The global marine plywood market is experiencing steady growth, driven by rising demand in shipbuilding, leisure crafts, and waterfront construction. According to a report by Mordor Intelligence, the marine plywood market was valued at USD 3.8 billion in 2023 and is projected to grow at a CAGR of over 4.5% from 2024 to 2029. Increasing infrastructure development in coastal regions and stringent regulations around durability and moisture resistance are pushing buyers toward high-quality, certified marine plywood. With Asia Pacific accounting for the largest share—led by key manufacturing hubs in China, India, and Malaysia—sourcing decisions are increasingly influenced by both product standards and supply chain reliability. As demand intensifies, identifying reputable manufacturers becomes critical for contractors, fabricators, and distributors aiming to balance cost, compliance, and quality. Here are the top 10 marine plywood manufacturers where buyers can source reliable, high-performance materials.

Top 10 Where Can I Buy Marine Plywood Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Buy Plywood Wholesale Direct from Manufacturer

Domain Est. 2018

Website: plyterra.com

Key Highlights: Plyterra is a trusted plywood manufacturer with over 20 years of expertise. Offering a wide range of plywood grades and types for wholesale buyers….

#2 Plywood Marine Grade Supplier

Domain Est. 1996

Website: mcilvain.com

Key Highlights: All plywood marine grade products, we can supply marine Okoume plywood or Douglas Fir. We are the Marine grade plywood near me destination….

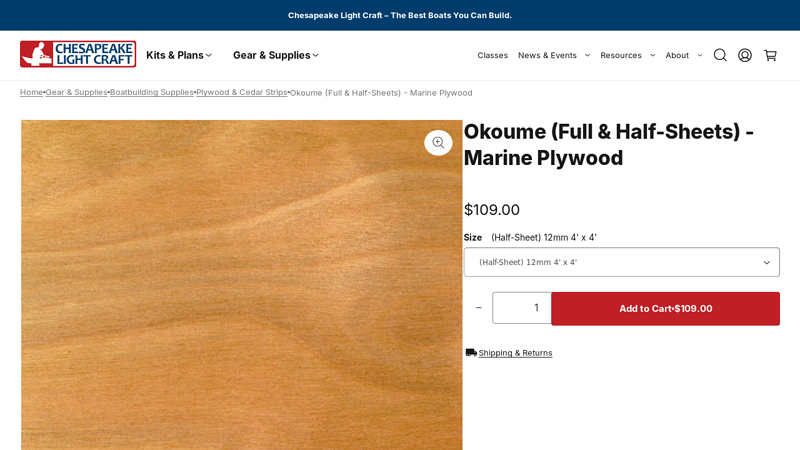

#3 Okoume Marine Plywood: BS 1088 Quality

Domain Est. 1997

Website: clcboats.com

Key Highlights: Chesapeake Light Craft’s Okoume marine grade plywood is manufactured in Europe’s finest mills to specs exceeding British Standard 1088 (BS1088). High-quality ……

#4 Inland Plywood

Domain Est. 1998 | Founded: 1967

Website: inlandplywood.com

Key Highlights: Founded in 1967 as a family owned business, Inland Plywood Co. has now grown into a nationally recognized supplier of plywood products to the marine industry ……

#5 Atlantic Plywood

Domain Est. 1999

Website: atlanticplywood.com

Key Highlights: Wholesale Supplier of Hardwood Plywood, Panel Product and More! Since our … Marine Products · New Items · Made-To-Order · Shop Supplies · Office Solutions ……

#6 Plywood Company

Domain Est. 1999

Website: plywoodcompany.com

Key Highlights: Plywood Company provides hardwood and softwood plywood, including MDO, marine grade, FSC certified, and fire-retardant panels, along with composite panels such ……

#7 Marine Plywood

Domain Est. 2000

Website: chesapeakeplywood.com

Key Highlights: Explore marine-grade plywood for boatbuilding and coastal projects—okoume and fir options with water-resistant construction, spec guidance, ……

#8 Marine Plywood

Domain Est. 2001

Website: lbifiberglass.com

Key Highlights: Marine-grade plywood is a good-quality, hardwood plywood made with waterproof glue. It tends to be lightweight, strong, and virtually free of defects….

#9 Marine Plywood by Homestead

Domain Est. 2003

Website: marine-plywood.us

Key Highlights: New wholesale pricing on marine plywood, douglas fir, cca treated fir, Joubert okoume and Hydro-tek meranti! We supply yacht, house boat and pleasure craft ……

#10 Marine Plywood

Domain Est. 2005

Website: recpro.com

Key Highlights: Free delivery · 30-day returnsShop RecPro’s marine-grade plywood—rot-resistant, durable, and ideal for boats, decks, and pontoons. Perfect for your next DIY marine project!…

Expert Sourcing Insights for Where Can I Buy Marine Plywood

H2: 2026 Market Trends for Where Can I Buy Marine Plywood

As we approach 2026, the market for marine plywood is undergoing significant transformation influenced by shifts in consumer behavior, technological advancements, sustainability demands, and global supply chain dynamics. Understanding where consumers can buy marine plywood in this evolving landscape requires an analysis of key trends shaping distribution channels, regional availability, and purchasing preferences.

-

Expansion of E-Commerce Platforms

By 2026, online marketplaces are expected to dominate the sale of marine plywood. Major e-commerce platforms such as Amazon, Home Depot’s online store, and specialized B2B portals like Alibaba and BuildDirect are streamlining the purchasing process with enhanced logistics, competitive pricing, and detailed product specifications. Consumers and contractors increasingly prefer buying marine plywood online due to convenience, availability of customer reviews, and doorstep delivery—especially for large-volume or remote-area orders. -

Growth of Direct-to-Consumer (DTC) Models

Manufacturers are increasingly bypassing traditional distributors by adopting direct-to-consumer sales models. This shift allows brands to offer better pricing, custom cutting services, and faster fulfillment. By 2026, several leading marine plywood producers are expected to operate dedicated online storefronts, providing region-specific inventory and real-time stock tracking. -

Regional Supply Chain Resilience

Post-pandemic supply chain disruptions have prompted a regional reevaluation of sourcing. In 2026, buyers are more likely to source marine plywood locally or regionally to reduce lead times and shipping costs. North America, Europe, and Southeast Asia are developing stronger regional supply networks, with local distributors partnering with certified mills. This trend enhances availability and reduces dependency on long-haul imports, particularly from traditional exporters like Malaysia and Indonesia. -

Rise of Sustainable and Certified Products

Environmental regulations and consumer demand for eco-friendly materials are pushing suppliers to offer FSC (Forest Stewardship Council) or PEFC-certified marine plywood. By 2026, major retailers and online vendors are expected to prominently label sustainable options, influencing where and how buyers make purchasing decisions. Buyers are increasingly directing their searches toward vendors that provide transparency in sourcing and environmental impact. -

Integration of AR and Digital Tools

Augmented reality (AR) and digital measurement tools are becoming standard features on retail websites. By 2026, consumers can use smartphone apps to visualize how marine plywood will look in their boat-building or construction project, check compatibility, and calculate required quantities. These tools are embedded into e-commerce platforms, enhancing the online buying experience and reducing return rates. -

Growth in Niche and Specialty Retailers

Alongside general home improvement stores, niche marine supply retailers—both physical and online—are expanding their plywood offerings. These specialized vendors cater to boat builders, marine contractors, and DIY enthusiasts, providing expert advice, project-specific grades (e.g., BS1088, A/B grade), and value-added services like sealing or pre-cutting. Their rise is reshaping where informed buyers choose to purchase. -

Influence of Regulatory Standards

As international standards for marine plywood (such as ISO 13255 and BS1088) become more rigorously enforced, authorized dealers and certified distributors are becoming preferred purchasing points. By 2026, buyers are more likely to purchase from vetted suppliers who guarantee compliance, especially in commercial and export markets.

Conclusion

By 2026, the question “Where can I buy marine plywood?” will increasingly be answered through a combination of digital platforms, regional distributors, and specialized retailers that emphasize sustainability, certification, and customer experience. Consumers will prioritize convenience, authenticity, and environmental responsibility, driving innovation across the supply chain and expanding access to high-quality marine-grade materials worldwide.

Common Pitfalls When Sourcing Marine Plywood (Quality, IP)

Logistics & Compliance Guide for Where Can I Buy Marine Plywood

Purchasing marine plywood involves not only selecting the right supplier but also ensuring that logistics and compliance requirements are met to guarantee quality, durability, and legal adherence. This guide outlines key considerations for sourcing marine plywood, covering transportation, certifications, import/export regulations, and quality control.

Understanding Marine Plywood Specifications

Before addressing logistics and compliance, it’s essential to understand what qualifies as marine plywood:

- Made from high-quality, durable hardwood (typically birch or tropical hardwoods)

- Bonded with waterproof phenolic resin (WBP – Weather and Boil Proof)

- Free from voids and delamination

- Complies with international standards such as BS 1088 (British Standard) or ISO 139:2005

Ensure your supplier provides certification that their marine plywood meets these standards.

Supplier Selection and Location

Choosing the right supplier impacts both cost and compliance:

- Local vs. International Suppliers: Local suppliers reduce shipping time and import costs, while international suppliers (e.g., from Southeast Asia) may offer lower prices but require compliance with import regulations.

- Certified Manufacturers: Prioritize suppliers with recognized certifications (e.g., FSC, PEFC) to ensure sustainable sourcing and legal compliance.

- Minimum Order Quantities (MOQ): Confirm MOQs and packaging options (palletized, banded, wrapped) to align with your logistics capacity.

Transportation and Packaging

Proper handling during transit is crucial to maintain the integrity of marine plywood:

- Moisture Protection: Marine plywood must be wrapped in waterproof plastic or shrink-wrapped to prevent moisture exposure during transport.

- Palletization: Boards should be securely stacked on wooden pallets and strapped to prevent shifting.

- Container Shipping: For international orders, use dry freight containers with desiccants to control humidity. Avoid open-top or flat-rack containers unless fully protected.

- Trucking and Last-Mile Delivery: Use covered trucks and confirm handling procedures at loading/unloading points to avoid warping or damage.

Import and Export Compliance

When sourcing marine plywood internationally, comply with the following:

- Customs Documentation: Ensure proper invoices, packing lists, bill of lading, and certificates of origin are provided.

- Phytosanitary Certificates: Required in many countries to prevent the spread of pests; especially important for raw wood products.

- Lacey Act (USA): Prohibits trade in illegally sourced wood. Suppliers must provide documentation proving legal harvest and chain of custody.

- EU Timber Regulation (EUTR): Requires due diligence for wood imports into the European Union.

- Tariffs and Duties: Research applicable tariffs based on country of origin and product classification (HS Code: typically 4412.31 or 4412.32 for plywood).

Quality Assurance and Inspection

To ensure compliance with marine-grade standards:

- Pre-Shipment Inspection: Arrange for third-party inspection (e.g., SGS, Bureau Veritas) to verify thickness, glue lines, absence of voids, and compliance with BS 1088 or equivalent.

- Batch Testing: Request sample testing for bond durability, moisture resistance, and formaldehyde emissions (if applicable).

- Traceability: Ensure each batch is traceable to the manufacturer and certified accordingly.

Storage and Handling Upon Delivery

Even after delivery, compliance and quality depend on proper storage:

- Dry, Ventilated Area: Store indoors on level ground, elevated off the floor, and covered to prevent moisture absorption.

- Rotation of Stock: Use a first-in, first-out (FIFO) system to avoid prolonged storage that may lead to warping or fungal growth.

- Acclimatization: Allow plywood to acclimate to the working environment before use, especially in humid or variable climates.

Environmental and Safety Compliance

- VOC Emissions: Confirm low formaldehyde emissions, particularly for indoor marine applications (look for CARB P2 or E0/E1 ratings).

- Sustainable Sourcing: Verify FSC or PEFC certification to meet corporate sustainability goals and regulatory requirements.

- Waste Disposal: Follow local regulations for disposal of wood offcuts and packaging materials.

Conclusion

Sourcing marine plywood requires careful attention to logistics and compliance at every stage—from supplier selection and transportation to customs clearance and storage. By ensuring adherence to international standards, environmental regulations, and quality controls, buyers can secure reliable, durable, and legally compliant materials for marine and outdoor applications. Always partner with reputable suppliers and use certified inspection services to mitigate risk and guarantee performance.

In conclusion, sourcing marine plywood requires careful consideration of quality, certification, and supplier reliability due to its specialized use in moisture-prone environments. You can purchase marine plywood from a variety of outlets, including large home improvement stores like Home Depot or Lowe’s, specialty lumberyards, and online retailers such as Amazon, BuildDirect, or local timber suppliers’ websites. For the best results, look for plywood certified under standards like BS 1088 (international marine grade) to ensure durability and water resistance. Additionally, buying from reputable suppliers who provide clear product specifications helps guarantee authenticity. Always compare prices, check availability, and consider shipping costs—especially for heavy materials—to make a cost-effective and informed purchase. By choosing the right source, you can ensure long-lasting performance for your marine or outdoor projects.