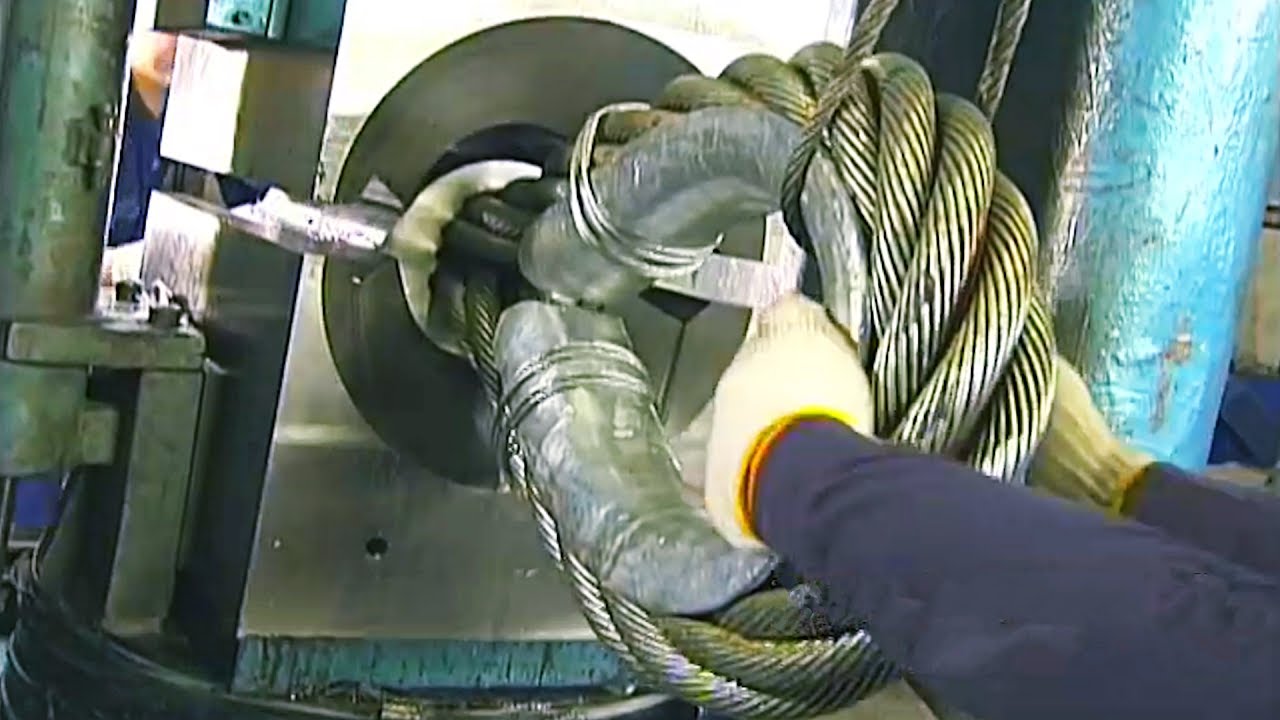

The global wire rope clamping market is experiencing steady growth, driven by rising demand across industries such as construction, marine, oil & gas, and material handling. According to Grand View Research, the global wire rope market size was valued at USD 10.3 billion in 2022 and is expected to expand at a compound annual growth rate (CAGR) of 5.8% from 2023 to 2030. This growth trajectory underscores the increasing reliance on secure, high-performance lifting and rigging solutions, where wire rope clamps play a critical role in ensuring safety and operational integrity. As infrastructure development accelerates worldwide and industrial automation expands, the need for reliable clamping methods—spanning U-bolt clamps, double saddle clamps, and engineered alternatives—has never been more pronounced. In this competitive landscape, a select group of manufacturers have emerged as leaders, combining innovation, compliance with international standards (such as ISO and OSHA), and robust product testing to meet evolving safety and performance demands. The following analysis highlights the top seven wire rope clamping method manufacturers shaping the industry through technological advancement, global reach, and data-backed reliability.

Top 7 Wire Rope Clamping Method Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Wire Rope Manufacturers

Website: wireropecompanies.com

Key Highlights: Clips (Wire Rope Clamps or Cable Clamps): Used for creating eye terminations or securing the loose end of a rope, vital for rigging and load-securing….

#2 High-Performance Rope Solutions

Domain Est. 1997

Website: teufelberger.com

Key Highlights: Explore our innovative rope solutions designed for various sectors. Get expertly crafted ropes with enhanced durability and efficiency….

#3 Steel Wire Rope

Domain Est. 1998

Website: steelwirerope.com

Key Highlights: We supply wire rope assemblies and machinery for production companies around the world, even as far as China….

#4 WRC Rope Clamp

Domain Est. 1998

Website: becker-mining.com

Key Highlights: WRC Rope Clamps provide a safe method for anchoring, suspending, or maneuvering of wire ropes. They can be used for permanent clamping or during installation ……

#5 Wire Rope Clips 101

Domain Est. 2000

Website: cranetech.com

Key Highlights: Wire rope clips diminish the working load limit of the wire rope to generally about 70-75% of its original strength….

#6 Wire Rope Clips / Clamps

Domain Est. 2005

Website: uscargocontrol.com

Key Highlights: Free delivery over $199 60-day returnsUS Cargo Control offers a wide selection of galvanized, stainless steel, zinc & malleable wire rope clips / wire rope clamps for rigging jobs….

#7 a Kito Crosby product brand setting the global standard in rigging …

Domain Est. 2022

Website: kitocrosby.com

Key Highlights: Discover Crosby, a Kito Crosby product brand leading in rigging and lifting hardware with trusted quality and innovative solutions for tough applications….

Expert Sourcing Insights for Wire Rope Clamping Method

H2: Market Trends in Wire Rope Clamping Methods for 2026

As the global industrial landscape evolves toward greater efficiency, safety, and sustainability, the wire rope clamping method sector is poised for significant transformation by 2026. Driven by technological advancements, regulatory changes, and shifting end-user demands, several key trends are expected to shape the market dynamics in the coming years.

1. Increased Adoption of High-Performance Materials

By 2026, manufacturers are anticipated to shift toward advanced materials such as high-tensile stainless steel, composite alloys, and corrosion-resistant coatings in wire rope clamps. These materials improve durability and performance in extreme environments—particularly in offshore, mining, and heavy construction applications—where reliability is critical. The demand for longer service life and reduced maintenance is accelerating this trend.

2. Growth in Smart and Sensor-Integrated Clamping Systems

A notable trend emerging by 2026 is the integration of smart technologies into wire rope clamping systems. Sensor-equipped clamps capable of monitoring tension, temperature, and wear are gaining traction, especially in industries like oil & gas, wind energy, and material handling. These smart clamps provide real-time data for predictive maintenance, enhancing operational safety and reducing downtime.

3. Emphasis on Standardization and Safety Compliance

Global safety regulations, including ISO 4309 and OSHA standards, are becoming more stringent. As a result, there is a growing market preference for clamps that meet or exceed international certification requirements. By 2026, manufacturers investing in standardized, traceable, and auditable clamping solutions are expected to gain a competitive edge, particularly in regulated industries.

4. Expansion in Renewable Energy Applications

The rapid growth of renewable energy infrastructure—especially offshore wind farms—will drive demand for reliable wire rope clamping methods. These applications require robust, weather-resistant clamping systems capable of withstanding harsh marine conditions. By 2026, the renewable energy sector is projected to be one of the fastest-growing end markets for advanced clamping solutions.

5. Regional Market Shifts and Manufacturing Localization

Asia-Pacific, led by China and India, is expected to dominate the wire rope clamping market by 2026 due to rapid industrialization and infrastructure development. However, reshoring trends in North America and Europe—driven by supply chain resilience and sustainability goals—are prompting localized production of high-quality clamps. This shift supports shorter lead times and reduced carbon footprints.

6. Sustainability and Eco-Friendly Manufacturing Practices

Environmental concerns are influencing design and production processes. By 2026, leading manufacturers are expected to adopt circular economy principles, such as recyclable materials and energy-efficient production methods. Customers are increasingly prioritizing suppliers with verified environmental, social, and governance (ESG) credentials.

In summary, the 2026 market for wire rope clamping methods will be defined by innovation, safety, and sustainability. Companies that embrace smart technologies, comply with global standards, and cater to high-growth sectors like renewables and infrastructure will be best positioned for success in an increasingly competitive and technologically advanced marketplace.

Common Pitfalls in Sourcing Wire Rope Clamping Methods (Quality, IP)

When sourcing wire rope clamps—critical components for securing wire rope ends and ensuring load safety—overlooking key quality and intellectual property (IP) considerations can lead to safety hazards, legal risks, and operational failures. Below are common pitfalls to avoid:

Poor Material Quality and Manufacturing Standards

One of the most frequent issues is selecting clamps made from substandard materials or manufactured without adherence to recognized industry standards (e.g., ISO 492, ASME B30.26). Low-quality clamps may use inferior-grade steel or incorrect heat treatment, reducing strength and corrosion resistance. This compromises safety and increases the risk of clamp failure under load.

Lack of Compliance with International Standards

Sourcing clamps that do not comply with international standards (such as DIN 6892, ASME, or EN 13889) can lead to compatibility issues, unpredictable performance, and non-compliance during safety audits. Non-certified clamps often lack proper load testing documentation, making it difficult to verify their rated working load limit (WLL).

Counterfeit or Non-Genuine Products

The market is rife with counterfeit clamps that mimic reputable brands but fail to deliver the same performance. These knock-offs often lack proper markings, certifications, or traceability. Relying on unverified suppliers increases the risk of receiving counterfeit goods that endanger operations and personnel.

Inadequate Intellectual Property Due Diligence

Sourcing clamps without verifying IP rights—such as patents on unique clamp designs (e.g., double-saddle clamps, quick-release mechanisms)—can expose companies to legal liability. Using patented designs without licensing may result in infringement claims, especially in regulated industries or export markets.

Insufficient Documentation and Traceability

Reputable suppliers provide mill test certificates, material traceability, and compliance documentation. Failure to obtain these documents makes it difficult to prove quality during inspections or accident investigations. Lack of traceability also complicates recalls or root cause analysis in case of failure.

Overlooking Corrosion Protection for Harsh Environments

In marine, offshore, or chemical environments, standard galvanized clamps may not suffice. Sourcing without considering appropriate corrosion-resistant finishes (e.g., hot-dip galvanizing, stainless steel, or epoxy coatings) can lead to premature degradation and failure.

Improper Sizing and Compatibility

Using clamps that do not match the wire rope diameter or lay type (e.g., right-lay vs. left-lay) reduces clamping efficiency and can damage the rope. Sourcing without verifying compatibility with the specific wire rope specification leads to weak terminations and safety risks.

Ignoring Supplier Qualification and Reputation

Relying on unvetted suppliers—especially from low-cost regions without third-party audits—increases exposure to quality inconsistencies. A lack of supplier qualification processes can result in receiving non-conforming products with no recourse.

By addressing these pitfalls proactively—focusing on certified quality, IP compliance, and supplier reliability—organizations can ensure the safe and legally sound use of wire rope clamping systems.

Logistics & Compliance Guide for Wire Rope Clamping Method

Proper application of wire rope clamps is critical for safety, structural integrity, and regulatory compliance in lifting, rigging, and tensioning operations. This guide outlines best practices for logistics handling and ensures adherence to relevant industry standards.

Selection and Procurement

Ensure wire rope clamps are selected based on the wire rope diameter, material grade, and application requirements. Procure clamps that conform to recognized standards such as ASME B30.26, ISO 498, or EN 13411-3. Verify manufacturer certifications and material test reports (MTRs) during procurement to confirm compliance.

Storage and Handling

Store wire rope clamps in a dry, corrosion-protected environment to prevent rust and degradation. Keep clamps organized by size and type to avoid mix-ups. Handle with care to prevent damage to threads or saddle surfaces—any deformation can compromise clamp effectiveness.

Installation Requirements

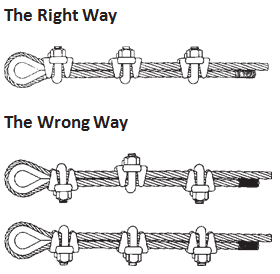

Always install wire rope clamps with the saddle on the live (load-bearing) end of the rope, never on the dead (tail) end. Use the correct number of clamps per loop or termination, typically following the “Rule of Six”: one clamp at the dead end, and at least three clamps spaced at six times the rope diameter apart. Tighten all bolts to the manufacturer’s specified torque using a calibrated torque wrench.

Inspection and Maintenance

Inspect clamps before and after each use for cracks, deformation, thread damage, or corrosion. Re-torque clamp bolts after initial loading, as wire rope may settle during first use. Replace any damaged or worn clamps immediately. Maintain documentation of inspections and maintenance per OSHA and company safety policies.

Regulatory Compliance

Adhere to OSHA 1926.251, ASME B30.5 (for mobile cranes), and other applicable regulations. Wire rope clamp installations must support at least 80% of the minimum breaking strength of the rope when properly applied. Employ qualified riggers for installation and ensure all personnel are trained in safe clamping procedures.

Transportation and Field Use

Secure clamps during transport to prevent movement and damage. On-site, protect clamps from impact, extreme temperatures, and chemical exposure. Use only compatible components (e.g., correct U-bolts and base saddles) from the same manufacturer to ensure performance consistency.

Documentation and Traceability

Maintain records of clamp specifications, installation dates, inspection logs, and replacement history. Use traceable batch numbers where available to support quality assurance and incident investigations.

Training and Certification

Ensure all personnel involved in clamping operations are trained and certified in rigging practices. Include wire rope clamp application as part of routine safety training to reinforce correct procedures and compliance.

Conclusion: Sourcing Wire Rope Clamping Method

After evaluating various wire rope clamping methods, it is evident that the proper selection, installation, and sourcing of clamps are critical to ensuring safety, reliability, and longevity in lifting, rigging, and load securement applications. The most widely accepted and recommended method—using U-bolt clamps installed with the U-bolt on the dead end and the saddle on the live (load-bearing) side—provides consistent performance when applied with the correct spacing (typically 6–8 times the rope diameter) and adequate torque.

Sourcing clamps from reputable manufacturers that adhere to recognized standards such as ASME B30.26, ISO 492, or WLL (Working Load Limit) certifications ensures product quality, material strength, and compatibility with the wire rope. Factors such as clamp size, material (e.g., malleable iron, forged steel, or stainless steel), and environmental resistance must align with the operational demands.

In conclusion, a successful wire rope clamping solution depends not only on correct installation technique but also on sourcing high-quality, standardized components from reliable suppliers. Investing in proper clamps and following best practices significantly reduces the risk of failure, enhances operational safety, and supports compliance with industry regulations. Regular inspection and maintenance further ensure continued performance, making informed sourcing an essential element in any wire rope application.