The global Electrical Discharge Machining (EDM) market is experiencing robust growth, driven by increasing demand for high-precision manufacturing across industries such as aerospace, automotive, and medical devices. According to a report by Mordor Intelligence, the EDM market was valued at approximately USD 5.8 billion in 2023 and is projected to grow at a compound annual growth rate (CAGR) of over 6.5% through 2029. This expansion is fueled by advancements in multi-axis CNC technology, the rising need for micro-machining capabilities, and the integration of automation and Industry 4.0 principles in production environments. As manufacturers prioritize precision, efficiency, and minimal material waste, EDM machines—particularly wire-cut and sinker variants—have become critical assets in modern machine shops. With market competition intensifying, several key players have emerged as leaders in innovation, reliability, and global reach. Based on market share data, technological capabilities, and industry reputation, the following analysis identifies the top 10 EDM machine manufacturers shaping the future of precision machining.

Top 10 What Is Edm Machine Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Accutex EDM Machines

Domain Est. 2001 | Founded: 2001

Website: accutex.com.tw

Key Highlights: Accutex is the original and professional wire cut EDM manufacturing company. We founded in 2001 by a group of engineers from Industrial Technology Research ……

#2 Chmer

Domain Est. 1997

Website: chmer.com

Key Highlights: CHMER is dedicated to advancing the technology and the quality of the EDM industry in Taiwan and worldwide EDM market….

#3 EDM Machine Manufacturer in India

Domain Est. 1997

Website: electronicagroup.com

Key Highlights: We are the leading manufacturer and exporter of various machine tools which includes CNC wire EDM, Sinker EDM machine, Metal cutting, EDM supply shopee, ……

#4 UNITED MACHINING

Domain Est. 1999

Website: gfms.com

Key Highlights: UNITED MACHINING delivers comprehensive, integrated solutions for manufacturers of precision parts, tools, and mold-making — helping them move seamlessly from ……

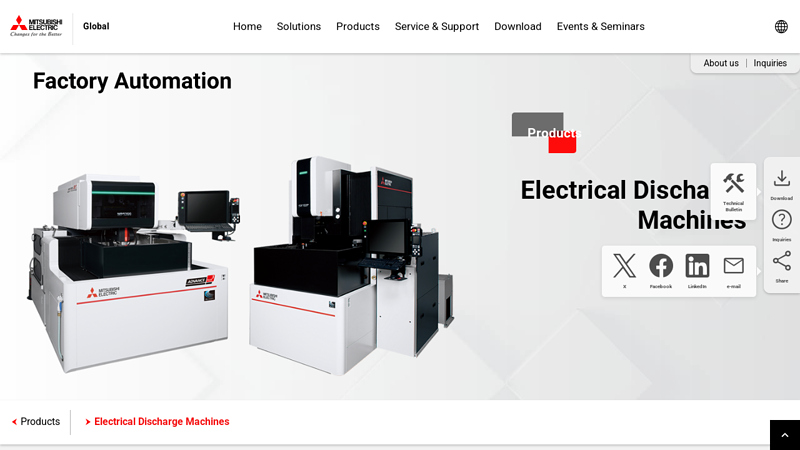

#5 Electrical Discharge Machines

Domain Est. 1996

Website: mitsubishielectric.com

Key Highlights: Mitsubishi Electric Die-sinking EDMs and Wire-cut EDMs enhance productivity with high-speed and high-accuracy. Besides mold making, it is also recognized as a ……

#6 Makino Electrical Discharge Machining

Domain Est. 1996

Website: makino.com

Key Highlights: Wire EDM machines are able to carefully remove excess material without exerting a strong cutting force and is most commonly used in mold and die manufacturing ……

#7 Sodick

Domain Est. 1998

Website: sodick.com

Key Highlights: Expand your capabilities, and increase productivity with Sodick’s cutting-edge EDM, high-speed milling, and additive manufacturing solutions….

#8 Metal Fabrication Machinery

Domain Est. 1998

Website: mcmachinery.com

Key Highlights: MC Machinery Systems, a supplier of metal fabrication machines, provides EDM, milling, laser, press brake, finishing, and automation solutions….

#9 EDM Technologies

Domain Est. 1999

Website: edmtechnologies.net

Key Highlights: EDM Technologies is the largest electrical discharge machining (EDM) shop in the southeast. We are an ISO 9001:2015 certified company and have specialized in ……

#10 Electrical Discharge Machining Companies

Domain Est. 2000

Website: electricaldischargemachining.com

Key Highlights: Find the leading electrical discharge machining companies who produce custom products from various materials, including aluminum, steel, copper, and brass….

Expert Sourcing Insights for What Is Edm Machine

2026 Market Trends for What Is EDM Machine

As industries continue to evolve with advancements in manufacturing technologies, the Electrical Discharge Machining (EDM) sector is poised for significant transformation by 2026. EDM machines, which use electrical discharges (sparks) to shape conductive materials with high precision, are becoming increasingly vital in sectors such as aerospace, automotive, medical device manufacturing, and mold-making. This analysis explores key market trends expected to shape the EDM machine industry in 2026.

Rising Demand for Precision Manufacturing

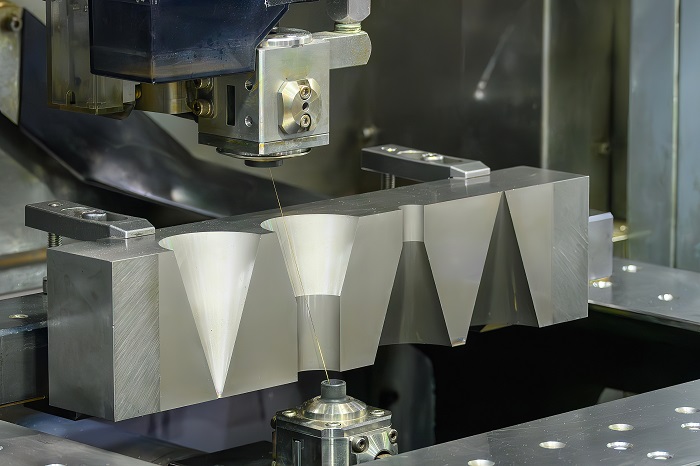

One of the primary drivers of EDM machine adoption is the growing demand for ultra-precision components in high-tech industries. By 2026, industries like aerospace and medical technology will require tighter tolerances and complex geometries that traditional machining methods struggle to achieve. EDM—particularly wire and sinker EDM—excels in producing intricate details on hard metals such as titanium, Inconel, and hardened steel, making it indispensable for advanced manufacturing workflows.

Integration of Smart Technologies and Industry 4.0

The integration of EDM machines with smart manufacturing ecosystems is set to accelerate. By 2026, expect widespread adoption of IoT-enabled EDM systems that offer real-time monitoring, predictive maintenance, and remote diagnostics. Machine learning algorithms will optimize cutting parameters, reduce cycle times, and improve surface finish quality. This digital transformation will enhance efficiency, reduce downtime, and support the shift toward fully automated smart factories.

Growth in Micro-EDM Applications

The miniaturization of components—especially in electronics, medical implants, and micro-molds—is fueling demand for micro-EDM technology. By 2026, micro-EDM machines capable of machining features at micron-level accuracy will see increased investment. These systems will be essential for manufacturing micro-gears, sensors, and catheter tips, where precision surpasses the capabilities of conventional machining.

Expansion in Emerging Markets

Developing economies in Asia-Pacific, Latin America, and Eastern Europe are investing heavily in industrial modernization. Countries like India, Vietnam, and Mexico are expanding their manufacturing bases, particularly in automotive and electronics sectors, which are major consumers of EDM technology. By 2026, these regions are expected to account for a growing share of global EDM machine demand, driven by rising infrastructure development and government incentives for advanced manufacturing.

Sustainability and Energy Efficiency Focus

Environmental regulations and corporate sustainability goals will influence EDM machine design. Manufacturers are expected to prioritize energy-efficient power supplies, reduced dielectric fluid consumption, and recycling systems. By 2026, eco-friendly EDM models with lower carbon footprints will become a competitive differentiator, especially in Europe and North America where green manufacturing standards are tightening.

Advancements in Hybrid and Multi-Function Machines

To improve productivity and reduce setup times, hybrid EDM machines that combine EDM with milling, grinding, or additive manufacturing functions are expected to gain traction. By 2026, multi-tasking machines capable of performing several operations in a single setup will be increasingly adopted, particularly by job shops and high-mix manufacturers seeking flexibility and faster turnaround times.

Conclusion

By 2026, the EDM machine market will be shaped by technological innovation, increasing precision demands, and digital integration. As industries continue to push the boundaries of what’s manufacturable, EDM technology will remain at the forefront of advanced machining solutions. Companies that invest in smart, sustainable, and versatile EDM systems will be best positioned to capitalize on emerging opportunities in the global manufacturing landscape.

Common Pitfalls When Sourcing EDM Machines: Quality and Intellectual Property Concerns

When sourcing Electrical Discharge Machining (EDM) machines, businesses often face a range of challenges that can compromise both operational efficiency and legal compliance. Two of the most critical areas of concern are machine quality and intellectual property (IP) risks. Understanding these pitfalls is essential for making informed procurement decisions.

1. Compromised Machine Quality

One of the most frequent pitfalls in sourcing EDM machines—especially from low-cost or offshore suppliers—is receiving equipment that fails to meet expected quality standards. Key issues include:

-

Inconsistent Manufacturing Standards: Machines from unverified manufacturers may not adhere to international standards (e.g., ISO, CE), leading to poor performance, frequent breakdowns, and safety hazards.

-

Use of Substandard Components: Some suppliers may cut costs by using inferior electrical, mechanical, or control system components, which directly impacts precision, reliability, and machine lifespan.

-

Lack of Rigorous Testing: Lower-tier suppliers may skip comprehensive factory acceptance testing (FAT), resulting in machines that require extensive troubleshooting upon installation.

-

Inadequate After-Sales Support: Poor quality often correlates with weak technical support, limited spare parts availability, and delayed service, increasing downtime and total cost of ownership.

2. Intellectual Property (IP) Risks

Sourcing EDM machines, particularly from certain regions, carries significant IP-related risks that many buyers overlook:

-

Counterfeit or Clone Machines: Some suppliers offer machines that closely mimic designs from reputable brands but are unauthorized replicas. These clones may infringe on patents, trademarks, or proprietary technology.

-

Embedded Pirated Software: Control systems on lower-cost EDM machines may use unlicensed or pirated versions of CAM, CNC, or simulation software, exposing the buyer to legal liability and cybersecurity threats.

-

Lack of IP Documentation: Reputable suppliers provide clear documentation of IP ownership and compliance. When this is missing, buyers risk purchasing machines with unclear legal standing.

-

Exposure to Legal Action: If a machine incorporates stolen or unlicensed technology, the end-user—not just the supplier—could face legal consequences, including fines, import bans, or reputational damage.

Mitigation Strategies

To avoid these pitfalls, buyers should:

- Conduct thorough due diligence on suppliers, including factory audits and reference checks.

- Request certifications (e.g., ISO, CE) and validate compliance.

- Verify software licensing and demand proof of IP ownership.

- Engage legal counsel to review contracts and include IP indemnification clauses.

- Consider purchasing through authorized distributors or OEMs to ensure authenticity and support.

By proactively addressing quality and IP concerns, organizations can secure reliable, compliant EDM machines that support long-term manufacturing success.

What Is an EDM Machine: Logistics & Compliance Guide

Understanding EDM Machines

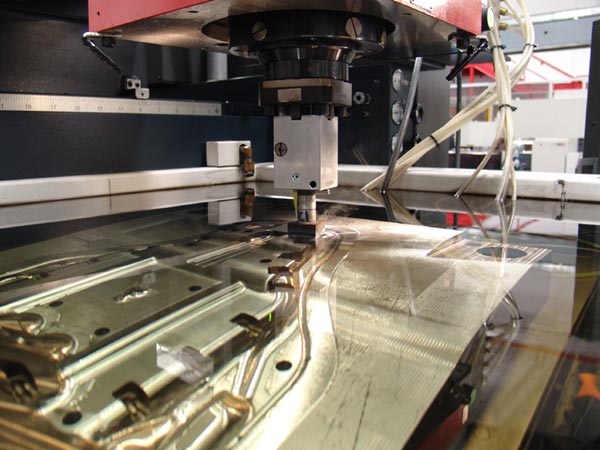

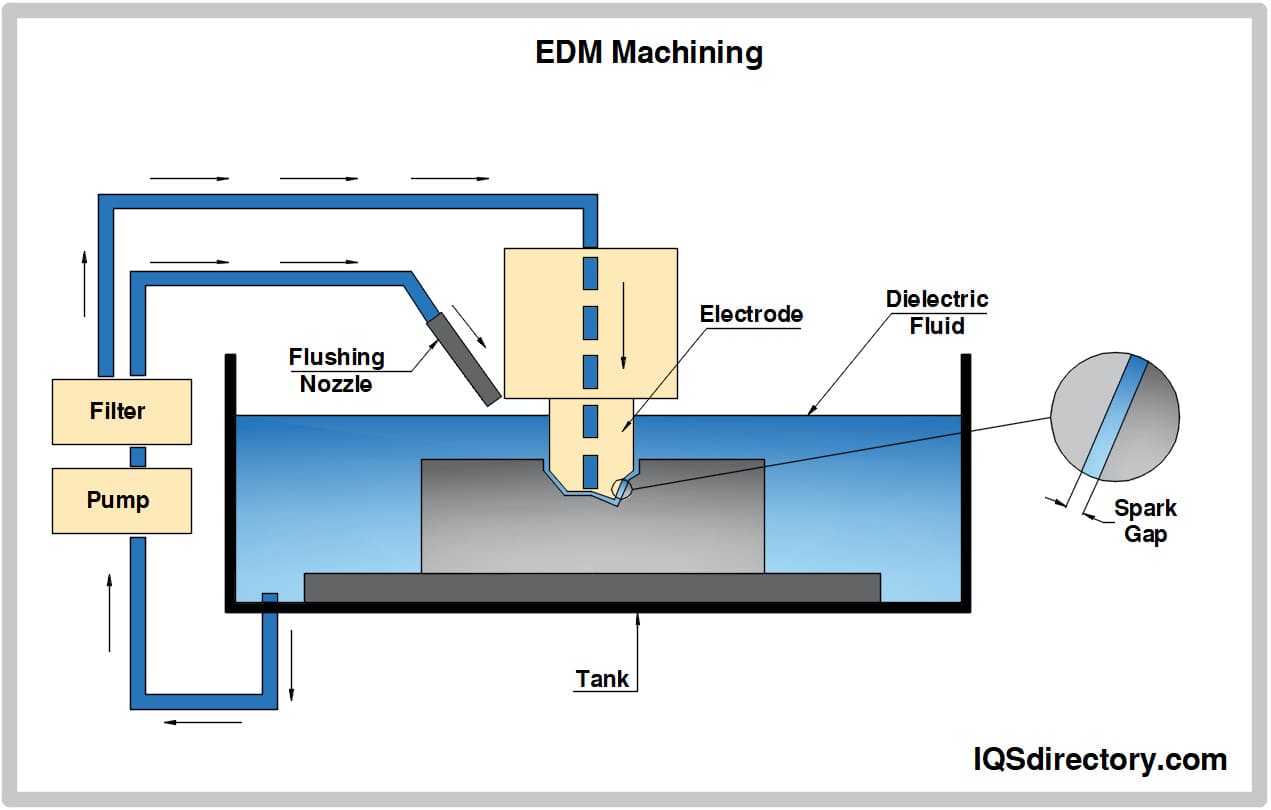

Electrical Discharge Machining (EDM) is a precision manufacturing process that uses electrical sparks to erode conductive materials into intricate shapes. Unlike traditional machining, EDM does not involve direct contact between the tool and the workpiece, making it ideal for creating complex geometries, fine details, and hard materials such as titanium, hardened steel, and exotic alloys. There are three primary types of EDM machines: Wire EDM, Sinker (or Ram) EDM, and Hole-Drilling EDM. Each serves specific industrial applications in aerospace, medical device manufacturing, tool and die making, and automotive sectors.

Logistics Considerations for EDM Machines

Transporting and installing EDM machines requires careful planning due to their size, weight, and sensitivity. Most industrial EDM units weigh several thousand pounds and require reinforced flooring to support their load. Proper site preparation includes ensuring adequate space for machine operation, coolant systems, power supply, and ventilation. These machines typically require three-phase electrical power (e.g., 208V or 480V) and stable voltage to prevent operational disruptions. Climate control is also essential, as temperature fluctuations can affect machining accuracy. Logistics planning should include professional rigging services, lead time for delivery, and scheduling installation during low-production periods to minimize downtime.

Health and Safety Compliance

EDM operations generate fine metal particles, mist from dielectric fluid (typically oil or deionized water), and potentially hazardous fumes. Compliance with occupational health and safety standards such as OSHA (U.S.) or similar national regulations is mandatory. Facilities must install proper ventilation and filtration systems, including fume extractors and mist collectors, to maintain air quality. Operators should wear appropriate personal protective equipment (PPE), including gloves, safety glasses, and respiratory protection when handling fluids or waste. Additionally, dielectric fluids must be stored and handled according to their Material Safety Data Sheets (MSDS/SDS) to prevent fire hazards and environmental contamination.

Environmental Regulations and Waste Management

Used dielectric fluids and sludge containing metal particles are classified as hazardous waste in many jurisdictions, including under the U.S. Environmental Protection Agency (EPA) Resource Conservation and Recovery Act (RCRA). Facilities must follow proper waste segregation, labeling, storage, and disposal procedures. Recycling used oil and reclaiming metal byproducts can reduce environmental impact and disposal costs. Compliance with local, state, and federal environmental laws—including spill prevention, stormwater runoff controls, and emission reporting—is essential. Regular audits and documentation help ensure ongoing regulatory adherence.

Machine Certification and Standards

EDM machines must comply with industry safety and performance standards. In North America, this includes UL 60204-1 (Safety of Machinery – Electrical Equipment of Machines) and compliance with NFPA 70 (National Electrical Code). In Europe, conformity with the CE marking under the Machinery Directive (2006/42/EC) and Low Voltage Directive is required. Buyers and operators should verify that the machine has the appropriate certifications for their region. Regular maintenance and calibration, following manufacturer guidelines and ISO 9001 quality standards, are crucial for sustained compliance and operational accuracy.

Import/Export and International Trade Compliance

For companies importing or exporting EDM machines, adherence to international trade regulations is necessary. This includes proper classification under the Harmonized System (HS Code), typically falling under 8456.30 (Electrical discharge machines). Export controls may apply if the machine has advanced precision capabilities that could be used in military or aerospace applications (e.g., under ITAR or EAR regulations in the U.S.). Accurate documentation—commercial invoices, packing lists, and certificates of origin—is required. Additionally, understanding local import duties, VAT, and customs clearance processes helps avoid delays and penalties.

Training and Operational Compliance

Proper training is critical for safe and compliant EDM machine operation. Employers must provide comprehensive training programs covering machine operation, emergency procedures, lockout/tagout (LOTO), and hazard communication (HazCom). Training records should be maintained to demonstrate compliance during inspections. Operators should also be trained in quality control processes and documentation, especially in regulated industries such as medical or aerospace, where traceability and process validation are required under ISO 13485 or AS9100 standards.

Conclusion

EDM machines are powerful tools for precision manufacturing, but their logistics and compliance requirements are complex. From safe transportation and environmental management to regulatory certifications and workforce training, a comprehensive approach ensures operational efficiency, legal compliance, and workplace safety. By addressing these factors proactively, organizations can maximize the benefits of EDM technology while minimizing risks and regulatory exposure.

In conclusion, sourcing an EDM (Electrical Discharge Machining) machine requires careful consideration of various factors such as the type of EDM (sinker, wire, or hole drilling), precision requirements, material compatibility, production volume, and budget. It is essential to identify reputable suppliers or manufacturers offering reliable machines with technical support, warranties, and service availability. Evaluating both new and used equipment, comparing specifications, and reviewing user feedback can help ensure a cost-effective and efficient acquisition. Ultimately, selecting the right EDM machine enhances manufacturing capabilities, improves accuracy in complex part production, and supports long-term operational success in industries such as aerospace, automotive, and mold-making.