The global pipe fittings market, including specialized products like weldolet fittings, is experiencing steady growth driven by rising demand in oil & gas, chemical processing, and power generation industries. According to Grand View Research, the global pipe fittings market size was valued at USD 33.8 billion in 2022 and is expected to expand at a compound annual growth rate (CAGR) of 6.4% from 2023 to 2030. This growth is fueled by increasing infrastructure development and stringent safety standards requiring reliable pipeline connections—conditions where weldolet fittings excel due to their branch connection integrity and weld strength. As demand intensifies, a select group of manufacturers have emerged as leaders, combining precision engineering, material quality, and global compliance certifications to meet evolving industrial needs. Based on market presence, product innovation, and production capacity, the following four companies stand out as the top weldolet fittings manufacturers shaping the industry today.

Top 4 Weldolet Fittings Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Branch Outlet Fitting

Domain Est. 2007

Website: mega-spa.com

Key Highlights: Discover our range of high-quality branch outlet fittings designed for industrial piping systems. Get reliable and durable solutions for your projects….

#2 Weldolet

Domain Est. 1996

Website: bonneyforge.com

Key Highlights: Weldolet, an economical butt-weld branch connection or butt weld pipe fitting, is designed to minimize stress concentrations and provide integral reinforcement….

#3 Weldolet

Domain Est. 2015

Website: zzsteels.com

Key Highlights: Weldolet is available in branch sizes from 1/8” to 24”, run pipe sizes from 1/4” to 36”, schedule STD, XS and Sch 160 according to MSS SP-97….

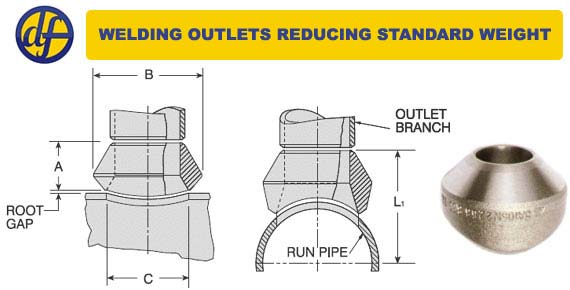

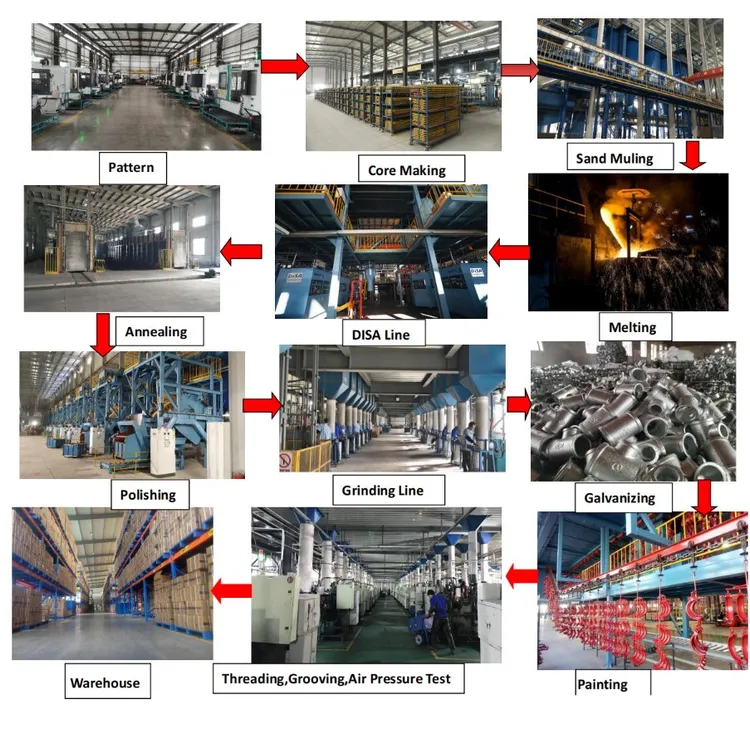

#4 Welding Olets / Outlets dimensions & specifications

Domain Est. 2016

Website: dynamicforgefittings.com

Key Highlights: Welding Olets / Outlets dimensions & specifications. Welding Outlets / Welding Olets Reducing Standard Weight….

Expert Sourcing Insights for Weldolet Fittings

H2: 2026 Market Trends for Weldolet Fittings

The global market for Weldolet fittings is poised for steady growth through 2026, driven by increasing demand across energy, industrial, and infrastructure sectors. Weldolets—branch connection fittings used in piping systems—offer reliable, leak-proof connections and are essential in high-pressure and high-temperature applications. Below are key market trends expected to shape the Weldolet fittings landscape by 2026:

-

Growth in Oil & Gas and Petrochemical Industries

The continued expansion of upstream, midstream, and downstream operations—particularly in regions like the Middle East, North America, and Asia-Pacific—is fueling demand for durable pipeline components. Weldolets are widely used in pipeline tie-ins, manifold systems, and process equipment, making them critical in new installations and maintenance projects. The push for energy security and increased LNG (liquefied natural gas) infrastructure development will further support market growth. -

Rising Infrastructure and Industrialization in Emerging Economies

Countries such as India, Indonesia, and Vietnam are investing heavily in industrial parks, refineries, and power plants. These developments require extensive piping networks, where Weldolets provide efficient and weld-strong branch connections. Government initiatives promoting urbanization and manufacturing growth are expected to boost demand for high-integrity piping solutions. -

Adoption of Advanced Materials and Standards

By 2026, the industry is expected to see greater use of corrosion-resistant alloys (CRAs), stainless steel, and duplex materials in Weldolet manufacturing. Regulatory standards from ASME, ASTM, and API are becoming stricter, pushing manufacturers to improve quality and traceability. Digital certifications and material test reports (MTRs) are becoming standard, especially for critical applications. -

Shift Toward Modular and Prefabricated Piping Systems

Modular construction in oil & gas, offshore platforms, and chemical plants is gaining traction due to cost and time efficiency. Weldolets are integral in prefabricated spools, allowing for faster on-site assembly and reduced welding errors. This trend is expected to increase demand for standardized and dimensionally accurate fittings. -

Sustainability and Maintenance-Driven Replacements

As aging infrastructure in North America and Europe undergoes upgrades, replacement and retrofitting activities are creating demand for high-performance fittings. Weldolets are preferred in repair scenarios due to their minimal intrusion and strong structural integrity. Additionally, the industry’s focus on reducing fugitive emissions favors leak-resistant connection methods. -

Regional Market Dynamics

- Asia-Pacific will remain the fastest-growing market due to rapid industrialization and energy investments.

- North America will see steady demand driven by shale gas projects and pipeline maintenance.

- The Middle East is expanding its refining and petrochemical capacity, increasing the need for high-quality Weldolets.

-

Europe’s market will be influenced by energy transition projects and stricter environmental regulations.

-

Technological Advancements and Digital Integration

Manufacturers are adopting automation, CNC machining, and digital quality control systems to enhance precision and consistency. Some suppliers are integrating IoT-enabled tracking for inventory and supply chain transparency, aligning with Industry 4.0 trends.

In conclusion, the Weldolet fittings market in 2026 will be shaped by energy demand, industrial modernization, and quality advancements. Companies that invest in material innovation, compliance, and efficient manufacturing will be well-positioned to capitalize on emerging opportunities across global markets.

Common Pitfalls Sourcing Weldolet Fittings (Quality, IP)

Sourcing Weldolet fittings requires careful attention to avoid compromises in quality and intellectual property (IP) integrity. Overlooking key factors can lead to safety hazards, project delays, and legal risks. Below are the most common pitfalls to watch for:

Poor Material Quality and Non-Compliance

One of the most frequent issues is receiving Weldolets made from substandard materials or that fail to meet required specifications (e.g., ASTM A105, A182, or A234). Inferior alloys can result in premature failure under pressure, temperature, or corrosive conditions. Always verify mill test certificates (MTCs) and ensure third-party inspection (e.g., third-party inspection agencies or in-house QA) is conducted. Avoid suppliers who cannot provide full traceability or who offer prices significantly below market rates.

Counterfeit or Non-Original Brand Products

Many suppliers falsely claim to offer branded Weldolets (e.g., from recognized manufacturers like Crane, Hydratight, or BJ Pipeline). Counterfeit fittings may mimic branding but lack the engineering, material integrity, or performance of genuine products. These pose serious safety and compliance risks. Always purchase through authorized distributors and verify authenticity with the original equipment manufacturer (OEM).

Inadequate or Fake Certifications

Suppliers may provide falsified documentation, such as fake ISO, API, or PED certifications. These documents are critical for project compliance and safety audits. Request original, stamped certifications and independently verify them with certification bodies. Lack of proper NACE MR0175 compliance in sour service environments is a particularly dangerous oversight.

Intellectual Property (IP) Infringement

Some manufacturers produce “copy” Weldolets that replicate patented designs without licensing. Using such fittings can expose the buyer to legal liability, especially in regulated industries or international projects. Genuine patented products (e.g., those under Crane’s registered designs) require proper licensing. Ensure your supplier respects IP rights and can demonstrate lawful production rights.

Inconsistent Dimensional Accuracy

Poorly manufactured Weldolets may have incorrect branch outlet alignment, wall thickness, or weld bevel dimensions. These inconsistencies compromise weld integrity and can lead to leaks or structural failure. Review dimensional reports and conduct random inspections using calibrated tools to verify conformance to ASME B16.11 or MSS SP-97 standards.

Lack of Traceability and Documentation

Without full material traceability (heat numbers, manufacturing records), it becomes impossible to validate quality during audits or incident investigations. Insist on complete documentation packages, including material test reports, inspection records, and compliance statements. Suppliers who cannot provide this are likely cutting corners elsewhere.

Choosing Based Solely on Price

Opting for the lowest-cost supplier often leads to compromised quality, delayed deliveries, or non-compliant products. The total cost of failure—downtime, repairs, safety incidents—far exceeds initial savings. Prioritize suppliers with proven track records, proper certifications, and transparent manufacturing practices.

Avoiding these pitfalls requires due diligence, supplier vetting, and a focus on long-term reliability over short-term savings. Always conduct factory audits when possible and partner with reputable, transparent suppliers.

Logistics & Compliance Guide for Weldolet Fittings

This guide outlines the essential logistics and compliance considerations for the procurement, handling, transportation, and regulatory adherence related to Weldolet fittings—branch connection fittings used in piping systems.

Procurement & Specification Compliance

Ensure Weldolet fittings are procured according to applicable standards such as ASME B16.9, MSS SP-97, or customer-specified requirements. Verify material grades (e.g., carbon steel, stainless steel, alloy), size (run and branch), schedule, and end preparation (beveled or plain ends). Include required certifications such as Mill Test Reports (MTRs) or Material Certification (e.g., EN 10204 3.1 or 3.2) with each shipment.

Packaging & Handling Requirements

Weldolets must be packaged to prevent damage during transit. Typically, fittings are bundled or boxed with protective end caps (especially on beveled ends) to avoid deformation or contamination. Use moisture-resistant wrapping for corrosion-prone materials. Handle with care using appropriate slings or lifting devices—avoid dropping or dragging to maintain dimensional integrity.

Transportation & Storage Conditions

Transport Weldolets in dry, covered vehicles to prevent exposure to weather and moisture. Store in a clean, dry, and well-ventilated area off the ground on pallets or racks. Segregate by material type and grade to avoid cross-contamination. For stainless steel fittings, ensure storage areas and tools are free from carbon steel residue to prevent galvanic corrosion.

International Shipping & Documentation

For international shipments, ensure compliance with export regulations including accurate HS (Harmonized System) codes—typically under 7307 (stainless or carbon steel pipe fittings). Provide a detailed commercial invoice, packing list, and certificate of origin. Include any export control classifications if applicable (e.g., EAR99 for most general-use fittings). Adhere to Incoterms defined in the contract (e.g., FOB, CIF, DDP).

Regulatory & Industry Standards Compliance

Confirm compliance with regional and industry-specific regulations:

– ASME B31.3 (Process Piping) for design and installation.

– API 5L/5CT if used in oil & gas applications.

– PED (Pressure Equipment Directive 2014/68/EU) for fittings placed in the European market—requires CE marking and involvement of a Notified Body for certain categories.

– CRN (Canadian Registration Number) may be required depending on the province and application.

Quality Assurance & Traceability

Maintain full traceability of Weldolet fittings from manufacturer to end-user. Each batch should be accompanied by documentation that includes heat number, manufacturing standard, material specification, and test results. Implement a quality control process to verify dimensions, weld prep, and surface finish upon receipt.

Environmental & Safety Compliance

Follow OSHA and local safety guidelines during handling and storage. Use proper PPE (gloves, safety glasses) when handling fittings to prevent injury from sharp edges. Dispose of packaging materials in accordance with local environmental regulations. Ensure facilities comply with ISO 14001 if applicable.

Import Clearance & Duties

Prepare for customs inspections by having all required documents readily available. Be aware of import duties, VAT, or tariffs that may apply based on the destination country and material composition. Engage a licensed customs broker when necessary to ensure smooth clearance.

By adhering to this logistics and compliance framework, stakeholders can ensure the safe, legal, and efficient movement of Weldolet fittings through the supply chain while maintaining quality and regulatory conformity.

Conclusion on Sourcing Weldolet Fittings:

In conclusion, sourcing Weldolet fittings requires careful consideration of material compatibility, dimensional accuracy, adherence to industry standards (such as ASME B16.11 and MSS SP-97), and reliable supplier credentials. High-quality Weldolets are essential for ensuring the integrity and longevity of branch connections in piping systems, especially in high-pressure and high-temperature applications across industries like oil & gas, petrochemicals, and power generation.

Prioritizing suppliers with proven quality certifications (e.g., ISO, PED, NACE), traceable material testing (e.g., MTRs), and a strong track record in the industry helps mitigate risks related to failure and non-compliance. Additionally, evaluating total cost—including logistics, lead times, and after-sales support—rather than focusing solely on unit price ensures long-term value and project success.

Ultimately, a strategic sourcing approach that balances quality, compliance, and supply chain reliability is key to securing dependable Weldolet fittings that meet engineering specifications and contribute to the safe and efficient operation of piping systems.