The global spray paint market is experiencing robust growth, driven by rising demand across automotive refinishing, construction, industrial maintenance, and DIY sectors. According to Grand View Research, the global aerosol spray paint market size was valued at USD 9.8 billion in 2022 and is expected to expand at a compound annual growth rate (CAGR) of 4.7% from 2023 to 2030. This expansion is fueled by product innovations, increasing urbanization, and growing emphasis on protective and decorative coatings. Additionally, Mordor Intelligence projects steady growth in the wholesale segment, with manufacturers scaling production to meet regional and international demand. As the market becomes increasingly competitive, identifying reliable wholesale spray cans manufacturers has become critical for distributors, retailers, and industrial buyers aiming to balance quality, compliance, and cost-efficiency. Here are the top 9 wholesale spray cans manufacturers leading the industry through scale, innovation, and global reach.

Top 9 Wholesale Spray Cans Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Colours, Inc.

Domain Est. 1999

Website: gocolours.com

Key Highlights: Commercial & Industrial. We are dedicate to delivering top-tier PPG paint products and tailored solutions for truck, fleet, and industrial manufacturing….

#2 Professional Wholesale Spray Cans Manufacturer

Domain Est. 2024

Website: cnpancan.com

Key Highlights: Leading wholesale spray cans manufacturer offering custom aerosol containers with advanced technology, comprehensive quality assurance, and global supply ……

#3 Graco Inc.

Domain Est. 1994

Website: graco.com

Key Highlights: Graco designs and manufactures thousands of fluid handling products and solutions for the industries we pursue around the world….

#4 CRC Industries

Domain Est. 1996

Website: crcindustries.com

Key Highlights: CRC manufactures over 1300 chemical MRO products for Automotive, Marine, Mining, Oil & Gas, Hardware, Electrical, Industrial, Welding, and more markets….

#5 SEM Products

Domain Est. 1999

Website: semproducts.com

Key Highlights: SEM is a leading manufacturer of innovative paints, adhesives and coating products. Our products are developed to exceed your automotive, aerospace and ……

#6

Domain Est. 1991

Website: ball.com

Key Highlights: Aluminum aerosol can. Aerosol Cans. Ball’s aluminum aerosol cans boast high-definition designs and award-winning innovations for your brand to shine. Learn ……

#7 Wholesale Van Os Imports B.V.

Domain Est. 2000 | Founded: 1939

Website: vanosimports.com

Key Highlights: Welcome on the B2B Website of Wholesale Van Os Imports! We operate as a Wholesale in the Military & Outdoor Industry since 1939….

#8 Custom Spray Can Orders in Bulk with Color Matching

Domain Est. 2016

Website: strandsindustrialcoatings.com

Key Highlights: We’ll fill your solvent-based or water-based coatings into custom spray cans for same-day shipment on orders received before 10:00 AM….

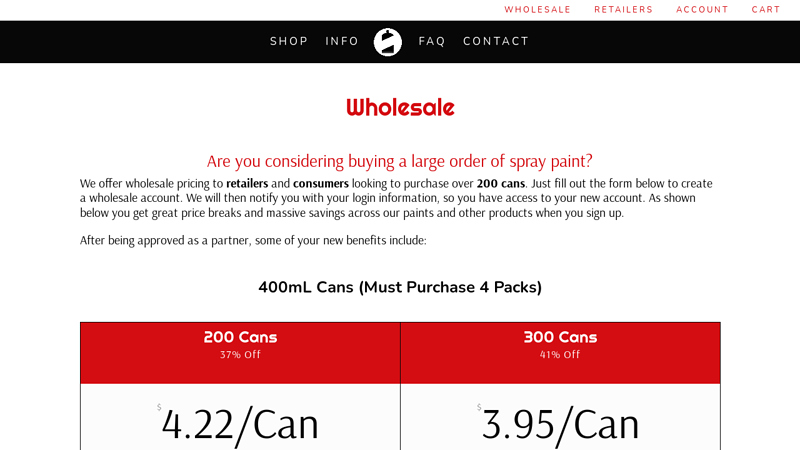

#9 Wholesale

Domain Est. 2021

Website: loopcolorsusa.com

Key Highlights: We offer wholesale pricing to retailers and consumers looking to purchase over 200 cans. Just fill out the form below to create a wholesale account….

Expert Sourcing Insights for Wholesale Spray Cans

H2: 2026 Market Trends for Wholesale Spray Cans

The wholesale spray cans market is poised for significant transformation by 2026, driven by technological innovation, sustainability mandates, and shifting consumer and industrial demands. Key trends shaping this sector include:

1. Rising Demand for Eco-Friendly and Sustainable Products

Environmental regulations and consumer awareness are pushing manufacturers and distributors to prioritize sustainable solutions. By 2026, spray cans made with recyclable materials, biodegradable propellants, and low volatile organic compound (VOC) formulations are expected to dominate the wholesale market. Governments in North America and Europe are enforcing stricter emissions standards, accelerating the shift toward green alternatives such as compressed air and hydrocarbon-based propellants over traditional chlorofluorocarbons (CFCs) and volatile solvents.

2. Growth in Industrial and DIY Applications

The construction, automotive, and do-it-yourself (DIY) sectors are major consumers of spray paint and specialty coating products. With increased infrastructure investments and a growing trend toward home improvement, especially in emerging economies, demand for wholesale spray cans is projected to climb. Specialty products such as heat-resistant coatings, anti-graffiti sprays, and rust inhibitors are seeing higher adoption, expanding the product portfolio available through wholesale channels.

3. Expansion of E-Commerce and Digital Distribution Platforms

Online B2B marketplaces are transforming the wholesale landscape. By 2026, digital platforms will play a crucial role in streamlining supply chains, offering bulk pricing, real-time inventory tracking, and faster delivery. Distributors who integrate e-commerce capabilities will gain competitive advantages through improved customer reach and operational efficiency. Additionally, data analytics will enable better demand forecasting and inventory management.

4. Regional Market Shifts and Emerging Economies

While North America and Europe remain strong markets due to regulatory frameworks and high consumption rates, Asia-Pacific—particularly China, India, and Southeast Asia—is expected to witness the fastest growth. Urbanization, rising disposable incomes, and expanding manufacturing bases are fueling demand for spray cans in industrial maintenance, automotive refinishing, and consumer goods. Localized production and distribution networks will become critical for cost-effective wholesale operations.

5. Innovation in Smart and Precision Spray Technologies

Technological advancements are leading to the development of precision spray cans with adjustable nozzles, smart triggers, and ergonomic designs. These innovations improve application accuracy and reduce waste, appealing to professional users in automotive, electronics, and aerospace sectors. Additionally, smart labeling with QR codes for product traceability and safety information is gaining traction, aligning with compliance and transparency requirements.

6. Supply Chain Resilience and Raw Material Volatility

The wholesale market remains sensitive to fluctuations in raw material prices, particularly aluminum and propellants. Geopolitical tensions and supply chain disruptions have highlighted the need for diversified sourcing and strategic inventory planning. By 2026, forward-thinking wholesalers will invest in resilient supply chains, including nearshoring and vertical integration, to mitigate risks and ensure consistent product availability.

In conclusion, the 2026 wholesale spray cans market will be defined by sustainability, digital transformation, and regional diversification. Companies that proactively adapt to environmental standards, embrace e-commerce, and innovate in product design will be best positioned to capture growth in this evolving industry.

Common Pitfalls When Sourcing Wholesale Spray Cans (Quality & Intellectual Property)

Sourcing wholesale spray cans can offer significant cost savings and supply chain advantages, but it also comes with notable risks—particularly concerning product quality and intellectual property (IP) protection. Avoiding these common pitfalls is essential for maintaining brand integrity, ensuring customer safety, and avoiding legal complications.

Poor Product Quality and Inconsistent Manufacturing

One of the most frequent challenges when sourcing spray cans wholesale is inconsistent or subpar product quality. Many suppliers, especially those from low-cost manufacturing regions, may cut corners to reduce prices. This can result in issues such as:

- Leaking or bursting cans due to poor canister construction or over-pressurization.

- Inconsistent spray patterns or clogging nozzles from low-quality valves or propellants.

- Faded or inaccurate colors caused by pigment instability or improper mixing.

- Short shelf life due to inadequate formulation or contamination.

These quality issues not only lead to customer dissatisfaction but can also pose safety hazards and result in product recalls or liability claims.

Lack of Regulatory Compliance

Spray cans are subject to strict international regulations regarding pressure vessels, chemical composition, labeling, and environmental standards (e.g., VOC limits, aerosol directives in the EU, OSHA and EPA standards in the US). Sourcing from non-compliant manufacturers can result in:

- Customs delays or shipment rejections.

- Fines or legal action due to unsafe or non-compliant products.

- Damage to brand reputation if products are deemed hazardous.

Always verify that your supplier adheres to relevant safety and environmental regulations and can provide necessary certifications (e.g., MSDS, TSCA, REACH, CPR).

Intellectual Property Infringement Risks

When sourcing spray cans—particularly those with branded formulations, unique color names, or proprietary designs—there’s a significant risk of IP violations. Common issues include:

- Counterfeit or imitation products that mimic well-known brands without authorization.

- Unauthorized use of patented formulations or technologies, such as specialty finishes (e.g., textured, heat-reactive).

- Copying of color names or packaging designs, which may infringe on trademarks or trade dress rights.

Using such products, even unknowingly, can expose your business to lawsuits, cease-and-desist orders, or seizure of inventory by customs authorities.

Inadequate Supplier Vetting and Transparency

Many buyers fall into the trap of selecting suppliers based solely on price or impressive online profiles without proper due diligence. Red flags include:

- Unwillingness to provide factory audits or third-party testing reports.

- Vague or missing information about raw material sources and manufacturing processes.

- No clear contracts protecting your IP or defining quality standards.

Always conduct background checks, request product samples, and consider third-party inspections before placing large orders.

Failure to Secure IP Ownership in Custom Formulations

If you’re developing custom colors, scents, or functional coatings, it’s critical to ensure that your contract with the manufacturer explicitly states that you own the IP or have exclusive rights to the formulation. Without this, the supplier may:

- Replicate and sell your product to competitors.

- Claim co-ownership or refuse to modify the formula later.

Use legally binding agreements that cover confidentiality, IP assignment, and non-compete clauses.

By understanding and proactively addressing these pitfalls, businesses can safeguard their supply chain, protect their brand, and ensure the delivery of high-quality, legally compliant spray can products.

Logistics & Compliance Guide for Wholesale Spray Cans

Overview of Spray Can Regulations

Spray cans are classified as hazardous materials (dangerous goods) due to their pressurized contents and flammable or potentially toxic propellants. This classification triggers strict regulatory requirements for storage, transport, labeling, and handling. Compliance is mandatory under international, national, and regional regulations, including those set by the International Air Transport Association (IATA), International Maritime Organization (IMO), Department of Transportation (DOT), and Occupational Safety and Health Administration (OSHA). Failure to comply can result in fines, shipment delays, safety incidents, and legal liability.

Classification and Hazard Identification

Spray cans typically fall under Hazard Class 2 (Gases) or Class 3 (Flammable Liquids) in the United Nations (UN) Dangerous Goods classification system. The specific classification depends on the product’s flashpoint, pressure, and chemical composition. Most aerosol products are categorized as UN 1950, Aerosols. Accurate classification requires reviewing Safety Data Sheets (SDS) and conducting necessary testing. Misclassification can lead to non-compliant packaging and transportation, posing safety risks and regulatory penalties.

Packaging and Labeling Requirements

Wholesale spray can shipments must use UN-certified packaging designed to withstand pressure and prevent leakage. Packaging must pass performance tests (e.g., drop, leakproofness). Each package must display proper hazard labels, including the Class 2 or Class 3 diamond label, UN number (e.g., UN 1950), proper shipping name, and orientation arrows. Labels must be durable and clearly visible. Inner packaging should prevent movement during transit, often using dividers or trays. Overpacks must also be marked appropriately.

Transportation Regulations by Mode

Transport regulations vary by shipping method:

– Air Freight (IATA DGR): Strict limits on quantity per package and aircraft type. Most passenger aircraft prohibit large shipments of aerosols. Shipments require detailed Shipper’s Declaration for Dangerous Goods.

– Ocean Freight (IMDG Code): Requires stowage and segregation based on hazard class. Placarding and documentation must comply with vessel safety plans.

– Ground Transport (DOT 49 CFR in the U.S.): Requires placarded vehicles for large quantities. Drivers must have appropriate training and documentation. State-specific rules may also apply.

Storage and Warehouse Compliance

Stored spray cans must be kept in well-ventilated, temperature-controlled areas away from ignition sources and direct sunlight. Storage facilities should comply with NFPA 30 and local fire codes. Flammable liquid storage cabinets or dedicated hazardous storage rooms may be required based on quantity. Segregation from incompatible materials (e.g., oxidizers) is essential. Secondary containment and spill control measures should be in place. Fire suppression systems and clear signage are mandatory.

Safety Data Sheets (SDS) and Documentation

A current 16-section SDS must accompany every wholesale shipment and be accessible to handlers, emergency responders, and customers. The SDS provides critical information on composition, hazards, first aid, firefighting measures, and safe handling. Additional documentation includes shipping manifests, declarations of hazardous goods, and compliance certificates. Records must be retained for at least three years.

Training and Personnel Requirements

All personnel involved in handling, packaging, or transporting spray cans must receive hazardous materials training per regulatory standards (e.g., DOT HAZMAT, IATA, ADR). Training must be refreshed every 1–3 years, depending on jurisdiction. Employees should be trained in emergency response, spill containment, proper use of PPE, and incident reporting procedures. Documentation of training completion is required.

International Shipping Considerations

Exporting spray cans requires compliance with destination country regulations, which may differ from U.S. or EU standards. Customs documentation must include accurate HS codes, product descriptions, and safety certifications. Some countries restrict or ban certain propellants (e.g., hydrocarbons). Language-specific labeling and SDS may be required. Use of a certified customs broker experienced in hazardous goods is recommended.

Environmental and Disposal Compliance

Empty or damaged spray cans are still considered hazardous waste until properly depressurized and recycled. Disposal must comply with EPA regulations (e.g., RCRA) and local waste management laws. Partner with licensed hazardous waste disposal providers. Consider sustainability by sourcing recyclable packaging and promoting refillable or eco-friendly alternatives where possible.

Risk Mitigation and Best Practices

- Conduct regular audits of packaging, labeling, and storage procedures.

- Use certified suppliers and carriers with hazardous goods experience.

- Implement a robust incident response plan, including spill kits and evacuation procedures.

- Maintain insurance coverage specific to hazardous materials transport and storage.

- Stay updated on regulatory changes through industry associations and government alerts.

In conclusion, sourcing wholesale spray cans requires careful consideration of several key factors to ensure quality, cost-efficiency, and reliability. By identifying reputable suppliers, comparing product specifications, and evaluating pricing and minimum order quantities, businesses can secure a steady supply of high-quality spray cans at competitive prices. Additionally, considering aspects such as shipping logistics, customization options, and compliance with safety and environmental regulations is essential for long-term success. Establishing strong relationships with dependable wholesalers not only enhances operational efficiency but also supports scalability and market competitiveness. Ultimately, a strategic and well-researched approach to sourcing wholesale spray cans lays the foundation for sustainable growth and customer satisfaction in industries ranging from automotive and construction to art and manufacturing.