The weld footprint (WFT) gauge market has seen steady expansion, driven by increasing demand for precision measurement tools in construction, manufacturing, and pipeline inspection. According to Grand View Research, the global non-destructive testing (NDT) equipment market—of which WFT gauges are a critical component—was valued at USD 2.1 billion in 2022 and is projected to grow at a compound annual growth rate (CAGR) of 7.3% from 2023 to 2030. This growth is fueled by stringent regulatory standards, rising infrastructure investments, and the need for enhanced weld quality assurance. As industries prioritize safety and compliance, the demand for accurate, reliable WFT measurement solutions has intensified, positioning leading manufacturers at the forefront of innovation and quality. Here, we profile the top five WFT gauge manufacturers shaping the industry through technological advancement, global reach, and trusted performance.

Top 5 Wft Gauge Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

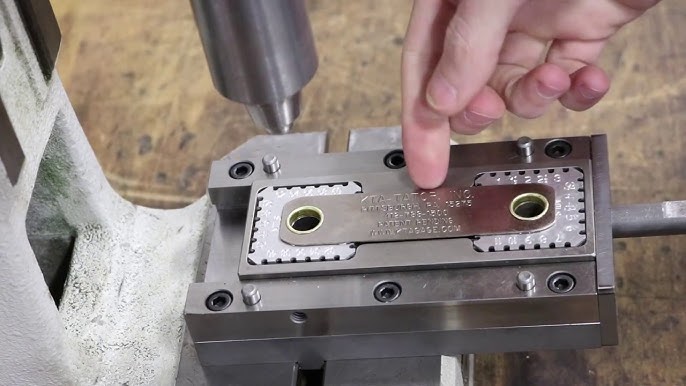

#1 DeFelsko Coating Thickness Gages and Inspection Instruments

Domain Est. 1995

Website: defelsko.com

Key Highlights: Notched Wet Film Thickness Gages measure the thickness of paint, enamels, and other wet films quickly and accurately · Certified Stainless 8-Sided WFT Gage ……

#2 Wet Film & Powder Thickness

Domain Est. 1996

Website: elcometer.com

Key Highlights: A range of Elcometer products for measuring uncured wet film thickness and powder thickness for high quality finish and minimal waste….

#3 Stainless Steel Wet Film Thickness Mil Gauges, 38 Mils To 80 Mils

Domain Est. 2002

Website: geionline.com

Key Highlights: This Wet Film Thickness Gauge measures the wet film thickness from 38 mils to 80 mils (0.038″ to 0.080″) and is quick, easy and simple to use even in unusual ……

#4 Wet Film Thickness Gauge

Domain Est. 2004

Website: petroleumservicecompany.com

Key Highlights: In stock Rating 5.0 (3) Buy our Wet Film Thickness Gauge (WFT gauge), designed to properly test the amount or thickness of a coating being applied to a flat surface in MIL or ……

#5 How to Measure Wet Film Thickness

Domain Est. 2005

Website: painttoprotect.com

Key Highlights: How to measure wet film thickness with a notched wet film gauge. Coating thickness is extremely important & must be measured and recorded accurately….

Expert Sourcing Insights for Wft Gauge

H2 2026 Market Trends Analysis for WFT Gauge

As of the second half of 2026 (H2 2026), the market for WFT (Wireless Flow Technology) Gauges is undergoing significant transformation driven by advancements in digitalization, increasing demand for real-time monitoring in industrial applications, and global shifts toward energy efficiency and sustainability. Below is a comprehensive analysis of the key market trends shaping the WFT Gauge sector during this period.

-

Accelerated Adoption in Oil & Gas and Water Management

WFT Gauges are experiencing heightened deployment across upstream, midstream, and downstream oil & gas operations. Real-time pressure, temperature, and flow monitoring capabilities are enabling predictive maintenance and reducing operational downtime. In parallel, municipal and industrial water management sectors are adopting WFT Gauges to combat water loss and improve distribution efficiency. The integration of these gauges into SCADA and IIoT (Industrial Internet of Things) platforms is a key growth driver. -

Expansion of IIoT and Edge Computing Integration

The convergence of WFT Gauges with IIoT ecosystems has matured by H2 2026. Manufacturers are embedding edge computing modules directly into gauges, allowing for on-site data processing, anomaly detection, and reduced latency in decision-making. This trend is particularly evident in remote or offshore installations where connectivity is limited. -

Regulatory Push for Emissions Monitoring and Leak Detection

Stringent environmental regulations—especially in North America and the EU—are mandating continuous emissions monitoring systems (CEMS) and methane leak detection. WFT Gauges equipped with wireless telemetry are being leveraged to monitor pipeline integrity and detect anomalies early, aligning with ESG (Environmental, Social, and Governance) compliance goals. -

Growth in Smart City and Utility Infrastructure Projects

Urban development initiatives, particularly in Asia-Pacific and the Middle East, are incorporating smart water and gas grid technologies. WFT Gauges are a foundational component of these smart utility networks, enabling remote metering and dynamic load balancing. Government investments in infrastructure resilience are accelerating adoption. -

Advancements in Battery Life and Low-Power Communication

With H2 2026 seeing wider deployment in hard-to-reach locations, manufacturers have significantly improved battery longevity—some models now offer 10+ years of service on a single charge. The adoption of low-power wide-area networks (LPWAN) such as NB-IoT and LoRaWAN has enhanced signal reliability while minimizing energy consumption. -

Consolidation and Strategic Partnerships

The WFT Gauge market is witnessing increased M&A activity and strategic alliances between sensor manufacturers, telecom providers, and cloud platform operators. These collaborations aim to deliver end-to-end monitoring solutions, enhancing data security, interoperability, and scalability. -

Cybersecurity as a Critical Concern

As wireless sensors become integral to critical infrastructure, cybersecurity threats are rising. By H2 2026, leading WFT Gauge providers have implemented advanced encryption, secure boot mechanisms, and over-the-air (OTA) update capabilities to protect against vulnerabilities. -

Regional Market Divergence

While North America and Europe lead in deployment due to regulatory support and mature infrastructure, emerging markets in Southeast Asia, Africa, and Latin America are showing high growth potential. Localized manufacturing and partnerships with regional distributors are becoming essential for global market penetration.

Conclusion

H2 2026 represents a pivotal phase for the WFT Gauge market, characterized by technological maturity, regulatory alignment, and expanding use cases. The convergence of wireless sensing, data analytics, and sustainability imperatives is driving robust growth, with the global WFT Gauge market projected to expand at a CAGR of over 12% through 2027. Companies that prioritize interoperability, security, and energy efficiency will be best positioned to capture market share in this evolving landscape.

Common Pitfalls Sourcing Wft Gauge (Quality, IP)

Sourcing Wft Gauges—particularly those used in critical applications such as oil and gas, aerospace, or industrial measurement systems—requires careful attention to both quality and intellectual property (IP) considerations. Overlooking these aspects can lead to operational failures, legal exposure, and reputational damage. Below are key pitfalls to avoid:

Quality-Related Pitfalls

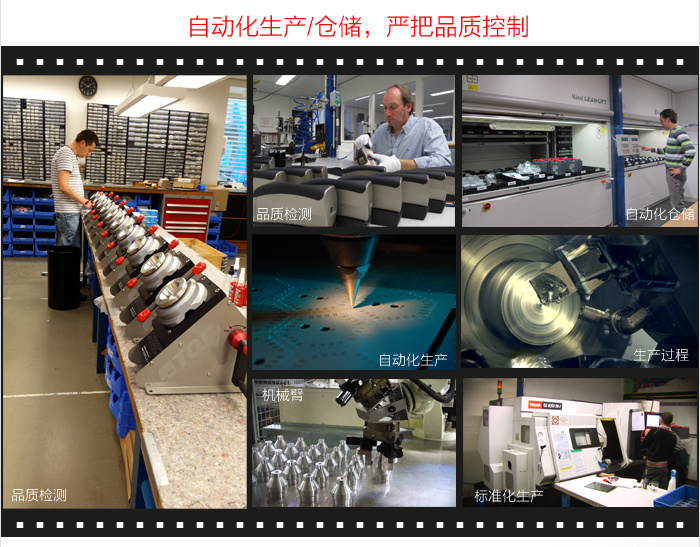

1. Insufficient Supplier Qualification

Failing to thoroughly vet suppliers can result in substandard gauges that do not meet required performance or safety standards. Many low-cost suppliers may lack proper certifications (e.g., ISO 9001, API, ASME), calibrated testing equipment, or traceable quality control processes.

2. Inadequate Material and Manufacturing Standards

Wft Gauges often operate in high-pressure or corrosive environments. Sourcing gauges made from inferior materials or using improper manufacturing techniques (e.g., poor weld integrity, non-compliant tolerances) can lead to premature failure and safety hazards.

3. Lack of Traceability and Documentation

Reputable suppliers provide full documentation, including material test reports (MTRs), calibration certificates, and inspection records. Absence of such documentation increases risk, especially in regulated industries where compliance audits are routine.

4. Poor Calibration and Accuracy Verification

Some suppliers may claim compliance with accuracy standards (e.g., ASME B40.100) without third-party validation. Accepting gauges without independent calibration reports can result in measurement errors that compromise process integrity.

5. Inconsistent Batch Quality

Even with an initially qualified supplier, inconsistent quality across production batches is common, especially with offshore manufacturers. Without ongoing quality audits and incoming inspection protocols, defects may go undetected until deployment.

Intellectual Property (IP)-Related Pitfalls

1. Risk of Counterfeit or Cloned Products

Unverified suppliers may offer “compatible” or “equivalent” Wft Gauges that infringe on patented designs or trademarks. These clones may mimic appearance but lack reliability and can expose the buyer to IP litigation.

2. Unauthorized Use of Proprietary Designs

Some manufacturers reverse-engineer branded gauges and reproduce them without licensing. Purchasing such products—even unknowingly—can make your organization complicit in IP violations, especially under strict international trade laws.

3. Lack of Licensing Agreements

If the Wft Gauge incorporates patented technology (e.g., specific pressure sensing mechanisms or digital interfaces), ensure the supplier has proper licensing. Sourcing from unlicensed producers may result in cease-and-desist orders or product recalls.

4. Ambiguous or Missing IP Clauses in Contracts

Procurement contracts that do not clearly define IP ownership, usage rights, or liability for infringement leave organizations vulnerable. Always include explicit IP warranties and indemnification clauses.

5. Grey Market Procurement

Purchasing from unauthorized distributors or grey market channels increases the risk of receiving non-genuine products with compromised IP status. These channels often lack accountability and may not honor original equipment manufacturer (OEM) warranties.

Mitigation Strategies

- Conduct thorough supplier audits, including on-site inspections.

- Require full compliance documentation and third-party test reports.

- Use trusted distributors or purchase directly from OEMs.

- Include robust IP protection terms in procurement contracts.

- Perform incoming quality inspections with independent verification.

By proactively addressing these quality and IP pitfalls, organizations can ensure reliable performance, regulatory compliance, and legal safety when sourcing Wft Gauges.

Logistics & Compliance Guide for Wft Gauge

This guide outlines the logistics and compliance considerations for the transportation, handling, and regulatory adherence related to the Wft Gauge, a critical measurement device used in industries such as oil and gas, petrochemicals, and utilities. Adhering to these protocols ensures operational safety, legal compliance, and equipment integrity.

Regulatory Compliance

The Wft Gauge must comply with national and international standards governing measurement accuracy, safety, and environmental protection. Key regulations include:

- Weights and Measures Act (Wft): In jurisdictions such as the Netherlands, the Wft (Wet op het financieel toezicht) governs financial supervision, but for gauges and measurement devices, the relevant legislation often falls under metrology laws (e.g., the Dutch Metrology Act, or Wet meet- en regeltechniek). Ensure the Wft Gauge is certified under applicable metrological standards (e.g., MID – Measuring Instruments Directive in the EU).

- ATEX/IECEx Compliance: If used in potentially explosive atmospheres, the gauge must meet ATEX (EU) or IECEx (international) directives for equipment safety.

- Pressure Equipment Directive (PED): If the gauge is part of a pressurized system, verify conformity with PED 2014/68/EU.

- Calibration and Certification: Maintain up-to-date calibration certificates traceable to national standards (e.g., NIST, PTB). Calibration intervals should follow manufacturer recommendations or industry standards (e.g., API, ISO).

Transportation & Handling

Proper logistics handling preserves the accuracy and functionality of the Wft Gauge:

- Packaging: Use manufacturer-approved packaging with shock-absorbing materials to prevent damage during transit. Include moisture protection if shipping in humid environments.

- Labeling: Clearly mark packages with “Fragile,” “This Side Up,” and any hazardous material labels if applicable (e.g., if the gauge contains small amounts of liquid or pressurized components).

- Temperature & Environment: Avoid exposure to extreme temperatures, humidity, and vibration. Transport within the gauge’s specified environmental range (typically -20°C to +60°C unless otherwise stated).

- Carrier Requirements: Use carriers experienced in handling precision instruments. Provide shipping documentation that includes handling instructions and compliance certifications.

Installation & Operational Compliance

Ensure proper installation and ongoing operational adherence:

- Qualified Personnel: Installation and maintenance must be performed by trained and certified technicians familiar with both the device and local safety regulations.

- Documentation: Keep records of installation, commissioning, calibration, maintenance, and any repairs. These documents may be required during audits or inspections.

- Leak Testing: After installation, conduct leak tests where applicable to ensure integrity in pressurized systems.

- Data Integrity: If the gauge is connected to monitoring or control systems, ensure data logging complies with industry standards and cybersecurity requirements (e.g., NERC CIP, ISO 27001).

Maintenance & Inspection

Regular maintenance ensures long-term compliance and reliability:

- Scheduled Inspections: Follow a preventive maintenance schedule based on manufacturer guidelines and operational conditions.

- Calibration Frequency: Recalibrate at least annually, or more frequently in high-use or harsh environments.

- Record Keeping: Maintain a compliance log that includes inspection dates, findings, actions taken, and responsible personnel.

- Non-Conformance Reporting: Establish a process for reporting and addressing deviations from compliance standards.

Disposal & End-of-Life

Environmental and regulatory compliance extends to decommissioning:

- Hazardous Components: Identify and handle any hazardous materials (e.g., mercury, batteries) according to local environmental regulations (e.g., WEEE, RoHS).

- Recycling: Use certified e-waste recyclers for proper disposal of electronic components.

- Documentation: Retain records of disposal to demonstrate compliance with environmental legislation.

Adherence to this logistics and compliance guide ensures the Wft Gauge operates safely, accurately, and in alignment with regulatory expectations throughout its lifecycle.

Conclusion for Sourcing WFT Gauge:

After a comprehensive evaluation of suppliers, technical specifications, quality standards, and cost considerations, sourcing the WFT (Wellhead Flow Temperature) gauge should be approached with a focus on reliability, accuracy, and long-term performance under operating conditions. It is recommended to select a supplier that offers certified, industry-compliant gauges—preferably meeting API, ASME, or ISO standards—with a proven track record in oil and gas applications. Factors such as material compatibility, environmental resilience, and after-sales support are critical to ensuring operational safety and minimizing downtime. By prioritizing quality and supplier credibility over initial cost savings, the organization can ensure accurate temperature monitoring, enhance process efficiency, and maintain compliance with safety and regulatory requirements. Final sourcing decisions should be supported by pilot testing, technical validation, and contractual agreements outlining warranty and service commitments.