The global market for wire management solutions has seen steady expansion, driven by increasing demand across industries such as automotive, electronics, construction, and consumer appliances. According to Grand View Research, the global cable management market size was valued at USD 7.8 billion in 2022 and is expected to grow at a compound annual growth rate (CAGR) of 6.3% from 2023 to 2030. This growth is fueled by rising infrastructure development, the proliferation of electronic devices, and stricter safety regulations requiring organized electrical installations. Within this expanding ecosystem, wire adhesive clips have emerged as essential components due to their ease of installation, space efficiency, and reliable cable bundling capabilities. As demand for compact and efficient wire management intensifies, manufacturers specializing in adhesive clips are scaling innovation and production. Based on market presence, product range, and technological advancements, here are the top seven wire adhesive clip manufacturers shaping the industry.

Top 7 Wire Adhesive Clips Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

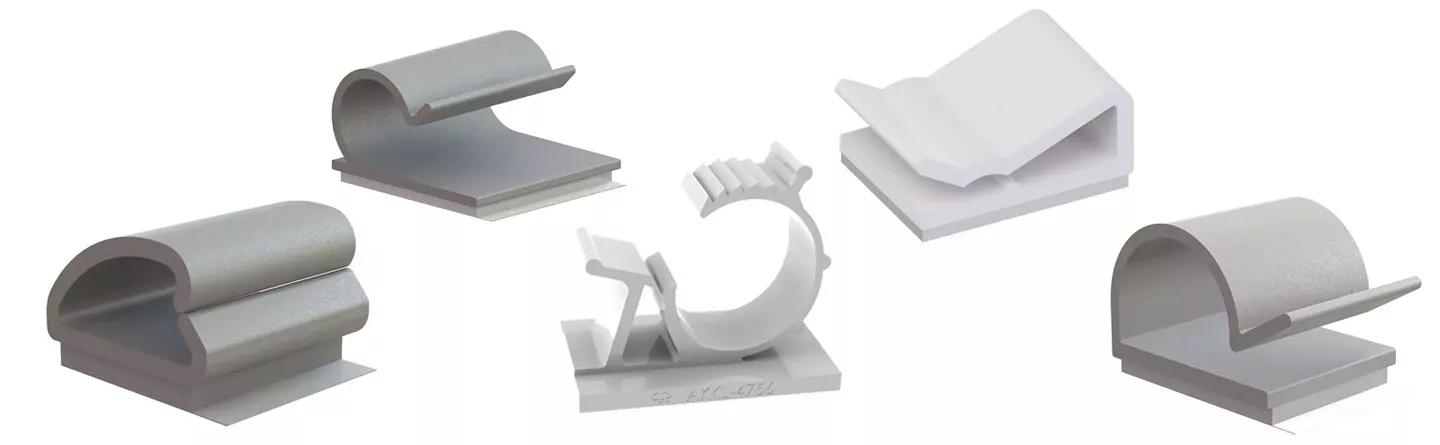

#1 Cable clips: adhesive, magnetic and screw

Domain Est. 1998

Website: hellermanntyton.com

Key Highlights: Cable management clips for routing wires in industry. Discover cable clips with adhesive, magnets and screws, for fluid management and multiple routing….

#2 Adhesive Cable Clips and Clamps

Domain Est. 1998

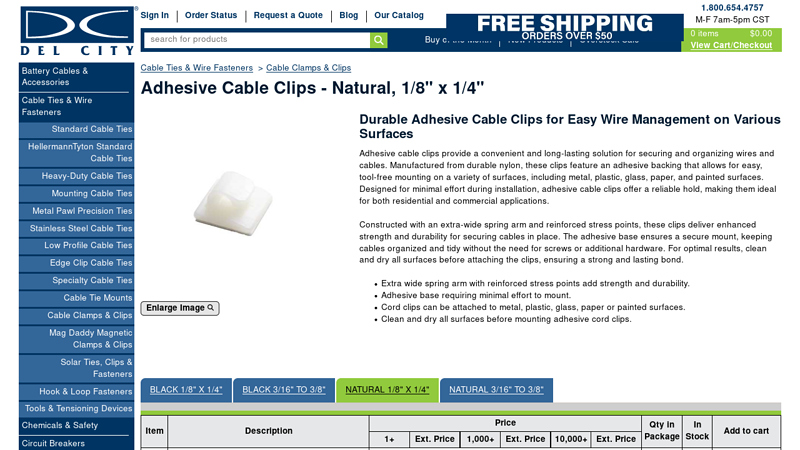

#3 Adhesive Cable Clips – Natural, 1/8″ x 1/4″

Domain Est. 1998

#4 100 Adhesive Cable Management Clips Black

Domain Est. 1998

Website: startech.com

Key Highlights: Free delivery 30-day returnsThese self adhesive one-piece black cable clamps provides an easy way to secure and organize cables in multiple locations. 100 Black cable clips are inc…

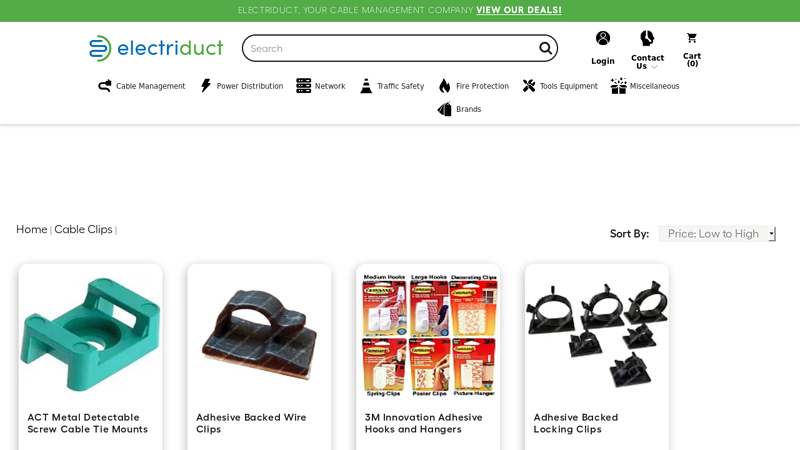

#5 Everything Cable Clips

Domain Est. 2003

Website: electriduct.com

Key Highlights: Free deliveryAdhesive backed cord clips are ideal for routing and holding a variety of types of cables. From: $1.99 View details…

#6 Adhesive Backed Plastic Wire Clips

Domain Est. 2006

#7 Cable Wire Clips with Strong Self

Domain Est. 2010

Website: viofo.com

Key Highlights: In stock $5 deliveryCable Wire Clips with Strong Self-adhesive for All the VIOFO Dash Cameras. Sale price$6.99. Add to cart….

Expert Sourcing Insights for Wire Adhesive Clips

H2: 2026 Market Trends for Wire Adhesive Clips

The global market for wire adhesive clips is poised for steady growth through 2026, driven by rising demand across construction, electronics, automotive, and consumer goods industries. These small but essential components are used to secure cables and wires neatly and safely, improving both functionality and aesthetics in a wide range of applications. Below are the key trends expected to shape the wire adhesive clips market in 2026:

-

Increased Adoption in Smart Homes and IoT Devices

With the proliferation of smart home technologies and the Internet of Things (IoT), there is growing demand for organized and efficient wiring solutions. Wire adhesive clips offer a quick, tool-free method for routing and securing cables in smart thermostats, security systems, lighting, and connected appliances. The rise in DIY installations among consumers further boosts the appeal of adhesive clips due to their ease of use. -

Expansion in Electric Vehicle (EV) Manufacturing

The automotive sector, particularly electric vehicle production, is projected to be a major growth driver. EVs require extensive and complex wiring harnesses for battery systems, infotainment, and driver assistance technologies. Adhesive clips provide a lightweight and vibration-resistant solution for securing wires in tight, sensitive spaces. As EV production scales globally, demand for reliable wire management solutions like adhesive clips will rise accordingly. -

Material Innovation and Sustainability Focus

Manufacturers are increasingly shifting toward eco-friendly materials such as recyclable plastics and biodegradable adhesives. In 2026, expect to see a broader range of adhesive clips made from sustainable or low-carbon materials, responding to stricter environmental regulations and corporate sustainability goals. Additionally, advancements in adhesive technology will improve temperature resistance, longevity, and bonding strength across diverse surfaces. -

Growth in E-Commerce and Retail Packaging Applications

Beyond industrial use, wire adhesive clips are finding new applications in retail and e-commerce, where they help bundle cords and accessories in product packaging. As consumer electronics continue to dominate online sales, manufacturers are integrating adhesive clips directly into packaging for convenience and safety—driving volume demand. -

Regional Market Dynamics

Asia-Pacific is expected to lead market growth due to rapid industrialization, booming electronics manufacturing in countries like China and India, and increased infrastructure investment. North America and Europe will maintain strong demand, supported by smart building initiatives and stringent safety standards in electrical installations. -

Product Customization and Branding Opportunities

Branded and customizable adhesive clips are gaining traction, especially among OEMs seeking to enhance user experience or promote brand identity. In 2026, expect more players to offer clips in different colors, sizes, and with printed logos—particularly for use in consumer electronics and premium appliances.

In conclusion, the wire adhesive clips market in 2026 will be shaped by technological advancements, sustainability demands, and expanding applications across high-growth industries. Companies that innovate in materials, design, and application-specific solutions will be well-positioned to capitalize on these evolving trends.

Common Pitfalls When Sourcing Wire Adhesive Clips (Quality, IP)

Sourcing wire adhesive clips may seem straightforward, but several critical pitfalls can compromise project performance, safety, and longevity—especially concerning quality and Ingress Protection (IP) ratings. Being aware of these issues helps ensure reliable installations.

Overlooking Adhesive Quality and Compatibility

Many low-cost clips use inferior adhesives that fail prematurely under temperature fluctuations, humidity, or UV exposure. Always verify the adhesive type (e.g., acrylic vs. rubber-based), bond strength, and compatibility with the intended surface (metal, plastic, painted finishes). Skipping surface preparation testing can lead to detachment and wire damage.

Assuming IP Ratings Without Verification

Suppliers may claim IP ratings (e.g., IP67) without certification or proper testing. Unverified ratings can mislead buyers into thinking clips are dustproof or waterproof when they are not. Always request test reports or certifications (such as IEC 60529) and confirm that the rating applies to the installed configuration, not just the housing.

Ignoring Material Durability and UV Resistance

Clips made from low-grade plastics may become brittle or discolored when exposed to sunlight or extreme temperatures. This compromises both mechanical retention and insulation properties. Ensure materials are UV-stabilized and suitable for the operating environment (indoor vs. outdoor, industrial vs. consumer).

Inconsistent Clip Dimensions and Tolerance

Poor manufacturing control leads to inconsistent clip sizes, resulting in loose wire retention or difficulty during installation. Variations in internal diameter or clip opening can cause wires to slip or damage insulation. Request samples and perform fit checks before bulk ordering.

Lack of Electrical Insulation Verification

For applications involving live conductors, inadequate dielectric strength or tracking resistance can create safety hazards. Confirm the material’s CTI (Comparative Tracking Index) and insulation rating, especially in high-voltage or humid environments.

Supplier Misrepresentation or Counterfeit Products

Some suppliers exaggerate performance claims or sell counterfeit products mimicking reputable brands. Conduct due diligence by checking certifications, customer reviews, and requesting traceable documentation. Avoid deals that seem too good to be true.

Neglecting Long-Term Environmental Testing

Short-term performance doesn’t guarantee durability. Clips should be evaluated for long-term resistance to vibration, thermal cycling, and chemical exposure. Ask for accelerated life testing data or conduct in-house validation for mission-critical applications.

Avoiding these pitfalls requires thorough vetting of specifications, supplier credibility, and real-world performance testing—ensuring the wire adhesive clips meet both quality and IP requirements for reliable, safe installations.

Logistics & Compliance Guide for Wire Adhesive Clips

This guide outlines key logistics considerations and compliance requirements for the distribution, handling, and use of Wire Adhesive Clips. Adhering to these standards ensures product integrity, regulatory compliance, and safe application.

Product Classification and Shipping Requirements

Wire Adhesive Clips are typically classified as non-hazardous goods under international shipping regulations (e.g., IATA, IMDG, ADR). They should be packed in sealed, moisture-resistant packaging to prevent adhesive degradation. Use rigid outer cartons to avoid crushing during transit. Label packages with standard handling symbols (e.g., “Fragile,” “This Way Up”) and include a product identifier and batch number for traceability.

Storage Conditions

Store Wire Adhesive Clips in a dry, well-ventilated area, with temperatures between 15°C and 25°C (59°F to 77°F) and relative humidity below 60%. Keep products away from direct sunlight, heat sources, and extreme cold to maintain adhesive performance. Store upright and off the floor, preferably on pallets, to prevent moisture absorption and contamination.

Regulatory Compliance

Ensure all Wire Adhesive Clips comply with relevant regional and international standards, including:

– RoHS (EU): Restriction of Hazardous Substances in electrical and electronic equipment.

– REACH (EU): Registration, Evaluation, Authorization, and Restriction of Chemicals.

– Proposition 65 (California, USA): Compliance with warnings for chemicals known to cause cancer or reproductive harm.

– UL/CSA (North America): Flame resistance and material safety, where applicable.

Manufacturers must provide a Declaration of Conformity (DoC) and Safety Data Sheet (SDS) upon request.

Labeling and Documentation

Each package must include:

– Product name and part number

– Quantity and batch/lot number

– Manufacturer or distributor information

– Date of manufacture or expiration (if applicable)

– Compliance markings (e.g., CE, UKCA, or other regional symbols)

– Handling and storage instructions

Shipping documents (e.g., commercial invoice, packing list, bill of lading) must accurately reflect product details and comply with destination country import regulations.

Import and Customs Clearance

Verify tariff classification (HS Code – typically 8536.90 or similar, depending on composition and use) for accurate customs declaration. Provide all required documentation, including certificates of origin if claiming preferential tariffs under trade agreements. Be aware of import restrictions or duties that may apply in certain countries, especially where adhesives contain regulated substances.

Environmental and Disposal Compliance

Dispose of unused or expired Wire Adhesive Clips in accordance with local waste management regulations. Adhesive components may require disposal as non-hazardous industrial waste; consult the SDS for specific guidance. Encourage recycling of packaging materials where possible.

Quality and Traceability

Implement a traceability system to track batches from production to end-user. Maintain records for a minimum of 5 years to support recalls or compliance audits. Conduct periodic quality checks during storage and before shipment to ensure product performance.

By following this guide, businesses can ensure efficient logistics operations and full compliance with regulatory standards for Wire Adhesive Clips across global markets.

Conclusion for Sourcing Wire Adhesive Clips

After evaluating various suppliers, material options, pricing structures, and performance requirements, it is concluded that sourcing wire adhesive clips requires a balanced approach focusing on quality, cost-efficiency, and reliability. Selecting a supplier that offers durable materials (such as UV-resistant plastic and strong adhesive backing), consistent product performance across different surfaces and environmental conditions, and competitive pricing is essential. Additionally, factors such as order lead times, minimum order quantities, and compliance with industry standards should be considered to ensure seamless integration into current operations.

Ultimately, establishing a partnership with a reputable manufacturer or distributor that provides sample testing, responsive customer support, and scalability will help maintain consistent quality and supply chain reliability. By prioritizing these criteria, organizations can effectively source wire adhesive clips that meet both technical requirements and operational demands, contributing to improved cable management, safety, and aesthetics in end applications.