The global wire basket and mesh manufacturing market is experiencing robust growth, driven by rising demand across industrial, automotive, food processing, and logistics sectors. According to Mordor Intelligence, the industrial wire mesh market was valued at USD 10.8 billion in 2023 and is projected to grow at a CAGR of over 5.2% through 2029. This expansion is fueled by increasing infrastructure development, stringent quality control standards, and the need for durable storage and transport solutions. As automation and supply chain efficiency become strategic priorities, demand for high-precision wire basket mesh—known for its strength, ventilation, and reusability—continues to climb. In response, leading manufacturers are investing in advanced manufacturing technologies and customization capabilities to meet evolving industry requirements. Based on production capacity, innovation, geographic reach, and sector-specific compliance, the following nine companies have emerged as key players shaping the future of wire basket mesh manufacturing worldwide.

Top 9 Wire Basket Mesh Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Wire Basket Manufacturing

Domain Est. 1997

Website: acmewire.com

Key Highlights: We specialize in crafting high-quality industrial wire baskets, offering customized solutions tailored to your specific needs. Our extensive range of custom ……

#2 Custom Wire Products and Metal Fabrication

Domain Est. 1999

Website: marlinwire.com

Key Highlights: Marlin Steel is a leading manufacturer in custom wire baskets, wire forms, sheet metal and engineering products….

#3 Specialist manufacturers on steel mesh cable trays, mesh cable …

Domain Est. 2002

Website: valdinox.com

Key Highlights: We specialize in manufacturing wire mesh cable trays, supports, and accessories. Our expertise and experience have allowed us to accumulate valuable ……

#4 Wire Basket Manufacturer

Domain Est. 2011

Website: wiremeshfabs.co.uk

Key Highlights: We are a wire bask manufacturer and can produce woven wire mesh basket related products to your specific requirements and are suitable for a wide range of ……

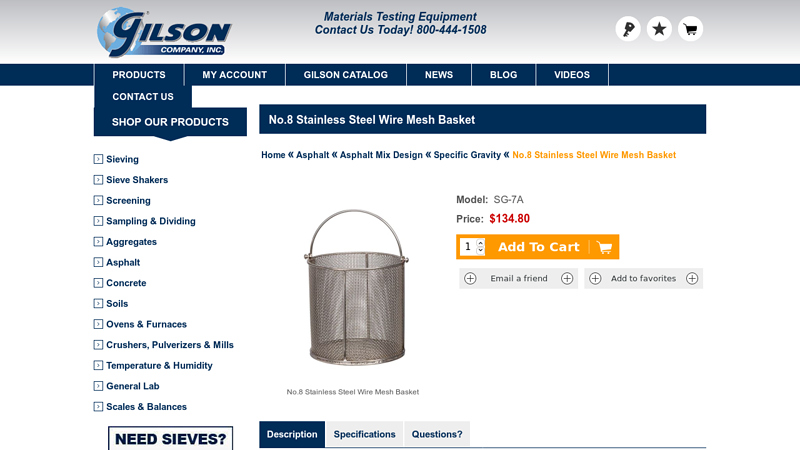

#5 No.8 Stainless Steel Wire Mesh Basket

Domain Est. 1995

#6 Custom Stainless Steel Wire Mesh Baskets

Domain Est. 1996

Website: newarkwire.com

Key Highlights: Newark Wire Cloth designs and fabricates durable, high-quality wire mesh baskets ideal for any application. Included are coarse retention Baskets for efficient ……

#7 Steel Wire Baskets

Domain Est. 1999

Website: prontoproducts.com

Key Highlights: Get a quote for custom steel wire baskets & wire racks for the foodservice industry at Pronto. We’re ISO Certified stainless steel wire mesh basket fabricators….

#8 Cablofil Cable Management

Domain Est. 2004

Website: legrand.us

Key Highlights: Explore the one-stop shop for innovative, fast, and dependable cable management systems including wire mesh tray, ladder cable tray, prefab assemblies, ……

#9 Personalized Wire Mesh Baskets

Domain Est. 2007

Website: anysizebasket.com

Key Highlights: We build to your specifications. No minimum order quantity. Quality High-quality, Made in the USA wire baskets. Workmanship guaranteed….

Expert Sourcing Insights for Wire Basket Mesh

2026 Market Trends for Wire Basket Mesh

Rising Demand Across Industrial and Consumer Sectors

By 2026, the wire basket mesh market is expected to experience robust growth, driven by expanding applications in industrial automation, logistics, and consumer storage solutions. Increased emphasis on efficient material handling in manufacturing and warehousing—especially within the e-commerce sector—is boosting demand for durable, reusable wire baskets. Their ventilation properties and structural strength make them ideal for storage, transport, and sorting in industries ranging from automotive to food processing.

Sustainability and Reusability Driving Adoption

Environmental regulations and corporate sustainability goals are accelerating the shift from single-use plastic containers to recyclable and long-lasting wire basket mesh solutions. By 2026, more companies are anticipated to adopt wire baskets as part of circular economy strategies, reducing waste and lifecycle costs. The metal composition—typically stainless steel or galvanized steel—ensures longevity and full recyclability, aligning with global green manufacturing trends.

Technological Integration and Customization

Advancements in automated guided vehicles (AGVs) and smart warehouse systems are prompting demand for wire baskets with integrated RFID tags or IoT-compatible designs. Manufacturers are responding with customizable mesh patterns, sizes, and coatings tailored to specific operational environments. This trend toward smart, modular storage solutions is expected to strengthen the wire basket mesh value proposition in high-efficiency supply chains.

Regional Growth and Supply Chain Localization

Asia-Pacific, particularly China and India, is projected to remain the largest market and production hub due to rapid industrialization and infrastructure development. Meanwhile, reshoring efforts in North America and Europe are encouraging localized manufacturing of wire baskets to reduce lead times and transportation emissions. This shift supports regional suppliers and enhances supply chain resilience by 2026.

Material Innovation and Cost Optimization

Ongoing R&D focuses on enhancing corrosion resistance and load capacity while minimizing material usage. Lightweight yet high-tensile alloys and improved welding techniques are expected to lower production costs and extend product lifespans. As a result, wire basket mesh solutions will become more cost-competitive against alternative materials, further expanding their market penetration.

Common Pitfalls When Sourcing Wire Basket Mesh (Quality and IP)

Sourcing wire basket mesh involves more than just selecting the right dimensions and material. Overlooking critical quality and intellectual property (IP) aspects can lead to supply chain disruptions, product failures, or legal complications. Here are key pitfalls to avoid:

Poor Material Quality and Inconsistent Specifications

One of the most frequent issues is receiving wire mesh that does not meet the specified material grade (e.g., incorrect stainless steel type like 304 vs. 316), wire diameter tolerance, or mesh count. Suppliers, especially low-cost offshore vendors, may substitute lower-grade materials or fail to adhere to tight tolerances, compromising durability and performance in demanding environments.

Inadequate Surface Finish and Corrosion Resistance

Wire baskets are often used in corrosive or high-temperature settings. A common oversight is neglecting surface treatment requirements such as passivation, electropolishing, or coating. Without proper finish specifications, the mesh may degrade prematurely, leading to contamination or structural failure, particularly in pharmaceutical, food processing, or chemical applications.

Lack of Traceability and Certification

Failing to require material test reports (MTRs), certificates of conformance (CoC), or mill certifications can expose buyers to counterfeit or substandard materials. Reliable traceability is essential for regulated industries where compliance with standards like ASTM, ISO, or FDA is mandatory.

Insufficient Quality Control and Testing

Some suppliers lack robust in-house testing protocols for tensile strength, weld integrity, or dimensional accuracy. Skipping third-party inspections or pre-shipment audits increases the risk of receiving defective batches, resulting in costly rework or production delays.

Intellectual Property Infringement Risks

When sourcing custom-designed wire baskets, there’s a risk that the design may inadvertently replicate patented structures or proprietary configurations. Failing to conduct due diligence or secure IP indemnification from the supplier can expose your company to litigation. Always clarify IP ownership in contracts—especially if you’re providing unique designs.

Inadequate Supplier Vetting and Long-Term Reliability

Choosing suppliers based solely on price often leads to problems with consistency, lead times, and communication. Without verifying a supplier’s manufacturing capabilities, quality management systems (e.g., ISO 9001), and financial stability, you risk supply chain interruptions or quality drift over time.

Non-Compliance with Industry Standards

Different applications require adherence to specific standards (e.g., sanitary design for food-grade baskets, explosion-proof ratings for industrial settings). Overlooking these requirements can result in non-compliant products that fail inspections or pose safety hazards.

Avoiding these pitfalls requires thorough supplier evaluation, clear technical specifications, robust contracts, and ongoing quality monitoring. Investing time upfront ensures reliable performance, regulatory compliance, and protection of your intellectual property.

Logistics & Compliance Guide for Wire Basket Mesh

This guide outlines key logistics considerations and compliance requirements for the transportation, storage, and use of wire basket mesh products. Adhering to these guidelines ensures safety, regulatory compliance, and product integrity throughout the supply chain.

Product Specifications and Handling

Wire basket mesh is typically manufactured from stainless steel, galvanized steel, or other metal alloys, formed into welded or woven mesh panels and assembled into baskets or containers. Proper handling is crucial to avoid deformation, corrosion, or damage. Always use appropriate lifting equipment such as forklifts with protective sleeves or slings to prevent edge damage. Never drag or drop baskets, and store them on flat, dry surfaces to maintain structural integrity.

Packaging and Unit Load Formation

Wire basket mesh is often shipped as nested or stacked units to optimize space. Secure palletizing using steel or plastic strapping and corner boards to prevent shifting during transit. For international shipments, ensure pallets comply with ISPM-15 regulations if made from untreated wood. Individual baskets may be wrapped in plastic film or VCI (Vapor Corrosion Inhibitor) paper to protect against moisture, especially in marine environments.

Transportation Requirements

Use enclosed trucks or containers to shield wire basket mesh from weather, dust, and contamination. When shipping internationally, ensure compliance with carrier-specific load securement rules (e.g., US DOT 49 CFR, EU Directive 2014/47/EU). Secure loads using load bars, straps, or dunnage to prevent movement. For air freight, verify weight and dimensional restrictions with the carrier. Declare the product accurately on shipping documents using the appropriate HS Code—commonly 7326.20 (Other articles of iron or steel) or 7314.00 (Steel grating, fencing, or mesh).

Import/Export Compliance

Verify import regulations in the destination country, including product standards, labeling, and certification requirements. In the EU, wire baskets used in industrial applications may need CE marking if they fall under machinery or material handling equipment directives. In the U.S., OSHA and ANSI standards may apply for workplace safety. Provide accurate commercial invoices, packing lists, and certificates of origin. Be aware of anti-dumping or countervailing duties on steel products in certain jurisdictions.

Storage and Inventory Management

Store wire basket mesh off the ground on racks or pallets in a dry, ventilated area to prevent rust and contamination. Separate different grades (e.g., stainless vs. galvanized) to avoid galvanic corrosion. Implement a first-in, first-out (FIFO) inventory system to minimize prolonged storage. Regularly inspect stored baskets for damage or degradation.

Environmental and Safety Compliance

Dispose of packaging materials in accordance with local waste regulations. Recycle metal scraps and damaged baskets through certified scrap metal processors. Ensure workplace handling complies with OSHA (U.S.) or equivalent safety standards, including proper training for lifting and equipment operation. Provide personnel with cut-resistant gloves when handling sharp edges.

Certifications and Documentation

Maintain available documentation such as Material Test Reports (MTRs), RoHS compliance (for EU), and REACH declarations if applicable. For food-grade or pharmaceutical applications, confirm compliance with FDA 21 CFR or equivalent standards and provide proof of sanitary design and cleanability.

Following this logistics and compliance guide ensures that wire basket mesh is handled, transported, and used safely and in accordance with global regulatory expectations.

In conclusion, sourcing wire basket mesh requires a careful evaluation of material quality, mesh specifications, supplier reliability, and cost-effectiveness. It is essential to select a supplier who offers durable, corrosion-resistant materials—such as stainless steel or galvanized steel—tailored to the intended application, whether for industrial, agricultural, or commercial use. Ensuring compliance with industry standards, verifying certifications, and assessing production capacity will contribute to consistent product quality and timely delivery. Additionally, building long-term relationships with trusted suppliers can lead to better pricing, customization options, and supply chain stability. By conducting thorough due diligence and prioritizing both performance and sustainability, businesses can secure a reliable source of wire basket mesh that meets technical requirements and supports operational efficiency.