The global chain link fencing market has experienced steady growth driven by rising demand in construction, infrastructure development, and agricultural sectors. According to Mordor Intelligence, the chain link fencing market was valued at approximately USD 6.8 billion in 2023 and is projected to grow at a CAGR of over 5.2% from 2024 to 2029. This expansion is fueled by increased urbanization, government investments in public infrastructure, and the need for durable, cost-effective perimeter security solutions across commercial and industrial applications. As demand rises, the role of wholesale manufacturers becomes increasingly critical in ensuring scalable supply, quality consistency, and competitive pricing. Below, we highlight the top 10 wholesale chain link supply manufacturers that are leading the market through innovation, production capacity, and global distribution networks.

Top 10 Wholesale Chain Link Supply Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Master Halco

Domain Est. 1996

Website: masterhalco.com

Key Highlights: Find all your fencing and decking supplies at Master Halco, your local manufacturer and wholesale distributor of chain link, decking, vinyl, ag, wood,…

#2 ChainlinkFence.com Chain link Fence, Nationwide Supplier …

Domain Est. 1997

Website: chainlinkfence.com

Key Highlights: Manufacturer and Wholesale Prices Materials Supply Company for Chain Link Fence, Vinyl , Aluminum, Ornamental, and Cedar Wood Fences. We ship NATIONWIDE…

#3 Eastern Chain

Domain Est. 2016

Website: easternchainlinkfence.com

Key Highlights: Eastern Chain-Link Fence is backed by over 50 years experience in the fence business as a manufacturer and distributor….

#4 Chain Link Fence

Domain Est. 1996

#5 American Fence and Supply

Domain Est. 1997

Website: afence.com

Key Highlights: We specialize in a wide variety of fencing products, including chain-link, split rail, vinyl rail, electric, ornamental, wood, and farm and ranch fencing. Our ……

#6 SPSFence.com

Domain Est. 2001

Website: spsfence.com

Key Highlights: CHAIN LINK · ORNAMENTAL · SQUARE TUBE · HARDWARE · ACCESS CONTROL · ALUM CHAIN LINK · GATES · ALUMINUM GATES · PVC · KENNELS · WOOD · REINFORCEMENT · TEMP PANEL….

#7 Atlantic Fence Supply

Domain Est. 2001

Website: afsfence.com

Key Highlights: Broad range of fencing from wood to vinyl and chain link supplies. We also distribute fence accessories, railings, gates, kennels and hardware….

#8 FENCE

Domain Est. 2008

Website: fence-material.com

Key Highlights: Easy to Order Wholesale Chain link Fence Materials online – Leading Nationwide Supplier – Chain link Fencing, Fence Parts, Commercial and Residential, Wholesale…

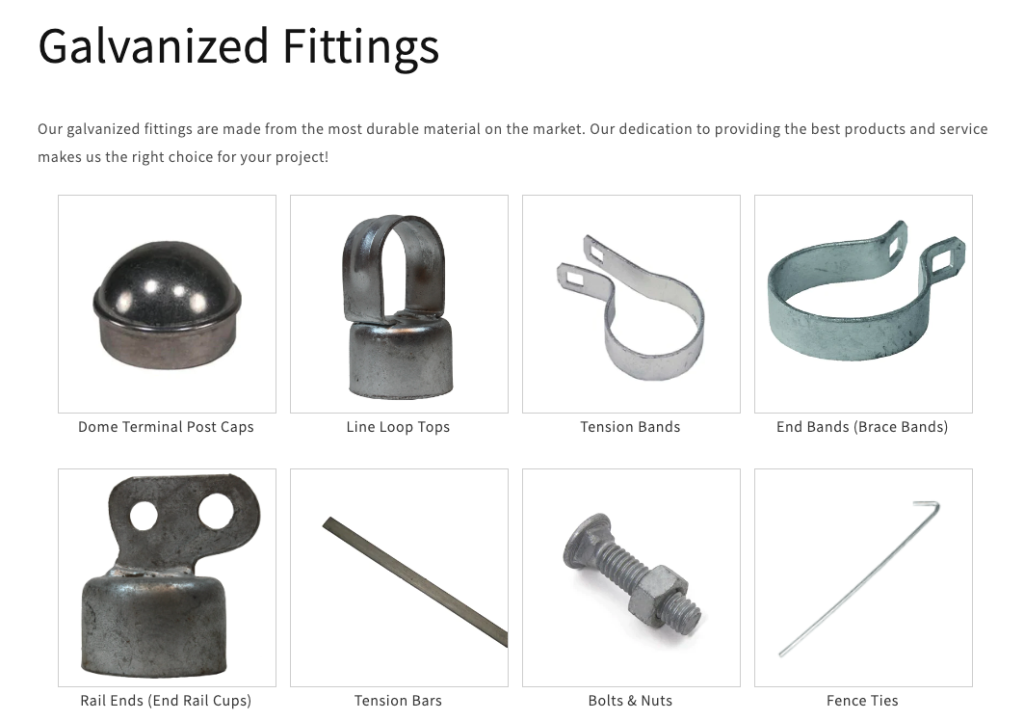

#9 Chain Link Fittings and Parts

Domain Est. 2008

Website: fencesupplyco.com

Key Highlights: 4-day deliveryFence fittings, parts, accessories, and related metal fencing items. These include -brace bands & tension bands, fence ties, post caps, hinges, fork latches ……

#10 Residential Chain Link Fence Supplies

Domain Est. 2009

Website: americasfencestore.com

Key Highlights: Free delivery over $499 30-day returnsFind all the residential chain link fence parts and supplies for the fence in your yard, or buy an entirely new chain link fence at America’s …

Expert Sourcing Insights for Wholesale Chain Link Supply

H2: 2026 Market Trends for Wholesale Chain Link Supply

The wholesale chain link supply market in 2026 is poised for steady growth, driven by infrastructure development, security demands, and evolving material technologies. While facing challenges like raw material volatility and labor constraints, the sector is adapting through innovation and strategic positioning. Here are the key trends shaping the industry:

1. Sustained Demand from Infrastructure and Construction: Government investments in transportation, public utilities, and urban development—particularly in emerging economies and North America—will continue to drive demand for chain link fencing. Projects such as highway expansions, rail corridors, and public facility upgrades require large volumes of durable, cost-effective perimeter solutions. Additionally, the residential and commercial construction rebound in key markets will support steady procurement by contractors and distributors.

2. Rising Emphasis on Security and Perimeter Protection: Heightened concerns around public safety, asset protection, and border security are increasing demand for robust fencing solutions. Chain link remains a preferred option due to its visibility, durability, and adaptability (e.g., integration with barbed wire or anti-climb features). Municipalities, industrial facilities, and schools are expected to prioritize secure perimeters, boosting wholesale orders.

3. Price Volatility and Supply Chain Resilience: The market will remain sensitive to fluctuations in steel prices, influenced by global trade policies, energy costs, and geopolitical tensions. In 2026, suppliers are likely to adopt hedging strategies, long-term supplier contracts, and regional sourcing to mitigate risks. Diversification of supply chains—away from over-reliance on single geographic sources—will be a key trend to ensure consistent delivery and cost stability.

4. Growth in Coated and Specialty Chain Link Products: Demand for corrosion-resistant chain link—especially PVC-coated and galvanized variants—will rise due to longer lifespans and low maintenance requirements. Coastal regions, high-moisture environments, and aesthetic-sensitive applications (e.g., schools, parks) are driving this shift. Additionally, specialty products like high-tensile chain link and anti-climb designs will gain traction in high-security sectors.

5. Sustainability and Recyclability as Competitive Advantages: With increasing environmental regulations and corporate sustainability goals, the recyclability of steel-based chain link will be a selling point. Wholesalers are expected to highlight eco-friendly attributes and explore energy-efficient manufacturing processes. Some suppliers may introduce recycled-content chain link to meet green procurement standards.

6. Digitalization and B2B E-Commerce Expansion: Wholesale distribution is shifting toward digital platforms. By 2026, more chain link suppliers will offer online catalogs, real-time inventory tracking, and streamlined ordering systems. Integration with construction management software and ERP systems will enhance efficiency for contractors and large buyers, improving order accuracy and fulfillment speed.

7. Regional Market Divergence: Growth will vary by region. North America and parts of Latin America are expected to see strong demand due to infrastructure stimulus. Asia-Pacific will remain a major production hub, but rising domestic consumption may reduce export availability. Europe may experience moderate growth, tempered by regulatory constraints and competition from alternative materials.

Conclusion:

The 2026 wholesale chain link supply market will be characterized by resilient demand, innovation in product offerings, and a focus on supply chain agility. Success will depend on suppliers’ ability to manage input costs, deliver value-added solutions, and leverage digital tools to serve a competitive and evolving customer base. Wholesalers who prioritize reliability, sustainability, and customer service will be best positioned to capture market share.

Common Pitfalls When Sourcing Wholesale Chain Link Supply (Quality, IP)

Sourcing wholesale chain link fencing can offer significant cost savings, but buyers often encounter critical pitfalls—particularly in quality and intellectual property (IP)—that can lead to project delays, safety issues, or legal complications. Being aware of these risks helps ensure a successful procurement process.

Quality-Related Pitfalls

Inconsistent Material Composition

One of the most common quality issues is inconsistent or substandard material composition. Some suppliers may use lower-grade steel or reduce zinc content in galvanization to cut costs. This leads to premature rusting, reduced structural integrity, and shorter lifespan—especially in harsh environments.

Poor Galvanization and Coating Standards

Chain link fencing relies heavily on protective coatings like hot-dip galvanizing or PVC coating. Poor application or non-compliance with ASTM A641 or A90 standards results in peeling, flaking, or inadequate corrosion resistance. Buyers may receive products that degrade quickly, leading to increased maintenance and replacement costs.

Inaccurate Mesh and Wire Gauge

Suppliers may misrepresent wire gauge (thickness) or mesh size. Thinner wire than specified compromises strength and security, while inconsistent mesh dimensions affect aesthetics and installation compatibility. These discrepancies are often discovered only after delivery, causing project disruptions.

Lack of Quality Control and Testing Documentation

Wholesale suppliers, especially overseas manufacturers, may lack rigorous quality control processes. Absence of mill test reports, third-party certifications (e.g., ISO, ASTM), or batch traceability makes it difficult to verify quality claims and increases the risk of receiving defective products.

Inadequate Packaging and Shipping Damage

Poor packaging—such as insufficient bundling or lack of moisture protection—can lead to kinks, bending, or corrosion during transit. This not only affects the usability of the product but also increases labor costs for sorting and discarding damaged sections.

Intellectual Property (IP) Pitfalls

Use of Counterfeit or Replica Designs

Some suppliers manufacture chain link products that mimic patented designs or branded components (e.g., proprietary tension bars, top rail fittings). Using such products can expose the buyer to legal liability, especially in commercial or government projects where IP compliance is strictly enforced.

Infringement of Patented Fittings and Accessories

While the basic chain link design is generic, many innovative fittings, tensioning devices, and anti-climb features are protected by patents. Sourcing from suppliers who replicate these without licensing can lead to cease-and-desist orders, shipment seizures, or lawsuits—particularly in IP-sensitive markets like the U.S. or EU.

Lack of Supplier Transparency on IP Compliance

Many wholesale suppliers do not disclose whether their products infringe on existing patents. Buyers who assume “generic” means “non-infringing” may unknowingly purchase IP-violating products. This risk is heightened when sourcing through intermediaries or online B2B platforms with limited oversight.

Branding and Trademark Misuse

Some suppliers falsely label products with well-known brand names (e.g., “equivalent to XYZ brand”) or use logos without authorization. This not only constitutes trademark infringement but can mislead buyers into believing they are purchasing certified, high-quality goods.

Mitigation Strategies

- Verify certifications (ASTM, ISO) and request material test reports.

- Conduct factory audits or use third-party inspection services.

- Review patent databases for key components and ask suppliers for IP indemnification.

- Use clear contracts specifying quality standards, inspection rights, and IP warranties.

- Work with reputable suppliers who have a track record and legal compliance history.

Avoiding these pitfalls requires due diligence, clear specifications, and proactive risk management throughout the sourcing process.

Logistics & Compliance Guide for Wholesale Chain Link Supply

This guide outlines essential logistics and compliance considerations for businesses engaged in the wholesale distribution of chain link products—such as chain link fencing, posts, hardware, and accessories. Adhering to these practices ensures efficient operations, regulatory compliance, and customer satisfaction.

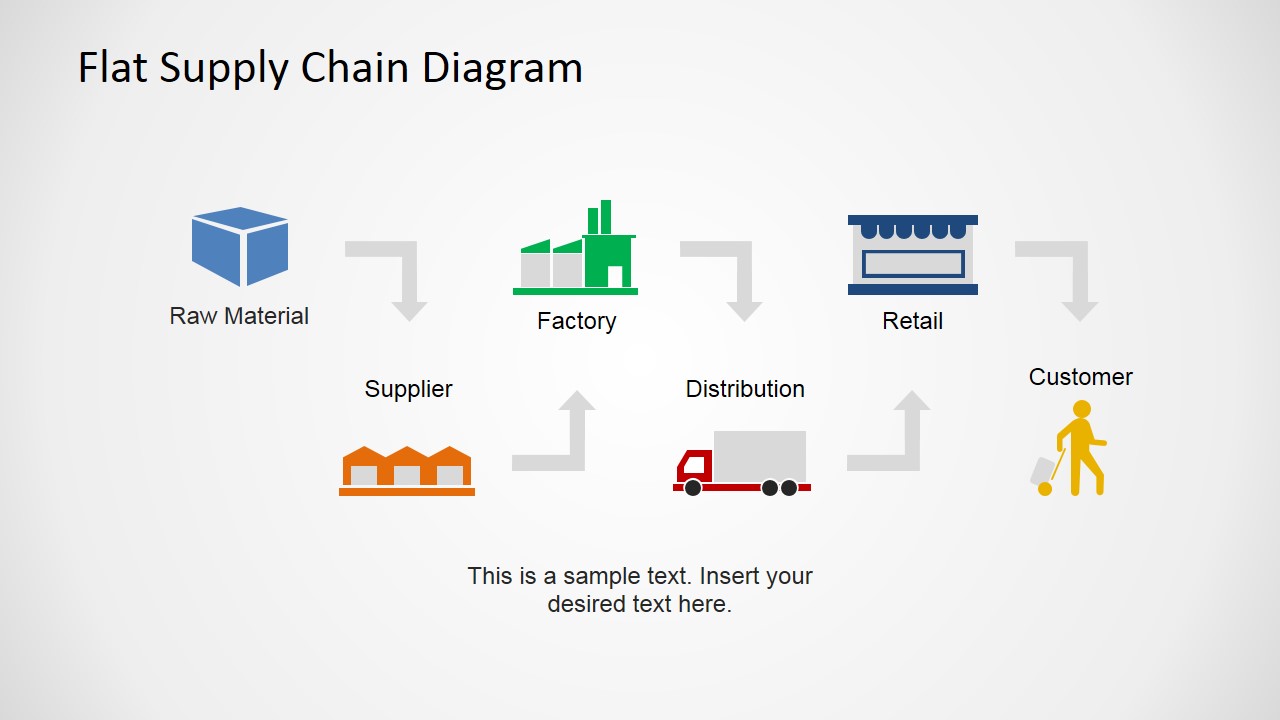

Supply Chain Sourcing & Procurement

Establish reliable sourcing channels from certified manufacturers or distributors. Verify that suppliers comply with international and local standards (e.g., ASTM, ISO) and provide material test reports where applicable. Maintain multiple supply sources to mitigate supply chain disruptions and ensure consistent inventory availability.

Inventory Management

Implement a robust inventory management system to track stock levels, turnover rates, and reorder points. Chain link products vary by gauge, height, mesh size, and coating (e.g., galvanized, PVC-coated), so categorize inventory meticulously. Use warehouse management systems (WMS) to reduce errors and optimize storage space, especially for bulky fencing rolls and posts.

Warehousing & Storage

Store chain link materials in dry, well-ventilated facilities to prevent corrosion, particularly for galvanized and coated products. Use racking systems to keep coiled fencing off the ground and organized by size and type. Protect materials from moisture and prolonged sun exposure to maintain product integrity and comply with warranty conditions.

Transportation & Distribution

Coordinate freight logistics using carriers experienced in handling long, heavy, and irregularly shaped materials. Secure chain link rolls, posts, and hardware properly during transit using straps, cradles, and protective wrapping to prevent damage. Optimize load configurations to reduce freight costs and ensure compliance with weight and dimension regulations (e.g., DOT, FMCSA in the U.S.).

Packaging & Labeling

Package products according to industry standards, ensuring rolls are tightly bound and posts are bundled securely. Clearly label shipments with product specifications, batch numbers, handling instructions, and safety warnings. Include compliance labels such as “Galvanized per ASTM A641” or “Meets ASTM A392” as applicable. Accurate labeling supports traceability and regulatory compliance.

Regulatory Compliance

Ensure all products meet relevant national and international standards:

- ASTM Standards: Confirm compliance with ASTM A392 (welded chain link fence fabric), ASTM A641 (zinc-coated steel wire), and ASTM F714 (plastic-coated steel wire).

- Local Building Codes: Verify that supplied chain link fencing meets municipal or regional requirements for residential, commercial, or industrial use.

- Environmental Regulations: Adhere to environmental laws regarding zinc runoff (for galvanized products) and proper disposal of packaging materials.

- Import/Export Requirements: For international trade, comply with customs documentation, tariffs, and standards such as CE marking (EU) or INMETRO (Brazil).

Safety & Handling Protocols

Train warehouse and delivery personnel in safe handling practices due to the sharp edges and weight of chain link materials. Provide personal protective equipment (PPE) such as gloves and steel-toed boots. Follow OSHA (or local equivalent) guidelines to prevent workplace injuries during loading, unloading, and storage.

Documentation & Traceability

Maintain comprehensive records including supplier certifications, inspection reports, shipping manifests, and compliance documentation. Implement a traceability system to track batches from origin to delivery, which is critical in case of product recalls or warranty claims.

Customer Compliance Support

Provide customers with product data sheets, installation guidelines, and compliance certificates. Assist contractors and municipalities in meeting project-specific requirements, such as submitting cut sheets or test reports for public infrastructure projects.

Continuous Improvement & Audits

Conduct regular internal audits of logistics processes and compliance documentation. Stay updated on changes to industry standards and regulations. Engage in supplier performance reviews and customer feedback loops to refine operations and maintain a competitive edge in the wholesale chain link market.

In conclusion, sourcing wholesale chain link fencing requires careful consideration of several key factors to ensure cost-effectiveness, quality, and reliability. By identifying reputable suppliers, comparing pricing and product specifications, and evaluating logistics and lead times, businesses can secure a consistent and economical supply. Additionally, building strong relationships with wholesalers, considering bulk purchasing benefits, and staying informed about market trends further enhance sourcing efficiency. Ultimately, a strategic approach to wholesale chain link supply supports long-term project success, reduces overall costs, and ensures the durability and performance of fencing solutions across various applications.