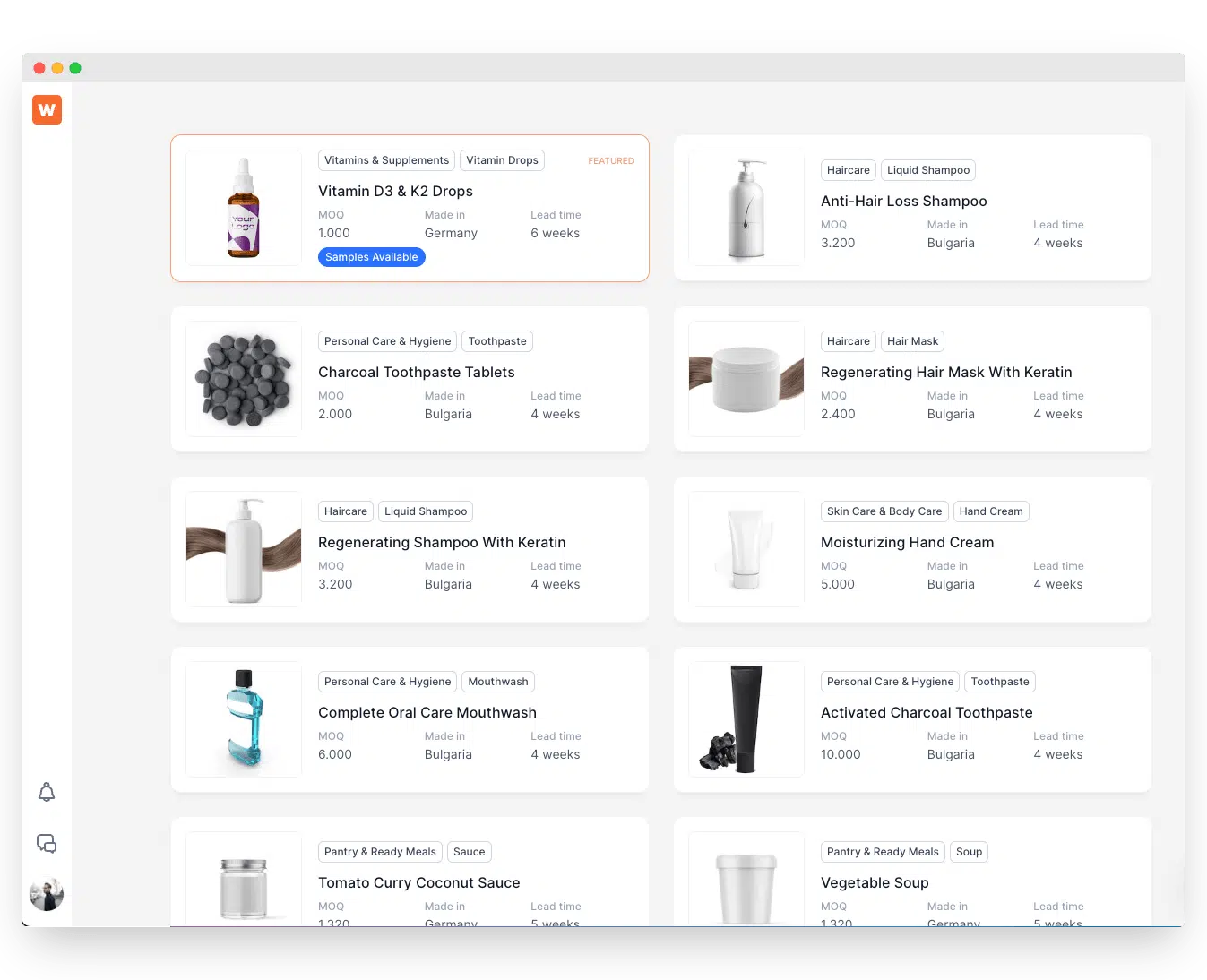

The global white label products market is experiencing robust expansion, driven by rising consumer demand for private-label goods across industries such as beauty, health, food & beverage, and household essentials. According to a report by Grand View Research, the global private label market size was valued at USD 560.8 billion in 2022 and is expected to grow at a compound annual growth rate (CAGR) of 3.8% from 2023 to 2030. Similarly, Mordor Intelligence projects continued momentum, attributing growth to increased retail penetration, e-commerce scalability, and shifting brand strategies toward cost-effective, customizable solutions. In this evolving landscape, manufacturers specializing in white label production are critical partners for startups and established brands alike, offering fast-to-market product development with minimal overhead. As competition intensifies, selecting the right manufacturing partner has become a strategic advantage — one that balances quality, compliance, scalability, and innovation. Here are the top 9 white label products manufacturers leading the industry, chosen based on production capacity, vertical expertise, customer reviews, and market presence.

Top 9 White Label Products Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Private Label Manufacturers Association

Domain Est. 1996

Website: plma.com

Key Highlights: A nationwide collaboration of retailers, wholesalers, and private label suppliers, promoting store brand products to the country’s grocery shoppers….

#2 Swedish Nutra

Domain Est. 2013

Website: swedishnutra.com

Key Highlights: We craft custom formulas and white-label solutions with precision and care, helping businesses deliver exceptional products to their customers….

#3 Cosmetic Contract Manufacturing & Private Labeling

Domain Est. 2014

Website: tropicallabs.com

Key Highlights: Create standout products with a top cosmetic private label manufacturer in the USA. Start fast with low MOQs and full-service support. Get started now!…

#4 Mayk

Domain Est. 2023

Website: mayk-factory.com

Key Highlights: One-stop platform for Korean skincare and cosmetics manufacturing. Partner with Korean skincare manufacturers to create and customize high-quality K-Beauty ……

#5 Products to Private Label – Skincare, Pharmaceutical

Domain Est. 1998

Website: covalence.com

Key Highlights: We provide custom products to private label specifications with a mix of quality ingredients, industry experience, and in-house capabilities. Learn more….

#6 Colorlab Private Label Cosmetics & Manufacturing

Domain Est. 2007

Website: colorlabprivatelabel.com

Key Highlights: Create your own private label cosmetics line or hire us for custom cosmetic manufacturing. We can help you start a new business or grow an existing one….

#7 Max Private Label

Domain Est. 2009

Website: maxprivatelabel.com

Key Highlights: Max Private Label offers packaging and filling services for all types of liquid and semi-liquid products, including hot fill, gels, alcohol-based….

#8 White Label MFG

Domain Est. 2014

Website: whitelabelmfg.com

Key Highlights: White Label MFG is a full-service apparel design and manufacturing company, delivering high-volume graphic programs and premium lifestyle collections….

#9 Private Label Productions

Domain Est. 2018

Website: theprivatelabelproductions.com

Key Highlights: Your trusted partner in manufacturing a diverse range of products, including private label skin care, haircare, makeup, cosmetics, beauty and wellness items….

Expert Sourcing Insights for White Label Products

2026 Market Trends for White Label Products

Rising Demand Across E-Commerce Platforms

By 2026, the white label product market is expected to experience significant growth, primarily driven by the continued expansion of e-commerce. Online retailers, especially small and medium-sized businesses (SMBs), are increasingly turning to white label solutions to launch branded products without the overhead of product development. Marketplaces like Amazon, Shopify, and Etsy are facilitating this trend by offering seamless integration for third-party suppliers, enabling entrepreneurs to scale quickly with minimal investment.

Expansion into Niche and Premium Segments

While white labeling has traditionally focused on mass-market, cost-effective goods, 2026 will see a shift toward premium and niche categories. Consumers are demanding higher quality, sustainability, and personalization—leading white label suppliers to offer customizable, eco-friendly, and ethically sourced products in sectors such as organic skincare, wellness supplements, and specialty foods. This evolution allows brands to differentiate themselves in crowded markets.

Increased Adoption in Emerging Markets

Emerging economies in Southeast Asia, Latin America, and Africa are becoming hotspots for white label product adoption. With growing internet penetration and mobile commerce, local entrepreneurs are leveraging white label solutions to launch fast-moving consumer goods (FMCG) under their own brands. By 2026, these regions are projected to account for a rising share of global white label transactions, supported by regional manufacturing hubs and digital payment infrastructures.

Technological Integration and Customization Tools

Advancements in digital platforms are enabling greater customization in white labeling. By 2026, many suppliers will offer AI-driven design tools, real-time inventory management, and on-demand manufacturing—allowing brands to personalize packaging, formulations, and labeling with minimal lead times. This level of agility supports rapid product testing and targeted marketing campaigns, giving businesses a competitive edge.

Focus on Sustainability and Transparency

Sustainability will be a key driver in the white label space by 2026. Consumers and regulators alike are demanding transparency in sourcing, manufacturing, and logistics. As a result, white label providers are investing in certifications (e.g., USDA Organic, Fair Trade), recyclable packaging, and carbon-neutral shipping. Brands that align with these values through their white label partners will gain stronger consumer trust and loyalty.

Consolidation and Strategic Partnerships

The white label industry is expected to see increased consolidation, with larger suppliers acquiring niche manufacturers to expand their product portfolios. Additionally, strategic partnerships between white label providers and logistics firms, e-commerce enablers, or marketing platforms will become more common. These alliances will offer turnkey solutions, making it easier for new brands to launch and scale efficiently.

Conclusion

By 2026, the white label product market will be more sophisticated, global, and consumer-focused than ever before. Driven by technology, sustainability, and evolving consumer preferences, white labeling will continue to empower entrepreneurs and established brands alike to innovate rapidly and cost-effectively across diverse industries.

Common Pitfalls Sourcing White Label Products (Quality, IP)

Sourcing white label products can be a fast track to market, but it comes with significant risks if not managed carefully. Two of the most critical pitfalls involve product quality and intellectual property (IP) issues.

Quality Inconsistencies and Lack of Control

One of the biggest challenges with white label products is maintaining consistent quality. Since you’re relying on a third-party manufacturer, you have limited oversight over their production processes. This can lead to:

- Variable product standards: The same product may differ in materials, durability, or performance between batches.

- Lack of transparency: Manufacturers may use lower-grade materials or cut corners to reduce costs, especially if contracts don’t specify exact quality benchmarks.

- No direct accountability: If issues arise, resolving them can be difficult, particularly with overseas suppliers where communication and legal recourse are more complex.

Without clear quality control agreements, on-site audits, or third-party inspections, brands risk damaging their reputation through subpar products.

Intellectual Property Risks and Brand Differentiation

White label products are inherently generic—designed to be rebranded by multiple companies. This creates two major IP-related pitfalls:

- Brand dilution: If your product is available under multiple brands (including competitors), it becomes difficult to establish a unique market position or customer loyalty.

- IP ownership ambiguity: While you typically own your branding (logo, packaging, trademarks), the underlying product design and formulation often remain the property of the manufacturer. This means:

- The manufacturer can sell the same product to your competitors.

- You may have no legal recourse if a competitor launches an identical product.

- Customizations may not be exclusive unless explicitly negotiated and documented.

Failing to secure exclusivity or clearly define IP rights in contracts can limit your long-term competitiveness and open the door to legal disputes.

To mitigate these risks, thorough due diligence, strong supplier contracts, quality assurance protocols, and IP agreements are essential when sourcing white label products.

Logistics & Compliance Guide for White Label Products

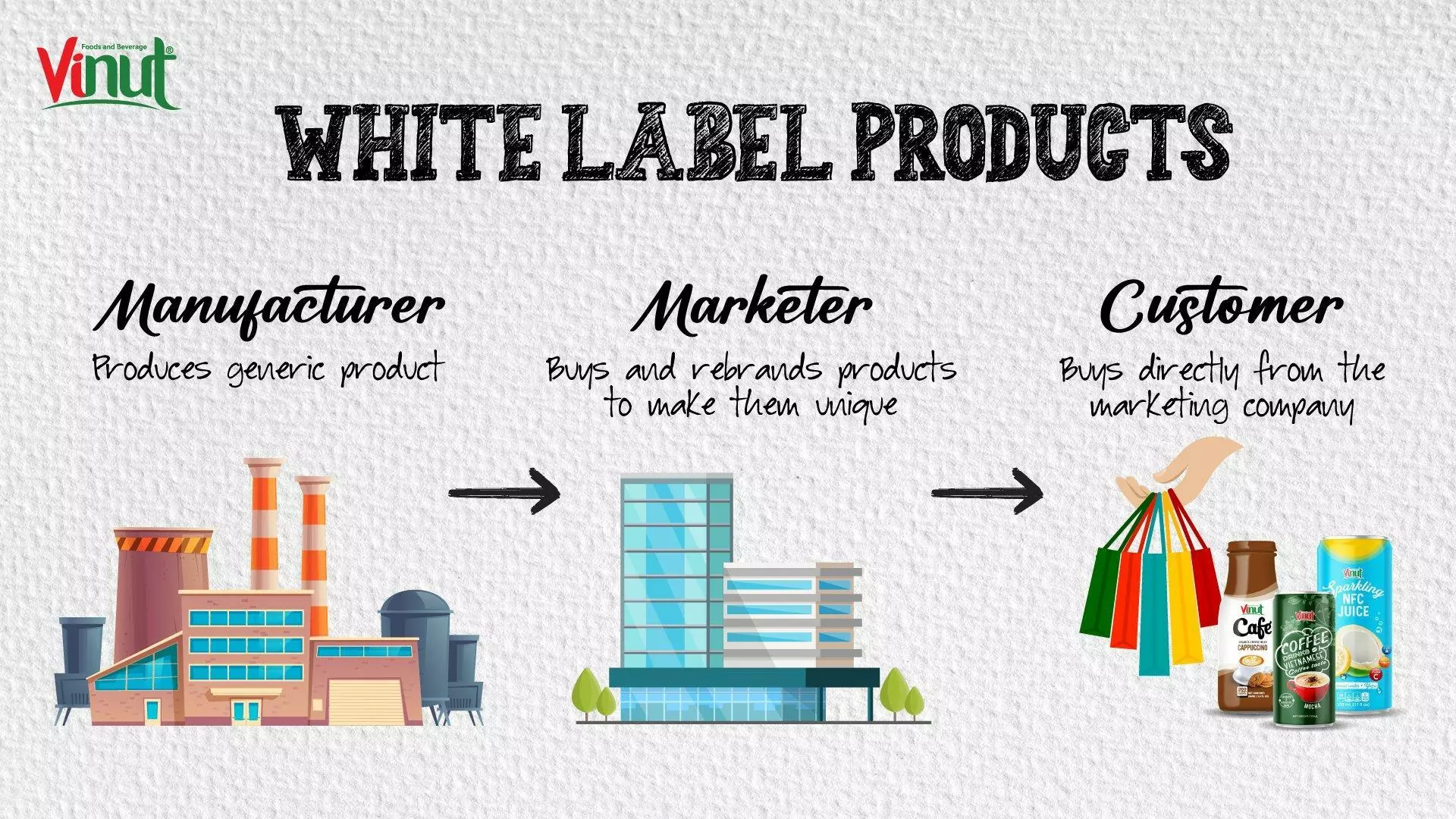

Understanding White Label Products

White label products are manufactured by one company but sold under another company’s brand. The retailer or brand partners with a third-party supplier to source generic goods, which are then rebranded and distributed as their own. This model offers speed to market and reduced development costs but requires careful management of logistics and compliance.

Supply Chain Management

Efficient supply chain management is crucial for white label success. Identify reliable manufacturers, negotiate favorable terms, and establish clear communication channels. Map the entire supply chain—from raw materials to final delivery—to identify potential bottlenecks and ensure continuity. Use inventory tracking systems to monitor stock levels and prevent overstocking or stockouts.

Product Sourcing & Supplier Vetting

Conduct thorough due diligence on potential suppliers. Verify certifications, production capabilities, quality control processes, and ethical practices. Request product samples and perform third-party audits if necessary. Ensure the supplier complies with international and local regulations relevant to your target markets.

Quality Assurance & Control

Implement strict quality control protocols. Define product specifications clearly in contracts and conduct regular inspections during and after production. Use third-party testing to verify safety, performance, and consistency. Establish a process for addressing defects or non-compliance, including returns or corrective actions.

Labeling & Packaging Compliance

Ensure all packaging and labeling meet regulatory requirements of the destination market. This includes language, ingredient disclosure, allergen warnings, country of origin, safety symbols, and mandatory certifications (e.g., FDA, CE, UKCA). Avoid misleading claims and ensure branding elements align with both legal standards and brand guidelines.

Regulatory Compliance by Region

Different regions have distinct compliance standards. For example:

– USA: FDA regulations for food, cosmetics, and supplements; FCC for electronics; CPSIA for children’s products.

– EU: CE marking, REACH (chemicals), RoHS (electronics), and EU cosmetic regulations.

– UK: UKCA marking post-Brexit, along with adherence to local safety and labeling laws.

Stay updated on regulatory changes and consult legal experts when entering new markets.

Import & Export Documentation

Prepare accurate documentation for international shipments, including commercial invoices, packing lists, certificates of origin, and any required permits or licenses. Ensure Harmonized System (HS) codes are correctly classified to avoid customs delays or penalties. Partner with experienced freight forwarders or customs brokers.

Product Liability & Insurance

White label brands assume legal responsibility for the products they sell. Obtain product liability insurance to protect against claims of injury or damage. Clearly define liability terms in supplier agreements and ensure the manufacturer carries appropriate insurance as well.

Intellectual Property Protection

Ensure your brand name, logo, and packaging design are trademarked. Confirm that the white label product does not infringe on existing patents or copyrights. Include IP ownership clauses in supplier contracts to prevent unauthorized use of your branding.

Sustainability & Ethical Sourcing

Consumers increasingly demand transparency. Source products from suppliers that adhere to ethical labor practices and environmental standards. Consider certifications like Fair Trade, FSC, or B Corp to strengthen brand credibility. Minimize packaging waste and explore eco-friendly materials.

Returns, Recalls & Crisis Management

Develop a clear returns policy and process for defective items. Establish a recall plan in case of safety issues, including communication protocols, logistics for retrieval, and regulatory reporting. Regularly test your crisis response procedures to ensure readiness.

Record Keeping & Audits

Maintain detailed records of supplier agreements, test results, compliance certifications, shipment documentation, and customer complaints. These records support audits, regulatory inspections, and continuous improvement. Use digital systems for secure, organized record storage.

Continuous Monitoring & Improvement

Regularly review supplier performance, customer feedback, and compliance status. Stay informed about evolving regulations and industry best practices. Adapt logistics and compliance strategies to improve efficiency, reduce risk, and enhance customer trust.

In conclusion, sourcing white label products from a reliable manufacturer offers a strategic advantage for businesses aiming to scale quickly, minimize development costs, and maintain brand consistency. By partnering with a reputable manufacturer, companies can leverage proven production capabilities, quality assurance processes, and industry expertise—allowing them to focus on branding, marketing, and customer experience. Key considerations such as product quality, compliance standards, minimum order quantities, pricing, and communication efficiency play a critical role in selecting the right manufacturing partner. Conducting thorough due diligence, requesting samples, and establishing clear terms ensure a successful, long-term collaboration. Ultimately, effective white label sourcing empowers businesses to bring high-quality products to market efficiently, enhancing competitiveness and accelerating growth in an increasingly dynamic marketplace.