The global cargo trailer market is experiencing steady expansion, driven by rising demand for efficient freight transportation across logistics, construction, and e-commerce sectors. According to Mordor Intelligence, the commercial trailers market was valued at over USD 50 billion in 2023 and is projected to grow at a CAGR of approximately 5.8% from 2024 to 2030. This growth is fueled by increased infrastructure development, stricter safety regulations, and a growing preference for lightweight, durable materials in trailer construction—particularly in window and glazing components designed to enhance visibility and security. As cargo trailers evolve to meet modern logistical demands, the integration of high-performance windows has become a critical design consideration. Below are the top nine manufacturers leading innovation in windows specifically engineered for cargo trailers, combining resilience, energy efficiency, and compliance with industry standards to meet the needs of a rapidly expanding market.

Top 9 Windows For Cargo Trailer Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 RV & Trailer Window Manufacturer

Domain Est. 1996

Website: corporate.lippert.com

Key Highlights: Our extensive inventory of windshields and side windows allows us to accommodate all makes and models of RVs, ensuring prompt and reliable service and delivery….

#2 Leonard Truck Outfitters

Domain Est. 1997

Website: leonardusa.com

Key Highlights: Leonard combines old-fashioned values with new technology to provide the very best in truck accessories, trailers & buildings for your home or business….

#3 Novae

Domain Est. 2000

Website: novae.com

Key Highlights: Novae is one of North America’s premier professional trailer manufacturers. We believe in treating people fairly and celebrating our partnerships….

#4 ATC Trailers

Domain Est. 2009

Website: atctrailers.com

Key Highlights: ATC is the leading manufacturer of aluminum toy hauler RVs, car haulers, cargo trailers, commercial, and custom solutions….

#5 High

Domain Est. 1999

Website: rvwindows.com

Key Highlights: Motion Windows specializes in providing high-quality, heavy-duty cargo trailer windows for both commercial and private use….

#6 Cargo Trailer Windows

Domain Est. 1999

#7 Windows

Domain Est. 2008

Website: stealthtrailer.com

Key Highlights: RV windows are available in several shapes and sizes. We carry full egress windows featuring the contemporary styling you’re looking for….

#8 Bravo Trailers

Domain Est. 2010

Website: bravotrailers.com

Key Highlights: Bravo has engineered a complete range of trailers for YOUR specific need. Both in durability and field tested options, Bravo makes a turn key trailer that will ……

#9 LOOK® Trailers

Domain Est. 2010

Website: looktrailers.com

Key Highlights: Built for durability and versatility, our enclosed cargo trailers are designed to keep your gear safe on every journey, from daily tasks to weekend getaways….

Expert Sourcing Insights for Windows For Cargo Trailer

H2: 2026 Market Trends for Windows in Cargo Trailers

The global market for windows in cargo trailers is poised for notable transformation by 2026, driven by technological advancements, regulatory changes, and evolving customer demands. As the transportation and logistics industry grows, cargo trailer manufacturers are increasingly focusing on enhancing functionality, safety, and energy efficiency—factors that directly impact window design and integration.

-

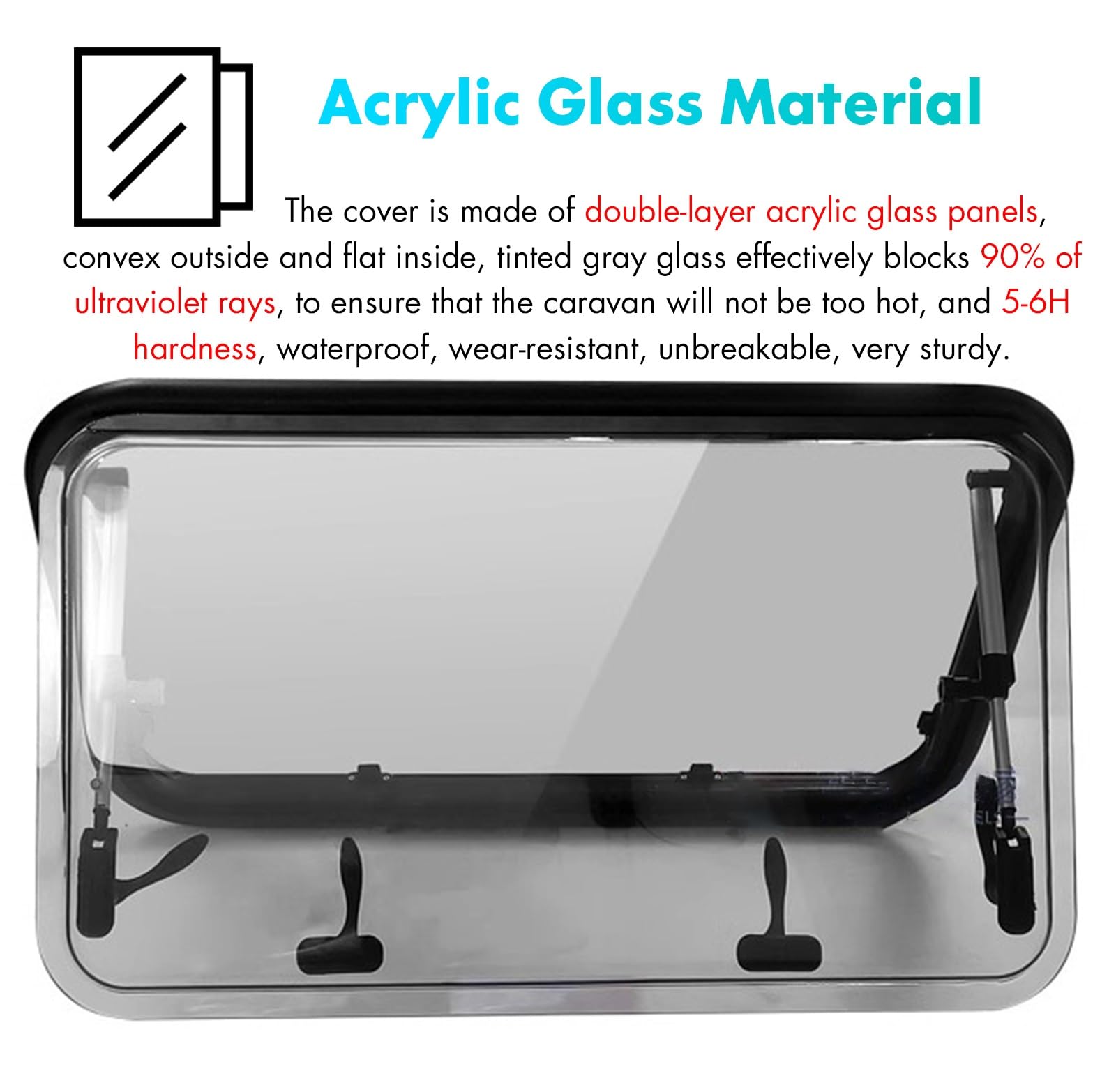

Increased Demand for Lightweight and Durable Materials

By 2026, there is expected to be a significant shift toward the use of advanced composite materials and polycarbonate-based windows in cargo trailers. These materials offer high impact resistance, reduced weight, and improved fuel efficiency compared to traditional glass. Aluminum-framed polycarbonate windows are gaining traction due to their corrosion resistance and ability to withstand harsh environmental conditions. -

Focus on Energy Efficiency and Thermal Insulation

With growing attention to sustainability and fuel economy, insulated and low-emissivity (Low-E) windows are becoming more common in climate-controlled cargo trailers. These windows help maintain internal temperatures, reducing the load on refrigeration systems and lowering fuel consumption. This trend is particularly strong in markets with strict emissions regulations, such as North America and the European Union. -

Integration of Smart Window Technologies

Smart glass or electrochromic windows—capable of adjusting tint levels based on sunlight exposure—are expected to enter niche segments of the cargo trailer market by 2026. While still cost-prohibitive for mass adoption, these technologies are being tested in premium and specialized trailers for pharmaceuticals and high-value goods requiring strict environmental control. -

Regulatory Influence and Safety Standards

Stringent safety regulations, especially in the U.S. and EU, are influencing window placement, size, and shatter resistance. Compliance with FMVSS (Federal Motor Vehicle Safety Standards) and ECE regulations will drive demand for safety-certified windows that minimize injury risks during accidents. Additionally, anti-vandal and tamper-proof window designs are gaining importance in urban delivery and last-mile logistics trailers. -

Growth in E-Commerce and Last-Mile Delivery

The boom in e-commerce is expanding the need for versatile and secure cargo trailers, including those with observation windows for monitoring deliveries. Windows with integrated locks or one-way visibility features are being adopted in delivery vans and small cargo trailers to enhance security while allowing drivers to supervise cargo. -

Regional Market Dynamics

North America and Europe are expected to lead in adopting high-performance windows due to mature logistics infrastructure and regulatory pressures. In contrast, the Asia-Pacific region will see rising demand driven by expanding cold chain logistics and industrial growth, particularly in India and Southeast Asia. Local manufacturers are likely to partner with global suppliers to meet evolving quality standards. -

Sustainability and Recyclability

By 2026, environmental concerns will push manufacturers to adopt recyclable window materials and eco-friendly production processes. Lifecycle assessments of trailer components, including windows, will become part of procurement decisions, favoring suppliers with green certifications.

In conclusion, the 2026 market for windows in cargo trailers will be defined by innovation in materials, energy efficiency, and smart technology integration. As the logistics sector becomes more sophisticated, window systems will evolve from simple ventilation components to critical elements in trailer performance, safety, and sustainability.

Common Pitfalls Sourcing Windows for Cargo Trailer (Quality, IP)

1. Compromised Build Quality

Sourcing low-cost windows often leads to substandard materials, such as thin aluminum frames or non-tempered glass, which are prone to cracking, leaking, or failing under stress. Poor sealing mechanisms can result in water ingress, reducing the trailer’s durability and potentially damaging cargo.

2. Inadequate Weather Resistance

Many off-the-shelf or generic trailer windows lack proper weatherproofing. Without UV-resistant coatings, effective drainage channels, or robust gaskets, these windows degrade quickly when exposed to sun, rain, and temperature fluctuations—common in transportation environments.

3. Lack of Industry-Specific Certification

Windows not certified to meet transportation or road safety standards (e.g., DOT, ANSI, or ECE regulations) may fail inspections or pose safety risks. Using uncertified components can also void trailer warranties and lead to compliance issues.

4. Intellectual Property (IP) Infringement Risks

Sourcing from manufacturers that replicate patented designs—such as unique locking mechanisms, aerodynamic profiles, or proprietary sealing systems—exposes buyers to IP litigation. This is especially common with counterfeit or “clone” products from unverified overseas suppliers.

5. Poor After-Sales Support and Spare Parts Availability

Low-cost suppliers may not offer technical support, installation guidance, or spare parts. If a window fails in the field, delays in sourcing replacements can lead to downtime and increased operational costs.

6. Inconsistent Dimensional Tolerances

Windows with poor manufacturing consistency may not fit standard cargo trailer cutouts, requiring costly modifications during installation. This leads to project delays and increased labor expenses.

7. Insufficient Security Features

Cargo trailers require secure windows to deter theft. Sourcing windows without reinforced frames, tamper-proof locks, or shatter-resistant glazing compromises cargo safety and increases liability.

8. Misrepresentation of IP Ratings

Some suppliers falsely claim high Ingress Protection (IP) ratings (e.g., IP65 for dust and water resistance). Without third-party testing verification, these claims can be misleading, resulting in unreliable performance in real-world conditions.

9. Use of Non-Durable Coatings and Finishes

Windows with low-quality powder coating or anodizing can chip, fade, or corrode over time—especially in coastal or industrial environments. This affects both aesthetics and long-term functionality.

10. Lack of Traceability and Documentation

Reputable suppliers provide material certifications, test reports, and traceable batch numbers. Sourcing without these documents increases risk, especially in regulated industries or during liability investigations.

Logistics & Compliance Guide for Windows for Cargo Trailer

When shipping windows for cargo trailers, meticulous attention to logistics and regulatory compliance is essential to ensure safe, timely, and legal delivery. This guide outlines best practices and requirements for handling, packaging, transportation, and documentation.

Packaging and Handling Requirements

Windows for cargo trailers are fragile and must be protected throughout the supply chain. Use the following standards:

– Package each window in edge-protected crates or sturdy cardboard with internal foam or bubble wrap to prevent breakage.

– Label all packages as “Fragile” and “This Side Up” to guide proper handling.

– Stack packages on pallets secured with stretch wrap; avoid overloading to prevent collapse.

– Store in a dry, temperature-controlled environment to avoid condensation or warping.

Transportation Mode and Carrier Selection

Choose transportation methods based on distance, urgency, and cost:

– For domestic shipments, flatbed or dry van trailers are commonly used. Flatbeds allow for secure strapping of palletized loads but require weather protection (tarps) if windows are not fully enclosed.

– For long-distance or international shipments, intermodal transport (truck-to-rail or truck-to-container ship) may be cost-effective.

– Select carriers with experience in handling fragile freight and proper insurance coverage for high-value glass products.

Domestic Compliance (U.S. Focus)

Ensure adherence to U.S. Department of Transportation (DOT) and Federal Motor Carrier Safety Administration (FMCSA) regulations:

– Secure loads per FMCSA’s Cargo Securement Rules (49 CFR Part 393, Subpart I) using tiedowns, load bars, or other approved methods.

– Maintain valid carrier liability insurance with minimum coverage as required by law.

– Drivers must comply with Hours of Service (HOS) regulations to prevent fatigue-related incidents.

– If transporting hazardous materials (e.g., certain glazing chemicals), follow Hazardous Materials Regulations (HMR) under 49 CFR.

International Shipping and Customs Compliance

For cross-border shipments, additional documentation and standards apply:

– Prepare a commercial invoice, packing list, bill of lading, and certificate of origin.

– Classify goods using the correct Harmonized System (HS) code (e.g., 7008.00 for non-wired glass).

– Comply with destination country import regulations, including building code standards (e.g., CE marking in the EU, CCC in China).

– Use Incoterms® (e.g., FOB, CIF) to clarify responsibilities for shipping, insurance, and customs clearance.

Safety and Environmental Considerations

- Train personnel in safe lifting techniques and use mechanical aids (e.g., forklifts) to handle heavy window units.

- Comply with OSHA standards for material handling and workplace safety.

- Recycle packaging materials where possible and follow EPA guidelines for disposal of any hazardous components (e.g., sealants or coatings).

Documentation and Traceability

Maintain accurate records for compliance and quality assurance:

– Track shipments via GPS or telematics for real-time visibility.

– Keep records of inspections, damage reports, and delivery confirmations.

– Retain documentation for at least three years for audit purposes.

By following this logistics and compliance guide, shippers and carriers can ensure the safe, efficient, and lawful delivery of windows for cargo trailers across all transportation networks.

In conclusion, sourcing windows for a cargo trailer requires careful consideration of several key factors, including window size, material durability, ventilation needs, security, weather resistance, and compliance with local regulations. Whether opting for fixed acrylic panels, opening vents, or tempered glass windows, it is essential to balance functionality, cost, and long-term reliability. Exploring reputable suppliers—such as RV part manufacturers, industrial vehicle outfitters, or custom fabrication shops—can provide high-quality options tailored to specific trailer uses, such as conversion for mobile businesses, living spaces, or equipment transport. Ultimately, selecting the right windows enhances not only the trailer’s usability and comfort but also its overall value and longevity. Conducting thorough research, comparing prices, and prioritizing quality installation will ensure a successful and efficient sourcing outcome.