The global smart and water-efficient bathroom fixtures market is witnessing robust growth, driven by increasing urbanization, rising environmental concerns, and a surge in demand for water-saving technologies. According to a report by Mordor Intelligence, the global bathroom fixtures market was valued at USD 56.8 billion in 2023 and is projected to grow at a CAGR of 4.2% through 2029. A critical component within this ecosystem is the toilet inlet valve, particularly the WDI (Water Distribution International) compliant variants, which ensure efficient water regulation, leak prevention, and compliance with stringent plumbing standards. With water conservation becoming a global priority—especially in commercial and multi-family residential buildings—demand for high-performance WDI toilet inlet valves is on the rise. This growing market has spurred innovation and competition among manufacturers, leading to advancements in durability, precision, and ease of installation. Based on market presence, product reliability, compliance with industry standards, and distribution reach, the following four manufacturers have emerged as leaders in the WDI toilet inlet valve space.

Top 4 Wdi Toilet Inlet Valve Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 WDI Technology Co Ltd

Domain Est. 2013

Website: wdiecoflush.com

Key Highlights: As the proud manufacturer of Ecoflush pressure-assisted flushing systems, WDI is here to save you time, money and frustration with our inventory….

#2 wdi technology inc

Domain Est. 2001 | Founded: 1993

Website: wdiplumbing.com

Key Highlights: Established in 1993, WDI is a an international company aimed at providing the best bath products and solutions to our valued customers….

#3 WDI

Domain Est. 2016

Website: sanitecph.com

Key Highlights: WDI is Asia’s largest leading provider of sanitary ware accessories. Its headquarters is located in Xiamen, China. It aims to provide world-class sanitary ware ……

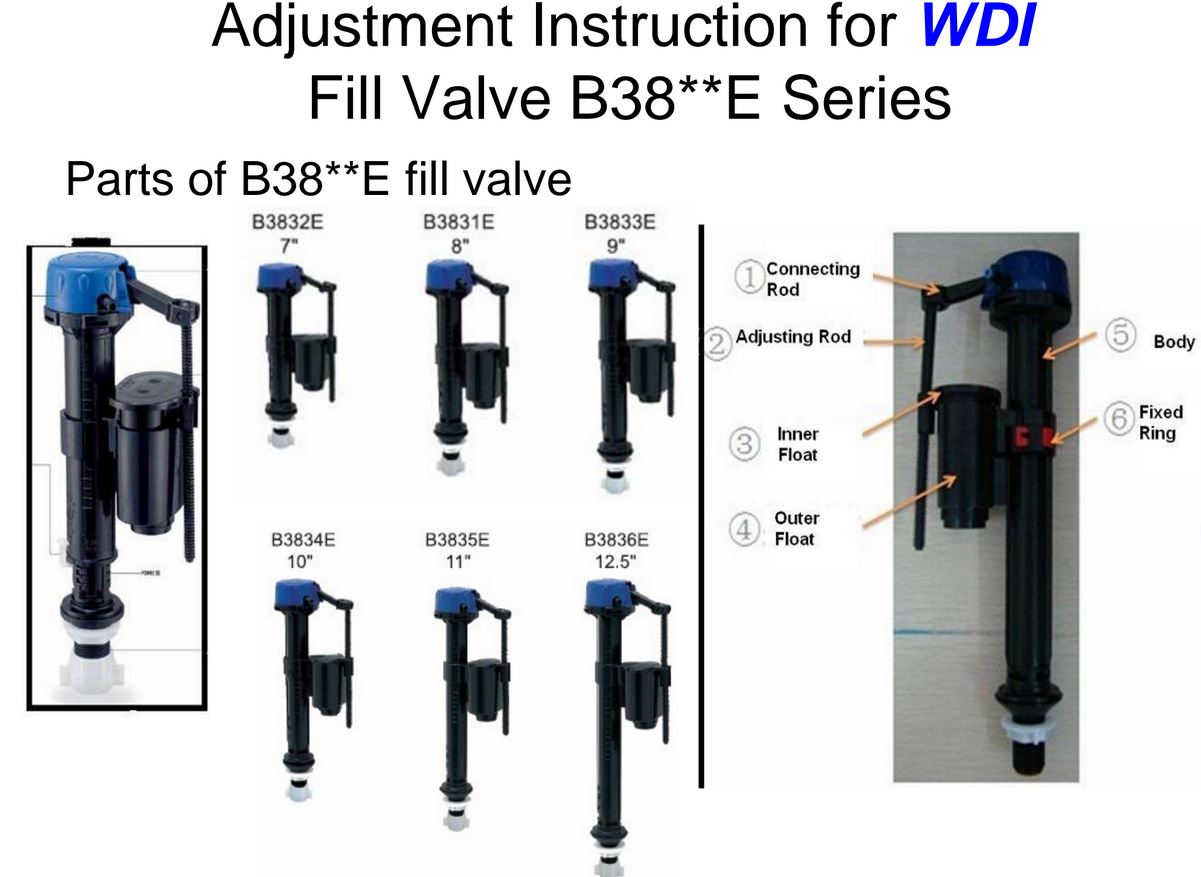

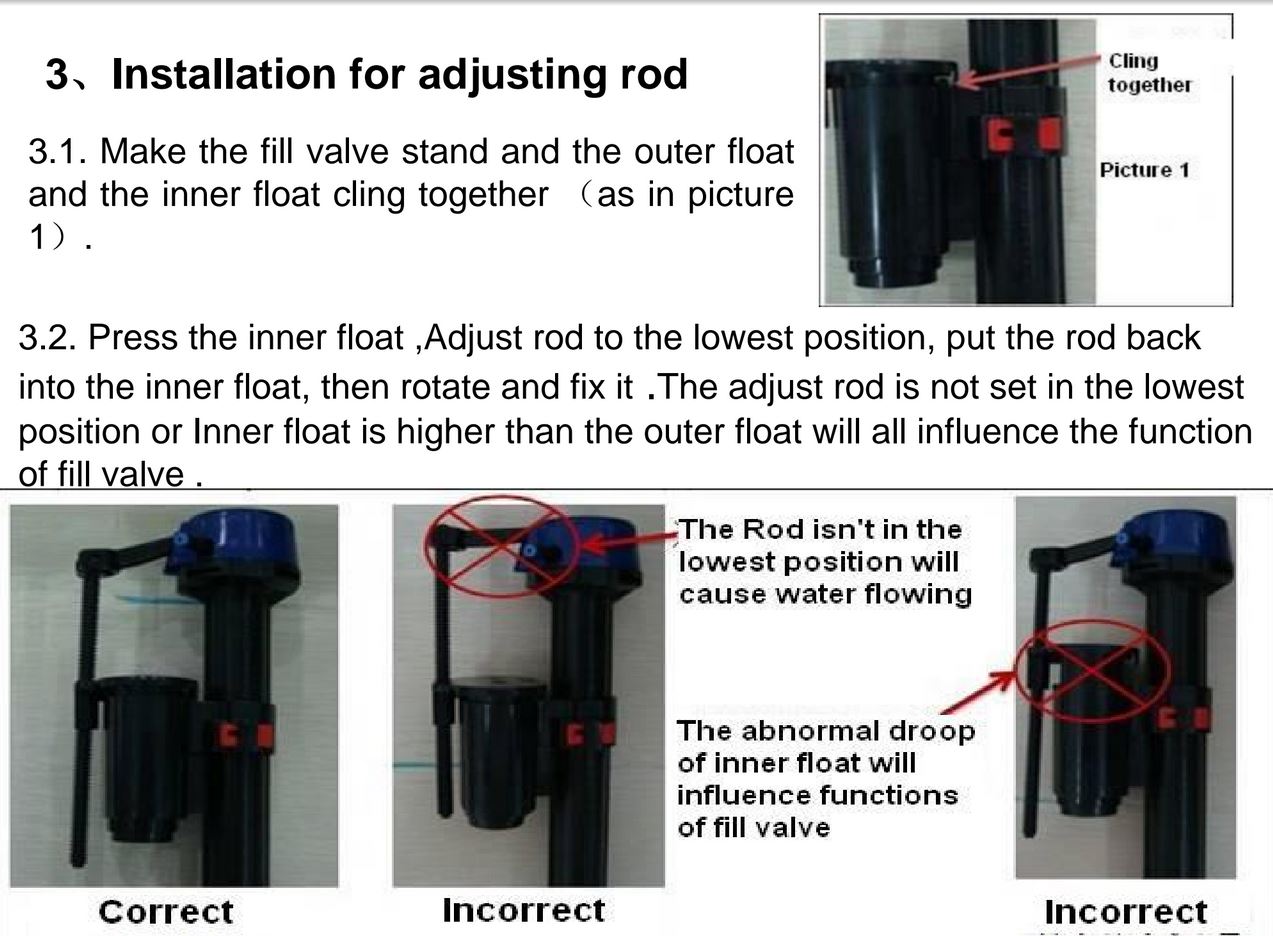

#4 WDI Fill Valve Maintenence Instructions

Domain Est. 2020

Website: support.gerber-us.com

Key Highlights: WDI Fill Valve Maintenence Instructions · 1 – Adjust the water level · 2 – Clean the filter screen · 3 – Troubleshoot common problems.Missing: inlet manufacturer…

Expert Sourcing Insights for Wdi Toilet Inlet Valve

2026 Market Trends for WD-40 Toilet Inlet Valve

The WD-40 Toilet Inlet Valve, leveraging the strong brand recognition of WD-40 beyond its iconic lubricant, is positioned for significant growth and evolution in the 2026 market. Driven by consumer demand for reliability, sustainability, and smart home integration, key trends will shape its trajectory.

Increasing Consumer Demand for Premium, Reliable Fixtures

By 2026, homeowners and property managers are prioritizing durable, high-performance plumbing components to reduce maintenance costs and water waste. The WD-40 brand’s association with quality and long-term protection translates into consumer trust for its toilet inlet valve. This trust, combined with the product’s design for leak resistance and extended lifespan, aligns with the trend toward investing in premium fixtures that minimize repair frequency and plumber visits.

Growth in Water Conservation and Regulatory Compliance

Water scarcity concerns and tightening plumbing regulations across the U.S. and other developed markets will continue to drive demand for water-efficient products. The WD-40 Toilet Inlet Valve is expected to meet or exceed 2026 water efficiency standards, such as those set by the EPA’s WaterSense program. Enhanced precision in fill control and reduced overfill incidents will be key selling points, appealing to eco-conscious consumers and municipalities incentivizing water-saving technologies.

Expansion of DIY Home Repair Market

The do-it-yourself (DIY) home improvement sector is projected to grow steadily through 2026, with more consumers opting to handle minor plumbing repairs independently. WD-40’s user-friendly design—featuring tool-free installation, clear instructions, and compatibility with standard toilet models—positions the inlet valve as an ideal product for this demographic. Retail partnerships with major home improvement chains and online tutorials will further boost accessibility and adoption.

Integration with Smart Home Ecosystems

While not a smart device itself, the WD-40 Toilet Inlet Valve may see indirect integration opportunities by 2026. As smart toilets and water monitoring systems gain popularity, reliable, leak-proof components like the WD-40 valve will be essential to prevent false alerts and ensure system accuracy. WD-40 could leverage this by marketing its valve as the “recommended component” for smart toilet installations, enhancing its relevance in tech-enabled bathrooms.

Competitive Pressure and Brand Extension Opportunities

The plumbing fixture market will remain competitive, with established brands and new entrants vying for market share. WD-40’s strength lies in brand extension—applying its reputation for solving household problems to new categories. In 2026, the company may expand its bathroom product line (e.g., flappers, flush valves) under the same trusted umbrella, using the inlet valve as a gateway product to capture broader market share in toilet repair and maintenance.

Sustainability and Packaging Innovation

By 2026, sustainability will be a critical differentiator. Consumers and retailers will favor products with recyclable packaging and reduced environmental impact. WD-40 is expected to respond by adopting eco-friendly materials in packaging and promoting the valve’s role in preventing water waste—aligning with corporate sustainability goals and enhancing brand loyalty among environmentally conscious buyers.

In summary, the WD-40 Toilet Inlet Valve is poised to benefit from converging trends in durability, water efficiency, DIY culture, and sustainability by 2026. Strategic branding, compliance with evolving standards, and potential product line expansion will be crucial to maintaining momentum in a competitive and increasingly eco-aware market.

Common Pitfalls When Sourcing WD-40 Toilet Inlet Valve (Quality, IP)

(Note: “WDi” appears to be a typo or misunderstanding—WD-40 is a lubricant brand and does not manufacture toilet inlet valves. This response assumes you are referring to sourcing a generic or OEM toilet inlet valve, possibly confused with a brand name. If “WDi” refers to a specific brand, clarify accordingly.)

Poor Quality Materials and Construction

One of the most frequent issues when sourcing toilet inlet valves is receiving units made from substandard materials. Low-cost valves often use brittle plastics, low-grade brass, or inferior rubber seals that degrade quickly. This leads to premature failures such as cracking, leaking, or inconsistent water flow. Valves lacking durability may require frequent replacements, increasing long-term costs and maintenance efforts.

Inaccurate or Missing IP (Ingress Protection) Rating

Many inlet valves—especially those marketed for modern or smart toilets—may claim environmental resistance, but often lack a verified IP rating. Without a proper IP67 or similar rating, valves may not be protected against moisture and dust ingress, posing risks in humid bathroom environments. Sourcing components without clear, certified IP ratings can result in malfunction or electrical hazards in electronically controlled valves.

Non-Compliance with Local Plumbing Standards

Sourcing valves from overseas suppliers may result in products that do not meet regional plumbing codes (e.g., UPC in the U.S., WRAS in the UK). Valves that aren’t certified for potable water use or pressure regulation can lead to health risks, leaks, or regulatory non-compliance during inspections.

Inconsistent Performance and Flow Regulation

Low-quality inlet valves often fail to maintain consistent water pressure or shut off completely, leading to phantom flushing or continuous water running. This inefficiency increases water consumption and utility bills. Poorly calibrated float mechanisms or diaphragms contribute to unreliable performance.

Misleading Branding and Counterfeit Products

The market includes counterfeit or deceptively labeled valves that mimic reputable brands. These may appear identical but lack quality control. Buyers may unknowingly purchase fake products that fail shortly after installation, undermining trust and system reliability.

Inadequate Supplier Verification

Sourcing from unverified suppliers—especially on open marketplaces—increases the risk of receiving inconsistent batches or incorrect specifications. Lack of traceability, poor customer support, and absence of warranties further compound sourcing challenges.

Conclusion

To avoid these pitfalls, always verify material specifications, demand certified IP ratings where applicable, ensure compliance with local plumbing standards, and source from reputable, vetted suppliers. Request product certifications (e.g., NSF, ASSE) and conduct sample testing before large-scale procurement.

Logistics & Compliance Guide for Wdi Toilet Inlet Valve

This guide outlines key logistics considerations and compliance requirements for the distribution, import, export, and use of the Wdi Toilet Inlet Valve to ensure smooth operations and adherence to relevant regulations.

Product Classification & Documentation

- HS Code: Confirm the Harmonized System (HS) code for the Wdi Toilet Inlet Valve (typically under 8481.80 – “Taps, cocks, valves and similar appliances for pipes, boiler shells, tanks, vats or the like, including pressure-reducing valves and thermostatically controlled valves”). Accurate classification ensures correct duty rates and import/export reporting.

- Product Specifications: Maintain detailed technical specifications including materials (e.g., brass, plastic, rubber seals), dimensions, flow rate, pressure ratings, and certifications. This supports customs clearance and compliance verification.

- Commercial Invoice & Packing List: Prepare accurate documentation including product description, quantity, unit price, total value, country of origin, and packaging details. Essential for customs authorities.

- Certificate of Origin: Required for preferential tariff treatment under trade agreements (e.g., ASEAN, USMCA). Must be accurately completed and certified if applicable.

Import & Export Regulations

- Destination Country Requirements: Research and comply with plumbing and building code regulations in each target market (e.g., UPC in the U.S., WRAS in the UK, AS/NZS in Australia/New Zealand). Some regions require local certification.

- Labeling & Language: Ensure product labeling and user instructions are in the official language(s) of the destination country. Include manufacturer details, model number, and safety warnings.

- Restricted Substances: Confirm the valve complies with restrictions on hazardous substances such as lead content (e.g., NSF/ANSI 61, NSF/ANSI 372 in the U.S., REACH in the EU). Documentation proving compliance may be required at customs.

- Export Controls: Verify that the product is not subject to dual-use or strategic export controls. Most plumbing valves are not controlled, but it’s prudent to confirm.

Transportation & Handling

- Packaging Standards: Use durable, moisture-resistant packaging to prevent damage during transit. Include protective materials to avoid impact damage to valve components.

- Shipping Modes: Choose appropriate transport (air, sea, or land) based on urgency, volume, and destination. Sea freight is typically cost-effective for bulk shipments.

- Storage Conditions: Store in a dry, temperature-controlled environment to prevent corrosion or degradation of seals and plastics. Avoid exposure to direct sunlight or extreme temperatures.

- Inventory Management: Implement FIFO (First In, First Out) practices to ensure older stock is distributed first, reducing the risk of obsolescence or material degradation.

Compliance & Certifications

- Plumbing Safety Standards: Ensure the Wdi Toilet Inlet Valve meets key international standards:

- NSF/ANSI 61: Health effects from products in contact with drinking water (required in U.S. and Canada).

- WRAS Approval: Water Regulations Advisory Scheme (UK).

- DVGW Certification: German standard for water fittings.

- AS/NZS 3500: Australian and New Zealand plumbing code compliance.

- Quality Management: Maintain ISO 9001 certification for manufacturing processes to ensure consistent product quality.

- RoHS & REACH Compliance: Confirm the product is free from restricted hazardous substances in electrical/electronic components (if applicable) and complies with EU chemical regulations.

- Warranty & Liability: Provide clear warranty terms and ensure product liability insurance covers potential failures related to water damage or non-compliance.

Returns & After-Sales Logistics

- Return Authorization Process: Establish a clear process for handling defective or incorrect shipments, including RMA (Return Merchandise Authorization) issuance.

- Warranty Claims: Define procedures for evaluating and processing warranty claims, including product return, inspection, and replacement.

- Recall Preparedness: Maintain traceability (batch/lot tracking) to enable rapid response in case of safety or compliance recalls.

Environmental & Sustainability Considerations

- Eco-Labeling: Consider pursuing environmental certifications (e.g., WaterSense in the U.S.) if the valve contributes to water efficiency.

- End-of-Life Disposal: Provide guidance on proper disposal and recycling of components in accordance with local e-waste or plumbing waste regulations.

Adhering to this logistics and compliance framework ensures the Wdi Toilet Inlet Valve can be distributed globally while minimizing risk, avoiding customs delays, and maintaining regulatory compliance.

Conclusion for Sourcing WDI Toilet Inlet Valve:

After a thorough evaluation of potential suppliers, quality standards, cost implications, and availability, sourcing the WDI toilet inlet valve presents a reliable and cost-effective solution for ensuring consistent product performance and customer satisfaction. WDI, known for its durable and innovative plumbing components, offers inlet valves that meet international quality certifications and are compatible with a wide range of cistern models. The availability of robust technical support, competitive pricing, and proven market reputation strengthens the decision to source from WDI. Additionally, establishing a long-term supply agreement can enhance supply chain efficiency, reduce lead times, and support scalability. Overall, sourcing the WDI toilet inlet valve aligns well with quality, reliability, and operational efficiency goals.