The global window pouch packaging market is experiencing robust growth, driven by rising demand for convenient, transparent, and tamper-evident packaging solutions across industries such as food & beverage, pharmaceuticals, and e-commerce. According to a 2023 report by Mordor Intelligence, the global stand-up pouch market—which includes window pouch variants—is projected to grow at a CAGR of over 6.2% from 2023 to 2028. Similarly, Grand View Research estimates that the global flexible packaging market, a broader category encompassing window pouches, will expand at a CAGR of 3.8% from 2023 to 2030, fueled by consumer preference for lightweight, durable, and visually appealing packaging. As brands increasingly prioritize shelf visibility and product protection, window pouches have emerged as a preferred solution, combining functional benefits with marketing advantages. This growing demand has led to a competitive landscape of manufacturers innovating in materials, sealing technologies, and sustainable production methods. Below are the top 7 window pouch manufacturers shaping the future of flexible packaging globally.

Top 7 Window Pouches Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1

Domain Est. 2011

Website: reynoldsconsumerproducts.com

Key Highlights: These new scented trash bags combine trusted strength, effective odor control technology, and six-in-one protection with the sweet scent of watermelon….

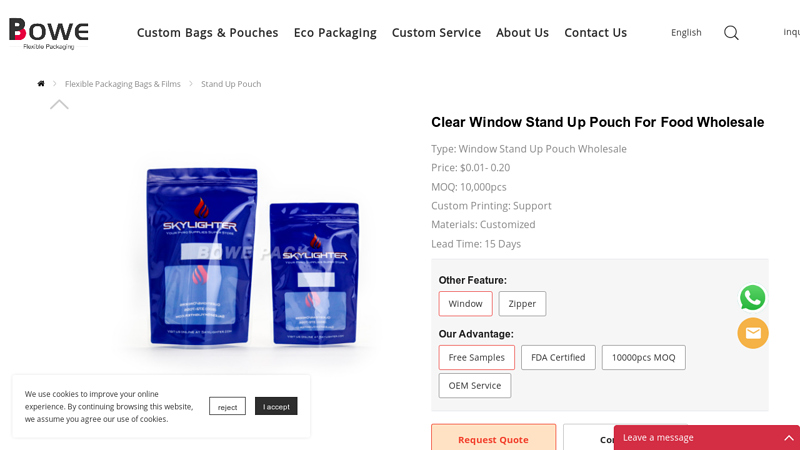

#2 Clear Window Stand Up Pouch For Food Wholesale

Domain Est. 2023

Website: bowepack.com

Key Highlights: Custom window stand up pouch is a unique and eye-catching packaging solution. OEM print & size. Made of high-quality material, get wholesale price now….

#3 Clear Bags

Domain Est. 1999

Website: clearbags.com

Key Highlights: $5.99 delivery · 60-day returnsClearBags provides clear plastic bags, shipping boxes, zipper pouches, and packaging supplies at wholesale prices. Custom and Eco-Friendly options ….

#4 Custom Window Stand Up Pouches

Domain Est. 1999

Website: aplasticbag.com

Key Highlights: Our Custom Window Stand Up Pouches are perfect for displaying small samples of perishable products that are packaged inside non-transparent materials. Custom ……

#5 Stand-Up Window Pouches & Bags

Domain Est. 2007

Website: dura-pack.com

Key Highlights: Showcase your products with stand-up pouches featuring windows from Dura-Pack.com. Elevate packaging and freshness in one. Made in the USA!…

#6 How a Clear Window Pouch Can Boost Your Brand and Sales

Domain Est. 2017

Website: pouch.me

Key Highlights: Clear window pouches are a creative way of packaging your food product. Their front and rear surface is large enough to not only hold your product but also ……

#7 Stand Up Pouch with Window

Domain Est. 2023

Website: enviroflexpack.com

Key Highlights: Free delivery over $350 Free 30-day returns…

Expert Sourcing Insights for Window Pouches

H2: Market Trends for Window Pouches in 2026

The window pouch market is poised for significant evolution by 2026, driven by shifting consumer preferences, sustainability mandates, technological advancements, and expanding applications across industries. As brands strive for product differentiation and enhanced consumer experience, the transparent window feature—offering visibility of contents without compromising package integrity—has become a strategic packaging solution. Below are key trends shaping the window pouch market in 2026:

-

Sustainability and Eco-Friendly Materials

Environmental concerns remain a dominant force influencing packaging decisions. By 2026, demand for recyclable, compostable, and mono-material window pouches is expected to surge. Brands are increasingly replacing traditional plastic films with bio-based or recyclable alternatives such as cellulose-based windows and fully recyclable PE/PE laminates. Regulatory pressures in regions like Europe and North America are accelerating the shift toward sustainable window films that maintain clarity and strength. -

Growth in E-Commerce and Retail Ready Packaging

The rise of online grocery shopping and direct-to-consumer models is driving demand for durable, visually appealing window pouches. Transparency allows consumers to verify product quality before purchase, increasing trust in e-commerce platforms. In 2026, window pouches are increasingly designed with resealable zippers, easy-tear notches, and enhanced puncture resistance to meet logistics challenges and improve user experience. -

Expansion in Food and Beverage Applications

The food sector continues to be the largest end-user of window pouches. In 2026, snack foods, coffee, tea, dried fruits, and premium pet foods are leading applications. The window feature provides a competitive advantage by showcasing product freshness and texture, influencing purchase decisions at shelf or online. Innovations in barrier technologies ensure extended shelf life while maintaining aesthetic appeal. -

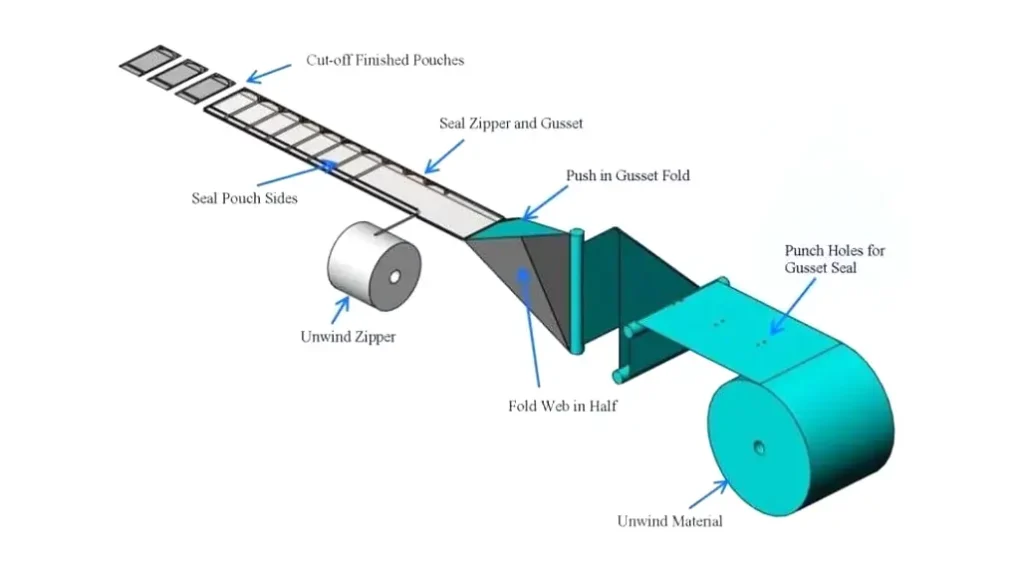

Technological Advancements in Lamination and Sealing

Advances in adhesive lamination and precision window-cutting technologies have improved production efficiency and reduced material waste. By 2026, inline inspection systems and AI-driven quality control are becoming standard in pouch manufacturing, ensuring consistent window alignment and seal integrity. These improvements support high-speed filling lines and reduce operational costs. -

Rise of Premiumization and Brand Differentiation

Brands are leveraging window pouches as a tool for premium positioning. The combination of high-clarity windows with matte finishes, metallic accents, or specialty inks enhances shelf appeal. In 2026, customization and limited-edition designs with strategic window placement are increasingly used to convey authenticity and quality. -

Emerging Markets Driving Demand

While mature markets focus on sustainability and innovation, emerging economies in Asia-Pacific, Latin America, and Africa are experiencing rapid growth in packaged food and FMCG sectors. As urbanization and retail infrastructure expand, demand for convenient, transparent packaging like window pouches is rising. Local manufacturers are investing in flexible packaging capabilities to meet this demand. -

Regulatory and Compliance Challenges

In 2026, stricter global regulations on plastic use and recyclability are impacting window pouch design. The integration of non-recyclable window materials (e.g., PVC) is declining in favor of compliant alternatives. Certifications such as RecyClass and How2Recycle are becoming essential for market access, pushing manufacturers toward transparent and responsible sourcing.

In conclusion, the 2026 window pouch market reflects a convergence of functionality, sustainability, and branding. Companies that adapt to eco-conscious consumer behavior, embrace innovative materials, and leverage transparency as a marketing tool are likely to lead the market. As technology and regulation evolve, the window pouch will remain a dynamic segment within the broader flexible packaging industry.

Common Pitfalls When Sourcing Window Pouches (Quality, IP)

Sourcing window pouches—flexible packaging with a transparent film window to showcase the product—can present several challenges, especially concerning quality consistency and intellectual property (IP) protection. Being aware of these pitfalls helps mitigate risks and ensures a reliable supply chain.

Quality Inconsistencies

One of the most frequent issues in sourcing window pouches is inconsistent quality across production batches. Variations can appear in seal strength, clarity of the window film, overall pouch durability, and print accuracy. Poor lamination between the window and the main pouch material can lead to delamination, compromising both aesthetics and functionality. Additionally, issues like misaligned windows, wrinkling, or air bubbles reduce perceived product quality and may lead to customer complaints or returns.

Material and Seal Integrity

Window pouches require precise alignment and bonding between dissimilar materials—the clear window film (often PET or PP) and the main pouch substrate (like PE or laminated films). If the materials are incompatible or processing parameters (temperature, pressure, adhesive quality) are not tightly controlled, weak seals or leaks can occur. Sourcing from suppliers without robust quality control systems increases the risk of receiving pouches that fail during filling, storage, or shipping.

Lack of Transparency in Supply Chain

Many suppliers outsource parts of the production process, such as printing or lamination, which can obscure visibility into where and how the pouches are made. This opacity makes it difficult to verify material sourcing, production standards, and compliance with food-grade or sustainability requirements. Without full traceability, brands face reputational and regulatory risks.

Intellectual Property Infringement

Window pouch designs often include branded graphics, unique structural features, or patented closure systems. When sourcing internationally, especially from regions with weaker IP enforcement, there’s a risk that your design could be copied or sold to competitors. Suppliers may also use similar designs across multiple clients, leading to market confusion and brand dilution.

Inadequate IP Protection in Contracts

A common oversight is failing to include strong IP clauses in supplier agreements. Without clear contractual language stating that the brand owns the design, tooling, and artwork—and prohibiting the supplier from reproducing or sharing them—there is little legal recourse if the design is duplicated. Non-disclosure agreements (NDAs) and explicit IP assignment terms are essential but often neglected.

Copycat Packaging and Market Saturation

Once a successful window pouch design enters the market, unauthorized manufacturers may reverse-engineer it, especially if it’s not protected by design patents or trademarks. This leads to counterfeit or lookalike products that erode brand equity and consumer trust. Proactive IP registration (e.g., design patents, trademarks) is critical but frequently delayed or overlooked during the sourcing phase.

Conclusion

To avoid these pitfalls, conduct thorough due diligence on suppliers, insist on material and process transparency, implement rigorous quality audits, and secure comprehensive IP protections before production begins. Partnering with reputable manufacturers who respect IP and maintain consistent quality standards is key to long-term success.

Logistics & Compliance Guide for Window Pouches

Window pouches, commonly used in packaging for retail, e-commerce, and industrial applications, combine durability with product visibility. To ensure smooth logistics operations and regulatory compliance, manufacturers, distributors, and retailers must adhere to specific standards and best practices. This guide outlines key considerations for the safe, efficient, and compliant handling of window pouches throughout the supply chain.

Material Composition & Regulatory Compliance

Window pouches typically consist of laminated films (e.g., PET/PE, BOPP/PE) with a transparent window (often PET or PP) for product visibility. Compliance begins with material selection:

- Food Contact Compliance: If used for food, packaging must meet FDA (U.S.), EFSA (EU), or other regional food contact regulations. Ensure materials are certified as food-grade and free from harmful substances such as BPA or phthalates.

- REACH & RoHS Compliance: For shipments to the EU, verify that raw materials comply with REACH (Registration, Evaluation, Authorisation and Restriction of Chemicals) and RoHS (Restriction of Hazardous Substances) directives.

- Recyclability & Environmental Claims: Clearly label recyclability status. Avoid misleading “biodegradable” claims unless certified (e.g., via TÜV OK Compost or similar). Follow FTC Green Guides to prevent greenwashing.

Packaging & Labeling Requirements

Proper labeling ensures regulatory adherence and supply chain efficiency:

- Product Information: Include product name, net weight, ingredients (if applicable), manufacturer details, and batch/lot numbers.

- Window Integrity: Ensure the transparent window is securely laminated and does not compromise the pouch’s barrier properties (e.g., against moisture or oxygen).

- Barcode & Trackability: Include scannable barcodes (UPC, EAN) and, if required, RFID tags for inventory and logistics tracking.

- Compliance Markings: Use required symbols (e.g., recycling codes, food-safe icons, CE marking for EU) as applicable.

Shipping & Handling Guidelines

Window pouches are generally lightweight but require careful handling to prevent damage:

- Palletization: Stack pouches uniformly on pallets. Use edge protectors and stretch wrap to prevent shifting during transit.

- Load Securing: In containers or trucks, secure loads to avoid movement. Avoid overloading or excessive stacking that could crush lower layers.

- Environmental Conditions: Store and transport in dry, temperature-controlled environments. Avoid exposure to UV light, extreme heat, or freezing temperatures that could degrade film integrity.

Import/Export Considerations

Cross-border shipments require additional documentation and checks:

- Customs Declarations: Provide accurate HS codes (e.g., 3923.29 for plastic sacks and bags) and commercial invoices.

- Phytosanitary & Safety Certifications: Required for certain goods (e.g., agricultural products). Ensure window pouches do not introduce contaminants.

- Country-Specific Regulations: Research local packaging laws (e.g., France’s AGEC Law, California’s SB 343) that may restrict certain materials or labeling.

Sustainability & End-of-Life

Environmental responsibility is increasingly critical:

- Waste Stream Compatibility: Design for mono-material or compatible lamination to improve recyclability.

- Take-Back Programs: Consider participation in extended producer responsibility (EPR) schemes where applicable.

- Documentation: Maintain records of material sourcing, compliance certifications, and sustainability claims for audits.

Quality Control & Audits

Implement routine checks throughout the supply chain:

- Incoming Inspection: Verify pouch specifications (seal strength, puncture resistance, window clarity).

- Batch Testing: Conduct periodic testing for compliance with safety and performance standards (e.g., ASTM D4169 for packaging performance).

- Supplier Audits: Ensure vendors comply with ISO 22000, ISO 9001, or other relevant standards.

By following this guide, stakeholders can ensure that window pouches meet logistical demands while remaining compliant with global regulatory frameworks, ultimately supporting brand integrity and customer trust.

Conclusion for Sourcing Window Pouches

In conclusion, sourcing window pouches requires a strategic approach that balances quality, cost, functionality, and sustainability. By carefully evaluating suppliers based on material standards, production capabilities, compliance certifications, and lead times, businesses can ensure a reliable supply chain that meets both operational needs and customer expectations. The inclusion of a transparent window offers enhanced product visibility, which can boost consumer trust and drive sales, making it a valuable packaging solution across various industries. Additionally, considering eco-friendly materials and custom design options supports brand differentiation and aligns with growing environmental concerns. Ultimately, a well-executed sourcing strategy for window pouches not only optimizes packaging performance but also contributes to overall brand value and market competitiveness.