The global fiber laser market, which includes MOPA (Master Oscillator Power Amplifier) laser technology, is experiencing robust expansion driven by increasing demand for precision laser sources in material processing, telecommunications, and medical applications. According to a 2023 report by Mordor Intelligence, the fiber laser market was valued at USD 2.5 billion in 2022 and is projected to grow at a compound annual growth rate (CAGR) of over 8.5% from 2023 to 2028. Similarly, Grand View Research notes that advancements in pulsed laser performance and rising adoption of MOPA lasers in micromachining, marking, and engraving applications are key growth accelerators. The unique ability of MOPA lasers to deliver adjustable pulse durations and high peak power makes them ideal for applications requiring fine control and superior surface quality—characteristics that are increasingly critical in industries such as electronics, automotive, and aerospace. As demand surges, a handful of manufacturers have emerged as leaders, combining innovation, reliability, and scalability to capture significant market share. Here’s a data-informed look at the top 8 MOPA laser manufacturers shaping the future of industrial and scientific laser solutions.

Top 8 What Is A Mopa Laser Manufacturers (2026 Audit Report)

(Ranked by Factory Capability & Trust Score)

#1 MOPA Fiber Lasers

Website: en.jptoe.com

Key Highlights: JPT is a leading laser manufacturer in the world, offering a full range of MOPA, CW, DPSS, and Diode lasers. Our products enable precise welding, cutting, micro ……

#2 MOPA Laser

Website: gravotech.us

Key Highlights: MOPA Laser: Boost your industrial marking performance with unmatched versatility & contrast · PERFORMANT With power outputs of 30W and 60W, this machine ……

#3 MOPA Fiber Laser Marking Machine 30W, 60W, 100W In Stock Now

Website: telesis.com

Key Highlights: Get faster marking, higher contrast & broader material use with XpressMark MOPA™ laser engraver. Autofocus & InLine Vision. Request a quote!…

#4 IPG Photonics

Website: ipgphotonics.com

Key Highlights: IPG Photonics manufactures high-performance fiber lasers, amplifiers, and laser systems for diverse applications and industries. Discover your solution….

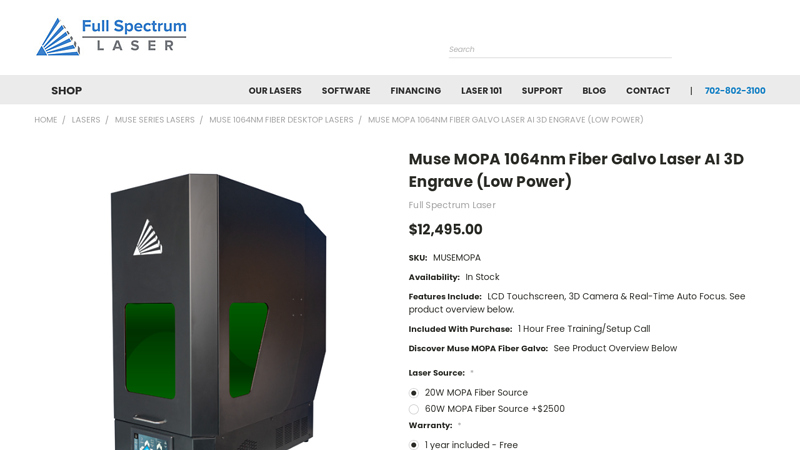

#5 Muse MOPA 1064nm Fiber Galvo Laser AI 3D Engrave (Low Power)

#6 What is a MOPA laser?

Website: justlaser.com

Key Highlights: A MOPA laser is a type of laser that consists of two main components: a master oscillator (MO) and a power amplifier (PA)….

#7 SMARTmark® VP MOPA Fiber Laser Marking System

Website: mecco.com

Key Highlights: Get cleaner, brighter laser marks on plastics, metals, and clear anodized aluminum using the variable pulse width of the VP MOPA Fiber Laser Engraver….

#8 The Definitive Guide to MOPA Fiber Lasers

Website: permanentmarking.com

Key Highlights: MOPA lasers are ideal laser technology for most manufacturers’ operations. Check out our post to learn key MOPA fiber laser insights, ……

Expert Sourcing Insights for What Is A Mopa Laser

2026 Market Trends for What Is A MOPA Laser

As industries continue to adopt advanced laser technologies for precision manufacturing, marking, and engraving, the MOPA (Master Oscillator Power Amplifier) laser is gaining significant traction. By 2026, several market trends are expected to shape the understanding, application, and demand for MOPA lasers. This analysis explores key developments that will define what a MOPA laser is and its role in various industrial sectors.

Rising Demand in Precision Industrial Applications

By 2026, the demand for high-precision laser systems in electronics, automotive, and aerospace industries is projected to grow substantially. MOPA lasers, known for their adjustable pulse durations and superior control over laser parameters, are becoming the preferred choice for fine marking on sensitive materials such as anodized aluminum, stainless steel, and plastics. Their ability to produce high-contrast marks without damaging substrates makes them ideal for serial number engraving, QR code marking, and medical device labeling—applications where accuracy and permanence are critical.

Technological Advancements Enhancing Flexibility

One of the defining trends in 2026 will be the integration of intelligent control systems and software-defined pulse shaping in MOPA lasers. Unlike standard fiber lasers, MOPA lasers allow independent control of pulse width and frequency, enabling manufacturers to switch between deep engraving and surface annealing without changing hardware. Ongoing R&D efforts are focused on enhancing this flexibility with AI-driven optimization tools, allowing real-time parameter adjustments for different materials and production speeds. These improvements are redefining what a MOPA laser is—from a static tool to a dynamic, adaptive system.

Expansion into New Material Processing Applications

MOPA lasers are breaking new ground in processing challenging materials such as copper, brass, and coated composites. Their tunable pulse characteristics reduce heat input, minimizing oxidation and discoloration—issues that have traditionally plagued standard fiber lasers. By 2026, adoption in electric vehicle (EV) battery manufacturing and renewable energy sectors is expected to increase, particularly for marking conductive and heat-sensitive components. This expansion is broadening the perception of MOPA lasers beyond traditional marking roles into high-value, high-tech manufacturing.

Growth in Asia-Pacific Markets

The Asia-Pacific region, particularly China, India, and Southeast Asia, will remain a key driver of MOPA laser adoption by 2026. Rapid industrialization, government support for smart manufacturing, and the rise of domestic laser technology companies are accelerating deployment. Local manufacturers are increasingly offering cost-effective MOPA laser systems with competitive performance, making the technology more accessible. As a result, awareness and understanding of what a MOPA laser is will grow beyond niche engineering circles into broader industrial communities.

Sustainability and Energy Efficiency Focus

Environmental considerations are shaping laser technology development. MOPA lasers are more energy-efficient than many conventional laser systems due to their precise energy delivery and reduced need for post-processing. By 2026, as industries face stricter sustainability regulations, MOPA lasers are expected to be favored for their lower power consumption and reduced material waste. This eco-friendly profile will further enhance their market appeal and reinforce their value proposition in green manufacturing initiatives.

Conclusion

By 2026, the MOPA laser will have evolved from a specialized tool into a cornerstone of modern laser processing. Its unique capabilities—adjustable pulse control, material versatility, and integration with smart systems—are driving widespread adoption across industries. As market trends emphasize precision, flexibility, and sustainability, the definition of what a MOPA laser is will increasingly include attributes of intelligence, adaptability, and environmental responsibility. These factors will solidify its position as a critical technology in the future of industrial automation.

Common Pitfalls When Sourcing a MOPA Laser: Quality and Intellectual Property Concerns

When sourcing a MOPA (Master Oscillator Power Amplifier) laser—commonly used in precision applications such as laser marking, engraving, and material processing—buyers often face critical challenges related to quality assurance and intellectual property (IP) protection. Understanding these pitfalls can help avoid costly mistakes and ensure reliable performance and legal compliance.

1. Compromised Build Quality and Component Sourcing

One of the most common pitfalls is selecting a MOPA laser based solely on price, which often leads to substandard components. Low-cost suppliers may use inferior optical elements, unstable pump diodes, or poor thermal management systems, resulting in:

- Reduced beam quality and inconsistent pulse performance

- Shorter operational lifespan and higher failure rates

- Increased maintenance costs and downtime

Always verify the manufacturer’s quality control processes, such as ISO certifications, and request reliability testing data (e.g., mean time between failures).

2. Inaccurate or Exaggerated Specifications

Some suppliers misrepresent key performance metrics, such as pulse width range, peak power, or repetition rate. For instance, a laser advertised as having a 2–500 ns pulse width range may only maintain stable output in a much narrower actual range. This can severely affect marking quality on sensitive materials like anodized aluminum or plastics.

Solution: Request third-party test reports or conduct in-house validation before full procurement.

3. Lack of Transparency in Manufacturing Origin

Many MOPA lasers are marketed by resellers or trading companies that obscure the actual manufacturer. This lack of transparency raises concerns about:

- Traceability of components

- Ability to obtain technical support or spare parts

- Compliance with international safety and environmental standards (e.g., CE, FDA, RoHS)

Always source directly from OEMs or authorized distributors and verify the manufacturing location.

4. Intellectual Property (IP) Risks

Purchasing MOPA lasers from unverified suppliers, particularly in regions with weak IP enforcement, may expose buyers to legal risks. Some manufacturers produce clones or reverse-engineered versions of patented laser designs, potentially infringing on:

- Optical cavity configurations

- Pulse control algorithms

- Driver and cooling system designs

Using such equipment could lead to third-party litigation or customs seizures in IP-protective markets (e.g., the U.S. or EU).

To mitigate this risk, conduct due diligence on the supplier’s R&D capabilities and request documentation proving original design ownership or licensing agreements.

5. Inadequate After-Sales Support and Warranty

Even with a high-quality laser, poor technical support can undermine operations. Many suppliers offer limited or non-existent service networks, leading to:

- Long repair turnaround times

- Unavailability of firmware updates or calibration tools

- Language and time zone barriers

Ensure the supplier provides comprehensive support, including training, troubleshooting, and spare parts availability.

Conclusion

Sourcing a MOPA laser requires careful evaluation beyond price. Prioritize suppliers with proven quality management systems, transparent manufacturing practices, legitimate IP ownership, and strong after-sales support to avoid performance issues and legal exposure.

What Is A MOPA Laser

A MOPA (Master Oscillator Power Amplifier) laser is a specialized type of fiber laser known for its exceptional control over pulse parameters, making it highly effective for precision marking, engraving, and surface treatment across various industries.

How MOPA Lasers Work

Unlike standard fiber lasers that integrate the oscillator and amplifier into a single unit, MOPA lasers separate these functions. The “Master Oscillator” generates a low-power laser beam with precisely controlled pulse characteristics such as duration, frequency, and shape. This beam is then fed into the “Power Amplifier” stage, where its energy is significantly boosted without altering the original pulse properties. This separation enables independent control over pulse width and frequency, a key advantage over conventional fiber lasers.

Key Features and Advantages

MOPA lasers offer several distinct benefits:

- Adjustable Pulse Width: Pulse duration can be finely tuned—typically from 2 to 500 nanoseconds—allowing for optimized processing of different materials.

- High Flexibility: Independent control over pulse parameters enables superior results on challenging materials like aluminum, stainless steel, and plastics.

- Color Marking on Metals: MOPA lasers excel at producing high-contrast, oxidation-based color marks on stainless steel and titanium without additives.

- Minimal Heat-Affected Zone: Precise pulse control reduces thermal damage, preserving material integrity and enabling fine detail work.

- High-Speed Marking: Efficient energy delivery supports fast processing speeds ideal for industrial production lines.

Common Applications

MOPA lasers are widely used in industries requiring high-precision marking and surface modification:

- Industrial Marking: Permanent serial numbers, barcodes, and logos on metal components.

- Electronics: Fine marking on circuit boards, connectors, and delicate parts.

- Medical Devices: High-contrast, biocompatible markings on surgical tools and implants.

- Automotive: Durable part identification and branding on engine components.

- Jewelry: Intricate engraving and decorative finishes on precious metals.

Logistics Considerations for MOPA Lasers

When acquiring and operating MOPA laser systems, proper logistics planning is essential:

- Shipping & Handling: Units should be shipped in manufacturer-approved packaging with shock detection labels. Secure crating is recommended for international transport.

- Installation Requirements: Ensure adequate space, stable power supply (typically 200–240 V AC), and proper ventilation or cooling systems.

- Inventory Management: Maintain spare parts such as protective lenses, focus heads, and fuses to minimize downtime.

- Training & Support: Schedule technician training during installation and establish access to remote or on-site technical support.

Compliance and Safety Standards

MOPA lasers must adhere to strict regulatory and safety requirements:

- Laser Safety Class: Most industrial MOPA lasers are Class 4 lasers, requiring safety interlocks, emergency stops, and protective enclosures.

- Regulatory Certifications: Ensure compliance with standards such as FDA/CDRH (U.S.), IEC 60825 (international), and CE marking (Europe).

- Workplace Safety: Operators must wear appropriate laser safety eyewear, and facilities should implement beam containment, warning signs, and access controls.

- Environmental Compliance: Follow local regulations for electronic waste disposal and manage cooling system fluids responsibly.

- Documentation: Maintain records of maintenance, safety inspections, and operator training to meet audit and compliance requirements.

Conclusion

MOPA lasers represent a significant advancement in laser technology, offering unmatched control and versatility for industrial applications. Understanding their operation, managing logistics effectively, and ensuring compliance with safety and regulatory standards are crucial for maximizing performance, safety, and return on investment.

In conclusion, sourcing information about a MOPA (Master Oscillator Power Amplifier) laser reveals that it is a specialized type of fiber laser known for its exceptional control over pulse duration, frequency, and shape. Unlike standard fiber lasers, MOPA lasers separate the oscillator and amplifier stages, allowing greater flexibility in laser output parameters. This makes them highly effective for precision applications such as laser marking, engraving, surface cleaning, and micro-machining—especially on sensitive or diverse materials like metals, plastics, and anodized surfaces.

When sourcing a MOPA laser—whether for industrial use or integration into a system—it’s important to consider factors like pulse width adjustability, peak power, repetition rate, wavelength, and beam quality. Additionally, evaluating the manufacturer’s reputation, technical support, and compliance with safety standards ensures reliability and performance.

Overall, MOPA lasers offer a superior level of customization and precision, making them a preferred choice in advanced laser processing applications where control and quality are critical.