The global demand for reliable water access in off-grid and rural areas has driven significant growth in the well pump infrastructure market. According to a report by Mordor Intelligence, the global water pumps market was valued at USD 51.7 billion in 2022 and is projected to grow at a CAGR of 6.2% from 2023 to 2028. This expansion is fueled by rising investments in residential water supply systems, agricultural irrigation, and decentralized water management—key areas where well pump house kits play a critical role. These prefabricated enclosures protect pumping systems from environmental damage, ensure operational efficiency, and support rapid deployment, making them essential components in modern groundwater extraction. As the need for durable, cost-effective, and scalable solutions grows, so does the importance of selecting manufacturers that combine innovation, quality, and technical expertise. Based on industry performance, product reliability, and market presence, the following list highlights the top 10 well pump house kits manufacturers leading the charge in this expanding sector.

Top 10 Well Pump House Kits Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Commercial Fiberglass Pump Houses

Domain Est. 1997

Website: shelterworks.com

Key Highlights: A Shelter Works fiberglass pump house offers superior protection. They are corrosion-resistant, weather-tight, and customizable. 25-year warranty.Missing: kits manufacturer…

#2 USEMCO

Domain Est. 1996

Website: usemco.com

Key Highlights: USEMCO (Universal Sanitary Equipment Manufacturing Company) is the industry leader for the custom engineering and manufacture of turnkey pump stations, ……

#3 Pioneer Pump

Domain Est. 1999

Website: pioneerpump.com

Key Highlights: Priming Assisted & Standard Centrifugal Pump Parts Kits. Pioneer Pump Parts Kits offer a single part number solution for various maintenance and repair tasks….

#4 Flint & Walling

Domain Est. 2000

Website: flintandwalling.com

Key Highlights: Flint & Walling offers innovative water management solutions and high-quality pumps. Discover reliable products for residential and commercial applications….

#5 Well Saver Pump Houses

Domain Est. 2003

Website: dillonmanuf.com

Key Highlights: Our industry-leading 1.25″ thick fiberglass well pump houses are designed to keep your well pump thawed all winter long and safe from the elements….

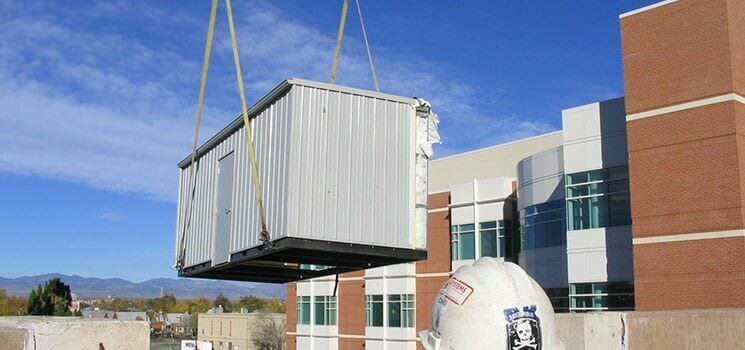

#6 Pump Houses

Domain Est. 2004

Website: panelbuilt.com

Key Highlights: Features & Options. Panel Built offers a variety of prefab well pump house options, providing durability, customization, and protection for your pump systems….

#7 Prefab Well Pump House Enclosures That Protect & Perform

Domain Est. 2004

Website: kabtechusa.com

Key Highlights: Protect pumps with durable prefab enclosures built to perform. KABTech offers turnkey, customizable well pump houses for demanding ……

#8 WELL HOUSES

Domain Est. 2014

Website: alltexirrigation.com

Key Highlights: Our pump and well houses are one-of-a-kind, high quality built insulated metal buildings. Sold exclusively at All-Tex Irrigation….

#9 Wellhouses

Domain Est. 2016

Website: polarsheds.com

Key Highlights: We specialize in Providing durable, insulated, easy to maintain well house options. Our difference lies in the quality, sustainability and care….

#10

Domain Est. 2024

Website: well-saver.com

Key Highlights: Well-Saver specializes in manufacturing sturdy, insulated well houses that are built to last and require minimal upkeep….

Expert Sourcing Insights for Well Pump House Kits

H2: 2026 Market Trends for Well Pump House Kits

The global market for well pump house kits is poised for significant transformation by 2026, driven by technological advancements, sustainability demands, and evolving consumer preferences. As water access becomes increasingly critical in both residential and agricultural sectors, well pump house kits—pre-fabricated enclosures designed to protect well pumps and related equipment—are gaining attention as essential infrastructure components. The following analysis outlines key trends expected to shape the market through 2026.

1. Rising Demand in Rural and Off-Grid Applications

Growing interest in off-grid living and decentralized water systems is fueling demand for well pump house kits, especially in rural and underserved areas. With increasing numbers of homeowners and small-scale farmers seeking independence from municipal water supplies, well pump systems have become a preferred solution. This trend is particularly strong in North America, Sub-Saharan Africa, and parts of Southeast Asia, where infrastructure gaps persist. By 2026, this demand is projected to drive market expansion, with manufacturers focusing on durable, weather-resistant, and easy-to-install kit designs.

2. Integration of Smart Technology

Smart water management systems are becoming more prevalent, and well pump house kits are beginning to incorporate IoT-enabled monitoring devices. By 2026, expect to see kits equipped with sensors for temperature, humidity, pump performance, and water pressure. These features allow remote diagnostics and early fault detection, reducing maintenance costs and preventing system failures. The integration of solar-powered monitoring systems will further enhance the appeal of smart well pump enclosures, especially in remote or energy-constrained locations.

3. Emphasis on Sustainability and Eco-Friendly Materials

Environmental concerns are influencing material choices in the construction of well pump house kits. Manufacturers are increasingly using recycled, recyclable, or low-impact materials such as recycled plastics, sustainably sourced wood composites, and corrosion-resistant galvanized steel. Additionally, energy-efficient insulation and passive ventilation designs are being incorporated to minimize environmental impact and improve operational efficiency. By 2026, eco-certifications and green building compatibility are likely to become key selling points.

4. Expansion of DIY and Modular Kit Solutions

The do-it-yourself (DIY) home improvement market continues to grow, and well pump house kits are benefiting from this trend. Modular, pre-cut, and pre-drilled kits that require minimal tools and technical expertise are becoming more popular. These user-friendly designs reduce installation time and labor costs, appealing to homeowners and small contractors alike. By 2026, expect increased innovation in modular design, including customizable sizes, color options, and compatibility with various pump models.

5. Regulatory and Code Compliance Drivers

As water conservation and infrastructure safety gain regulatory focus, local and national codes are increasingly mandating proper protection for well pumps. This includes requirements for freeze protection, tamper resistance, and pest control—functions that well pump house kits can fulfill. By 2026, compliance with regional building codes and environmental standards will be a major factor in product design and marketing, particularly in colder climates where freeze protection is critical.

6. Regional Market Growth and Emerging Economies

While North America and Europe maintain strong markets due to aging infrastructure and rural development, the fastest growth is expected in emerging economies. In countries like India, Nigeria, and Brazil, increasing investment in rural water access programs and agricultural development is creating new opportunities for well pump house kits. By 2026, localized manufacturing and distribution partnerships are anticipated to emerge, reducing costs and improving accessibility.

7. Competitive Landscape and Product Differentiation

The market is becoming increasingly competitive, with both established manufacturers and new entrants vying for market share. Differentiation is occurring through innovation in design (e.g., lockable, insulated, pest-proof enclosures), value-added features (e.g., integrated power management, ventilation), and customer support (e.g., installation guides, online tools). By 2026, brands that offer comprehensive solutions—combining durability, ease of use, and smart functionality—are likely to dominate.

In conclusion, the well pump house kit market in 2026 will be shaped by a confluence of technological innovation, sustainability imperatives, and global water access challenges. As demand grows across both developed and developing regions, manufacturers that adapt to these trends with forward-thinking designs and customer-centric solutions will be best positioned for success.

Common Pitfalls When Sourcing Well Pump House Kits (Quality & IP)

Sourcing Well Pump House Kits involves more than just finding the lowest price. Overlooking quality and intellectual property (IP) aspects can lead to significant long-term issues, including structural failure, safety hazards, and legal exposure. Below are key pitfalls to avoid:

Poor Material Quality and Construction Standards

Many low-cost kits use substandard materials such as thin-gauge steel, low-grade plastics, or untreated wood that degrade quickly under weather exposure. Inferior fasteners, seals, and insulation compromise durability and energy efficiency. Always verify material specifications, look for corrosion-resistant coatings, and ensure compliance with regional building codes (e.g., snow load, wind resistance). Skipping third-party testing or certifications (such as ASTM or ISO) increases the risk of premature failure and costly repairs.

Lack of Design Validation and Engineering Certification

Some suppliers offer kits without engineered drawings or stamped structural calculations. This poses safety risks, especially in areas prone to extreme weather. Using unverified designs may void insurance coverage and fail municipal inspections. Ensure the kit comes with certified engineering documentation tailored to your geographic location and site conditions.

Inadequate Thermal and Moisture Protection

Poorly insulated kits or those with improper vapor barriers can lead to freezing, condensation, and equipment damage. Kits marketed as “weather-resistant” may lack proper R-value ratings or drainage features. Verify insulation specs, ventilation design, and moisture management features to protect sensitive pump and control components.

Intellectual Property Infringement Risks

Sourcing from manufacturers who replicate patented designs or use copyrighted technical drawings exposes buyers to legal liability. Some overseas suppliers copy branded kits without authorization. Always vet suppliers for IP compliance—request proof of design ownership or licensing agreements. Purchasing counterfeit or infringing products can result in cease-and-desist orders, fines, or forced removal of installed units.

Insufficient Technical Support and Documentation

Low-quality suppliers may provide incomplete assembly instructions, missing hardware, or no post-sale support. This increases installation errors and safety risks. Confirm that kits include detailed manuals, CAD drawings (if applicable), and access to technical assistance. Lack of documentation also complicates maintenance and future upgrades.

Non-Compliance with Local Regulations and Standards

Kits designed for one region may not meet the electrical, plumbing, or zoning requirements of another. For example, NEMA ratings for electrical enclosures or ADA accessibility features may be overlooked. Ensure the kit meets all local codes and can pass permitting inspections to avoid costly rework or regulatory penalties.

Avoiding these pitfalls requires due diligence: request samples, audit supplier credentials, verify certifications, and consult legal or engineering professionals when necessary. Prioritizing quality and IP integrity protects both your investment and operational reliability.

Logistics & Compliance Guide for Well Pump House Kits

This guide outlines the essential logistics and compliance considerations for the transportation, handling, and installation of Well Pump House Kits. Adhering to these guidelines ensures safe delivery, regulatory compliance, and optimal performance of the kit components.

Shipping and Transportation

Well Pump House Kits are typically shipped via freight carriers (LTL or FTL) due to their size and weight. Proper preparation and documentation are critical. All kits must be securely crated or palletized, with components protected from weather and physical damage. Standard shipping documentation—such as a bill of lading, packing list, and commercial invoice—must accompany each shipment. Notify the receiving party in advance to ensure availability for unloading. Confirm site accessibility for large trucks, especially in remote or rural locations where well installations commonly occur.

Import and Customs Compliance

For international shipments, ensure compliance with the import regulations of the destination country. This includes proper HS code classification (commonly under 7308.90 or 9406.00 for prefabricated structures), accurate valuation, and adherence to local standards. Required documentation may include a certificate of origin, import permits, and customs declarations. Be aware of any anti-dumping duties or trade restrictions that may apply. Engage a licensed customs broker when necessary to facilitate smooth clearance.

Regulatory Standards and Certifications

Well Pump House Kits and their components must comply with relevant regional and national standards. In the United States, this may include adherence to the International Building Code (IBC) and International Plumbing Code (IPC), where applicable. Electrical components (e.g., junction boxes, outlets) should be UL or ETL listed. Insulation materials should meet ASTM or local fire safety standards. Verify that any integrated ventilation or heating systems comply with HVAC codes. Local environmental regulations—such as those governing runoff, emissions, or material disposal—must also be observed.

Environmental and Site Compliance

Prior to installation, conduct a site assessment to ensure compliance with local environmental regulations. Confirm that the placement of the pump house does not interfere with protected wetlands, waterways, or floodplains. Erosion and sediment control measures must be implemented during and after installation. If the kit includes chemical-resistant materials or secondary containment features, verify they meet EPA or state environmental protection guidelines. Obtain necessary permits from local authorities, such as grading, building, or environmental permits.

Handling and Storage On-Site

Upon delivery, inspect the kit for damage before signing the delivery receipt. Store components in a dry, level area protected from moisture, UV exposure, and extreme temperatures. Avoid stacking materials in a way that could cause warping or damage. Keep packaging intact until installation to prevent contamination or loss of small parts. Follow the manufacturer’s storage recommendations for sensitive materials such as seals, gaskets, or electrical components.

Installation and Local Permitting

Installation must be performed by qualified personnel in accordance with the manufacturer’s instructions and local codes. A building or mechanical permit may be required prior to beginning work. Final installation should allow for proper drainage, ventilation, and access for maintenance. After completion, schedule any required inspections (e.g., building, electrical, plumbing) to obtain certificates of occupancy or compliance. Maintain records of all permits, inspections, and as-built documentation for future reference.

Safety and Hazard Communication

All personnel involved in handling and installing the kit must follow OSHA safety standards. Provide appropriate personal protective equipment (PPE) during installation. If the kit contains materials with potential hazards (e.g., treated wood, insulation with chemical binders), ensure Safety Data Sheets (SDS) are accessible and that handling procedures are communicated. Clearly label any integrated electrical or mechanical systems to warn of potential risks during operation and maintenance.

Recordkeeping and Documentation

Maintain a comprehensive compliance file including:

– Shipping and delivery records

– Import documentation (for international shipments)

– Certificates of conformity and product testing

– Permits and inspection reports

– As-built drawings and installation manuals

– Warranty and maintenance guidelines

This documentation supports compliance audits, warranty claims, and future servicing of the well pump system.

Conclusion:

Sourcing well pump house kits offers a practical, cost-effective, and efficient solution for protecting wellhead equipment from environmental elements, vandalism, and freezing temperatures. These pre-engineered kits provide a standardized yet customizable option that simplifies installation and ensures consistent quality compared to custom-built structures. When sourcing, it is essential to evaluate factors such as material durability (e.g., UV-resistant polyethylene, galvanized steel, or treated wood), insulation properties, ease of assembly, and local climate requirements. Additionally, considering suppliers with strong reputations, clear warranties, and responsive customer support enhances long-term reliability and satisfaction.

Furthermore, proper sizing, compliance with local codes, and integration with existing well systems are critical to ensuring optimal performance. By carefully selecting the right kit from a reputable source, property owners, municipalities, and contractors can secure a long-lasting, low-maintenance enclosure that ensures the functionality and longevity of well pump systems. Ultimately, investing in a high-quality well pump house kit is a proactive step toward safeguarding vital water infrastructure.