The global textile market, particularly within the realm of printed fabrics, has seen steady growth driven by rising demand for ethnic and traditional apparel across Africa, Europe, and North America. According to Grand View Research, the global textile printing market was valued at USD 13.9 billion in 2022 and is expected to grow at a compound annual growth rate (CAGR) of 5.8% from 2023 to 2030. A significant portion of this expansion is attributed to the increasing popularity of wax print fabrics, which remain a cultural staple in West African fashion and have gained traction in international markets due to their vibrant designs and heritage appeal. With production hubs expanding across Asia and Africa to meet evolving demand, supply chain dynamics are shifting to prioritize quality, authenticity, and sustainable manufacturing. In this context, leading wax print cloth manufacturers are investing in advanced digital printing technologies, eco-friendly dyes, and localized production to maintain competitiveness. Based on market presence, production capacity, and innovation, the following nine manufacturers represent the forefront of the wax print fabric industry.

Top 9 Wax Print Cloth Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

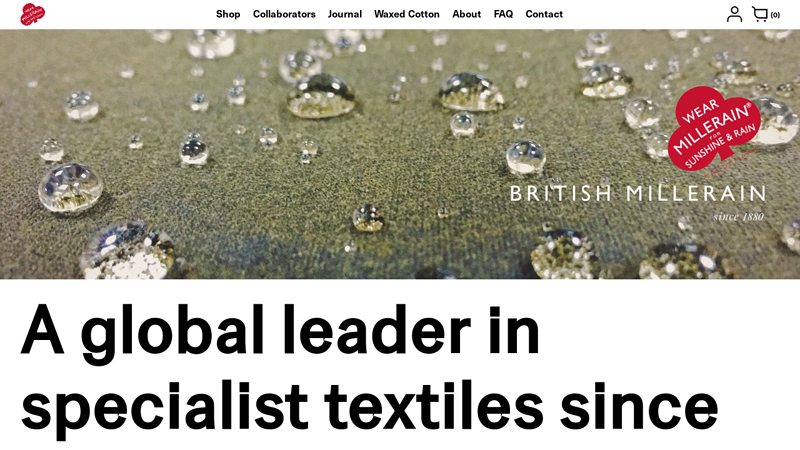

#1 British Waxed Fabric & Textile Manufacturers

Domain Est. 2002

Website: britishmillerain.com

Key Highlights: Headquartered in Greater Manchester, England, British Millerain is a global leader in manufacturing premium outerwear and industrial fabrics since 1880….

#2 African Fabric Retailer,Wholesaler and Manufacturer from New York …

Domain Est. 2014

Website: fabricsusainc.com

Key Highlights: Free delivery over $75TOP COLLECTIONS · Wax Hollandais Java Prints Fabric · Best Selling Design · Hitarget Wax Block Prints Fabric · Meba Wo Abrokyere African Ankara Wax Print Fabr…

#3 Julius Holland Wax

Domain Est. 2000

Website: jansenholland.com

Key Highlights: Free delivery 14-day returnsJulius Holland offers premium-quality African wax prints for young, vibrant, and modern women and men, with an exceptional quality-to-price ratio. Curio…

#4 Côte d’Ivoire

Domain Est. 2000

Website: uniwax.com

Key Highlights: 100% cotton, non-wax fabric of high quality and 120 cm wide, made with a direct digital printing process, in a minimum quantity of 2 yards….

#5 Aaron International

Domain Est. 2004

Website: aaroninternational.com

Key Highlights: Free delivery over $135 15-day returns…

#6 Wax Fabric

Domain Est. 2004

Website: yytex.net

Key Highlights: The company has created four independent brands of wax printing, including CHIGANVY, FLYGLE, HOLLANTEX and JOYUETA, which now occupy the top 3 in the high-end ……

#7 Empire Textiles: African Fabrics

Domain Est. 2010

Website: empiretextiles.com

Key Highlights: Empire Textiles supplies a vast range of materials & products including Swiss voile fabric, Swiss laces, wax prints, brocades by the meter or yard and much more ……

#8 Julius Holland

Domain Est. 2015

Website: juliusholland.com

Key Highlights: Our goal is to get the best price/quality ratio wax prints. Worldwide … Get inspired by the designs made by our clients and others who made beautiful clothing ……

#9 African fabrics

Domain Est. 2018

Website: africanfabs.com

Key Highlights: 2–16 day delivery 14-day returnsHigh quality African fabrics. This African wax print fabric is perfect for making your own colorful clothes. 100% quality cotton which is printed on…

Expert Sourcing Insights for Wax Print Cloth

2026 Market Trends for Wax Print Cloth: Key Developments and Outlook

The wax print cloth market is poised for significant evolution by 2026, driven by shifting consumer preferences, technological advancements, and dynamic global trade patterns. This analysis explores the key trends shaping the industry in the coming years.

H2: Rising Demand for Authenticity and Premiumization

By 2026, consumers—particularly in Africa and among the diaspora—are increasingly discerning, demanding higher quality and authentic designs. This trend is fueling a shift away from mass-produced, low-cost imitations toward premium wax prints that emphasize craftsmanship, unique patterns, and cultural significance. Established brands like Vlisco, Woodin, and ABC Wax are leveraging their heritage and storytelling to justify premium pricing. Simultaneously, local African designers are gaining prominence by blending traditional motifs with contemporary aesthetics, creating limited-edition collections that command higher value. This premiumization trend is expected to boost profit margins and reinforce brand loyalty.

H2: Sustainability and Ethical Production Gaining Momentum

Environmental and social responsibility are becoming critical factors in consumer decision-making. By 2026, there is a growing expectation for transparency in the wax print supply chain. Consumers and retailers are demanding eco-friendly production methods, including the use of organic dyes, reduced water consumption, and biodegradable packaging. Manufacturers are responding by investing in cleaner production technologies and obtaining sustainability certifications. Ethical labor practices and fair wages are also becoming non-negotiable for brand reputation, especially among younger, socially conscious buyers in urban markets.

H2: Digital Transformation and E-Commerce Expansion

The digital landscape is revolutionizing how wax print cloth is marketed and sold. By 2026, e-commerce platforms—both global (like Amazon, Etsy) and regional (such as Jumia, Kilimall)—are expected to dominate retail channels. Social media, especially Instagram and TikTok, plays a pivotal role in trendsetting and direct-to-consumer sales, enabling designers to reach global audiences instantly. Augmented reality (AR) tools are emerging, allowing customers to virtually “try on” fabrics or visualize patterns on garments before purchase. This digital shift is accelerating innovation and personalization in the market.

H2: Regional Production Growth and Import Substitution

In response to import dependencies and logistical challenges, several African nations are investing in local textile manufacturing. Policies promoting “Made in Africa” initiatives, coupled with improved infrastructure and access to financing, are encouraging domestic production of wax print cloth. Countries like Nigeria, Ghana, and Côte d’Ivoire are expanding their manufacturing capabilities to reduce reliance on imports from Asia and Europe. This trend supports economic development, job creation, and faster response to regional fashion trends.

H2: Diversification into Fashion and Lifestyle Applications

Wax print is transcending traditional apparel (such as Ankara dresses and headwraps) and entering broader lifestyle markets. By 2026, expect increased use of wax print in home décor (cushions, curtains, tableware), accessories (bags, shoes, phone cases), and even tech accessories. Luxury fashion collaborations—such as partnerships between African designers and global brands—are elevating the fabric’s status and expanding its appeal in high-end markets. This diversification opens new revenue streams and enhances brand visibility.

H2: Challenges from Counterfeiting and Market Saturation

Despite growth opportunities, the wax print market faces persistent challenges. Counterfeit products—especially low-quality imitations from Asia—undermine legitimate brands and erode consumer trust. By 2026, intellectual property protection and anti-counterfeiting technologies (like blockchain-based authentication) will become essential tools for reputable producers. Additionally, market saturation in certain regions may lead to price wars, pressuring smaller players to innovate or consolidate.

Conclusion

The wax print cloth market in 2026 will be defined by a convergence of tradition and innovation. Success will depend on brands’ ability to balance cultural authenticity with sustainable practices, digital engagement, and product diversification. While challenges remain, the global appreciation for African textiles continues to grow, positioning wax print as a vibrant and resilient segment of the global fashion industry.

Common Pitfalls When Sourcing Wax Print Cloth: Quality and Intellectual Property Issues

Sourcing authentic and high-quality Wax Print Cloth can be challenging due to widespread quality inconsistencies and intellectual property (IP) concerns. Buyers often encounter several key pitfalls that can impact product integrity, brand reputation, and legal compliance.

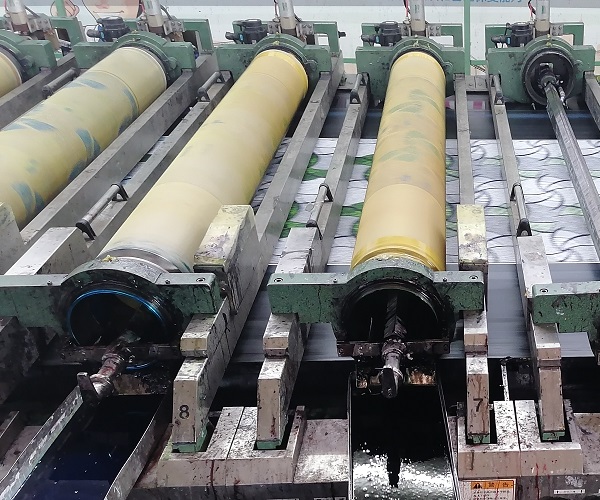

Poor Fabric Quality and Inconsistent Dyeing

One of the most frequent issues is receiving wax print fabric with substandard materials or uneven dye application. Low-quality cotton may result in thin, rough, or easily torn textiles, while inconsistent wax-resist dyeing leads to blurred patterns, color bleeding, or fading after washing. These defects often stem from unregulated production processes or cost-cutting measures by suppliers, particularly those prioritizing volume over authenticity.

Misrepresentation of Origin and Authenticity

Many suppliers falsely label fabrics as “authentic Dutch wax” or “Ghanaian wax print” when they are mass-produced imitations from Asia or other regions. True wax print fabrics—such as those from renowned producers like Vlisco, GTP, or ATL—undergo specific production techniques and quality controls. Sourcing from unreliable vendors increases the risk of receiving counterfeit products, which lack the cultural significance and durability of genuine wax prints.

Intellectual Property and Design Infringement

Wax print designs are often protected under copyright or trademark laws, especially those created by major manufacturers. Unauthorized replication or sale of these patterns constitutes IP infringement. Buyers who source from third-party suppliers may unknowingly purchase and distribute counterfeit designs, exposing their business to legal risks, product seizures, or reputational damage. It’s crucial to verify design licensing and ensure supply chain transparency.

Lack of Supply Chain Transparency

Opaque supply chains make it difficult to trace the origin of the fabric and confirm ethical production practices. Without clear documentation or factory audits, buyers may inadvertently support exploitative labor practices or environmentally harmful manufacturing methods. This lack of transparency also complicates efforts to verify authenticity and quality claims.

Inadequate Quality Control and Sampling Processes

Skipping proper sampling or failing to conduct on-site quality inspections can lead to large shipments of defective goods. Some suppliers provide high-quality samples but deliver inferior bulk orders. Implementing rigorous pre-shipment inspections and working with third-party quality assurance services can mitigate this risk.

Avoiding these pitfalls requires due diligence, partnerships with reputable suppliers, and a solid understanding of both the cultural value and legal framework surrounding wax print textiles.

Logistics & Compliance Guide for Wax Print Cloth

Product Overview and Classification

Wax print cloth, also known as African wax print or Ankara fabric, is a 100% cotton or cotton-blend textile characterized by vibrant patterns and a wax-resist dyeing technique. It is commonly used in fashion, home décor, and cultural apparel. For logistics and compliance purposes, accurate classification under international trade systems is critical. The Harmonized System (HS) code typically applied is 5208.32.00 (woven fabrics of cotton, containing >=85% cotton by weight, weighing <=200 g/m², unbleached or bleached), though variations may apply depending on fiber content, weight, and finish. Confirm the exact HS code with local customs authorities to ensure proper tariff application and regulatory compliance.

Import/Export Regulations

Exporting and importing wax print cloth is subject to country-specific regulations. Key considerations include:

– Textile Quotas and Restrictions: Some countries impose quotas or restrictions on textile imports to protect domestic industries. Verify if the destination country applies any safeguard measures under the World Trade Organization (WTO) or bilateral agreements.

– Country of Origin Labeling: Most markets (e.g., the U.S., EU, UK) require clear country-of-origin marking on textiles. This must be durable, legible, and permanently affixed.

– Import Permits and Licenses: Certain regions may require import licenses for textiles. For example, Nigeria and Kenya may regulate textile imports to support local manufacturers.

– Duty Rates and Free Trade Agreements: Leverage preferential tariff treatment under trade agreements such as AGOA (African Growth and Opportunity Act) if exporting from eligible African countries to the U.S., or the EU’s Everything But Arms (EBA) initiative.

Customs Documentation Requirements

Complete and accurate documentation is essential for smooth customs clearance. Required documents typically include:

– Commercial Invoice (with detailed product description, HS code, value, and country of origin)

– Packing List (specifying quantities, weights, dimensions, and packaging type)

– Bill of Lading or Air Waybill

– Certificate of Origin (especially for claiming preferential tariffs)

– Textile Declaration (if required by destination country, e.g., FTC regulations in the U.S.)

Ensure all documents are consistent and match physical shipments to avoid delays or penalties.

Packaging and Handling Standards

Wax print cloth should be packed to prevent damage during transit:

– Rolls or folds must be wrapped in polyethylene or kraft paper to protect against moisture and contamination.

– Use sturdy cartons or export-grade packaging with internal dividers to avoid creasing or tearing.

– Label packages clearly with product details, batch numbers, and handling instructions (e.g., “Fragile,” “Keep Dry,” “This Side Up”).

– Avoid over-packing to reduce the risk of compression damage.

Transportation and Logistics

Choose reliable freight partners with experience in textile logistics. Consider:

– Mode of Transport: Sea freight is cost-effective for large volumes; air freight is suitable for urgent, smaller shipments.

– Transit Time and Routing: Account for port congestion, customs inspections, and seasonal delays (e.g., holiday periods).

– Insurance: Ensure full cargo insurance coverage against loss, damage, or theft during transit.

– Incoterms: Clearly define responsibilities using recognized Incoterms (e.g., FOB, CIF, DDP) to allocate costs and risks between buyer and seller.

Compliance with Environmental and Safety Standards

Wax print cloth must comply with chemical and safety regulations in target markets:

– REACH (EU): Restricts the use of hazardous substances such as azo dyes and formaldehyde.

– Oeko-Tex Standard 100: Certification ensures textiles are free from harmful levels of toxic substances (recommended for consumer trust).

– Proposition 65 (California, USA): Requires warning labels if products contain chemicals known to cause cancer or reproductive harm.

– Labeling Requirements: Fiber content must be accurately labeled (e.g., “100% Cotton”) per FTC (U.S.) or EU Textile Regulation (EU No 1007/2011).

Post-Import Considerations

After arrival, ensure:

– Customs duties and taxes are paid promptly.

– Local product standards and labeling laws are fully met before distribution.

– Maintain records of all import documentation for a minimum of 5 years (as required by many customs authorities).

Adhering to this logistics and compliance guide ensures efficient, lawful movement of wax print cloth across international borders while minimizing risks and supporting market access.

In conclusion, sourcing wax print cloth requires a strategic approach that balances quality, authenticity, cost, and ethical considerations. Whether sourcing from traditional West African manufacturers or international suppliers, it is essential to establish reliable partnerships, verify production methods (such as authentic wax print versus imitation roller print), and ensure compliance with sustainability and fair labor practices. Market demand for vibrant, culturally rich fabrics continues to grow, making due diligence in sourcing crucial for brand reputation and long-term success. By prioritizing authentic craftsmanship, transparent supply chains, and responsive supplier relationships, businesses can effectively meet consumer expectations while supporting the cultural and economic significance of wax print textiles.