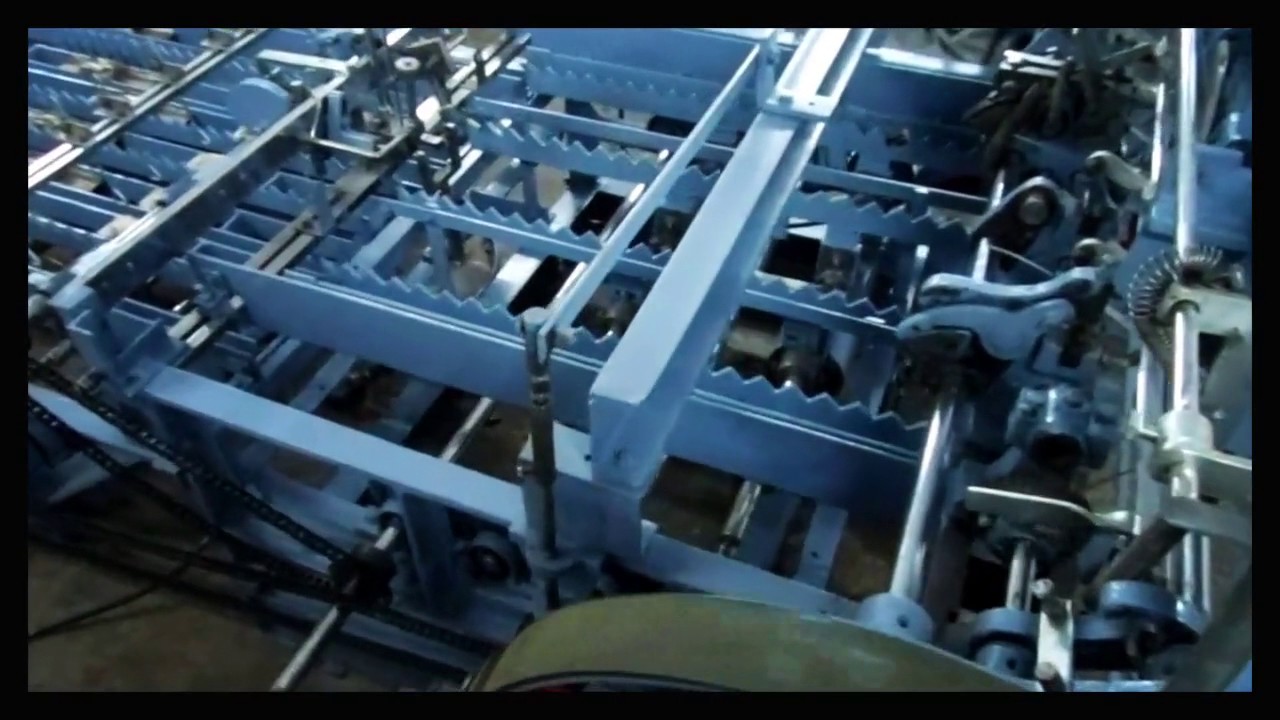

The global wire healds market is experiencing steady growth, driven by rising demand from the textile manufacturing sector, particularly in Asia-Pacific regions like China, India, and Bangladesh. According to a report by Mordor Intelligence, the textile accessories market—under which wire healds fall—is projected to grow at a CAGR of over 4.5% from 2023 to 2028. This growth is fueled by increasing automation in weaving processes and the need for high-precision components that enhance fabric quality and production efficiency. Wire healds, essential elements in shuttleless looms, play a critical role in guiding warp yarns and ensuring smooth fabric formation, making them indispensable in modern textile operations.

With the global push toward industrial modernization and sustainable textile production, manufacturers are investing in durable, high-performance wire healds to minimize downtime and improve loom productivity. Grand View Research highlights that advancements in material engineering and the integration of smart textile machinery are further accelerating demand for precision-engineered healds. As the market becomes increasingly competitive, key players are focusing on innovation, scalability, and strategic partnerships to gain market share. In this evolving landscape, identifying the top manufacturers becomes crucial for textile producers seeking reliable, high-quality components. Below is a data-driven overview of the top 9 wire healds manufacturers shaping the industry’s future.

Top 9 Wire Healds Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Producer of weaving accessories

Domain Est. 1998

Website: groz-beckert.com

Key Highlights: For weaving mills Groz-Beckert offers high-quality heald frames, healds, reeds, warp stop motions and products for leno weaving….

#2 Maksteel

Domain Est. 2000 | Founded: 1980

Website: maksteelindia.com

Key Highlights: Maksteel Wire Healds Pvt. Ltd. Established in 1980 is a leading textile weaving machine accessories manufacturer in India. Maksteel has made rapid progress ……

#3 Wire Healds

Domain Est. 2002

Website: royalheddles.com

Key Highlights: Royal Industries is manufacturer of SUN BRAND weaving and textile accessories like Dropwires, Heddles, Frames, Reeds, Narrow Fabric Healds & Wire Healds….

#4 Heald wire,drop wire,ribbon heddle etc

Domain Est. 2021

Website: healdanddropwire.com

Key Highlights: We are a professional manufacturer of automatic warp crossing healds, steel healds, warp stopper healds, gauze healds, twisted healds, woven healds, ribbon ……

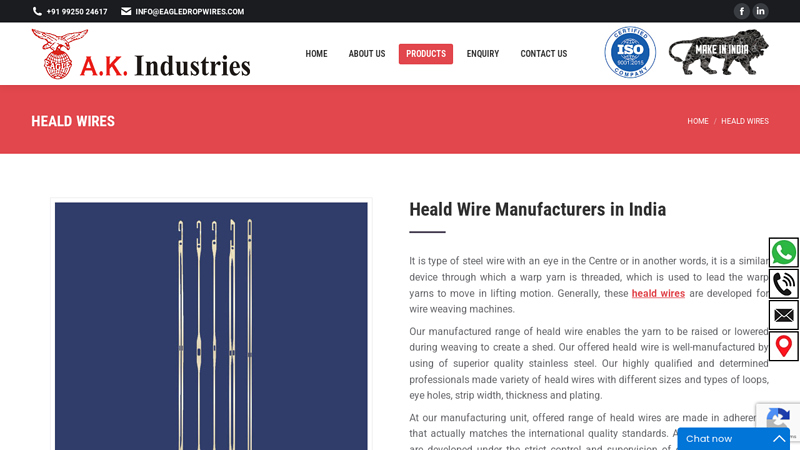

#5 Heald Wire Manufacturers in India

Domain Est. 2021

Website: eagledropwires.com

Key Highlights: Our offered heald wire is well-manufactured by using of superior quality stainless steel. Our highly qualified and determined professionals made variety of ……

#6 Wire Heald

Domain Est. 2008

Website: guryaytekstil.com

Key Highlights: NON-STOP WEAVING, HIGH EFFICIENCY. Güryay Textile has been manufacturing complete spring wire healds and jacquard accessories for weaving looms….

#7 Wire Heald

Domain Est. 2008

Website: healdindia.co.in

Key Highlights: Our product range includes wire Healds for: Carpet felt and filter fabrics; Frame Weaving; Plastic woven sac; Jute weaving; Jacquard Weaving ……

#8 Healds Tech

Domain Est. 2024

Website: healds.tech

Key Highlights: While we specialize in producing high-quality healds, we also manufacture essential spare products such as tubes, leg pins, and springs. Our mission is to ……

#9 Wire Healds

Website: steintex.de

Key Highlights: steintex Flat Steel Healds is made from high tempered steel wire or stainless steel wire for wire and metal weaving….

Expert Sourcing Insights for Wire Healds

H2: Market Trends for Wire Healds in 2026

As the global textile industry continues to evolve, the demand for precision components such as wire healds is expected to reflect broader technological, economic, and sustainability-driven shifts by 2026. Wire healds—critical elements in weaving looms that guide warp yarns during fabric formation—are witnessing transformational trends influenced by automation, material innovation, and regional manufacturing dynamics.

-

Increased Demand from Technical and Industrial Textiles

By 2026, the growing use of technical textiles in automotive, medical, aerospace, and geotextile applications is projected to boost demand for high-performance looms and, by extension, durable wire healds. These specialized fabrics require tighter weave precision and consistent tension control, driving adoption of advanced wire healds made from high-tensile steel and corrosion-resistant alloys. -

Automation and Smart Weaving Technologies

The integration of Industry 4.0 technologies into textile manufacturing is accelerating. Smart looms equipped with real-time monitoring and predictive maintenance are becoming standard. In response, wire healds are being designed to work seamlessly with digital loom systems, enabling better yarn control, reduced downtime, and improved fabric quality. By 2026, compatibility with automated weaving systems will be a key differentiator in the wire heald market. -

Material Innovation and Longevity Focus

Manufacturers are increasingly investing in surface treatments and advanced alloys to enhance the wear resistance and fatigue life of wire healds. Coatings such as chrome plating, nitriding, or ceramic-based finishes are expected to gain traction, reducing maintenance costs and extending service life—especially critical in high-speed weaving environments. -

Regional Shifts in Textile Manufacturing

Asia-Pacific, particularly India, Vietnam, and Bangladesh, will remain central to global textile production. These regions are modernizing their weaving infrastructure, creating strong demand for high-quality imported and locally produced wire healds. Meanwhile, nearshoring trends in North America and Europe may lead to modest growth in domestic weaving capacity, supporting niche demand for premium wire healds. -

Sustainability and Circular Economy Pressures

Environmental regulations and sustainability goals are influencing equipment design. By 2026, recyclability of metal components and energy-efficient weaving processes will be key considerations. Wire heald manufacturers may adopt circular design principles—such as modular or repairable heald systems—to reduce waste and appeal to eco-conscious textile producers. -

Consolidation and Vertical Integration

The wire heald market is likely to see increased consolidation among suppliers, with larger players acquiring niche manufacturers to expand product portfolios and geographic reach. Vertical integration—where heald producers also offer loom accessories or digital monitoring tools—will become a competitive advantage. -

Price Pressure and Cost Optimization

While demand for high-end wire healds grows, price sensitivity in emerging markets will push manufacturers to optimize production costs through automation and localized supply chains. This may lead to a two-tier market: premium healds for technical weaving and cost-effective solutions for standard apparel production.

In conclusion, the 2026 wire heald market will be shaped by the interplay of technological advancement, regional manufacturing trends, and sustainability imperatives. Companies that innovate in materials, embrace digital compatibility, and align with evolving textile production models will be best positioned for growth.

Common Pitfalls When Sourcing Wire Healds: Quality and Intellectual Property Concerns

When sourcing wire healds—critical components in weaving looms that control warp yarn movement—buyers often encounter significant challenges related to quality consistency and intellectual property (IP) risks. Overlooking these pitfalls can lead to production delays, increased costs, and legal complications. Below are key issues to watch for:

Quality Inconsistencies and Defects

One of the most prevalent issues in sourcing wire healds is inconsistent product quality. Suppliers, particularly in low-cost regions, may lack rigorous quality control processes, resulting in:

- Dimensional inaccuracies: Slight deviations in wire diameter, loop size, or frame geometry can lead to misalignment in the loom, causing fabric defects or machine downtime.

- Material defects: Use of substandard steel or improper heat treatment can reduce the healds’ durability, leading to premature wear, breakage, or fatigue during high-speed weaving operations.

- Surface imperfections: Poor finishing, burrs, or coating inconsistencies increase friction and accelerate wear on both the healds and warp yarns.

- Lack of traceability: Inadequate batch tracking or documentation makes it difficult to diagnose and resolve recurring quality issues.

To mitigate these risks, buyers should establish clear technical specifications, conduct regular supplier audits, and require third-party inspection reports.

Intellectual Property (IP) Infringement Risks

Wire heald designs, especially proprietary profiles or patented manufacturing techniques, are often protected under intellectual property laws. Sourcing from unverified suppliers increases the risk of:

- Unauthorized replication: Some suppliers may reverse-engineer branded or patented heald designs without licensing, exposing the buyer to infringement claims.

- Use of counterfeit components: Purchasing “compatible” or “generic” healds may inadvertently involve IP violations if they closely mimic protected designs.

- Lack of legal recourse: Contracts with offshore suppliers may not enforce IP protections effectively, making it difficult to pursue action in case of disputes.

To protect against IP exposure, buyers should:

– Verify supplier legitimacy and design authorization.

– Include IP indemnification clauses in procurement contracts.

– Source only from reputable manufacturers with documented design rights or licensing agreements.

Neglecting these aspects can result in legal liabilities, shipment seizures, or reputational damage. A strategic, due-diligence-driven sourcing approach is essential to ensure both quality reliability and IP compliance.

Logistics & Compliance Guide for Wire Healds

Overview of Wire Healds

Wire Healds are precision components used in weaving looms to control the vertical movement of warp yarns, enabling the formation of fabric sheds. Due to their specialized nature and application in textile manufacturing, their logistics and compliance requirements involve careful handling, accurate classification, and adherence to international trade and safety standards.

Material Classification and HS Code

Proper classification is essential for customs clearance and tariff assessment.

– Recommended HS Code: 8448.39 (Other parts and accessories for textile machinery, specifically for weaving machinery)

– Confirm with local customs authorities to ensure accurate classification based on country-specific tariff schedules.

– Provide detailed product descriptions, including material composition (e.g., steel wire, nickel-plated) and intended use.

Packaging and Handling Requirements

Wire Healds are sensitive to deformation and corrosion, necessitating protective packaging.

– Use moisture-resistant, anti-corrosion packaging (e.g., VCI paper or sealed plastic wraps).

– Pack in sturdy, labeled cartons with internal dividers to prevent movement and damage.

– Label packages with “Fragile,” “This Side Up,” and product details (part number, quantity, batch/lot number).

– Avoid exposure to humidity, extreme temperatures, and direct sunlight during storage and transit.

Transportation and Shipping

Choose appropriate transport modes and carriers to ensure product integrity.

– Domestic Shipping: Use temperature-controlled or enclosed vehicles; avoid open trucks.

– International Shipping:

– Sea freight: Ensure containers are dry and secured; consider desiccants for long voyages.

– Air freight: Opt for faster delivery to reduce exposure risks; comply with IATA regulations.

– Provide accurate shipping documents, including commercial invoice, packing list, and bill of lading/air waybill.

Import and Export Compliance

Adhere to international trade regulations and documentation standards.

– Obtain export licenses if required by the country of origin (e.g., for dual-use or high-precision components).

– Comply with import regulations in destination countries, including certification requirements (e.g., CE, RoHS if applicable).

– Conduct due diligence on restricted parties and embargoed regions (e.g., via OFAC, EU sanctions lists).

– Maintain records of all transactions for audit and traceability purposes.

Regulatory and Safety Standards

Ensure Wire Healds meet relevant safety and environmental standards.

– Confirm compliance with REACH (EU) for chemical content (e.g., nickel, chromium).

– Adhere to RoHS directives if electronic components are integrated (rare, but verify).

– Provide Safety Data Sheets (SDS) if requested, particularly for plated or treated wire components.

– Follow workplace safety guidelines during handling (e.g., use gloves to prevent cuts or contamination).

Quality and Traceability Documentation

Support logistics with comprehensive quality assurance records.

– Include batch/lot numbers on packaging and documentation for traceability.

– Provide certificates of conformance (CoC) or inspection reports upon request.

– Implement quality control checks pre-shipment to verify dimensions, plating, and structural integrity.

Returns and Reverse Logistics

Establish clear procedures for returns due to defects or shipping errors.

– Require a Return Merchandise Authorization (RMA) number for all returns.

– Inspect returned items promptly and document condition for warranty or replacement processing.

– Follow environmental regulations for disposal or recycling of non-conforming parts.

Conclusion

Effective logistics and compliance management for Wire Healds ensures timely delivery, regulatory adherence, and customer satisfaction. By focusing on proper classification, protective packaging, regulatory alignment, and documentation, businesses can minimize delays, reduce costs, and maintain reliability in global supply chains. Regular review of international trade policies and industry standards is recommended to remain compliant.

Conclusion for Sourcing Wire Healds

In conclusion, sourcing high-quality wire healds is a critical factor in ensuring the efficiency, reliability, and longevity of weaving operations in textile manufacturing. The selection process should prioritize suppliers with a proven track record of precision engineering, consistent material quality, and rigorous quality control standards. Key considerations such as wire diameter, surface finish, tensile strength, and compatibility with specific loom types must be carefully evaluated to minimize downtime and reduce fabric defects.

Partnering with reputable manufacturers who offer technical support, timely delivery, and competitive pricing can significantly enhance operational performance. Additionally, establishing long-term relationships with suppliers fosters better communication, customization options, and supply chain resilience.

Ultimately, a strategic and informed approach to sourcing wire healds not only improves fabric quality and production speed but also contributes to cost savings and sustainable manufacturing practices. Investing in superior wire healds is, therefore, an essential step toward maintaining a competitive edge in the global textile industry.