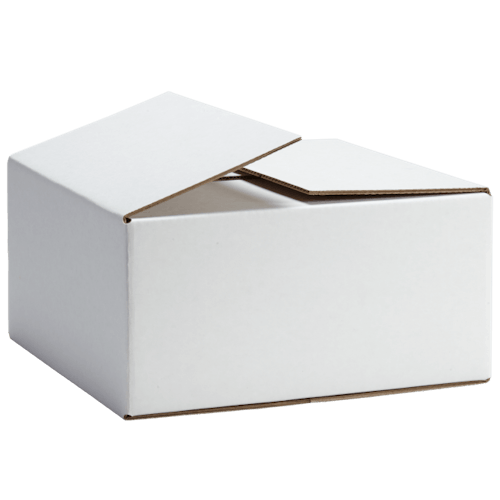

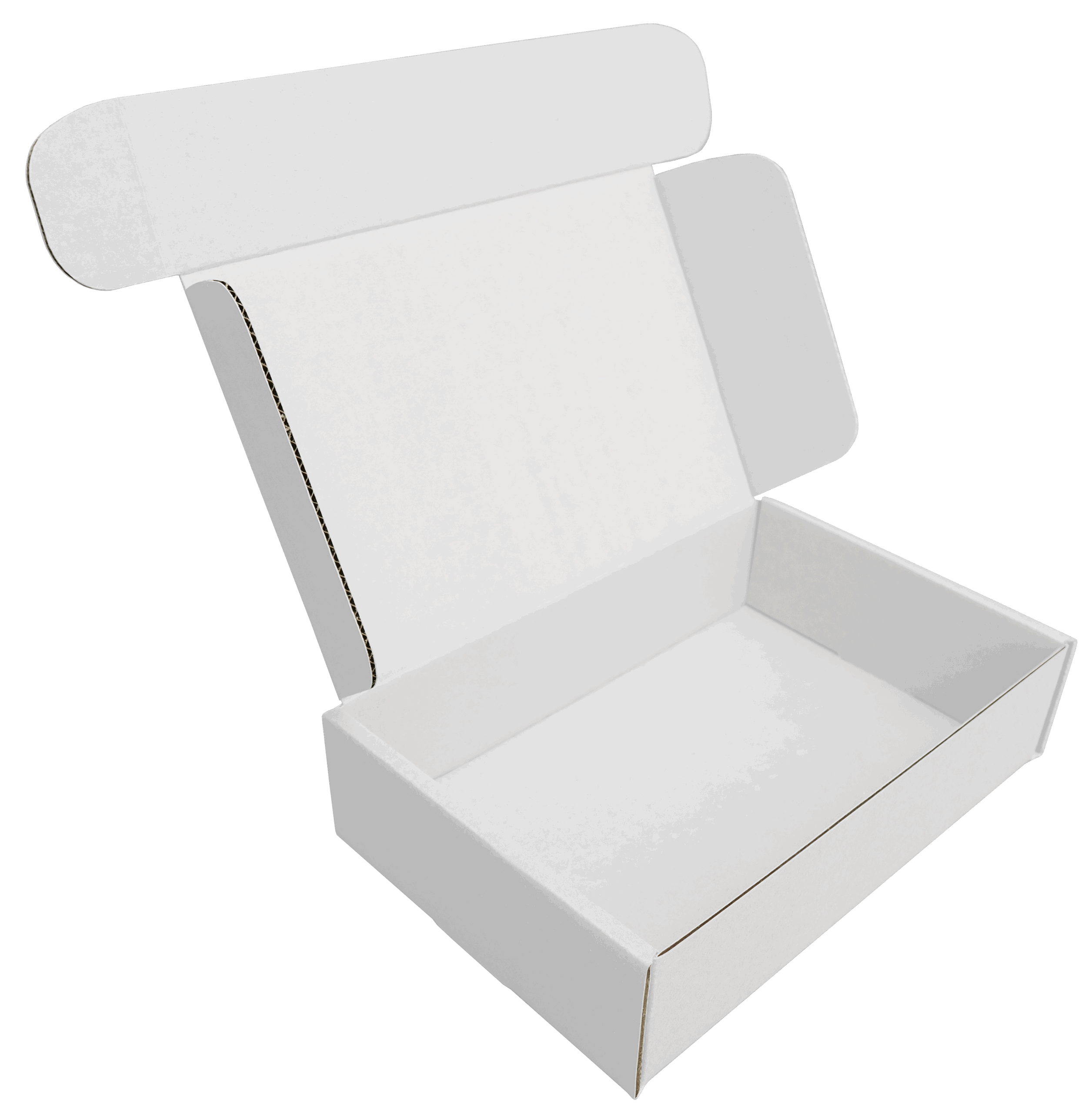

The global packaging industry continues to experience robust growth, driven by rising e-commerce activity, increasing consumer demand for sustainable materials, and expanding supply chains. According to a 2023 report by Mordor Intelligence, the global corrugated packaging market was valued at USD 210.72 billion and is projected to grow at a CAGR of 5.2% from 2023 to 2028. White cardboard packing boxes, known for their clean aesthetic, printability, and recyclability, are becoming increasingly popular in retail, luxury goods, food and beverage, and e-commerce sectors. This shift has catalyzed intense competition among manufacturers to deliver high-quality, customizable, and eco-friendly solutions. As brands prioritize both functionality and brand image, the demand for premium white cardboard packaging has surged. In this dynamic landscape, a select group of manufacturers are leading the way through innovation, scale, and sustainability. Based on production capacity, geographic reach, environmental commitments, and customer reviews, here are the top 10 white cardboard packing box manufacturers shaping the future of the industry.

Top 10 White Cardboard Packing Boxes Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Custom Corrugated Packaging Solutions from Pratt Industries

Domain Est. 1999 | Founded: 1985

Website: prattindustries.com

Key Highlights: The fifth largest corrugated packaging company in the United States, producer of 100% recycled containerboard since 1985….

#2 Cardboard Boxes: Wholesale Corrugated Boxes

Domain Est. 1995

Website: papermart.com

Key Highlights: 3–6 day delivery · 30-day returnsSave money on cardboard boxes by shopping at Paper Mart! We offer a variety of shapes and sizes of cardboard boxes at wholesale prices. Shop now!…

#3 All Purpose Household Moving Boxes

Domain Est. 1996

Website: newhaven-usa.com

Key Highlights: 1-day delivery 30-day returnsNew Haven offer a full range of high quality household cartons for all purposes. These include standard storage boxes in four different sizes….

#4 McLEAN Packaging

Domain Est. 1997

Website: mcleanpackaging.com

Key Highlights: Corrugated Displays & Packaging · Folding Cartons & Rigid Set Boxes….

#5 International Paper

Domain Est. 1997

Website: internationalpaper.com

Key Highlights: We transform renewable resources into innovative and sustainable packaging solutions, corrugated cardboard boxes, pulp and paper products, ……

#6 BoxUp

Domain Est. 1998

Website: boxup.com

Key Highlights: Showcase your small business by adding your company logo and branding to any of BoxUp’s designs. Choose from custom mailers, gable boxes, or shipping boxes….

#7 Welch Packaging

Domain Est. 1999

Website: welchpkg.com

Key Highlights: Welch Packaging manufactures custom cardboard boxes, retail packaging, and e-commerce packaging. We offer design services, assembly, fulfilment, ……

#8 Wholesale Shipping Boxes

Domain Est. 1999

Website: thecarycompany.com

Key Highlights: 30-day returnsThe Cary Company’s selection of corrugated cartons includes standard boxes, heavy duty boxes, multi-depth boxes, Hazmat boxes, and sheets and pads….

#9 Custom Boxes Now

Domain Est. 2006

Website: customboxesnow.com

Key Highlights: White Shipping Boxes … We are a shipping box manufacturing company that specializes in creating custom made boxes with corrugated cardboard….

#10 Smurfit Westrock

Domain Est. 2023

Website: smurfitwestrock.com

Key Highlights: We create, design and manufacture paper-based packaging made from renewable materials that protect and promote our customers’ products. In 2024, we manufactured ……

Expert Sourcing Insights for White Cardboard Packing Boxes

2026 Market Trends for White Cardboard Packing Boxes

The global market for white cardboard packing boxes is poised for significant transformation by 2026, driven by evolving consumer preferences, sustainability imperatives, and advancements in packaging technology. As brands across industries—from luxury goods and cosmetics to food and e-commerce—prioritize both aesthetics and environmental responsibility, white cardboard has emerged as a preferred material due to its clean appearance, printability, and recyclability. This analysis explores the key trends expected to shape the white cardboard packing box market in 2026.

Rising Demand for Sustainable and Eco-Friendly Packaging

One of the most influential drivers of the white cardboard packaging market in 2026 is the growing demand for sustainable solutions. Consumers and regulatory bodies alike are pushing for reduced plastic use and increased adoption of recyclable materials. White cardboard, typically made from virgin or recycled fiber, aligns with these goals when sourced responsibly. By 2026, manufacturers are expected to increasingly use FSC-certified or PEFC-certified pulp and implement closed-loop recycling systems. Additionally, demand for chlorine-free bleaching processes to produce brighter white cardboard without harmful environmental impact is anticipated to rise.

Growth in E-Commerce and Premium Retail Packaging

The continued expansion of e-commerce is a major catalyst for the white cardboard packaging market. As online shopping becomes the norm, brands are investing in high-quality, visually appealing packaging to enhance unboxing experiences. White cardboard boxes offer a pristine canvas for branding, custom printing, and embossing, making them ideal for premium product presentation. By 2026, the integration of smart packaging features—such as QR codes, AR-enabled designs, and tamper-evident seals—into white cardboard boxes is expected to grow, especially in fashion, beauty, and electronics sectors.

Innovation in Material and Design Efficiency

Technological advancements are enabling lighter, stronger, and more resource-efficient white cardboard packaging. In 2026, expect increased use of lightweight yet durable board grades that reduce shipping costs and carbon footprint without compromising protection. Design innovations such as modular box formats, foldable structures, and minimal adhesive usage will support sustainability goals while improving logistics efficiency. Moreover, water-based coatings and bio-based inks will become standard to enhance recyclability and reduce volatile organic compound (VOC) emissions.

Regional Market Dynamics and Regulatory Influence

Regional markets will experience varied growth trajectories. North America and Europe are expected to lead in adopting eco-conscious packaging, driven by stringent regulations like the EU Packaging and Packaging Waste Directive (PPWD) and extended producer responsibility (EPR) schemes. In contrast, the Asia-Pacific region—particularly China, India, and Southeast Asia—will witness rapid market expansion due to rising consumerism, urbanization, and growth in local e-commerce platforms. By 2026, local manufacturers in these regions will likely invest in upgrading production capabilities to meet international quality and sustainability benchmarks.

Competitive Landscape and Brand Differentiation

The white cardboard packaging market will become increasingly competitive, with suppliers differentiating through customization, speed-to-market, and end-to-end sustainability reporting. Major packaging companies and niche designers will collaborate closely with brands to co-develop packaging solutions that reflect brand identity while minimizing environmental impact. Subscription boxes, limited-edition releases, and seasonal packaging using white cardboard are expected to gain popularity, further fueling demand.

Conclusion

By 2026, the white cardboard packing box market will be defined by sustainability, innovation, and brand-centric design. As environmental regulations tighten and consumer expectations evolve, white cardboard will remain a material of choice—provided it is produced responsibly and integrated with smart, efficient solutions. Companies that invest in circular economy models, digital integration, and regional adaptation will be best positioned to capitalize on emerging opportunities in this dynamic market.

Common Pitfalls When Sourcing White Cardboard Packing Boxes (Quality and Intellectual Property)

Sourcing white cardboard packing boxes may seem straightforward, but overlooking key quality and intellectual property (IP) considerations can lead to costly delays, reputational damage, and legal issues. Here are common pitfalls to avoid:

Overlooking Material Quality and Specifications

Many buyers assume “white cardboard” means a uniform standard, but variations in material composition, thickness (caliper), and finish can significantly impact performance. Sourcing without precise specifications—such as GSM (grams per square meter), burst strength, or coating type—can result in boxes that are too flimsy, prone to discoloration, or unsuitable for printing. Always request physical samples and verify compliance with industry standards (e.g., ISO, FSC certification).

Ignoring Moisture and Durability Factors

White cardboard, especially uncoated or low-grade varieties, can be vulnerable to moisture and compression during transit. Buyers often fail to assess the box’s resistance to humidity or stacking strength, leading to collapsed packaging or damaged goods. Ensure suppliers provide data on edge crush test (ECT) and box compression test (BCT) results relevant to your shipping and storage conditions.

Assuming All White Boxes Are Food-Safe or Compliant

Not all white cardboard is suitable for food, pharmaceuticals, or regulated products. Some may contain recycled content with contaminants or use inks and adhesives that aren’t food-grade. Always confirm compliance with FDA, EU food contact regulations, or other relevant standards. Request material safety data sheets (MSDS) and compliance certifications.

Failing to Protect Custom Design IP

When sourcing custom-designed boxes, buyers often neglect to formalize intellectual property ownership. Without a clear contract, the supplier may retain rights to your unique artwork, logo placement, or structural design. This can lead to unauthorized replication or resale to competitors. Always include IP assignment clauses in your sourcing agreements.

Allowing Suppliers to Copy or Resell Your Design

Some manufacturers, especially in regions with weak IP enforcement, may reproduce your box design for other clients. This undermines brand exclusivity and can flood the market with counterfeit packaging. Conduct due diligence on suppliers, use non-disclosure agreements (NDAs), and consider watermarking or embedding covert design elements to trace unauthorized use.

Skipping On-Site Quality Audits or Third-Party Inspections

Relying solely on supplier-provided samples or certifications is risky. Without independent quality audits or pre-shipment inspections, defects like color variance, printing misalignment, or structural flaws may go unnoticed until delivery. Invest in third-party inspection services to verify batch consistency and adherence to agreed-upon specs.

Underestimating the Impact of Printing and Finish Quality

White boxes are often chosen for their clean, premium appearance, making print quality critical. Poor color matching, ink smudging, or inconsistent lamination can damage brand perception. Ensure the supplier uses calibrated equipment and provides Pantone color proofs. Also, confirm whether finishes (matte, gloss, spot UV) are durable and scuff-resistant.

Not Securing Long-Term Supply and IP Continuity

If a supplier holds the tooling (e.g., die-cut molds) or digital print files, switching vendors later can be difficult and expensive. Ensure your contract includes the right to retrieve all design files and physical tooling upon request. This protects against supply chain disruption and maintains IP control.

Avoiding these pitfalls requires clear specifications, strong contracts, proactive quality control, and vigilant IP protection—key steps toward reliable, brand-safe packaging sourcing.

Logistics & Compliance Guide for White Cardboard Packing Boxes

Overview

White cardboard packing boxes are widely used across industries for retail packaging, e-commerce, food service, and product shipping due to their clean appearance, printability, and recyclability. Ensuring efficient logistics and compliance with relevant regulations is essential for safe, sustainable, and legal distribution. This guide outlines key considerations for handling, transporting, and complying with standards when using white cardboard packing boxes.

Material Specifications & Sourcing Compliance

- Fiber Content: Ensure boxes are made from virgin or recycled fibers meeting FSC (Forest Stewardship Council), SFI (Sustainable Forestry Initiative), or PEFC (Programme for the Endorsement of Forest Certification) standards.

- Food-Grade Certification: If used for food or pharmaceutical packaging, confirm compliance with FDA (U.S.) or EU food contact material regulations (EC No 1935/2004). Inks and adhesives must also be food-safe.

- Bleaching Process: Verify that chlorine-free (TCF) or elemental chlorine-free (ECF) bleaching methods are used to minimize environmental impact.

Structural Design & Durability

- Box Strength: Use boxes with appropriate ECT (Edge Crush Test) and Burst Strength ratings based on product weight and stacking requirements (e.g., 32 ECT for standard shipping).

- Moisture Resistance: For high-humidity environments, consider moisture-resistant coatings or liners, but ensure these are compostable or recyclable where possible.

- Dimensional Standards: Design boxes to standard pallet configurations (e.g., 48” x 40” in North America) to optimize space utilization and reduce shipping costs.

Packaging & Handling Best Practices

- Proper Loading: Avoid overfilling or underfilling; use void fill (e.g., recycled paper) to prevent product movement.

- Sealing Methods: Use water-activated tape or pressure-sensitive tape that supports recyclability. Avoid plastic tapes that contaminate recycling streams.

- Labeling: Clearly label boxes with handling instructions (e.g., “This Side Up,” “Fragile”), barcodes, and shipping addresses using soy- or water-based inks.

Transportation & Storage

- Palletization: Secure boxes on pallets using stretch wrap made from recyclable materials. Avoid overhang to prevent damage during transit.

- Stacking Limits: Adhere to manufacturer-recommended stacking heights to prevent crushing.

- Environmental Conditions: Store in dry, temperature-controlled areas to prevent warping or weakening of cardboard.

Regulatory & Environmental Compliance

- Recyclability Claims: Only label boxes as “recyclable” if local infrastructure supports cardboard recycling. Avoid greenwashing.

- Toxicity Standards: Ensure compliance with REACH (EU) and CPSIA (U.S.) regarding restricted substances in inks, dyes, or coatings.

- Waste Management: Follow local regulations for disposal and recycling. In some jurisdictions, producers may be subject to Extended Producer Responsibility (EPR) schemes.

International Shipping Considerations

- ISPM 15 Compliance: While not required for cardboard, ensure wooden pallets or dunnage meet ISPM 15 phytosanitary standards if used.

- Customs Documentation: Accurately declare box materials and contents on shipping manifests. Non-compliance can lead to delays or fines.

- Country-Specific Regulations: Research packaging laws in destination countries (e.g., Germany’s Packaging Act, Japan’s Containers and Packaging Recycling Law).

Sustainability & End-of-Life

- Design for Recyclability: Minimize mixed materials (e.g., plastic windows, laminated coatings) to support easy recycling.

- Take-Back Programs: Consider offering box return or recycling incentives to enhance brand sustainability.

- Carbon Footprint: Optimize box size and weight to reduce transport emissions. Partner with carriers offering carbon-neutral shipping options.

Recordkeeping & Audits

- Maintain documentation of material sourcing, compliance certifications (e.g., FSC chain-of-custody), and supplier audits.

- Conduct periodic reviews of packaging compliance, especially when entering new markets or updating materials.

By adhering to this logistics and compliance guide, businesses can ensure that their use of white cardboard packing boxes is efficient, environmentally responsible, and aligned with global regulatory standards.

In conclusion, sourcing white cardboard packing boxes requires careful consideration of quality, cost, sustainability, and supplier reliability. These boxes offer a clean, professional appearance ideal for branding and retail presentation, while also providing adequate protection for a wide range of products. By evaluating suppliers based on material durability, customization options, lead times, and environmental certifications, businesses can secure packaging that aligns with both operational needs and sustainability goals. Establishing strong partnerships with reputable manufacturers—whether local or international—can ensure consistent supply, improve cost-efficiency, and support long-term branding strategies. Ultimately, investing time in strategic sourcing of white cardboard boxes contributes to enhanced customer experience, reduced environmental impact, and overall supply chain efficiency.