The global window clamp market is experiencing steady growth, driven by rising construction activities, increasing demand for energy-efficient building solutions, and stringent regulatory standards for façade safety. According to Grand View Research, the global architectural hardware market—of which window clamps are a critical component—was valued at USD 74.3 billion in 2022 and is expected to expand at a compound annual growth rate (CAGR) of 6.8% from 2023 to 2030. This growth trajectory reflects the expanding adoption of advanced clamping systems in commercial and high-rise residential buildings, where structural integrity and ease of installation are paramount. As demand surges across North America, Europe, and the Asia Pacific, manufacturers are focusing on innovation in materials, load capacity, and corrosion resistance to meet evolving industry standards. In this competitive landscape, a select group of manufacturers has emerged as leaders, setting benchmarks in performance, reliability, and technological advancement. The following analysis highlights the top nine window clamp manufacturers shaping the future of modern fenestration and building envelope systems.

Top 9 Window Clamp Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 1

Domain Est. 1995

Website: fastenal.com

Key Highlights: 1-5/8″ Window Type Strut to Beam Clamp. SKU. 48845. UNSPSC. 31162905. Manufacturer. FASTENAL APPROVED VENDOR. Online Price. $62.80. / package of 5….

#2 Window Beam Clamps

Domain Est. 1997

Website: techlinemfg.com

Key Highlights: TechLine Mfg. provides a comprehensive selection of channel strut products and accessories. Ideal for structural support in various industries….

#3 Clamps for kitchen doors and windows

Domain Est. 1997

Website: scmgroup.com

Key Highlights: Clamps for doors and windows or Automation Systems for furniture manufacturing and wood construction industries. Discover SCM Group technological units….

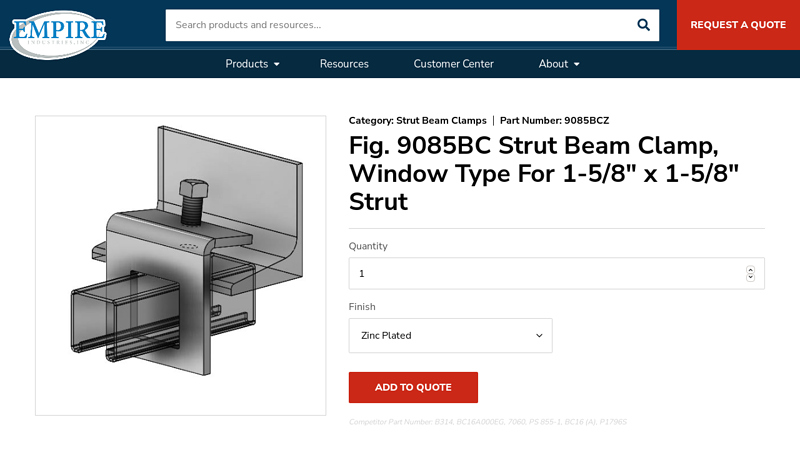

#4 Fig. 9085BC Strut Beam Clamp, Window Type For 1

Domain Est. 1998

#5 PVC Coated Window Clamp

Domain Est. 1999

Website: plastibond.com

Key Highlights: PVC coated beam clamps are used to securely support conduit runs by attaching them to beams, angles, trusses and other structural members….

#6 Window Clamp

Domain Est. 2003

Website: scottelectricusa.com

Key Highlights: Buy electrical window clamp from the Scott Electric online store….

#7 P1796S

Domain Est. 2009

Website: unistrut.biz

Key Highlights: In stockDesign Load = 500 lbs (2.22 kN) each. Notes: Design loads only apply to Unistrut brand products. Look for “UNISTRUT” on the part. Use in pairs only….

#8 Unistrut P2785 Window Beam Clamp, Defender

Domain Est. 2018

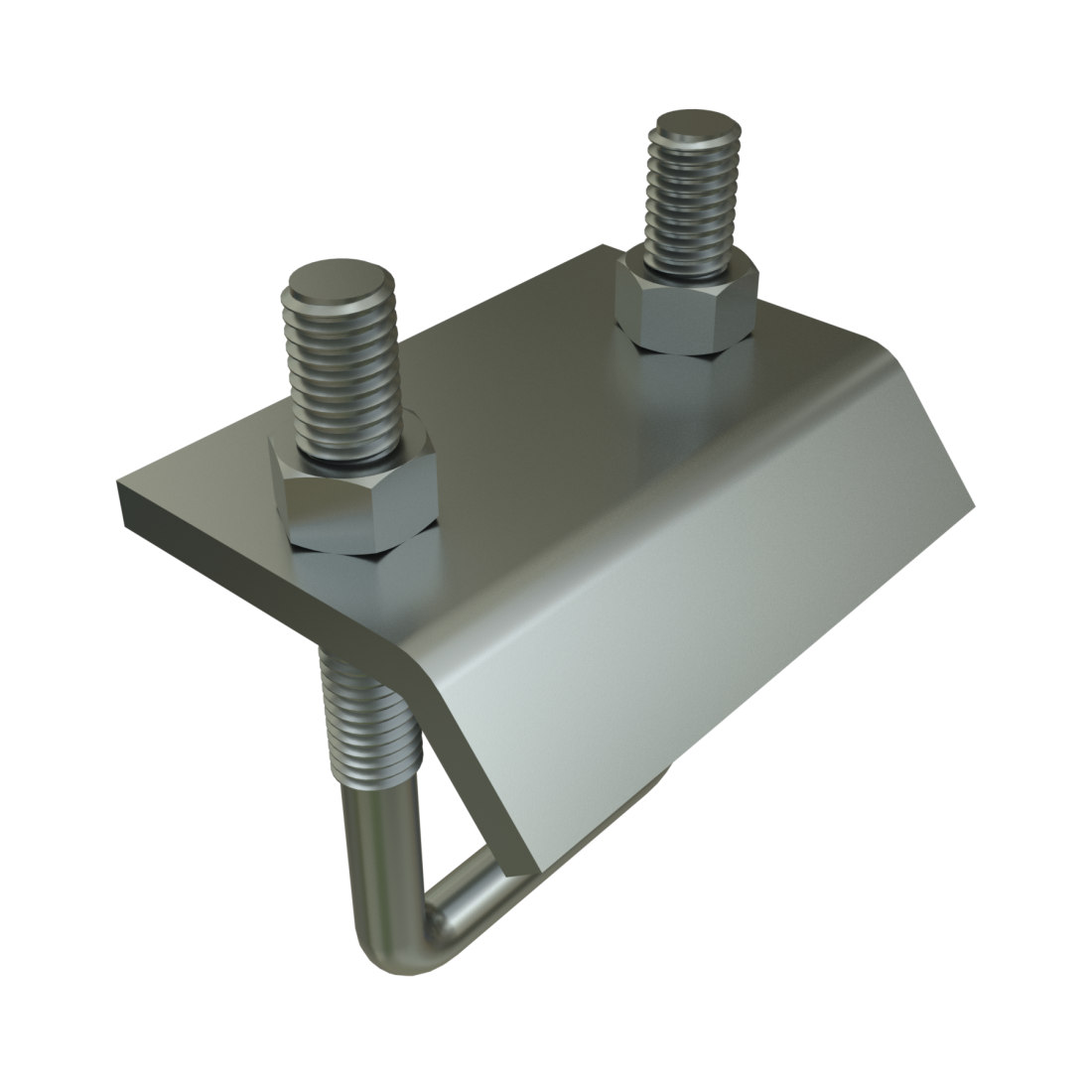

#9 Armortex Aluminum Window Clamp On Frame

Domain Est. 2020

Website: protogetic.com

Key Highlights: Searching for Armortex’s Ballistic Resistant Aluminum Window – Clamp On Frame? Protogetic carries this UL 752 rated windows in Levels 1-8. | Shop Now….

Expert Sourcing Insights for Window Clamp

H2: 2026 Market Trends for Window Clamps

The global window clamp market is poised for notable evolution by 2026, driven by advancements in construction technologies, increasing demand for energy-efficient building solutions, and growing emphasis on safety and ease of installation. As a critical component in window installation and glazing systems, window clamps are experiencing shifts in design, material composition, and application scope. Below are the key market trends expected to shape the window clamp industry in 2026:

1. Rising Demand in Residential and Commercial Construction

Urbanization and infrastructure development—especially in emerging economies across Asia-Pacific, Latin America, and Africa—are fueling construction activities. The surge in demand for modern, aesthetically pleasing, and energy-efficient windows is directly increasing the need for reliable window clamping systems. Prefabricated and modular construction methods, which rely heavily on precision fixtures like window clamps, will further boost market growth.

2. Shift Toward Lightweight and Corrosion-Resistant Materials

Manufacturers are increasingly adopting aluminum, stainless steel, and high-grade polymers in window clamp production to improve durability, reduce weight, and resist environmental corrosion. This shift supports longer product lifespans and lowers maintenance costs, making them ideal for coastal and high-humidity regions.

3. Integration with Smart Building Systems

By 2026, smart buildings are expected to represent a larger share of new constructions. Window clamps are beginning to incorporate features that support integration with automated window controls, sensors, and monitoring systems. While still in early stages, clamps designed for compatibility with smart glazing and ventilation systems are expected to gain traction.

4. Sustainability and Eco-Friendly Manufacturing

Environmental regulations and green building certifications (e.g., LEED, BREEAM) are pushing manufacturers toward sustainable practices. Recyclable materials, energy-efficient production processes, and reduced carbon footprints are becoming competitive advantages. Window clamps made from recycled metals or bio-based composites may emerge as niche but growing segments.

5. Focus on Ease of Installation and Adjustable Designs

Labor costs and construction timelines are key concerns in the industry. As a result, window clamps with quick-install features, tool-less adjustments, and universal fitments are becoming more popular. These innovations appeal to contractors seeking efficiency and reduced dependency on specialized labor.

6. Regional Market Expansion and Localization

While North America and Europe remain mature markets with steady demand, the fastest growth is anticipated in Southeast Asia, India, and the Middle East. Localized manufacturing and distribution networks are expected to rise, reducing lead times and import costs.

7. Competitive Landscape and Innovation

The market is witnessing increased competition among established players and new entrants. Companies are investing in R&D to differentiate products through ergonomic designs, enhanced load-bearing capacity, and aesthetic integration with modern window frames. Strategic partnerships with window manufacturers and construction firms are likely to define market leadership.

Conclusion

By 2026, the window clamp market will be shaped by technological innovation, sustainability demands, and global construction dynamics. Stakeholders who adapt to modular construction trends, embrace smart infrastructure compatibility, and prioritize eco-conscious manufacturing will be best positioned to capture growth opportunities in this evolving landscape.

Common Pitfalls When Sourcing Window Clamps (Quality, IP)

Sourcing window clamps—especially for specialized applications like temporary access, maintenance, or mounting equipment on building facades—requires careful attention to quality and Ingress Protection (IP) ratings. Overlooking key factors can lead to safety hazards, equipment failure, or non-compliance. Below are common pitfalls to avoid:

Poor Material Quality and Durability

Many low-cost window clamps use substandard metals or plastics that degrade quickly under UV exposure, temperature fluctuations, or mechanical stress. This can result in cracking, corrosion, or structural failure, especially in outdoor environments. Always verify material specifications (e.g., anodized aluminum, stainless steel hardware) and request test reports or certifications.

Inadequate Load-Bearing Capacity

A frequent mistake is selecting clamps rated for loads lower than required. Overloading can cause slippage or breakage, posing serious safety risks. Ensure the clamp’s working load limit (WLL) exceeds the maximum expected load, including dynamic forces from wind or movement.

Misunderstanding IP Ratings

Window clamps used with electrical or electronic components (e.g., cameras, sensors) often require specific IP ratings for dust and moisture resistance. A common pitfall is assuming all outdoor-rated clamps are waterproof. Verify the exact IP rating (e.g., IP65, IP66) matches the environmental conditions—especially for coastal or high-humidity areas.

Lack of Weather and UV Resistance

Even if a clamp has a decent IP rating, its structural components may not be UV-stabilized. Prolonged sun exposure can weaken plastics and degrade seals. Confirm that gaskets, arms, and housing materials are designed for long-term outdoor use.

Incompatible Window Types or Thicknesses

Not all clamps fit every window profile. Sourcing a clamp without verifying compatibility with the glass thickness, frame type (e.g., tilt-and-turn, double-hung), or glazing system can lead to improper installation or damage. Always provide window specifications to the supplier.

Absence of Certifications or Compliance

Using non-certified clamps may violate safety regulations or void insurance. Look for compliance with relevant standards (e.g., OSHA, EN 131 for ladders, IEC 60529 for IP ratings). Reputable suppliers should provide documentation upon request.

Overlooking Adjustability and Ease of Installation

Clamps with limited adjustability may not secure properly across different installations. Poor ergonomics or complex assembly can increase installation time and error risk. Opt for user-friendly designs with secure locking mechanisms.

Ignoring Long-Term Maintenance Requirements

Some clamps require periodic inspection or lubrication to maintain performance. Failing to account for maintenance needs can lead to unnoticed wear and unexpected failures. Choose designs that support easy inspection and servicing.

Logistics & Compliance Guide for Window Clamp

This guide outlines the essential logistics and compliance considerations for the distribution, import/export, and safe handling of Window Clamps. Adhering to these standards ensures regulatory compliance, product safety, and efficient supply chain operations.

Product Classification and HS Code

Window Clamps are typically classified under Harmonized System (HS) codes related to hardware, clamping devices, or mounting accessories. A common classification is 8302.41 or 8302.42 (Base metal mountings, fittings, and similar articles). Confirm the exact HS code based on material composition (e.g., steel, aluminum) and intended use to ensure accurate customs declarations and tariff application.

Packaging and Labeling Requirements

- Packaging: Use durable, moisture-resistant packaging to prevent damage during transit. Individual units should be protected from scratches or deformation; bulk shipments must be securely palletized and shrink-wrapped.

- Labeling: Each package must include:

- Product name and model number

- Quantity per package

- Manufacturer name and contact information

- Country of origin

- Safety warnings (e.g., “For indoor use only,” “Avoid over-tightening”)

- Compliance marks (e.g., CE, UKCA if applicable)

Shipping and Transportation

- Mode of Transport: Window Clamps can be shipped via air, sea, or ground freight. Choose method based on volume, urgency, and destination.

- Weight and Dimensions: Confirm net/gross weight and dimensional data for accurate freight classification and cost estimation.

- Hazardous Materials: Window Clamps are generally non-hazardous. However, packaging materials (e.g., certain plastics) must comply with IMDG/IATA regulations if shipped by air or sea.

Import/Export Documentation

Ensure the following documents are prepared for international trade:

– Commercial Invoice

– Packing List

– Bill of Lading or Air Waybill

– Certificate of Origin (if claiming preferential tariffs)

– Import License (if required by destination country)

– Customs Declaration Form

Regulatory Compliance

- CE Marking (EU): Required if the product is sold in the European Economic Area. Ensures conformity with health, safety, and environmental protection standards. Documentation must include a Declaration of Conformity and technical file.

- UKCA Marking (UK): Mandatory for products placed on the market in Great Britain. Follow UK regulations post-Brexit.

- REACH and RoHS Compliance: Window Clamps must comply with REACH (Registration, Evaluation, Authorisation and Restriction of Chemicals) and RoHS (Restriction of Hazardous Substances) if applicable, particularly regarding metal alloys and surface coatings.

- Product Safety Standards: Comply with relevant mechanical and load-bearing safety standards in the target market (e.g., EN standards in Europe).

Storage and Handling

- Store in a dry, well-ventilated area away from corrosive substances.

- Avoid exposure to extreme temperatures or direct sunlight.

- Use appropriate handling equipment (e.g., forklifts) when moving pallets to prevent injury and product damage.

End-of-Life and Environmental Considerations

- Window Clamps are typically recyclable due to their metal content. Provide disposal guidance on packaging or in product documentation.

- Comply with WEEE (Waste Electrical and Electronic Equipment) directives if the clamp includes electronic components (e.g., sensor-integrated models).

Quality Assurance and Traceability

- Implement batch or lot numbering for traceability.

- Maintain records of material sourcing, manufacturing dates, and compliance testing.

- Conduct periodic audits to ensure continued adherence to logistics and regulatory standards.

Following this guide ensures that Window Clamps are distributed efficiently and in full compliance with international and regional regulations.

Conclusion for Sourcing Window Clamp:

After a thorough evaluation of suppliers, product specifications, cost considerations, and quality standards, the sourcing strategy for window clamps has been finalized. The selected supplier offers a competitive balance of durability, compliance with industry standards, and cost-efficiency, ensuring reliable performance in various installation environments. Additionally, their consistent delivery timelines and responsive customer support contribute to long-term operational efficiency. This sourcing decision supports project requirements while allowing for scalability and future procurement needs. Ongoing performance monitoring and periodic reviews will ensure continued satisfaction and quality assurance.