The global wire granulator market is experiencing robust growth, driven by rising demand for metal recycling and increasing environmental regulations around e-waste management. According to a report by Mordor Intelligence, the Wire Recycling Machine Market was valued at USD 865.2 million in 2024 and is projected to reach USD 1,176.4 million by 2029, growing at a CAGR of 6.25% during the forecast period. This expansion is fueled by heightened industrialization, stricter sustainability mandates, and the economic incentive of recovering valuable metals such as copper and aluminum from scrap wires. With recycling rates improving and automation in recycling plants on the rise, wire granulators have become critical equipment in modern e-waste and metal recovery operations. As demand surges, a select group of manufacturers has emerged at the forefront, combining advanced engineering, high throughput, and energy efficiency to meet evolving industry standards. Here’s a data-driven look at the top 6 wire granulator manufacturers shaping the future of metal recycling.

Top 6 Wire Granulator Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

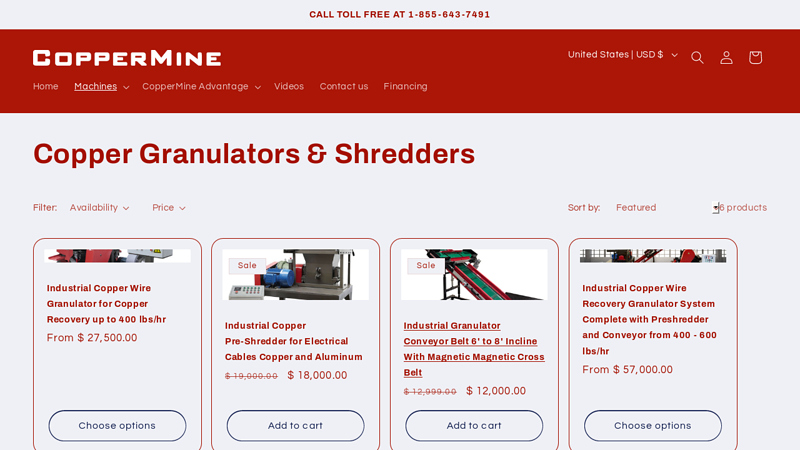

#1 Industrial Copper Wire Granulators, Shredders, and Choppers

Domain Est. 2013

Website: copperminetools.com

Key Highlights: Free delivery 30-day returnsCopperMine industrial copper granulator, and copper shredding systems. Providing copper wire chopping and separating solutions for operations large and …

#2 China Copper Wire Granulator Manufacturers, Suppliers

Domain Est. 2016

Website: enmagranulators.com

Key Highlights: As one of the most professional copper wire granulator manufacturers and suppliers in China, we warmly welcome you to wholesale bulk copper wire granulator ……

#3 Cable Wire Recycling Machine

Domain Est. 2022

Website: bsghgranulator.com

Key Highlights: BSGH Granulator is the best cable wire recycling machine factory in China, we have been serving the copper recycling market fields for more than 25years….

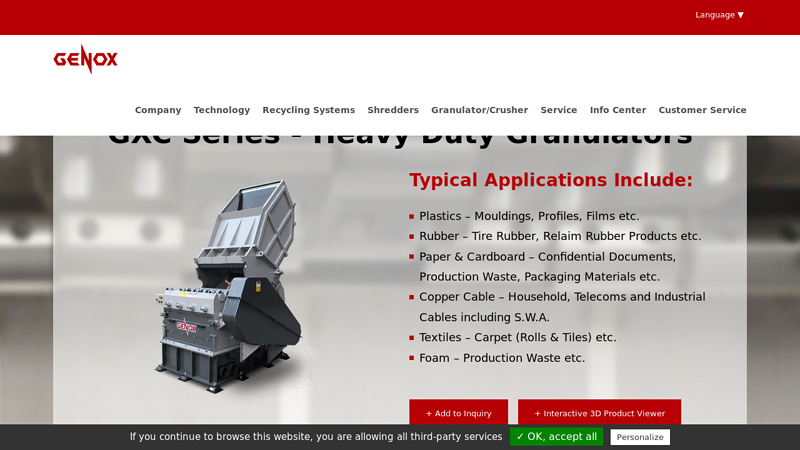

#4 GXC Series Heavy Duty Granulators

Domain Est. 2010

Website: genoxtech.com

Key Highlights: Rating 4.8 (291) GXC Series Heavy Duty Granulators with power ratings of 55kw to 315kw are designed for high throughput processing….

#5 Copper Wire Granulator for Sale

Domain Est. 2016

Website: solidequip.com

Key Highlights: Boost wire recycling with our reliable wire granulators. As a leading supplier, we sell high-quality wire granulator machines across the U.S…..

#6 Best performance BSGH copper wire granulator cable recycling …

Domain Est. 2015

Website: bsghequipment.com

Key Highlights: This mini copper wire granulator machine BS-D75 processing capacity is about 80-100kg per hour, has a quick processing speed, and has high work efficiency….

Expert Sourcing Insights for Wire Granulator

H2: Projected 2026 Market Trends for Wire Granulators

Based on current trajectories in recycling, regulation, technology, and raw material economics, the wire granulator market is poised for significant evolution by 2026. Key trends shaping this landscape include:

-

Surge in E-Waste Recycling Demand: The exponential growth in electronic waste (e-waste), driven by shorter product lifecycles and increasing global electronics consumption, will be the primary market driver. Wire granulators are essential for recovering high-purity copper and aluminum from end-of-life cables and wiring harnesses. Stricter global e-waste regulations (like extended producer responsibility – EPR schemes) will further mandate efficient recycling, boosting demand for advanced granulation systems.

-

Heightened Focus on Purity & Yield Optimization: Market competition and the value of recovered non-ferrous metals (especially copper) will push manufacturers and recyclers towards granulators delivering higher separation efficiency. Expect strong demand for models integrated with sophisticated air tables, electrostatic separators, and advanced multi-stage screening to achieve purities exceeding 99.9% for copper, minimizing plastic contamination and maximizing revenue.

-

Integration of Smart Technologies & Automation: Granulators in 2026 will increasingly feature IoT connectivity, real-time monitoring (vibration, temperature, power consumption), predictive maintenance algorithms, and remote diagnostics. This “smart granulator” trend will enhance operational efficiency, reduce downtime, ensure consistent output quality, and lower the total cost of ownership, making automation a key differentiator.

-

Demand for Specialized & Flexible Machines: The market will see growth in granulators designed for specific applications:

- Fine Wire Processing: Enhanced capabilities for handling very thin wires (e.g., from electronics, automotive harnesses).

- High-Throughput Systems: Larger, more robust machines for large-scale industrial recyclers and cable manufacturers.

- Compact & Modular Units: Smaller, mobile, or modular systems for smaller recyclers, repair workshops, or on-site processing.

- Multi-Material Capability: Systems better adapted to handle complex cable types (e.g., with steel armoring, multiple insulation layers).

-

Sustainability & Environmental Compliance as Core Drivers: Stringent environmental regulations regarding dust emissions, noise levels, and plastic residue disposal will be paramount. Granulators will need integrated, high-efficiency dust collection systems (like advanced cartridge filters) and noise enclosures. The ability to produce clean, marketable plastic fractions (PVC, PE, PP) with minimal metal carryover will become a critical selling point, driven by circular economy goals.

-

Geographical Shifts & Emerging Markets: While established markets (North America, Western Europe) focus on upgrading technology and meeting regulatory demands, significant growth will come from:

- Asia-Pacific: Rapid urbanization, infrastructure development, and growing e-waste volumes in China, India, and Southeast Asia.

- Latin America & Africa: Increasing awareness, regulatory development, and investment in formal recycling infrastructure.

- Eastern Europe: Modernization of recycling facilities.

-

Raw Material Price Volatility Influence: Fluctuations in copper prices will directly impact the investment case for wire granulation. Periods of high copper prices will accelerate capital expenditure on granulators, while sustained low prices might slow new investments but emphasize efficiency gains in existing operations.

-

Consolidation and Service Focus: The market may see consolidation among granulator manufacturers, with leading players offering comprehensive solutions (granulator + separator + control systems + service contracts). After-sales service, spare parts availability, and technical expertise will become crucial competitive advantages.

In summary, the 2026 wire granulator market will be characterized by technological sophistication, driven by the imperative to recover valuable non-ferrous metals from e-waste efficiently and sustainably. Success will hinge on delivering high purity, automation, reliability, and compliance within a rapidly evolving global recycling landscape.

Common Pitfalls When Sourcing a Wire Granulator: Quality and Intellectual Property Risks

Logistics & Compliance Guide for Wire Granulator

Overview of the Wire Granulator

A wire granulator is a specialized industrial machine used to process scrap electrical wires and cables by separating the metal (typically copper or aluminum) from the insulating materials (plastic, rubber, etc.). Due to its size, weight, and technical nature, transporting and operating a wire granulator involves specific logistics and compliance requirements.

International Shipping Considerations

Wire granulators are typically heavy machinery requiring freight shipping via sea, air, or land depending on destination and urgency. Key logistics steps include:

– Packaging & Crating: Use sturdy wooden or metal crates suitable for ocean freight; include moisture barriers and vibration protection.

– Weight & Dimensions: Confirm exact dimensions and weight for accurate freight class and carrier selection (LTL, FTL, or containerized shipping).

– Export Documentation: Prepare commercial invoice, packing list, bill of lading, and certificate of origin.

– Incoterms Selection: Define responsibility using standard Incoterms (e.g., FOB, CIF, DDP) to clarify shipping cost and risk allocation.

– Customs Clearance: Ensure all import documentation is complete and accurate to avoid delays; include HS code classification (typically under 8477.80 for recycling machinery).

Regulatory Compliance Requirements

Wire granulators must comply with various regional and international regulations:

– Electrical Safety Standards: Comply with IEC 60204-1 (safety of machinery – electrical equipment) and local standards such as UL (USA), CE (EU), or CCC (China).

– Environmental Regulations: Adhere to local waste processing and emissions standards; ensure dust collection and noise suppression systems meet required thresholds.

– RoHS & REACH (EU): Verify that components used in the granulator comply with hazardous substance restrictions.

– Waste Handling Compliance: In jurisdictions like the EU (WEEE Directive) and the US (EPA regulations), operators must follow certified recycling practices for processed wire scrap.

Installation & Site Preparation

- Space Requirements: Allocate adequate space for the machine, feed conveyors, output bins, and dust extraction systems (minimum clearance of 1 meter recommended).

- Power Supply: Confirm voltage, phase, and amperage requirements (typically 3-phase, 380V–480V); ensure proper grounding and circuit protection.

- Ventilation & Dust Control: Install a compatible dust collection system meeting OSHA or equivalent standards to minimize airborne particulate.

- Foundation & Leveling: Place on a reinforced concrete foundation; use leveling jacks to ensure stability and prevent vibration damage.

Operational Safety & Worker Compliance

- Personal Protective Equipment (PPE): Mandate use of safety goggles, hearing protection, gloves, and steel-toed boots.

- Machine Guarding: Ensure all moving parts are properly guarded per OSHA 29 CFR 1910.212 or ISO 14120 standards.

- Lockout/Tagout (LOTO): Implement LOTO procedures for maintenance to prevent accidental startup.

- Operator Training: Provide documented training on safe operation, emergency stops, and maintenance protocols.

Import/Export Licensing and Restrictions

- Export Controls: Check if the granulator contains components subject to export controls (e.g., dual-use technology under EAR or ITAR).

- Import Permits: Some countries require import licenses for industrial recycling equipment; verify requirements with local customs authorities.

- Restricted Destinations: Be aware of trade sanctions or embargoes that may prohibit shipping to certain countries.

After-Sales Support & Spare Parts Logistics

- Spare Parts Inventory: Maintain a local stock of critical wear parts (knives, screens, belts) to minimize downtime.

- Technical Support Access: Confirm availability of remote or on-site technical assistance, especially for international installations.

- Warranty & Service Agreements: Clarify terms, response times, and responsibilities for repairs under warranty or service contracts.

Environmental & Recycling Certification

- Certification for Processed Output: Ensure separated metal and plastic fractions meet purity standards for resale (e.g., >99% metal recovery).

- Audit Readiness: Maintain records of material input, output, waste disposal, and compliance with ISO 14001 or local environmental management standards.

- End-of-Life Equipment Disposal: Follow WEEE or local guidelines when decommissioning the granulator to ensure environmentally sound recycling.

Conclusion

Proper logistics planning and regulatory compliance are critical for the successful deployment and operation of a wire granulator. Engaging with experienced freight forwarders, legal counsel, and compliance officers ensures adherence to international standards and avoids costly delays or penalties.

Conclusion for Sourcing a Wire Granulator:

Sourcing a wire granulator is a strategic investment that enhances operational efficiency, promotes environmental sustainability, and supports cost recovery through effective recycling of scrap copper and aluminum wires. After evaluating various suppliers, machine types, capacity requirements, and technological features, it is clear that selecting the right granulator involves balancing performance, durability, ease of maintenance, and compliance with environmental and safety standards.

Key considerations such as throughput capacity, separation efficiency, noise level, dust control, and after-sales support should guide the final decision. Additionally, opting for a reputable manufacturer with proven experience and positive customer feedback ensures long-term reliability and return on investment.

Ultimately, integrating a high-quality wire granulator into the recycling or production process not only streamlines waste management but also contributes to a circular economy by recovering valuable raw materials. With proper sourcing and maintenance, a wire granulator becomes a vital asset in achieving both economic and environmental sustainability goals.