The global market for electrical wire and cable is experiencing robust growth, driven by rising infrastructure development, increased demand from the construction and automotive sectors, and the expansion of renewable energy projects. According to a 2023 report by Mordor Intelligence, the global wire and cable market was valued at USD 188.8 billion and is projected to grow at a CAGR of over 4.5% from 2023 to 2028. This growth is further supported by Grand View Research, which highlights the surging need for energy-efficient transmission solutions and stricter regulatory standards across industrial applications. Within this expanding market, 10 AWG wire—a popular gauge for residential wiring, solar installations, and automotive uses—has become a critical component due to its optimal balance of current-carrying capacity and flexibility. As demand intensifies, manufacturers are scaling production, investing in copper and aluminum innovations, and prioritizing compliance with UL, CSA, and RoHS standards. In this competitive landscape, identifying the top-performing 10 AWG wire manufacturers is essential for sourcing reliable, high-quality products that meet technical and sustainability benchmarks.

Top 9 Wire 10 Awg Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 THHN Wire, Stranded, 10 AWG, 1 Conductor, Copper, 600 Volts …

Domain Est. 1996

Website: stateelectric.com

Key Highlights: In stock $12 deliveryWire Copper. THHN Wire, Stranded, 10 AWG, 1 Conductor, Copper, 600 Volts, Black, 500 ft. SKU: WCUTHHN10STRBK. Manufacturer Part Number: THHN10STRBK. $0.35294 ….

#2 Allied Wire & Cable

Domain Est. 1997

Website: awcwire.com

Key Highlights: We specialize in the latest wire, cable, and connectivity products, as well as tailored solutions, serving diverse industries such as Communications, OEM, Data ……

#3 THHN Building Wire

Domain Est. 2007

Website: lapptannehill.com

Key Highlights: 5-day deliveryThis 10 AWG THHN building wire can be used in conduit and cable trays for services, feeders, and branch circuits in commercial or industrial applications….

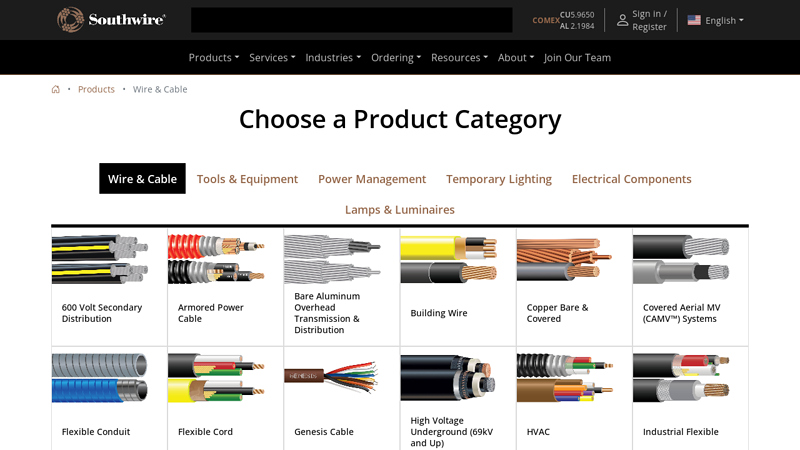

#4 Wire & Cable

Domain Est. 1994

Website: southwire.com

Key Highlights: Choose a Product Category: Wire & Cable, Tools & Equipment, Power Management, Temporary Lighting, Electrical Components, Lamps & Luminaires….

#5 Alpha Wire

Domain Est. 1997

Website: alphawire.com

Key Highlights: Help. Browse our FAQ or fill out a quick form to get support. Learn More ; Get a Sample. Request a free product sample. Get Sample ; Distributor. Find an Alpha ……

#6 WireMasters: Mil

Domain Est. 1998

Website: wiremasters.com

Key Highlights: We have more than 150 million feet of wire and cable in stock across the globe, but we’re also your trusted source for connectors, harness management products….

#7 American Wire Group

Domain Est. 2000

Website: buyawg.com

Key Highlights: Empower your next project with AWG! Turn to us for aluminum, copper, steel, fiber optic, specialty cables and more. View all Products….

#8 In

Domain Est. 2012

#9 10 AWG THHN/THWN

Domain Est. 2015

Website: wireandcableyourway.com

Key Highlights: In stock Free delivery over $1,00010 Gauge THHN Solid Copper Building Wire. Sold by the spool. Applications: Type THHN/THWN-2 building wire is intended for general purpose applicat…

Expert Sourcing Insights for Wire 10 Awg

H2: 2026 Market Trends for 10 AWG Wire

The global market for 10 AWG (American Wire Gauge) wire is poised for significant transformation in 2026, driven by evolving energy demands, technological advancements, and regulatory shifts. As a standard conductor size used widely in residential, commercial, and industrial applications—including electrical wiring, solar installations, electric vehicle (EV) charging, and renewable energy systems—10 AWG wire is at the center of several key market trends.

1. Growth in Renewable Energy and Solar Installations

The expansion of solar photovoltaic (PV) systems remains a primary driver for 10 AWG wire demand. With global commitments to carbon neutrality and increasing government incentives for solar adoption, residential and small-scale commercial solar installations—where 10 AWG is commonly used for DC wiring between panels and inverters—are expected to grow. In 2026, markets such as the U.S., Germany, India, and Australia will likely see heightened demand for UL-listed photovoltaic wire (PV wire) and USE-2 cables in 10 AWG, particularly in rooftop solar projects.

2. Electrification and EV Charging Infrastructure

The rapid deployment of electric vehicle charging stations, especially Level 2 chargers, is another key trend. A typical Level 2 EV charger operating at 240 volts and up to 40 amps often requires 10 AWG copper wire for circuitry. As governments and private sectors ramp up EV infrastructure—such as the U.S. NEVI program and EU Green Deal initiatives—installation of 10 AWG wire in residential garages, commercial parking, and public charging hubs will increase significantly in 2026.

3. Smart Building and Home Automation Trends

The rise of smart homes and energy-efficient buildings is influencing wiring standards. While lower-gauge wires are used for main power feeds, 10 AWG continues to be a preferred choice for dedicated circuits powering high-load smart appliances (e.g., HVAC systems, water heaters, and heat pumps). Integration with home energy management systems (HEMS) will require more reliable and code-compliant wiring, reinforcing demand for durable 10 AWG cables.

4. Material and Supply Chain Dynamics

Copper remains the dominant conductor material for 10 AWG wire due to its conductivity and reliability. However, fluctuating copper prices—driven by mining output, geopolitical factors, and growing demand from electrification—could impact manufacturing costs in 2026. Some manufacturers may explore copper-clad aluminum (CCA) alternatives, though safety and performance concerns may limit adoption in critical applications. Supply chain resilience, including localized production and inventory buffering, will remain a strategic focus for wire manufacturers.

5. Regulatory and Safety Standards

In 2026, stricter adherence to National Electrical Code (NEC) and international equivalents (e.g., IEC standards) will shape product specifications. The NEC continues to emphasize arc-fault and ground-fault protection, influencing how 10 AWG circuits are designed and installed. Additionally, fire safety regulations may drive demand for low-smoke zero-halogen (LSZH) or flame-retardant 10 AWG cables in commercial and high-occupancy buildings.

6. Regional Market Variations

North America and Europe will remain steady markets due to building codes and electrification policies. Meanwhile, emerging economies in Southeast Asia and Africa may see rising demand as urbanization accelerates and grid infrastructure expands. However, adoption will depend on local electrical standards, affordability, and availability of skilled labor.

Conclusion

The 10 AWG wire market in 2026 will be shaped by the convergence of energy transition, infrastructure development, and regulatory evolution. With strong demand from solar, EV, and smart infrastructure sectors, manufacturers and distributors must focus on product compliance, supply chain stability, and innovation in insulation materials to remain competitive. Overall, the outlook for 10 AWG wire remains robust, reflecting broader trends toward electrification and sustainable energy systems.

Common Pitfalls When Sourcing 10 AWG Wire (Quality & IP)

Sourcing 10 AWG wire may seem straightforward, but overlooking key quality and IP (Ingress Protection) considerations can lead to safety hazards, performance issues, and costly failures. Avoid these common pitfalls:

Inadequate Conductor Quality

Using substandard copper or incorrect gauge can result in overheating, voltage drops, and fire risks. Be wary of:

– Oversized or undersized diameters – Confirm the wire meets exact 10 AWG (5.26 mm²) cross-sectional area per ASTM B3 or IEC 60228.

– Impure or recycled copper – Look for OFHC (Oxygen-Free High-Conductivity) copper; low-purity conductors increase resistance.

– Insufficient strand count – Ensure proper stranding for flexibility and current handling, especially in applications requiring movement.

Poor Insulation Materials and Thickness

Low-quality insulation compromises safety and longevity:

– Thin or inconsistent insulation increases risk of short circuits and electrical shock.

– Non-compliant materials – Verify insulation meets standards like UL 1063, UL 83, or IEC 60227 for the intended use (e.g., THHN, XHHW, PVC, XLPE).

– Lack of UV, heat, or chemical resistance – Outdoor or industrial environments demand appropriate jacketing; otherwise, degradation occurs rapidly.

Misunderstanding IP Ratings for Cable Assemblies

IP ratings apply to enclosures and complete cable entries—not individual wires. A common mistake is:

– Expecting bare 10 AWG wire to have an IP rating – Single conductors do not carry IP ratings. IP protection is achieved at the system level (e.g., conduit, junction box, connector).

– Using wire in wet/dirty environments without proper conduit or jacketing – Even with high-IP-rated enclosures, improper cable routing or sealing renders protection ineffective.

Overlooking Environmental and Installation Conditions

Choosing wire without considering the operating environment leads to premature failure:

– Temperature rating mismatch – Ensure insulation is rated for ambient and load temperatures (e.g., 90°C vs. 60°C).

– Ignoring moisture exposure – In wet locations, use wires like XHHW-2 or USE-2 with moisture-resistant jackets.

– Neglecting mechanical stress – In high-vibration or flexing applications, standard 10 AWG may not suffice; consider stranded, reinforced, or specialty cables.

Sourcing from Unverified Suppliers

Procuring from unreliable vendors increases the risk of counterfeit or non-compliant products:

– Missing certifications – Verify UL, CSA, CE, or other regional approvals are present and legitimate.

– Lack of traceability – Reputable suppliers provide lot numbers, test reports, and compliance documentation.

– Unrealistically low pricing – Extremely cheap 10 AWG wire often indicates inferior materials or gauge inaccuracies.

Failure to Match Application Requirements

Using general-purpose wire in specialized settings can be dangerous:

– DC vs. AC applications – Some insulation types perform differently under DC stress, especially in solar installations.

– Voltage rating mismatch – Ensure the wire’s voltage rating (e.g., 600V) meets or exceeds system requirements.

– Incorrect use in power vs. signal circuits – While 10 AWG is typically for power, using it without proper shielding in noisy environments can cause interference.

Avoiding these pitfalls ensures reliable, safe, and code-compliant installations when sourcing 10 AWG wire. Always prioritize certified materials, proper specifications, and application-specific suitability.

Logistics & Compliance Guide for 10 AWG Wire

This guide outlines the essential logistics and compliance considerations for the handling, transportation, storage, and regulatory adherence of 10 AWG (American Wire Gauge) electrical wire. Proper management ensures safety, product integrity, and legal compliance throughout the supply chain.

Regulatory Compliance

Ensure all 10 AWG wire shipments and storage practices meet relevant national and international standards:

- Electrical Safety Standards: Wire must comply with recognized standards such as UL 1063 (for appliance wiring), UL 83 (Thermoplastic Insulated Wire), or UL 44 (Rubber-Insulated Wire), depending on type and application.

- NEC (National Electrical Code): Confirm wire insulation type (e.g., THHN, THWN, XHHW) meets NEC Article 310 requirements for ampacity, temperature rating, and installation environment.

- RoHS & REACH Compliance: Verify wire is free of restricted hazardous substances (e.g., lead, cadmium, phthalates) as required in the EU and other jurisdictions.

- Country-Specific Approvals: For international shipments, ensure certification marks such as CSA (Canada), CE (Europe), or CCC (China) are present if applicable.

Packaging & Handling

Proper packaging and handling maintain wire quality and prevent damage:

- Reel/Spool Specifications: 10 AWG wire is typically supplied on wooden, plastic, or composite reels. Ensure reels are undamaged and meet load-bearing requirements for stacking.

- Protective Wrapping: Use moisture-resistant wrapping (e.g., polyethylene film) and end caps to prevent contamination, kinking, and oxidation.

- Labeling Requirements: Each reel must be clearly labeled with:

- Wire gauge (10 AWG)

- Conductor material (e.g., Copper, Aluminum)

- Insulation type and temperature rating

- Length (feet or meters)

- Manufacturer name and part number

- Compliance marks (UL, CSA, etc.)

- Handling Equipment: Use forklifts or pallet jacks with appropriate attachments to avoid reel damage. Never drag or drop reels.

Storage Conditions

Maintain optimal storage conditions to preserve wire integrity:

- Environment: Store indoors in a dry, temperature-controlled area (10°C to 30°C / 50°F to 86°F recommended).

- Humidity: Keep relative humidity below 60% to prevent corrosion and insulation degradation.

- Ventilation: Ensure adequate airflow to prevent condensation and chemical fume buildup.

- Stacking: Limit stack height to manufacturer specifications (typically no more than 3–4 reels high) to prevent crushing. Use pallets and interlocking patterns.

- Sunlight Exposure: Avoid direct UV exposure, which can degrade insulation materials (especially PVC).

Transportation Requirements

Follow best practices for safe and compliant wire transport:

- Securement: Reels must be strapped or braced to prevent movement during transit. Use edge protectors when banding.

- Climate Control: For long-distance or extreme climate transport, consider enclosed or climate-controlled vehicles.

- Documentation: Include packing lists, safety data sheets (SDS), and certificates of compliance with each shipment.

- Hazard Classification: Most 10 AWG wire is non-hazardous (UN3082, environmentally hazardous substance, only if insulation contains harmful materials). Confirm classification based on composition.

- International Shipments: Comply with IMDG (sea), IATA (air), or ADR (road) regulations as applicable. Provide proper export documentation (e.g., Commercial Invoice, Packing List, Certificate of Origin).

Quality Assurance & Traceability

Implement systems to ensure wire traceability and performance:

- Batch Tracking: Maintain lot or batch numbers for each reel to support recall or quality investigations.

- Incoming Inspection: Verify wire gauge, insulation thickness, and labeling accuracy upon receipt.

- Test Reports: Request and archive manufacturer test reports (e.g., continuity, insulation resistance) as part of compliance records.

Environmental & Disposal Compliance

Address end-of-life and environmental responsibilities:

- Recycling: Copper 10 AWG wire is highly recyclable. Partner with certified e-waste recyclers for scrap processing.

- Disposal: Follow local regulations for disposal of non-recyclable insulation materials. Never incinerate PVC-insulated wire without proper emission controls.

Adhering to this guide ensures safe, compliant, and efficient management of 10 AWG wire across all stages of the logistics chain.

In conclusion, sourcing 10 AWG wire requires careful consideration of application requirements, material quality, insulation type, and compliance with relevant electrical standards such as NEC or local regulations. Copper is typically preferred for its superior conductivity, though aluminum may be considered for cost and weight savings in certain installations. It is essential to purchase from reputable suppliers to ensure product authenticity, performance reliability, and safety. Evaluating factors such as environmental conditions, required length, and pricing from multiple vendors will lead to an optimal balance between cost-efficiency and long-term performance. Proper sourcing of 10 AWG wire ensures safe, efficient, and code-compliant electrical installations across residential, commercial, or industrial applications.