mesh more accessible to small studios and commercial clients. This technological shift will also support on-demand manufacturing, minimizing waste and supporting circular economy principles.

Growth in Sustainable and Eco-Friendly Applications

Environmental considerations will play a pivotal role in the wire sculpting mesh market. Recyclable metals such as stainless steel and aluminum are increasingly favored, and manufacturers are adopting low-impact production methods. By 2026, demand will rise for mesh products that contribute to green building certifications like LEED and BREEAM, particularly in commercial and public projects aiming for sustainability benchmarks.

Increasing Use in Retail and Hospitality Environments

Retail spaces and luxury hospitality venues are expected to incorporate wire sculpting mesh more extensively for feature walls, room dividers, and decorative lighting fixtures. Its modern aesthetic and functional benefits—such as acoustic modulation and air flow—make it ideal for creating immersive brand experiences. The customization potential allows businesses to tailor designs to their brand identity, a trend that will accelerate through 2026.

Global Market Expansion and Regional Growth

While North America and Europe remain key markets, the Asia-Pacific region is anticipated to experience the fastest growth by 2026, driven by urbanization and increased investment in infrastructure and design-forward developments. Countries like China, India, and South Korea are embracing innovative building materials, positioning wire sculpting mesh as a premium option in both public and private construction projects.

Influence of Digital Marketplaces and E-Commerce

Online platforms specializing in architectural materials and custom fabrication are expected to gain prominence by 2026. These digital marketplaces will connect designers directly with manufacturers, streamline quoting and ordering processes, and provide visualization tools for clients. This shift will democratize access to wire sculpting mesh, enabling smaller firms and independent artists to participate in high-end design projects.

Common Pitfalls When Sourcing Wire Sculpting Mesh (Quality, IP)

Sourcing wire sculpting mesh for artistic, architectural, or industrial applications requires careful attention to both material quality and intellectual property (IP) considerations. Overlooking these aspects can lead to project delays, increased costs, or legal complications. Below are common pitfalls to avoid:

Poor Material Quality and Inconsistent Specifications

One of the most frequent issues is receiving wire mesh that does not meet technical or aesthetic standards. Suppliers may offer mesh with inconsistent wire gauge, uneven weave patterns, or substandard metallurgy (e.g., low-grade stainless steel prone to corrosion). This can compromise structural integrity and visual appeal, especially in public art or outdoor installations.

Lack of Certifications and Traceability

Reputable projects—particularly in commercial or public installations—require material certifications (e.g., mill test reports, ASTM compliance). Sourcing from suppliers who cannot provide traceable documentation increases the risk of using non-compliant or unsafe materials, potentially leading to liability issues.

Misrepresentation of Mesh Type and Performance

Some suppliers may inaccurately label mesh types (e.g., calling galvanized steel “stainless” or misrepresenting tensile strength). This misalignment can lead to premature failure in load-bearing or weather-exposed applications. Always verify specifications with independent testing if large-scale or critical use is planned.

Ignoring Intellectual Property in Design Elements

When sourcing custom-designed mesh patterns or proprietary weaves, there’s a risk of inadvertently using protected designs. Some artistic weaves or architectural mesh patterns are trademarked or patented. Using them without proper licensing can expose the buyer to IP infringement claims, especially in high-visibility projects.

Unauthorized Use of Branded or Patented Mesh Systems

Certain wire mesh systems—such as tensioned cable net facades or sculptural grids—are protected by design patents or trade dress rights. Sourcing generic copies of these systems may appear cost-effective but can result in legal action from original manufacturers or designers.

Failure to Secure Usage Rights in Contracts

Even when working with custom-designed mesh, contracts with suppliers may not clearly assign usage rights or licensing for artistic reproduction. Without explicit terms, the buyer may be restricted from using the mesh in promotional materials, derivative works, or future installations.

Overlooking Export and Sourcing Compliance

Importing wire mesh from overseas suppliers may involve customs issues, especially if materials contain restricted alloys or lack proper export documentation. Additionally, some countries have labor or environmental regulations that affect the legitimacy and ethics of sourcing—impacting brand reputation and compliance.

Conclusion

To mitigate these risks, buyers should conduct due diligence on suppliers, request material certifications, verify IP status of designs, and include clear IP and quality clauses in procurement contracts. Engaging with trusted, transparent suppliers and consulting legal experts when using distinctive designs can prevent costly setbacks.

Logistics & Compliance Guide for Wire Sculpting Mesh

Product Classification and Documentation

Ensure accurate classification of wire sculpting mesh under the appropriate Harmonized System (HS) code, typically falling under 7314.50 (steel wire mesh, not otherwise specified). Maintain detailed technical specifications including wire gauge, mesh size, material composition (e.g., galvanized steel, stainless steel), and intended use. Prepare commercial invoices, packing lists, and certificates of origin for all international shipments.

Packaging and Handling Requirements

Package wire sculpting mesh securely to prevent deformation, corrosion, and handling damage. Use moisture-resistant wrapping, edge protectors, and robust palletization. Clearly label packages with product details, handling instructions (e.g., “Fragile,” “This Side Up”), and safety warnings. For large or custom rolls, use protective end caps and strapping to maintain structural integrity during transit.

Transportation and Shipping Regulations

Comply with international freight regulations (IMDG for sea, IATA for air, ADR for road) when shipping wire mesh, particularly if coated with zinc or other protective finishes. Declare any hazardous treatments or coatings. Confirm weight and dimensional constraints with carriers, especially for oversized rolls or rigid panels. Use freight forwarders experienced in metal products for efficient routing and customs clearance.

Import/Export Compliance

Verify import regulations in destination countries, including adherence to construction, safety, or environmental standards (e.g., CE marking in the EU, ASTM standards in the U.S.). Some regions may require conformity assessments or third-party testing. Ensure export controls are met, especially when shipping dual-use materials or to sanctioned regions. Maintain records for audit and traceability.

Environmental and Safety Standards

Confirm that wire sculpting mesh complies with REACH (EU), RoHS, or other chemical restriction regulations if applicable. Provide Safety Data Sheets (SDS) when required, particularly for galvanized or coated variants. Follow OSHA or local occupational safety guidelines for worker handling, including glove use to prevent cuts and proper lifting techniques.

Customs Clearance and Duties

Prepare accurate declarations to avoid delays. Include value, origin, and classification details. Be aware of anti-dumping duties that may apply on steel mesh from certain countries. Utilize preferential trade agreements where eligible (e.g., USMCA, ASEAN) to reduce duty costs. Engage customs brokers for complex markets.

Quality Assurance and Traceability

Implement a traceability system linking production batches to shipment records. Conduct periodic quality audits to ensure compliance with customer and regulatory specifications. Retain inspection reports and mill test certificates for raw materials to demonstrate compliance during audits or customer inquiries.

End-of-Life and Recycling Considerations

Promote recyclability of wire sculpting mesh—most steel mesh is 100% recyclable. Provide guidance on proper disposal or recycling to customers, aligning with local waste management regulations. Document recycling rates or sustainability efforts to support green compliance initiatives.

In conclusion, sourcing wire sculpting mesh requires careful consideration of material quality, mesh specifications, supplier reliability, and cost-effectiveness. Whether for artistic projects, architectural models, or industrial applications, selecting the appropriate gauge, aperture size, and material—such as galvanized steel, stainless steel, or copper—is crucial for achieving the desired structural integrity and aesthetic outcome. Establishing relationships with reputable suppliers, comparing samples, and evaluating shipping and minimum order requirements can significantly impact project success. Ultimately, thorough research and due diligence in sourcing ensure access to high-quality wire mesh that meets both creative and practical demands, supporting efficient workflow and superior end results.