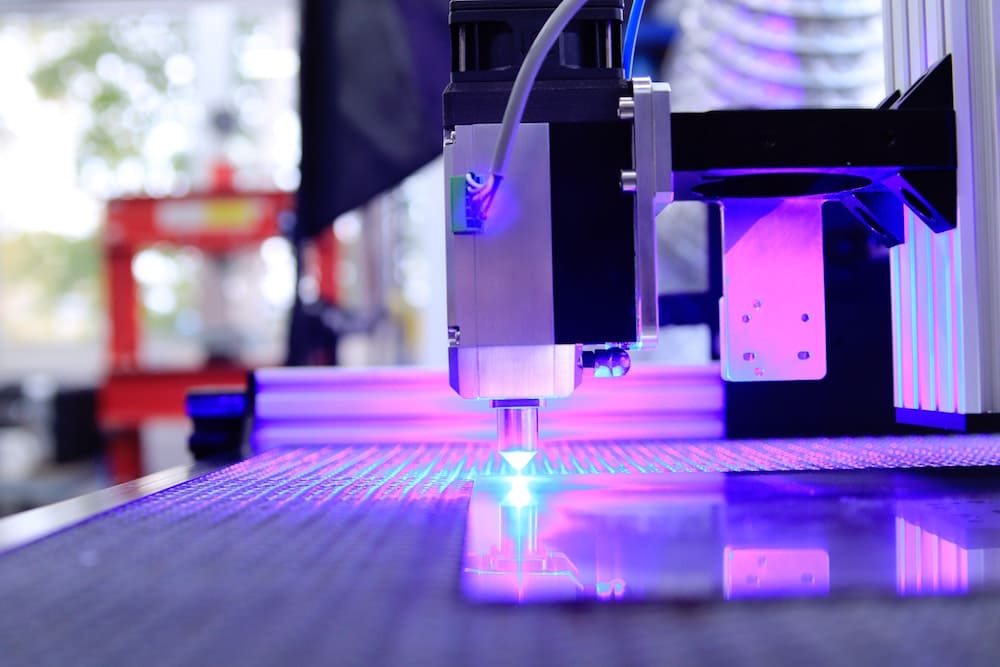

The global laser cutting equipment market is experiencing robust growth, driven by rising demand for precision manufacturing across industries such as automotive, aerospace, electronics, and healthcare. According to a report by Grand View Research, the global laser cutting machine market size was valued at USD 6.8 billion in 2022 and is expected to expand at a compound annual growth rate (CAGR) of 7.4% from 2023 to 2030. This growth is fueled by advancements in laser technology, increasing automation in production processes, and the ability of laser cutters to work with a diverse range of materials—including metals, plastics, wood, ceramics, and composites. As industries prioritize efficiency, accuracy, and versatility, manufacturers are innovating to expand the material compatibility and performance of laser cutting systems. In this competitive landscape, nine key manufacturers have emerged as leaders in producing laser cutters capable of handling the broadest and most challenging material types, setting new benchmarks in industrial and small-scale fabrication alike.

Top 9 What Materials Does A Laser Cutter Cut Manufacturers (2026 Audit Report)

(Ranked by Factory Capability & Trust Score)

#1 The Complete Laser Cutting Materials List

Website: xtool.com

Key Highlights: Wood is one of the most popular laser cutter materials. It has a natural and warm appearance that can suit many laser cutting projects….

#2 Laser Cutting Plastic and Other Non

Website: espemfg.com

Key Highlights: Laser cutting is a highly efficient, precise, and cost-effective way to cut plastics, electrical insulation materials, and other non-metals for use in a wide ……

#3 12 Common Laser Cutting Materials

Website: xometry.com

Key Highlights: There are several laser cutting materials available ranging from wood, acrylic, metals, and foam. Learn more about laser cutting and the ……

#4 Laser Cutter Materials

Website: source.dallasmakerspace.org

Key Highlights: The laser can cut or etch. The materials that the laser can cut materials like wood, paper, cork, and some kinds of plastics. Etching can be ……

#5 What can laser cutting do? Everything you need to know about laser …

Website: seeedstudio.com

Key Highlights: Common laser cutters are primarily used to cut materials like wood, acrylic, cardboard, paper and etc. For this, we’ve launch an affordable ……

#6 Introduction to Materials for Laser Module

Website: wiki.bambulab.com

Key Highlights: Bambu’s plywood uses high-quality poplar wood as the core material to minimize charring and provide smooth cut. This creates a high-quality decorative panel….

#7 Materials

Website: cutlasercut.com

Key Highlights: We can supply most materials suitable for laser work, not all are listed here. We do not generally supply materials not related to a laser project….

#8 Stuff you shouldn’t laser

Website: community.glowforge.com

Key Highlights: Polystyrene foam: melts, catches fire. · Polypropylene foam: melts, catches fire. · Thick ( > 1mm) polycarbonate / Lexan: cuts poorly, discolors, ……

#9 Beginner’s Guide to Materials for Laser Engraving and Cutting

Website: acmerlaser.com

Key Highlights: Paper and cardboard are versatile materials suitable for laser cutting, making them useful for creating intricate paper crafts, custom invitations, and ……

Expert Sourcing Insights for What Materials Does A Laser Cutter Cut

2026 Market Trends: What Materials Does a Laser Cutter Cut?

As laser cutting technology continues to evolve, so too does its application across industries. By 2026, advancements in laser systems and materials science are reshaping what materials can be effectively and efficiently cut. This analysis explores the key materials compatible with laser cutters and how market trends are influencing their use.

Metals

Metal cutting remains a dominant application of industrial laser technology. By 2026, fiber lasers are expected to dominate the metal processing sector due to their high efficiency, precision, and lower operational costs. Common metals cut include:

- Steel (mild, stainless, and tool steel): Widely used in automotive, aerospace, and construction industries. High-powered lasers (3–12 kW) enable faster, cleaner cuts with minimal burring.

- Aluminum: Increasingly popular in electric vehicle (EV) manufacturing and consumer electronics. Advances in laser pulsing techniques reduce reflectivity issues and improve edge quality.

- Copper and Brass: Traditionally challenging due to high thermal conductivity and reflectivity, but new green and blue wavelength lasers are making these materials more accessible for precision cutting in electronics and decorative applications.

The trend toward lightweighting in transportation and demand for high-precision components will drive metal laser cutting innovation through 2026.

Plastics

Laser cutting of plastics is expanding rapidly, especially in medical devices, electronics, and consumer goods. By 2026, the focus will be on clean, flame-free processing with minimal thermal distortion.

- Acrylic (PMMA): Remains a top choice for signage and displays due to its ability to produce polished edges when cut with CO₂ lasers.

- Polycarbonate and ABS: Common in automotive interiors and enclosures. However, care is required due to potential melting or toxic fume emission—leading to demand for enclosed systems with filtration.

- PET, PTFE, and Polyimide: Used in flexible circuits and insulation materials. UV and CO₂ lasers with precise control are enabling micro-cutting applications.

Environmental regulations are pushing manufacturers to adopt laser systems that minimize waste and volatile organic compound (VOC) emissions, favoring laser over mechanical or chemical cutting.

Wood and Composites

Sustainability and customization trends are fueling demand for laser cutting in woodworking and composite materials, particularly in furniture, architecture, and DIY markets.

- Plywood, MDF, and Solid Wood: CO₂ lasers are ideal for intricate designs and prototyping. By 2026, integration with CAD/CAM software will allow mass customization in cabinetry and interior design.

- Laminates and Engineered Wood: Growing use in modular construction. Lasers enable precise joinery and cut-to-fit manufacturing, reducing material waste.

- Carbon Fiber and Fiberglass: Used in aerospace, sports equipment, and automotive sectors. Fiber lasers and hybrid systems are improving cut quality while minimizing delamination.

The rise of Industry 4.0 and digital fabrication is making laser cutting a core process in on-demand and decentralized manufacturing ecosystems.

Textiles and Fabrics

The textile industry is embracing laser cutting for its precision, speed, and ability to prevent fraying.

- Natural Fabrics (cotton, silk, wool): CO₂ lasers provide clean, sealed edges ideal for fashion and technical apparel.

- Synthetics (polyester, nylon, spandex): Increasingly used in sportswear and smart textiles. Lasers allow for complex patterns without mechanical stress.

- Technical Textiles: Used in medical devices (e.g., stents, wound dressings) and filtration systems. Ultrafast lasers (femtosecond/picosecond) enable micron-level precision.

Automation and integration with roll-to-roll systems will make laser cutting a standard in high-volume textile production by 2026.

Glass and Ceramics

Though challenging, laser processing of brittle materials is advancing with ultrafast laser technology.

- Glass: Used in consumer electronics (smartphone covers, displays) and architectural design. Pulsed lasers create micro-cracks for controlled separation, enabling complex shapes without chipping.

- Ceramics: Applied in semiconductors, medical implants, and insulation. Picosecond lasers minimize thermal damage, making them ideal for high-integrity components.

These niche but high-value applications are expected to grow as laser systems become more affordable and reliable.

Emerging Materials

By 2026, laser cutting will expand into new frontiers:

- Graphene and 2D Materials: Ultrafast lasers are being explored for patterning atom-thin materials in next-gen electronics.

- Biodegradable Polymers: In response to sustainability goals, lasers are used to cut PLA and other compostable materials in packaging and medical devices.

- Hybrid and Smart Materials: Materials with embedded sensors or shape-memory properties require contamination-free, precise cutting—ideal for laser systems.

Conclusion

The 2026 laser cutting market is defined by versatility, precision, and sustainability. With ongoing improvements in laser sources (fiber, CO₂, ultrafast), software integration, and material compatibility, laser cutters are becoming indispensable across manufacturing, design, and high-tech industries. Businesses that leverage these trends will gain a competitive edge in efficiency, customization, and environmental compliance.

Common Pitfalls When Sourcing Materials for Laser Cutting (Quality & IP)

When sourcing materials for laser cutting, overlooking critical quality and intellectual property (IP) considerations can lead to production delays, safety hazards, or legal complications. Below are common pitfalls to avoid:

Inadequate Material Specifications

One of the most frequent mistakes is failing to define precise material properties such as thickness tolerance, composition, and surface finish. Slight deviations in material consistency can result in uneven cuts, charring, or incomplete processing, especially with sensitive materials like acrylic or thin metals.

Ignoring Material Certification and Traceability

Sourcing materials without proper certification (e.g., ASTM, ISO) or traceability documentation risks using substandard or non-compliant stock. This is particularly critical in regulated industries like aerospace or medical devices, where material provenance directly impacts product safety and quality.

Overlooking Flammability and Safety Risks

Certain plastics, such as PVC or polycarbonate, emit toxic fumes when laser-cut. Sourcing such materials without assessing their safety profile not only compromises operator health but may also void equipment warranties or violate workplace safety regulations.

Assuming All “Laser-Cuttable” Materials Perform Equally

Not all materials labeled as “laser-cuttable” deliver consistent results. For instance, acrylics from different manufacturers may vary in optical clarity or flame resistance. Failing to test samples before bulk procurement can result in poor edge quality or unexpected material behavior during cutting.

Neglecting Intellectual Property in Custom or Branded Materials

When sourcing proprietary or branded materials (e.g., fire-retardant composites or patented polymers), buyers may inadvertently violate licensing agreements or use materials outside permitted applications. Always verify IP rights and usage permissions, especially when producing commercial products.

Relying Solely on Supplier Claims Without Testing

Suppliers may overstate a material’s compatibility with laser cutting. Without conducting in-house testing or requesting cutting samples, you risk discovering issues only after production has begun, leading to costly rework or material waste.

Failing to Consider Environmental and Regulatory Compliance

Materials may contain restricted substances (e.g., halogens, heavy metals) that conflict with environmental regulations like RoHS or REACH. Sourcing without verifying compliance can result in shipment rejections or legal penalties, particularly in international markets.

Inadequate Documentation for Quality Audits

Poor record-keeping—such as missing batch numbers, supplier certifications, or test reports—can hinder quality audits and traceability. This is a major pitfall in high-reliability sectors where full documentation is required for compliance and liability protection.

Avoiding these pitfalls requires due diligence in vetting suppliers, demanding detailed material data, and validating performance through testing—ensuring both quality output and IP integrity in laser cutting operations.

What Materials Does a Laser Cutter Cut? – Logistics & Compliance Guide

When utilizing laser cutting technology, it is essential to understand not only the materials compatible with the process but also the logistical and compliance considerations involved in handling, storing, transporting, and processing these materials. This guide outlines common materials suitable for laser cutting and details the associated logistics and regulatory requirements to ensure safe and compliant operations.

Wood and Wood-Based Materials

Common Types: Plywood, MDF (medium-density fiberboard), balsa, hardwoods (e.g., birch, oak), and bamboo.

Logistics Considerations:

– Store in dry, climate-controlled environments to prevent warping or moisture absorption.

– Secure stacking with spacers to allow airflow and prevent mold growth.

– Use protective wrapping during transport to avoid surface damage.

Compliance Requirements:

– Verify that wood is sourced from sustainably managed forests (FSC or PEFC certification recommended).

– Monitor for formaldehyde emissions in MDF; comply with EPA TSCA Title VI or CARB Phase 2 standards.

– Ensure proper ventilation during cutting to manage airborne particulates; use dust collection systems compliant with OSHA PEL (Permissible Exposure Limits).

Plastics

Common Types: Acrylic (PMMA), polycarbonate (limited use), ABS (not recommended), PET, PETG, polystyrene (avoid due to toxic fumes).

Logistics Considerations:

– Store flat to prevent warping; protect from UV exposure and high temperatures.

– Handle with care to avoid surface scratching; use anti-static packaging if necessary.

– Segregate incompatible plastics (e.g., PVC from acrylic) to prevent cross-contamination.

Compliance Requirements:

– PVC (Polyvinyl Chloride) must never be laser cut—it releases chlorine gas, a hazardous substance regulated under OSHA and EPA standards.

– Use only plastics rated for laser processing; verify manufacturer specifications.

– Implement fume extraction systems meeting ANSI Z9.7 or local air quality regulations.

– Maintain SDS (Safety Data Sheets) for all plastics on site.

Metals (With Fiber Laser Cutters)

Common Types: Steel (mild and stainless), aluminum, brass, copper (limited).

Logistics Considerations:

– Store in dry areas to prevent rust; use protective coatings or films on polished surfaces.

– Use non-marring handling equipment to avoid scratches.

– Package with edge protectors during shipping to prevent deformation.

Compliance Requirements:

– Follow OSHA guidelines for handling metal dust and fumes; use appropriate PPE (respirators, gloves, eye protection).

– Employ fume extraction systems capable of capturing fine metal particulates (NIOSH-approved).

– Comply with local fire codes—metal cutting may generate sparks requiring fire suppression systems.

– Ensure laser systems are Class 1 enclosures or interlocked for operator safety (compliant with IEC 60825-1).

Fabrics and Textiles

Common Types: Cotton, felt, polyester, leather, neoprene.

Logistics Considerations:

– Store in low-humidity environments to prevent mildew.

– Keep materials clean and free of oils or contaminants before cutting.

– Use rolls or flat storage to avoid creasing.

Compliance Requirements:

– Use ventilation or filtration to control airborne fibers (especially synthetic textiles).

– Avoid cutting materials treated with flame retardants or coatings that may emit toxic fumes.

– Comply with textile flammability standards (e.g., 16 CFR Part 1610 in the U.S.) if producing consumer goods.

Paper and Cardboard

Common Types: Standard paper, cardstock, corrugated board.

Logistics Considerations:

– Store flat and away from moisture to prevent curling.

– Handle in clean environments to avoid dirt transfer.

Compliance Requirements:

– Fire risk is elevated—ensure laser workspace is free of paper buildup and equipped with fire suppression.

– Use dust extraction to maintain air quality; paper dust is combustible (NFPA 652 compliance recommended).

Composites and Other Materials

Common Types: Carbon fiber (limited), fiberglass (not recommended), laminates.

Logistics Considerations:

– Store flat and protected from moisture.

– Mark orientation and grain direction for precision cutting.

Compliance Requirements:

– Cutting carbon fiber generates conductive dust—requires specialized filtration (explosion-proof) and grounding protocols.

– Fiberglass releases hazardous respirable fibers; avoid laser cutting unless using enclosed, HEPA-filtered systems compliant with OSHA silica and fiber exposure limits.

General Compliance and Safety Best Practices

- Laser Safety: All laser operations must comply with ANSI Z136.1 (U.S.) or IEC 60825 standards. Use appropriate laser protective eyewear.

- Ventilation & Filtration: Install exhaust systems with activated carbon and HEPA filters to capture VOCs and particulates.

- Waste Disposal: Segregate and dispose of waste materials according to local environmental regulations (e.g., RCRA for hazardous waste in the U.S.).

- Training: Ensure operators are trained in material compatibility, emergency procedures, and regulatory compliance.

- Documentation: Maintain logs of maintenance, material usage, and safety inspections for audit readiness.

By aligning material selection with logistical planning and strict compliance protocols, businesses can maximize the efficiency, safety, and legality of their laser cutting operations.

In conclusion, laser cutters are highly versatile tools capable of cutting a wide range of materials, including wood, acrylic, plastic, fabric, leather, rubber, paper, and certain types of thin metals—depending on the laser type (CO2, fiber, or Nd:YAG) and machine power. However, not all materials are suitable; substances like PVC or polycarbonate can release harmful fumes or melt unevenly, posing safety and quality risks. Therefore, proper material selection is crucial for both optimal cutting performance and operator safety. Understanding the compatibility between the laser cutter and the intended material ensures efficient, precise, and safe operation across various industrial, artistic, and prototyping applications.