The global fiber laser marking machine market is experiencing robust growth, driven by increasing demand for precision labeling and traceability across industries such as automotive, electronics, medical devices, and consumer goods. According to Mordor Intelligence, the global laser marking machines market was valued at USD 1.45 billion in 2023 and is projected to reach USD 2.23 billion by 2029, growing at a CAGR of approximately 7.5% during the forecast period. This expansion is fueled by the superior performance of fiber lasers—including longer lifespans, lower maintenance costs, and higher efficiency compared to traditional marking technologies. As industries prioritize automation and permanent product identification, the demand for reliable wholesale fiber laser marking solutions has surged. In response, a competitive ecosystem of manufacturers has emerged, particularly concentrated in China, Germany, and the United States, offering scalable systems tailored for high-volume production environments. The following list highlights the top 10 wholesale fiber laser marking machine manufacturers leading innovation, quality, and market share in this rapidly evolving industry.

Top 10 Wholesale Fiber Laser Marking Machine Manufacturers (2026 Audit Report)

(Ranked by Factory Capability & Trust Score)

#1 Wholesale Fiber Laser Marking Machine Manufacturer and Supplier …

Website: feeltek.net

Key Highlights: We unleash the technology in multiple 3D laser processing industries, such as 3D laser marking, engraving, laser welding, drilling, additive manufacturing, ……

#2 Fiber Laser Engraving Machine

Website: haotianlasers.com

Key Highlights: As a leading manufacturer, not a reseller, we specialize in crafting high-quality CO2 laser engraving machines, UV laser marking machines, and fiber laser ……

#3 Laserax

Website: laserax.com

Key Highlights: Laserax works with the world’s leading manufacturers to implement laser cleaning, welding, texturing, and marking solutions….

#4 China Wholesale Fiber Laser Marking Machines manufacturers …

Website: suntoplaser.com

Key Highlights: Suntop is a leading China Wholesale Fiber Laser Marking Machines manufacturer, supplier and exporter. Adhering to the pursuit of perfect quality of products ……

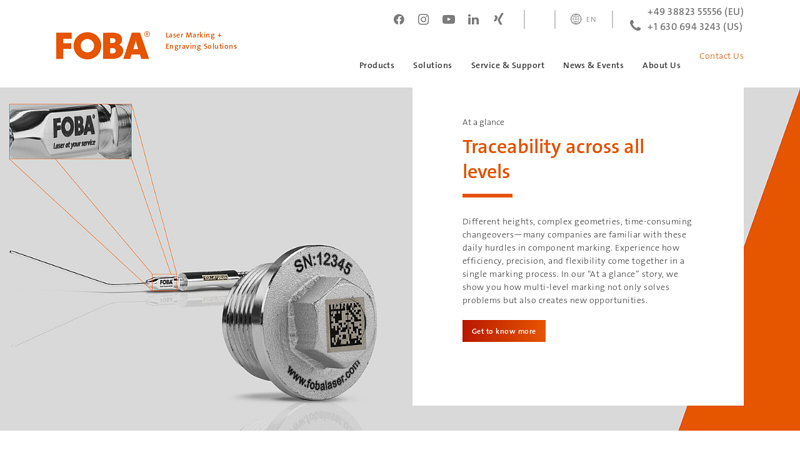

#5 Experts in Industrial Laser Marking + Engraving

Website: fobalaser.com

Key Highlights: For five decades, we have been writing with light, developing and manufacturing leading laser marking solutions for direct part and product marking….

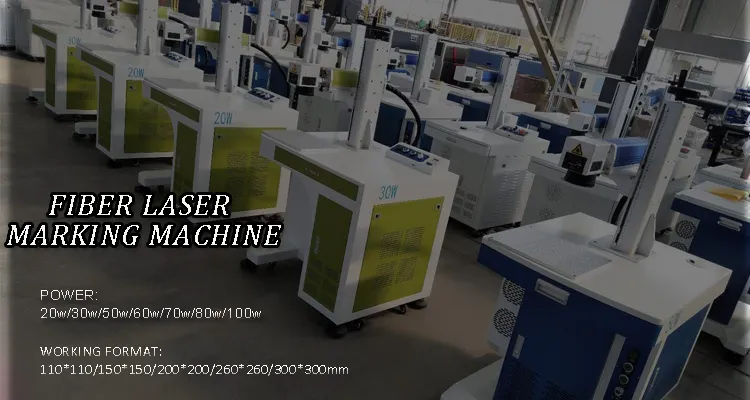

#6 Factory wholesale Raycus Fiber Laser Marking Machine

Website: beclaser.com

Key Highlights: This machine is a fiber laser marking machine with high photoelectric conversion rate, good laser beam quality, long life, maintenance-free within 100,000 hours ……

#7 Fiber Laser Marking Machines

Website: acctekgroup.com

Key Highlights: AccTek Group’s fiber laser marking machines feature long service life, stable performance, and advanced control systems for easy operation and customization….

#8 Fiber laser marking machine

Website: pengwocnclaser.com

Key Highlights: The working principle of the laser coding machine is to gather the laser at a very high energy density on the surface of the object to be engraved….

#9 Handheld High Precision Fiber Laser Marking Machine

Website: riselaser.com

Key Highlights: Handheld High Precision Fiber Laser Marking Machine. Riselaser is a full service marking laser company,with nearly 10 years of experience as an industry pioneer ……

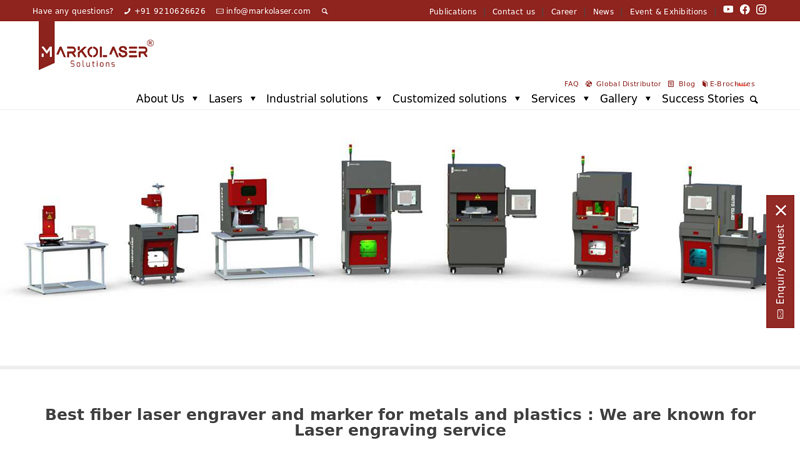

#10 Best fiber laser engraver and marker for metals and plastics

Website: markolaser.com

Key Highlights: We are a global supplier of laser marking, laser engraving machines for metal. We make Best fiber laser engraver and marker for plastics, pp, abs, nylon 66, ……

Expert Sourcing Insights for Wholesale Fiber Laser Marking Machine

H2: 2026 Market Trends for Wholesale Fiber Laser Marking Machines

The wholesale market for fiber laser marking machines is poised for significant transformation by 2026, driven by technological advancements, rising industrial automation, and expanding applications across diverse sectors. As global manufacturing continues to prioritize precision, efficiency, and traceability, fiber laser marking systems are becoming indispensable tools in production lines. This analysis explores the key trends shaping the wholesale landscape of fiber laser marking machines in 2026.

1. Increased Demand from Automotive and Electronics Industries

The automotive and electronics sectors are expected to be primary growth drivers. In automotive manufacturing, the need for permanent part traceability—driven by regulatory compliance and quality control—fuels demand for high-speed, durable marking solutions. Similarly, the electronics industry relies on fiber laser systems to mark serial numbers, barcodes, and logos on delicate components without causing thermal damage. As production volumes rise, especially in emerging markets, bulk procurement of reliable and scalable laser marking systems will boost wholesale activity.

2. Technological Advancements Enhancing Performance and Accessibility

By 2026, fiber laser technology will see notable improvements in power efficiency, beam quality, and software integration. Innovations such as AI-powered marking control systems, real-time monitoring, and IoT-enabled remote diagnostics will enhance machine usability and reduce downtime. These advancements are lowering total cost of ownership, making high-performance systems more accessible to small and medium-sized enterprises (SMEs), thereby expanding the wholesale customer base.

3. Rise of Customization and Smart Manufacturing Integration

With the global shift toward Industry 4.0, fiber laser marking machines are increasingly integrated into smart factory ecosystems. Wholesalers are responding to demand for customizable, network-compatible machines that can interface with MES (Manufacturing Execution Systems) and ERP platforms. This trend favors modular designs and scalable solutions that support serialization, product tracking, and digital twin technologies, increasing the appeal of bulk purchases for large-scale industrial deployments.

4. Growth in Asia-Pacific and Emerging Markets

The Asia-Pacific region, particularly China, India, and Southeast Asia, will dominate wholesale demand due to rapid industrialization and government initiatives promoting manufacturing self-reliance. Local production hubs for electronics, medical devices, and consumer goods are investing heavily in automation, creating strong demand for cost-effective fiber laser marking systems. Wholesalers are adapting by establishing regional distribution networks and offering localized technical support.

5. Competitive Pricing and Market Consolidation

As the number of manufacturers—especially in China—increases, competition is intensifying. This has led to aggressive pricing strategies and a focus on value-added services such as training, installation, and maintenance. Market consolidation is expected, with larger players acquiring smaller brands or forming strategic alliances to expand their wholesale reach. This dynamic benefits end buyers through lower prices and broader product availability.

6. Sustainability and Energy Efficiency as Differentiators

Environmental regulations and corporate sustainability goals are influencing purchasing decisions. Fiber lasers are inherently more energy-efficient than traditional marking methods, and newer models in 2026 will emphasize low power consumption, longer lifespans, and recyclable components. Wholesalers are highlighting these eco-friendly attributes to appeal to environmentally conscious industrial clients.

7. Expansion of Applications in Medical and Aerospace Sectors

Stringent traceability requirements in medical device manufacturing and aerospace components are opening new avenues for fiber laser adoption. These industries require high-precision, non-contact marking on metals and composites, where fiber lasers excel. The need for UDI (Unique Device Identification) compliance in healthcare is particularly driving demand, prompting wholesalers to offer specialized high-resolution systems.

In conclusion, the 2026 wholesale market for fiber laser marking machines will be shaped by technological innovation, industry-specific demands, and global manufacturing trends. Wholesalers who adapt to these dynamics—by offering integrated, scalable, and sustainable solutions—will be well-positioned to capitalize on expanding opportunities across multiple high-growth sectors.

Common Pitfalls When Sourcing Wholesale Fiber Laser Marking Machines (Quality & IP)

Sourcing wholesale fiber laser marking machines can offer significant cost advantages, but it also comes with notable risks—especially concerning product quality and intellectual property (IP) issues. Being aware of these pitfalls helps buyers make informed decisions and avoid costly mistakes.

Poor Build Quality and Component Selection

Many low-cost wholesale machines use substandard materials and components to reduce manufacturing costs. This includes inferior laser sources, optics, cooling systems, and control electronics. Machines built with poor-quality parts often suffer from inconsistent marking results, frequent breakdowns, and shorter lifespans, leading to higher total cost of ownership despite the lower initial price.

Inaccurate or Misleading Specifications

Suppliers may exaggerate key performance metrics such as laser power output, marking speed, or beam quality. For example, a machine advertised as a “50W fiber laser” might deliver significantly less actual power due to inefficient components or power throttling. Always request third-party test reports or verify specifications through independent testing before bulk purchases.

Lack of Quality Control and Certification

Reputable manufacturers implement strict quality control processes and hold certifications such as ISO 9001, CE, or FDA compliance. Many wholesale suppliers, particularly from less-regulated markets, skip these steps. Without proper quality assurance, each unit in a wholesale batch may vary in performance and reliability, making integration into production lines unpredictable.

Intellectual Property Infringement Risks

Some wholesale machines are unauthorized copies or clones of patented designs and technologies. Using such equipment could expose your business to legal liability, especially in regions with strong IP enforcement (e.g., the U.S. or EU). Infringing machines may also lack software updates, technical documentation, or long-term support due to their illicit origin.

Inadequate Technical Support and Software Limitations

Wholesale suppliers often provide minimal after-sales support. This includes limited access to firmware updates, technical troubleshooting, or spare parts. Additionally, cloned or reverse-engineered control software may lack customization features, have bugs, or be incompatible with industry-standard file formats, reducing operational efficiency.

Hidden Costs from Downtime and Maintenance

While the upfront cost may be low, poor-quality machines require frequent maintenance and repairs. Unplanned downtime disrupts production and increases labor costs. Without reliable spare parts supply chains, sourcing replacements can take weeks, further impacting return on investment.

Non-Compliance with Regional Safety and Regulatory Standards

Many wholesale lasers fail to meet international safety standards (e.g., IEC 60825 for laser safety). Importing or operating non-compliant equipment can lead to fines, shipment rejections, or workplace safety violations. Always verify that the machine meets the regulatory requirements of your target market.

Conclusion

To avoid these pitfalls, conduct thorough due diligence: request factory audits, demand sample testing, verify IP rights, and confirm compliance certifications. Partnering with transparent, reputable suppliers—even at a slightly higher cost—ensures long-term reliability, legal safety, and better overall value.

Logistics & Compliance Guide for Wholesale Fiber Laser Marking Machine

This guide outlines key logistics and compliance considerations when sourcing and distributing fiber laser marking machines in wholesale quantities. Adhering to these guidelines ensures smooth operations, legal compliance, and customer satisfaction.

Shipping and Handling

Fiber laser marking machines are precision industrial equipment that require careful handling during transport. Use sturdy, custom-fitted packaging with shock-absorbing materials to protect sensitive components. Clearly label packages as fragile and include orientation arrows. Choose reputable freight carriers experienced in handling heavy machinery. For international shipments, ensure compliance with Incoterms (e.g., FOB, CIF) to define responsibilities between buyer and seller. Consider using insured freight services to mitigate risk of damage or loss.

Import and Export Regulations

Compliance with international trade laws is essential. Verify the correct Harmonized System (HS) code for fiber laser marking machines—typically under 8456.30 or similar, depending on specifications. Obtain necessary export licenses if required by the country of origin, especially for high-power laser systems. Importers must comply with destination country regulations, including customs declarations, import duties, and value-added taxes (VAT). Maintain accurate commercial invoices, packing lists, and certificates of origin to facilitate customs clearance.

Safety and Laser Classification

Fiber laser marking machines fall under laser safety standards such as IEC 60825-1. Ensure all units are classified correctly (typically Class 1 or Class 4 depending on enclosure and operation) and labeled accordingly. Machines must include appropriate safety features, including emergency stop buttons, interlocks, and protective housings. Provide users with comprehensive safety instructions and training materials. In the U.S., compliance with the FDA/CDRH regulations for laser products (21 CFR 1040.10 and 1040.11) is mandatory for import and sale.

Electromagnetic Compatibility (EMC)

Laser marking machines must meet electromagnetic compatibility standards to prevent interference with other electronic devices. Confirm compliance with relevant directives such as the EU’s EMC Directive 2014/30/EU or the FCC Part 15 regulations in the United States. Machines should undergo EMC testing and carry the appropriate certification marks (e.g., CE, FCC) before distribution.

Product Certification and Standards

Ensure machines comply with regional safety and quality standards:

– CE Marking: Required for sale in the European Economic Area, indicating conformity with health, safety, and environmental protection standards.

– RoHS Compliance: Restricts the use of hazardous substances in electrical and electronic equipment (EU Directive 2011/65/EU).

– REACH: Regulates chemical substances and may apply to components used in machine construction.

– UL/CSA Certification: Recommended or required for the North American market to demonstrate electrical safety.

Documentation and Labeling

Provide complete technical documentation, including user manuals, maintenance guides, and EC Declaration of Conformity (for CE-marked products). Labels on the machine must include:

– Manufacturer name and address

– Model and serial number

– Electrical specifications (voltage, current, frequency)

– Laser classification and warning symbols

– CE, FCC, or other applicable certification marks

Warranty and After-Sales Support

Establish clear warranty terms (typically 12–24 months) covering parts and labor. Define procedures for handling returns, repairs, and technical support. For international wholesale customers, consider partnerships with local service providers to ensure timely maintenance and troubleshooting. Maintain inventory of critical spare parts to minimize downtime for end users.

Environmental and Disposal Compliance

Inform customers about proper end-of-life disposal procedures. Laser marking machines contain electronic components and optical parts that may be subject to WEEE (Waste Electrical and Electronic Equipment) Directive requirements in the EU. Offer take-back programs or guidance on recycling to support environmental compliance.

By following this logistics and compliance guide, wholesale distributors can ensure legal operation, enhance product reliability, and build trust with business customers globally.

Conclusion: Sourcing a Wholesale Fiber Laser Marking Machine

Sourcing a wholesale fiber laser marking machine is a strategic decision that can significantly enhance production efficiency, product traceability, and brand value for businesses in industries such as manufacturing, automotive, electronics, and medical devices. When sourcing in bulk, it’s essential to partner with reliable suppliers who offer high-quality, durable machines backed by technical support and service.

Key factors to consider include machine specifications (laser power, marking speed, precision), software compatibility, warranty, customer service, and certification standards (such as CE, FDA). Purchasing wholesale provides cost advantages, making it ideal for resellers, integrators, or large-scale operations aiming to reduce per-unit investment.

By conducting thorough market research, comparing quotes, and possibly visiting manufacturers—especially in hubs like China—buyers can secure competitive pricing without compromising on quality. Ultimately, investing in wholesale fiber laser marking machines not only reduces operational costs but also future-proofs manufacturing processes with scalable, automation-ready technology. With the right due diligence, this investment delivers a strong return through improved marking accuracy, longevity, and versatility across diverse materials.