The global well screen market is experiencing steady growth, driven by increasing demand for groundwater in agriculture, industrial, and municipal sectors. According to Grand View Research, the global water well screen market size was valued at USD 2.1 billion in 2022 and is expected to expand at a compound annual growth rate (CAGR) of 5.3% from 2023 to 2030. This growth is fueled by rising water scarcity, infrastructure development, and increased focus on sustainable water management. As a critical component in groundwater extraction systems, well screens play a vital role in ensuring efficient and long-term well performance. With advancements in materials and manufacturing technologies, leading producers are enhancing screen durability, corrosion resistance, and filtration efficiency. In this evolving landscape, identifying the top manufacturers becomes essential for engineers, contractors, and water resource managers seeking reliable, high-performance solutions. Based on market presence, innovation, product range, and global reach, the following nine companies have emerged as leaders in the well screen manufacturing industry.

Top 9 Well Screen Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 JetScreens

Domain Est. 2018

Website: jetscreens.com

Key Highlights: JETSCREENS can help you to increase water quality by good intake, safe energy in water production with good strainer and well screen, rack screen for your ……

#2 professional well screens manufacturer

Domain Est. 2022

Website: hdwellscreen.com

Key Highlights: We have been in the line with well screens & casings and wedge wire filters for more than 20 years. Factory audited by ISO9001….

#3 Johnson Screens

Domain Est. 1995

Website: johnsonscreens.com

Key Highlights: Johnson Screens is a leading manufacturer of stainless steel and PVC well screens for water well, environmental, and oil and gas applications….

#4 Johnson Screens A brand of Aqseptence Group

Domain Est. 2016

Website: aqseptence.com

Key Highlights: Johnson Screens is the leading manufacture of screens in industrial filters, water well, architectural elements as well as the Energy and Chemical Processing ……

#5 Well Screen Manufacturer and Supplier in China

Domain Est. 2016

Website: filsonfilters.com

Key Highlights: Filson has over 18 years of experience in manufacturing well screens, with our specialized engineers, skilled workers and advanced production equipment….

#6 Well Screens

Domain Est. 1996

Website: weatherford.com

Key Highlights: From conventional to specialty sand screens such as our shunt-tube designs, our tailor-engineered solutions help you to increase tool longevity and achieve ……

#7 Superior Energy Services

Domain Est. 1996

Website: superiorenergy.com

Key Highlights: From drilling equipment rentals to oilfield services, our portfolio of global companies provides industry expertise and specialized solutions….

#8 Well Screen Co.

Domain Est. 2000 | Founded: 1983

Website: centerlinemanufacturing.com

Key Highlights: Centerline Well Screen Company was established in 1983 and has been growing ever since. From the original, manually operated screen machine in 1983, to the ……

#9 Water Well Screens

Domain Est. 2002

Website: f-e-t.com

Key Highlights: Variperm is a trusted leader in the design and manufacture of high-performance water well screens and filtration systems for Water Wells….

Expert Sourcing Insights for Well Screen

H2: Projected 2026 Market Trends for Well Screens

Based on current industry dynamics, technological advancements, and macroeconomic factors, the well screen market in 2026 is expected to be shaped by several key trends, driven primarily by sustainability demands, technological innovation, and evolving regulatory landscapes.

1. Accelerated Shift Towards Sustainable & Corrosion-Resistant Materials:

The demand for well screens made from advanced materials like high-grade stainless steels (e.g., 316L, duplex), super duplex alloys, and non-metallic composites (e.g., fiberglass-reinforced polymer – FRP) will intensify. This shift is fueled by:

* Stringent Environmental Regulations: Stricter water quality standards (e.g., EU Water Framework Directive, US EPA guidelines) necessitate materials that minimize leaching and contamination, especially in potable water and sensitive ecosystems.

* Long-Term Cost Efficiency: Despite higher initial costs, corrosion-resistant materials offer significantly longer service life and reduced maintenance, making them economically favorable over time, particularly in aggressive environments (high salinity, acidic groundwater, oil & gas applications).

* Sustainability Goals: Operators in mining, oil & gas, and municipal sectors are prioritizing ESG (Environmental, Social, Governance) compliance, favoring durable, recyclable materials that reduce environmental footprint.

2. Dominance of Advanced Manufacturing & Precision Engineering:

Manufacturing processes will increasingly focus on precision, customization, and efficiency:

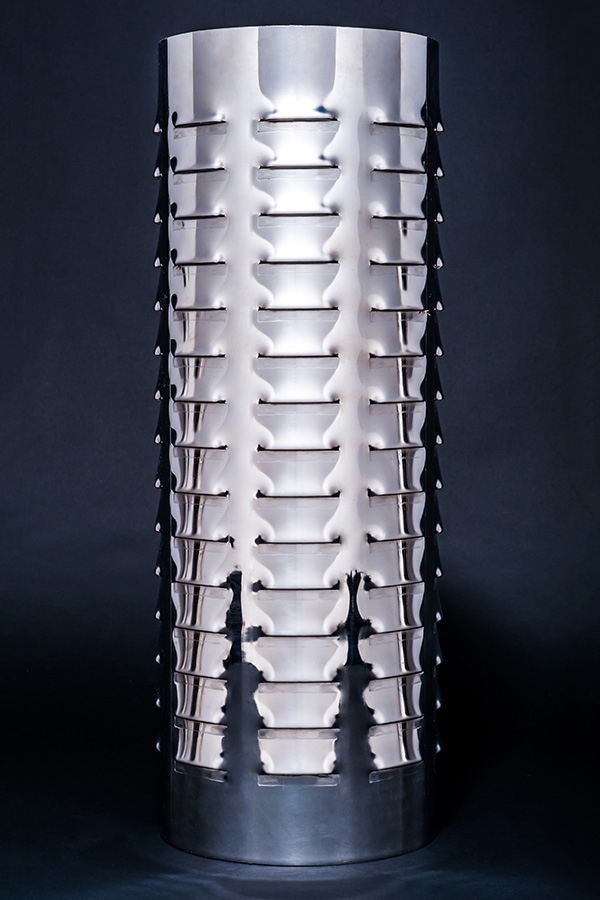

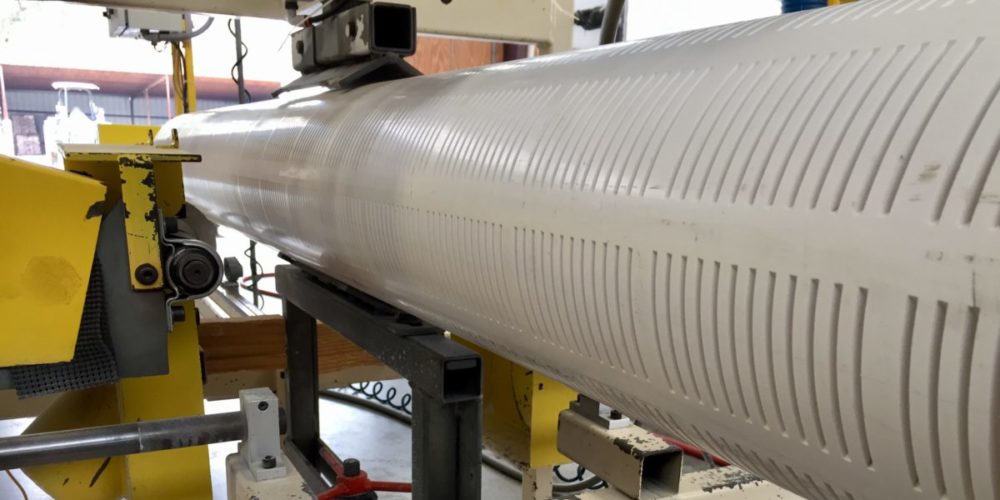

* Laser Cutting & CNC Technology: Wider adoption of laser cutting and CNC machining will enable highly precise slot configurations (e.g., variable slot widths, optimized slot geometries like “V-wire” or “Johnson screen” with micro-tapers) for superior sand control and flow rates, reducing plugging.

* Additive Manufacturing (3D Printing) Pilots: While not mainstream for large screens yet, 2026 will see increased R&D and niche applications of metal 3D printing for complex, customized screen designs and rapid prototyping.

* Automated Welding & Quality Control: Enhanced automation in welding (e.g., orbital welding) and inline quality inspection (e.g., automated optical inspection) will improve consistency, reduce defects, and meet higher quality demands.

3. Growth in Smart & Monitoring-Integrated Screens:

The integration of sensors and IoT (Internet of Things) technology into well screens will move beyond pilot projects towards commercial adoption:

* Real-Time Performance Monitoring: Screens embedded with sensors for flow rate, pressure, temperature, and sand ingress will provide real-time data, enabling predictive maintenance, optimizing pump operation, and preventing well failure.

* Data-Driven Asset Management: Integration with SCADA systems and cloud platforms will allow operators to manage well fields more efficiently, reducing downtime and operational costs, particularly in large-scale water supply and geothermal projects.

4. Demand Driven by Water Security & Alternative Energy:

Key application sectors will drive market growth:

* Groundwater Management: Increasing global water stress will boost demand for efficient, reliable well screens in municipal water supply, agricultural irrigation, and industrial water sourcing, emphasizing high-capacity, long-life solutions.

* Geothermal Energy Expansion: As geothermal energy gains traction for decarbonization, demand for high-temperature, corrosion-resistant screens capable of withstanding harsh geothermal brines will surge.

* Mining Dewatering & Recharge: Sustainable mining practices and stricter dewatering regulations will require robust, reliable screens. Managed Aquifer Recharge (MAR) projects will also increase demand for specialized screens.

5. Regional Market Dynamics & Supply Chain Resilience:

Asia-Pacific Growth: Countries like India, China, and Southeast Asian nations will remain key growth engines due to urbanization, industrialization, and agricultural water needs.

* North America & Europe Modernization: Focus will shift towards retrofitting aging infrastructure and replacing legacy screens with modern, efficient solutions, driven by regulatory updates.

* Supply Chain Localization:* Geopolitical factors and the need for resilience may encourage regional manufacturing hubs to reduce dependence on global supply chains, particularly for critical materials and large-diameter screens.

In conclusion, the 2026 well screen market will be characterized by a strong emphasis on material innovation, precision manufacturing, digitalization, and sustainability. Success will favor manufacturers who offer high-performance, application-specific solutions with integrated intelligence and a demonstrable commitment to environmental responsibility, meeting the evolving needs of water security and the energy transition.

Common Pitfalls When Sourcing Well Screens (Quality and IP)

Sourcing well screens involves more than just selecting a vendor—poor decisions can lead to system failure, contamination, or legal complications. Understanding the common pitfalls related to quality and intellectual property (IP) is essential for ensuring long-term performance and compliance.

Poor Material Quality and Manufacturing Standards

One of the most frequent issues is selecting well screens made from substandard materials or manufactured without adherence to industry specifications (e.g., ASTM, ISO). Low-quality stainless steel or PVC may corrode, degrade, or fail under downhole conditions, leading to screen collapse, biofouling, or reduced water yield. Always verify material certifications and require third-party test reports.

Inadequate Slot Tolerance and Precision

Well screen performance depends heavily on precise slot size and uniformity. Poorly manufactured screens with inconsistent slot dimensions can allow sand incursion or restrict flow, reducing well efficiency. Ensure suppliers use advanced cutting techniques (e.g., wire EDM, laser cutting) and provide slot size verification reports.

Lack of Compliance with Hydraulic and Geological Requirements

Using off-the-shelf screens without tailoring design to site-specific conditions (e.g., aquifer grain size, water chemistry, pumping rates) leads to premature failure. Customization based on hydrogeological data is critical—avoid one-size-fits-all solutions.

Hidden Intellectual Property (IP) Infringement Risks

Some suppliers may use patented screen designs, slot patterns, or manufacturing processes without proper licensing. Purchasing such products—even unknowingly—can expose your project to legal liability, shipment seizures, or forced retrofitting. Always request IP compliance documentation and conduct due diligence on proprietary technologies.

Insufficient Testing and Quality Assurance Documentation

Reliable suppliers provide comprehensive QA/QC documentation, including pressure tests, weld integrity reports, and dimensional inspections. Accepting screens without verifiable test data increases the risk of undetected defects and field failures.

Misrepresentation of Origin and Certification

Counterfeit or misrepresented products—such as falsely labeled “316 stainless steel”—are prevalent in global supply chains. Require mill test certificates (MTCs), origin traceability, and consider third-party inspection at the factory to verify authenticity.

Overlooking Long-Term Support and Warranty Clarity

Some suppliers offer attractive pricing but lack post-purchase support or provide ambiguous warranty terms. Ensure clear warranty coverage for material defects and performance issues, and confirm availability of replacement parts and technical assistance.

By addressing these quality and IP-related pitfalls during procurement, stakeholders can ensure the reliability, legality, and longevity of their well infrastructure.

Logistics & Compliance Guide for Well Screen

This guide outlines the essential logistics and compliance considerations for the handling, transportation, storage, and regulatory adherence related to Well Screen products. Proper adherence ensures product integrity, regulatory compliance, and operational efficiency.

Product Handling and Storage

Well Screen products must be handled and stored according to manufacturer specifications to maintain structural integrity and performance. Store in a clean, dry, and covered environment, protected from direct sunlight, extreme temperatures, and moisture. Avoid contact with corrosive substances or contaminants. Always handle with appropriate lifting equipment—such as slings or cranes rated for the load—and avoid dragging or dropping to prevent damage to screen joints or slots.

Transportation Requirements

Transport Well Screen units on flatbed trailers or specialized carriers that prevent movement during transit. Secure loads using straps or chains to avoid shifting. For long shipments, ensure overhang complies with local transportation regulations. Provide protective end caps on threaded connections and cover screening surfaces to prevent debris ingress. Documentation, including packing slips and safety data sheets (SDS), must accompany each shipment.

Regulatory Compliance

Well Screen products may be subject to regional, national, and international regulations, particularly when used in water, oil & gas, or environmental monitoring wells. Ensure all products meet relevant standards such as API (American Petroleum Institute), ASTM (American Society for Testing and Materials), or ISO (International Organization for Standardization) specifications. Verify compliance with local environmental regulations, including those from the EPA (Environmental Protection Agency) or equivalent bodies, especially when deployed in potable water zones.

Documentation and Traceability

Maintain complete traceability for all Well Screen components. Each batch or unit should have a unique identification number linked to mill test reports, material certifications (e.g., 3.1 or 3.2 EN 10204), and quality inspection records. Retain all compliance documentation for a minimum of 10 years or as required by project or regulatory specifications.

Import/Export Controls

For international shipments, comply with export control regulations such as EAR (Export Administration Regulations) or ITAR (International Traffic in Arms Regulations), if applicable. Verify customs requirements, including HS codes, import permits, and duties. Ensure all paperwork, including commercial invoices, certificates of origin, and packing lists, is accurate and complete to avoid delays.

Environmental and Safety Compliance

Adhere to OSHA (Occupational Safety and Health Administration) and local safety standards during handling and installation. Provide proper training for personnel on safe lifting practices and hazard communication. In environmentally sensitive areas, follow protocols to prevent soil or groundwater contamination during storage and deployment.

Quality Assurance and Audits

Implement a documented quality management system (e.g., ISO 9001) to oversee logistics and compliance processes. Conduct periodic internal audits and prepare for third-party inspections. Address non-conformances promptly and maintain records of corrective actions.

By following this guide, stakeholders can ensure that Well Screen products are delivered and deployed in full compliance with regulatory and operational standards, minimizing risk and ensuring long-term performance.

Conclusion for Sourcing Well Screens

In conclusion, sourcing well screens is a critical step in ensuring the long-term efficiency, durability, and performance of water production or monitoring wells. Selecting the appropriate well screen material, slot size, length, and configuration based on site-specific hydrogeological conditions—such as aquifer grain size, water quality, and expected yield—is essential for optimizing well intake and minimizing issues like sand pumping or clogging.

The sourcing process should involve evaluating reputable manufacturers and suppliers who adhere to industry standards (e.g., ASTM, ISO) and can provide certified materials, technical support, and customization options. Cost considerations must be balanced with quality, as investing in high-performance screens—such as those made from stainless steel, PVC, or corrosion-resistant alloys—can significantly reduce maintenance costs and extend the well’s service life.

Additionally, proper collaboration between engineers, contractors, and suppliers during the procurement phase ensures that screens are manufactured and delivered to exact specifications, minimizing project delays and performance issues. Ultimately, a well-informed sourcing strategy for well screens contributes directly to sustainable groundwater resource management and the overall success of water well projects.