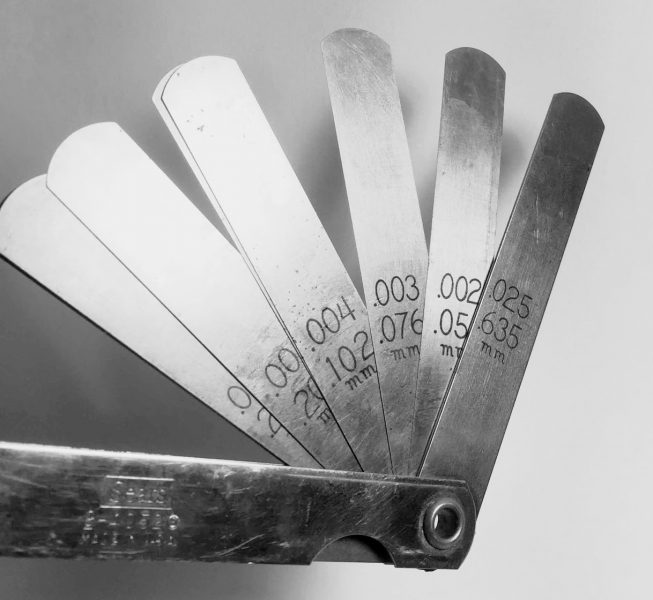

The global precision measurement tools market, driven by increasing demand in automotive, aerospace, and manufacturing sectors, is experiencing steady growth. According to Mordor Intelligence, the global feeler gauge market is projected to grow at a CAGR of approximately 4.2% from 2023 to 2028. This expansion is fueled by the rising need for accurate gap measurement in engine maintenance, quality control processes, and industrial equipment calibration. As wire feeler gauges—prized for their flexibility and precision in tight spaces—gain traction across maintenance and repair operations, manufacturers are innovating to meet evolving industry standards. With market dynamics shaped by technological advancements and stringent quality requirements, identifying leading suppliers becomes critical for procurement professionals. Based on performance metrics, global reach, product range, and customer reviews, here are the top nine wire feeler gauge manufacturers shaping the industry landscape.

Top 9 Wire Feeler Gauge Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

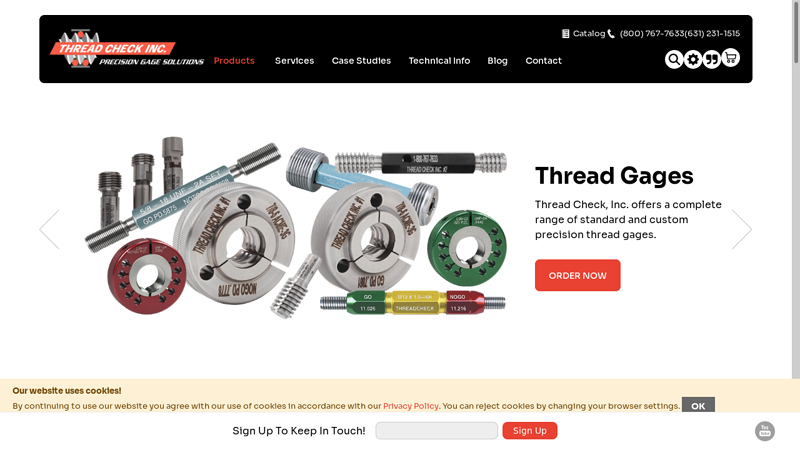

#1 Thread Check – January 2026

Domain Est. 1999

Website: threadcheck.com

Key Highlights: Thread Check Inc. is a full service gage company offering a line of thread plug & ring gages, plain cylindrical gages & measuring instruments….

#2 Eastern Gage

Domain Est. 2001

Website: easterngage.com

Key Highlights: Eastern Gage is a leading manufacturer of catalog feeler gauges and custom feeler gauge products and solutions….

#3 Manufacturer, Supplier

Domain Est. 2014

Website: m.dasquatools.com

Key Highlights: Wire Feeler Gauge Factories – DASQUA IP65 Waterproof 300mm / 12” Digital Electronic Height Gauge 0.001mm / 0.00005” Resolution Heavy Duty DHG with ……

#4 Feeler Gage

Domain Est. 1996

Website: precisionbrand.com

Key Highlights: Feeler Gage ; Plastic Thickness Gage. 1/2″ x 12″ Blades · 1/2″ x 5″ Blades ; Brass Thickness Gage. 1/2″ x 5″ Blades · 1/2″ x 12″ Blades ; Stainless Steel Thickness ……

#5 Feeler Gauges and Gauge Sets

Domain Est. 1996

Website: kmstools.com

Key Highlights: 4.7 27 Feeler Gauges and Gauge Sets ; Lisle Deluxe 32 Blade Feeler Gauge. Lisle. Lisle Deluxe 32 Blade Feeler Gauge · 17.99 · 18.99 ; Proto 25 Blade Feeler Gauge – 12″ ……

#6 Feeler Gauges—New Style Spark Plug Wire Gauge

Domain Est. 1997

Website: wrighttool.com

Key Highlights: New style spark plug wire gauge designed for longer and heavier usage. Contains 1 electrode bender and 8 wire gauges. Equipped with knurled lock-nut….

#7 Plug Gappers & Feeler Gauges

Domain Est. 1998

Website: lislecorp.com

Key Highlights: Standard / High Energy Spark Plug Gauge & Gapper Gauges and Gaps all Types of Spark Plugs from .020″ to .100″ (.50mm to 2.53mm)….

#8 Thickness or Feeler Gage Stock

Domain Est. 1998

Website: starrett.com

Key Highlights: 15-day returnsSHOP FEELER STOCK. Having the thickness stock in a case makes it very useful for cutting off the required length for adjusting tappets, spark plugs, ……

#9 Feeler Gauges

Domain Est. 2000

Website: ctatools.com

Key Highlights: Free delivery over $150Feeler Gauges ; A310 – 12-Blade Offset Feeler Gauge · $15.95 · $15.95 ; A308 – Offset Valve Tappet Gauge Set · $24.95 · $24.95 ; A322 – 17-Blade Mini Feeler …

Expert Sourcing Insights for Wire Feeler Gauge

2026 Market Trends for Wire Feeler Gauge

The wire feeler gauge market is poised for steady evolution by 2026, shaped by persistent demand in traditional industries and emerging influences from technological advancements and global economic dynamics. While not a high-growth sector, it remains essential for precision measurement in critical applications, with distinct trends expected to define its trajectory.

Consolidation of Demand in Core Manufacturing Sectors

Continued reliance on wire feeler gauges in automotive, aerospace, and industrial machinery maintenance ensures stable baseline demand. In the automotive sector, the complexity of internal combustion engines (ICE) and hybrid systems still necessitates precise gap measurements during assembly and servicing. Aerospace maintenance, repair, and overhaul (MRO) operations depend on feeler gauges for turbine blade clearances and engine tolerances, where accuracy is non-negotiable. Additionally, heavy equipment and power generation industries contribute to sustained industrial use. Despite electrification trends, the need for precision mechanical assembly and maintenance in these fields will anchor market demand through 2026.

Increased Focus on Quality and Standardization

As global manufacturing standards become more stringent, especially in ISO-certified environments, demand for calibrated, high-precision wire feeler gauges made from durable materials like stainless steel will rise. End-users are increasingly prioritizing gauges with traceable calibration certificates and consistent thickness tolerances. This trend favors established manufacturers with quality control systems over generic or low-cost providers, potentially leading to market segmentation where premium products command higher margins.

Niche Innovation Amid Limited Digital Disruption

Unlike other measurement tools, wire feeler gauges are unlikely to face major displacement from digital technologies due to their simplicity, reliability, and cost-effectiveness in specific tactile applications. However, niche innovations may emerge—such as hybrid tools integrating feeler blades with digital readouts or smart handles that log measurement data—catering to Industry 4.0 environments. These innovations will likely remain supplementary rather than dominant, preserving the traditional wire feeler gauge’s role in hands-on diagnostics.

Geographic Shifts and Supply Chain Adjustments

Asia-Pacific, particularly China and India, will continue to be key manufacturing and consumption hubs, driving both production and local demand. Meanwhile, nearshoring and supply chain resilience initiatives in North America and Europe may benefit regional manufacturers offering localized production and faster delivery. Trade policies and material costs—especially for specialty steels—could influence pricing and sourcing strategies, pushing companies toward supply chain optimization and material efficiency.

Sustainability and Longevity as Value Drivers

With growing emphasis on tool lifecycle and sustainability, manufacturers may highlight the long service life and repairability of high-quality wire feeler gauges. This positions them favorably against disposable or short-lived alternatives. Marketing efforts are likely to emphasize durability, recyclability of materials, and reduced need for replacement, aligning with broader industrial sustainability goals.

In summary, the 2026 wire feeler gauge market will be characterized by stability in core applications, heightened quality expectations, and incremental innovation. While not undergoing radical transformation, the market will adapt through precision enhancement, regional customization, and sustainability-focused positioning, ensuring continued relevance in precision engineering and maintenance workflows.

Common Pitfalls When Sourcing Wire Feeler Gauge: Quality and Intellectual Property Concerns

Logistics & Compliance Guide for Wire Feeler Gauge

This guide outlines the essential logistics and compliance considerations for the safe, efficient, and legal handling, transport, and use of Wire Feeler Gauges. These precision tools are commonly used in automotive, manufacturing, and maintenance applications to measure clearance between components.

Regulatory Compliance

Ensure all Wire Feeler Gauges meet relevant international and local regulatory standards. Key compliance areas include:

- Material Safety Data Sheets (MSDS/SDS): Maintain up-to-date Safety Data Sheets for the gauge materials (typically spring steel or stainless steel), especially if coated or treated. This is critical for workplace safety and hazardous material regulations.

- REACH and RoHS Compliance (EU): Verify that the gauge materials do not contain restricted substances (e.g., lead, cadmium, or phthalates) above permissible limits, particularly for products exported to the European Union.

- Customs and Import Regulations: When shipping internationally, ensure accurate product classification under the Harmonized System (HS Code). Wire Feeler Gauges typically fall under 9031.80 (measuring or checking instruments) or 8205.59 (hand tools). Provide correct documentation including commercial invoices, packing lists, and certificates of origin.

- Product Labeling: Include necessary compliance markings (e.g., CE, UKCA if applicable), country of origin, and traceable batch/lot numbers on packaging.

Packaging and Handling

Proper packaging ensures product integrity and facilitates smooth logistics operations:

- Protective Packaging: Use durable, anti-static or non-corrosive packaging materials to prevent bending, scratching, or oxidation of the wire blades. Individual gauges or sets should be housed in protective cases or sleeves.

- Moisture Protection: Include desiccant packs in packaging, especially for long-term storage or shipping in humid environments, to prevent rust.

- Labeling: Clearly label outer packaging with handling instructions such as “Fragile,” “Do Not Bend,” and “Protect from Moisture.” Include SKU, quantity, weight, and handling pictograms.

- Unit Load Stability: Secure packaged units on pallets using stretch wrap or strapping. Maximize pallet utilization while ensuring load stability during transit.

Transportation and Shipping

Adhere to best practices for domestic and international shipping:

- Carrier Requirements: Comply with dimensional and weight restrictions set by carriers (e.g., FedEx, UPS, DHL, or freight carriers). Use standardized box sizes where possible.

- Hazardous Materials: Wire Feeler Gauges are generally non-hazardous. However, if shipped with lubricants or cleaning agents, ensure proper classification and packaging per IATA/IMDG/ADR regulations.

- Temperature and Environment: Avoid exposure to extreme temperatures or humidity during transit, which may affect packaging integrity or cause condensation.

- Tracking and Documentation: Provide customers with tracking numbers and ensure all shipping documents are accurate and complete to prevent customs delays.

Storage Requirements

Store Wire Feeler Gauges under controlled conditions to maintain accuracy and longevity:

- Environment: Store in a dry, temperature-controlled environment (15°C–25°C recommended) with low humidity (<60% RH).

- Positioning: Keep gauges flat or vertically stored in their cases to prevent deformation. Avoid stacking heavy items on top.

- Inventory Management: Implement FIFO (First In, First Out) stock rotation. Regularly inspect inventory for damage or corrosion.

Quality and Calibration Compliance

Maintain measurement reliability and meet industry quality standards:

- Calibration Records: Provide a certificate of calibration with each gauge or set, traceable to national or international standards (e.g., NIST, ISO/IEC 17025).

- Periodic Recalibration: Recommend end-users recalibrate gauges annually or as per usage frequency to ensure accuracy.

- ISO Standards: Align manufacturing and testing processes with ISO 9001 (Quality Management) and ISO/IEC 17025 (Testing and Calibration Laboratories) where applicable.

End-of-Life and Environmental Responsibility

Support sustainable practices through responsible disposal:

- Recyclability: Wire Feeler Gauges are typically made from recyclable metals. Encourage proper recycling through metal scrap channels.

- Waste Disposal: Follow local regulations for disposing of damaged or obsolete gauges. Avoid landfill when possible.

- Environmental Management: Comply with ISO 14001 standards if applicable, and minimize packaging waste through reusable or recyclable materials.

By following this guide, businesses can ensure that Wire Feeler Gauges are handled, transported, and used in full compliance with legal, safety, and quality standards across the supply chain.

Conclusion for Sourcing Wire Feeler Gauge:

In conclusion, sourcing a wire feeler gauge requires careful consideration of application requirements, material quality, accuracy, and supplier reliability. Unlike traditional blade-type feeler gauges, wire feeler gauges are ideal for measuring tight or hard-to-reach gaps, especially in confined spaces such as spark plug electrodes, hydraulic systems, or mechanical assemblies. When selecting a supplier, it is essential to prioritize precision-manufactured wires made from durable, non-compressive materials like hardened steel to ensure consistent and reliable measurements.

Evaluating suppliers based on certification, traceability, calibration options, and customer support can significantly impact long-term performance and cost-efficiency. Additionally, considering customization options—such as specific wire diameters, handles, or protective cases—can enhance usability in specialized environments.

Ultimately, investing in high-quality wire feeler gauges from reputable sources not only improves measurement accuracy but also contributes to equipment longevity, operational safety, and overall process reliability. A strategic sourcing approach ensures that the selected gauges meet both technical standards and application-specific demands.