The global decking materials market is experiencing robust growth, driven by rising demand for durable, low-maintenance outdoor living solutions in residential and commercial construction. According to Mordor Intelligence, the global decking materials market was valued at USD 22.5 billion in 2023 and is projected to grow at a CAGR of 6.8% from 2024 to 2029. This expansion is fueled by increasing urbanization, growing outdoor lifestyle trends, and advancements in composite and engineered materials that offer superior water resistance and longevity. As sustainability and performance become key decision drivers, manufacturers are prioritizing innovation in watertight, weather-resistant decking solutions. In this competitive landscape, a select group of companies are leading the way in product development, scalability, and market reach. Based on market presence, material innovation, and performance data, here are the top 10 watertight decking material manufacturers shaping the future of outdoor architecture.

Top 10 Watertight Decking Material Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Pli

Domain Est. 1998

Website: plidek.com

Key Highlights: Pli-Dek is a tried-and-true cementitious waterproofing solution for numerous substrates in both residential, commercial, and industrial applications….

#2 Premium Waterproof Deck Coatings

Domain Est. 2018

Website: lifespecialtycoatings.com

Key Highlights: Life Specialty Coatings has been the premier manufacturer of waterproof decking systems for nearly 60 years….

#3 Waterproof Vinyl Decking

Domain Est. 2019

Website: ondekvinylworx.com

Key Highlights: OnDek Vinyl Worx Inc. is a North American-made waterproof vinyl decking and roofing membrane that meets and exceeds national building codes….

#4 Composite Decking Boards & Products

Domain Est. 1996

Website: trex.com

Key Highlights: Discover high-performance, low-maintenance composite decking products from Trex. Explore our variety of deck boards for creating your outdoor living oasis!…

#5 Dec-Tec

Domain Est. 1998

Website: dec-tec.com

Key Highlights: Discover Dec-Tec, the ultimate solution for waterproofing various areas such as balconies, boathouses, walkways, stairs, and boats. With its sophisticated ……

#6 FIBERDECK

Domain Est. 2000

Website: fiberdeck.com

Key Highlights: Our material is waterproof and not affected by weathering. It does not warp and keeps its aesthetics for a very long time. Investing in a Fiberdeck product ……

#7 Waterproof Decking Material – PVC Membrane

Domain Est. 2003

Website: tufdek.com

Key Highlights: Tufdek is a PVC sheet vinyl product that comes on a roll and is used to waterproof outdoor living spaces including roof decks, sundecks, balconies, roof-top ……

#8 Deck Coatings, Concrete Deck Coatings, Vehicular Deck Coatings

Domain Est. 2003

Website: polytuffus.com

Key Highlights: We provide fully warranted products to the waterproofing, architectural and decking industries. We are a manufacturing, marketing and sales team….

#9 Wolf Outdoor Decking Materials

Domain Est. 2011

Website: wolfhomeproducts.com

Key Highlights: Choose Wolf Home Products for superior outdoor decking and porch materials. Durable decking boards designed for outdoor living spaces. View collection now….

#10 Aluminum Deck Products

Domain Est. 2022

Website: wahoobuildingproducts.com

Key Highlights: Wahoo Building Products designs and manufactures the highest quality aluminum decking, aluminum railing, and aluminum deck drainage systems available….

Expert Sourcing Insights for Watertight Decking Material

H2: Projected 2026 Market Trends for Watertight Decking Materials

The global market for watertight decking materials is poised for significant transformation by 2026, driven by evolving consumer demands, regulatory shifts, and technological innovation. Here are the key trends expected to shape the landscape:

1. Sustainability as a Core Driver: Environmental responsibility will move from a niche concern to a primary purchase criterion. Consumers and commercial developers will increasingly demand decking materials with verified low carbon footprints, high recycled content (especially post-consumer plastics), and full recyclability at end-of-life. Expect stricter regulations (particularly in the EU and North America) mandating sustainable sourcing and circular economy principles, pushing manufacturers to innovate in bio-based composites and closed-loop recycling systems.

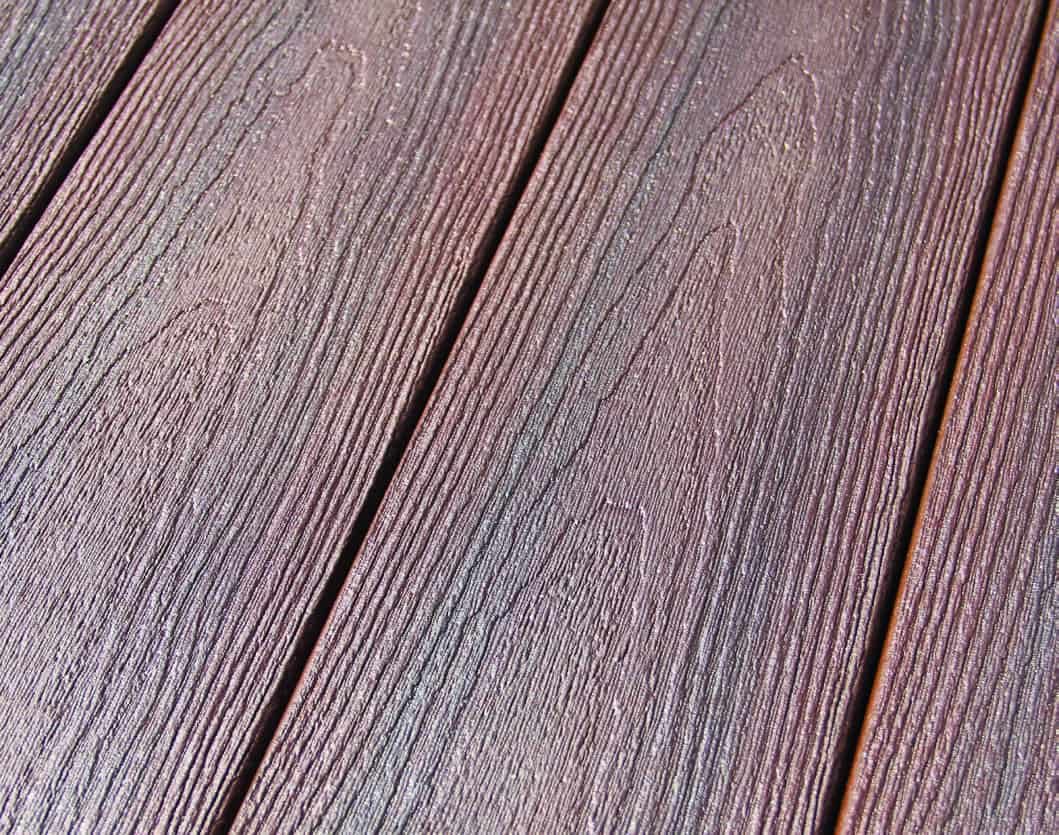

2. Dominance of Composite & Engineered Materials: Traditional wood will continue its gradual decline in favor of high-performance composites. By 2026, capped polymer composites (WPCs with protective polymer shells) will dominate the premium segment due to their superior durability, minimal maintenance, and enhanced resistance to fading, staining, and moisture intrusion. Solid plastic decking (polyolefins like HDPE, PP) will gain significant share, especially in high-moisture environments, due to its inherent waterproof nature, high recycled content potential, and improved aesthetics mimicking real wood grain.

3. Technological Integration for Performance: Innovation will focus on pushing material performance boundaries:

* Enhanced Moisture Resistance: Development of advanced polymer formulations and co-extrusion techniques creating truly “watertight” barriers, minimizing capillary action and internal moisture absorption, even in submerged or constantly damp applications.

* Improved Slip Resistance: Integration of advanced texturing and non-slip additives (including photoluminescent options) will be standard, driven by safety regulations, especially for commercial, multi-family, and senior living projects.

* Thermal Management: Materials incorporating reflective pigments or phase-change materials to reduce surface temperatures (mitigating the “hot deck” problem) will become more prevalent, enhancing user comfort and energy efficiency.

4. Growth in Commercial & Multi-Family Sectors: While residential remains significant, the commercial, hospitality, and multi-family housing sectors will be the fastest-growing markets. The demand for low-maintenance, durable, safe, and aesthetically consistent decking that withstands high traffic and reduces long-term operational costs will fuel adoption of premium watertight composites and plastics in hotels, rooftop terraces, senior living facilities, and apartment complexes.

5. Digitalization & Customization: The design and specification process will become more digital. Augmented Reality (AR) apps allowing consumers to visualize decking options in their space and sophisticated online configurators for commercial projects will become standard. Demand for customization – unique colors, patterns, textures, and even integrated lighting or heating elements – will grow, pushing manufacturers towards flexible production lines.

6. Supply Chain Resilience & Localization: Ongoing global supply chain volatility will push manufacturers to diversify sourcing, increase regional manufacturing, and build greater inventory resilience. This may lead to higher localized production, potentially impacting costs but improving delivery times and reducing carbon footprint from transportation.

7. Focus on Whole-Life Cost & Durability: The market will shift beyond initial price to emphasize Total Cost of Ownership (TCO). Consumers and developers will increasingly value the long-term savings from minimal maintenance (no staining, sealing, sanding), extended lifespan (25-50+ years), and reduced replacement cycles offered by high-quality watertight composites and plastics, justifying higher upfront investments.

In summary, the 2026 watertight decking market will be characterized by sustainability leadership, the supremacy of advanced composites and plastics, heightened performance demands, strong commercial adoption, digital engagement, and a focus on durability and lifecycle value, fundamentally reshaping product offerings and competitive dynamics.

Common Pitfalls When Sourcing Watertight Decking Material (Quality & Intellectual Property)

Sourcing high-performance watertight decking materials requires careful attention to both quality assurance and intellectual property (IP) considerations. Overlooking these aspects can lead to project delays, cost overruns, performance failures, or legal complications. Below are key pitfalls to avoid:

1. Prioritizing Cost Over Long-Term Quality

One of the most common mistakes is selecting materials based solely on upfront cost. Cheaper decking alternatives may appear watertight initially but often degrade quickly under UV exposure, moisture, or thermal cycling. Look for certified test data (e.g., ASTM, ISO) on water permeability, tensile strength, and dimensional stability to ensure long-term performance.

2. Inadequate Verification of Waterproofing Claims

Suppliers may market products as “watertight” without standardized testing or third-party validation. Always request independent lab reports or certifications (e.g., UL, CE, ICC-ES) that confirm the material’s ability to resist water intrusion under real-world conditions, including hydrostatic pressure and freeze-thaw cycles.

3. Ignoring System Compatibility

Watertight performance depends not only on the decking material but also on the compatibility of sealants, fasteners, and underlayment systems. Using mismatched components can compromise the entire assembly, leading to leaks at joints or fastener penetrations. Ensure the supplier provides a complete, tested system with documented compatibility.

4. Overlooking Installation Requirements

Even high-quality materials can fail if not installed correctly. Some watertight decking systems require specialized training or proprietary tools. Failing to verify installer qualifications or skipping manufacturer-recommended procedures can void warranties and lead to water infiltration.

5. Assuming All Composite or Polymer Materials Are Equal

Not all synthetic decking materials offer the same level of water resistance. Some composites absorb moisture over time, leading to swelling, warping, or mold growth. Confirm whether the material is truly non-porous and evaluate its resistance to hydrolysis and microbial attack.

6. Disregarding Intellectual Property Rights

Using materials or designs protected by patents, trademarks, or trade secrets without authorization can result in legal action, project shutdowns, or financial liability. Always verify that the product and its manufacturing process do not infringe on existing IP—especially when sourcing from low-cost or offshore suppliers.

7. Relying on Unverified Supplier Claims

Some suppliers may misrepresent product origins, certifications, or performance data. Conduct due diligence by requesting references, visiting manufacturing facilities (if possible), and verifying certifications through official databases. Beware of counterfeit or rebranded materials that lack proper IP licensing.

8. Failing to Secure Licensing for Proprietary Technologies

If the decking system incorporates patented technology (e.g., interlocking mechanisms, drainage channels), ensure your contract includes proper licensing for use. Unauthorized use—even unknowingly—can expose your project to infringement claims from the IP holder.

9. Neglecting Warranty and Liability Clauses

A comprehensive warranty should cover both material defects and water intrusion failures. Ensure the warranty is transferable, clearly defines coverage scope, and does not exclude damage caused by “improper installation” if installation was performed per guidelines. Poorly drafted agreements may leave you liable despite using approved materials.

10. Not Documenting Material Provenance and Compliance

Maintain detailed records of material specifications, test reports, IP clearances, and supplier contracts. This documentation is critical during audits, warranty claims, or legal disputes. Lack of traceability can undermine quality assurance and complicate liability determinations.

By proactively addressing these pitfalls, project stakeholders can ensure the selection of reliable, legally compliant watertight decking systems that deliver lasting performance and peace of mind.

Logistics & Compliance Guide for Watertight Decking Material

Product Overview and Classification

Watertight decking material refers to construction products engineered to prevent water infiltration while providing structural support and aesthetic finish in outdoor or high-moisture environments. These materials are commonly used in residential, commercial, and marine applications. Typical types include composite decking, PVC decking, modified wood, and rubber-based systems. Accurate classification is essential for both logistics and regulatory compliance. Most watertight decking materials fall under HS Code 3918 (floor coverings of plastics) or 4418 (builders’ joinery and carpentry of wood), depending on composition.

International Shipping and Transportation

Transporting watertight decking materials requires careful planning due to their size, weight, and susceptibility to environmental damage. Materials must be securely palletized and shrink-wrapped to prevent shifting during transit. Use moisture-resistant packaging to maintain watertight integrity before installation. For ocean freight, ensure compliance with IMO (International Maritime Organization) standards for cargo securing. Air freight may be used for urgent, smaller shipments, but dimensional weight pricing must be considered. Always label shipments with handling instructions (e.g., “This Way Up,” “Protect from Moisture”).

Import/Export Regulations

Compliance with import and export regulations is critical when shipping watertight decking materials across borders. Exporters must provide accurate commercial invoices, packing lists, and bills of lading. Importers should verify country-specific requirements, such as phytosanitary certificates for wood-based products (ISPM 15 standards for wood packaging material). Materials containing recycled plastics may be subject to EPA or EU environmental regulations. Check destination country restrictions on chemical treatments (e.g., restrictions on certain preservatives under REACH in the EU).

Building Code and Safety Compliance

Watertight decking materials must meet local and international building codes to ensure safety and performance. In the United States, compliance with the International Building Code (IBC) and International Residential Code (IRC) is required. Key standards include ASTM E84 for surface burning characteristics and ASTM D7032 for establishing performance ratings of composite decking. In the EU, CE marking under Construction Products Regulation (CPR) is mandatory, with testing for fire performance (Euroclass), slip resistance, and structural load capacity.

Environmental and Sustainability Standards

Many watertight decking materials—especially composites and PVC—are evaluated for environmental impact. Manufacturers and distributors should ensure compliance with sustainability certifications such as FSC (Forest Stewardship Council) for wood components or SCS Recycled Content for plastic-based products. VOC (volatile organic compound) emissions must meet standards like CA 01350 for indoor air quality, even if the product is used outdoors. Some green building programs (e.g., LEED, BREEAM) offer credits for using certified sustainable decking materials.

Documentation and Traceability

Maintain comprehensive documentation for full supply chain traceability. Required documents include material safety data sheets (MSDS/SDS), product test reports, certificates of compliance, and origin declarations. Digital tracking systems (e.g., blockchain or ERP integrations) can enhance transparency, especially for projects requiring auditable sustainability claims. Ensure batch-level traceability to facilitate recalls or quality investigations if non-compliance is identified.

Customs Clearance and Duties

Customs clearance efficiency depends on accurate tariff classification and declared value. Misclassification can lead to delays, fines, or seizure. Engage licensed customs brokers familiar with construction materials. Be aware of anti-dumping or countervailing duties that may apply—e.g., composite decking from certain countries has historically faced U.S. trade remedies. Duty rates vary by country; use binding tariff information (BTI) rulings where available to preempt disputes.

Storage and Handling at Destination

Upon arrival, decking materials should be stored on flat, elevated surfaces under cover to prevent warping, moisture absorption, or UV degradation. Keep bundles separated from ground contact and ensure proper ventilation. Rotate stock using the first-in, first-out (FIFO) method to avoid prolonged exposure. Follow manufacturer guidelines for maximum stacking height to prevent damage. Personnel should be trained in safe handling to avoid injury from heavy or sharp-edged materials.

End-of-Life and Recycling Compliance

Environmental regulations increasingly require responsible end-of-life management. PVC and composite decking materials may be recyclable but often require specialized facilities. Confirm local regulations on disposal—landfill bans may apply in certain jurisdictions. Provide customers with take-back programs or recycling guidance to support compliance with extended producer responsibility (EPR) laws in regions like the EU or Canada.

Conclusion

Successfully managing the logistics and compliance of watertight decking materials demands attention to detail across transportation, regulatory adherence, documentation, and sustainability practices. By following this guide, stakeholders can ensure timely delivery, legal compliance, and environmental responsibility throughout the product lifecycle.

In conclusion, sourcing watertight decking material requires careful consideration of durability, moisture resistance, longevity, and maintenance requirements. Materials such as composite decking, PVC decking, and certain high-performance hardwoods or engineered woods with advanced sealants offer strong options for water-resistant outdoor spaces. Key factors to evaluate include the product’s warranty, resistance to mold, rot, and warping, as well as installation method and long-term cost-effectiveness. By prioritizing certified, high-quality materials from reputable suppliers and ensuring proper installation and sealing techniques, property owners can achieve a durable, low-maintenance, and aesthetically pleasing deck that withstands the elements and delivers lasting performance. Ultimately, investing in reliable watertight decking solutions enhances both the functionality and value of outdoor living areas.