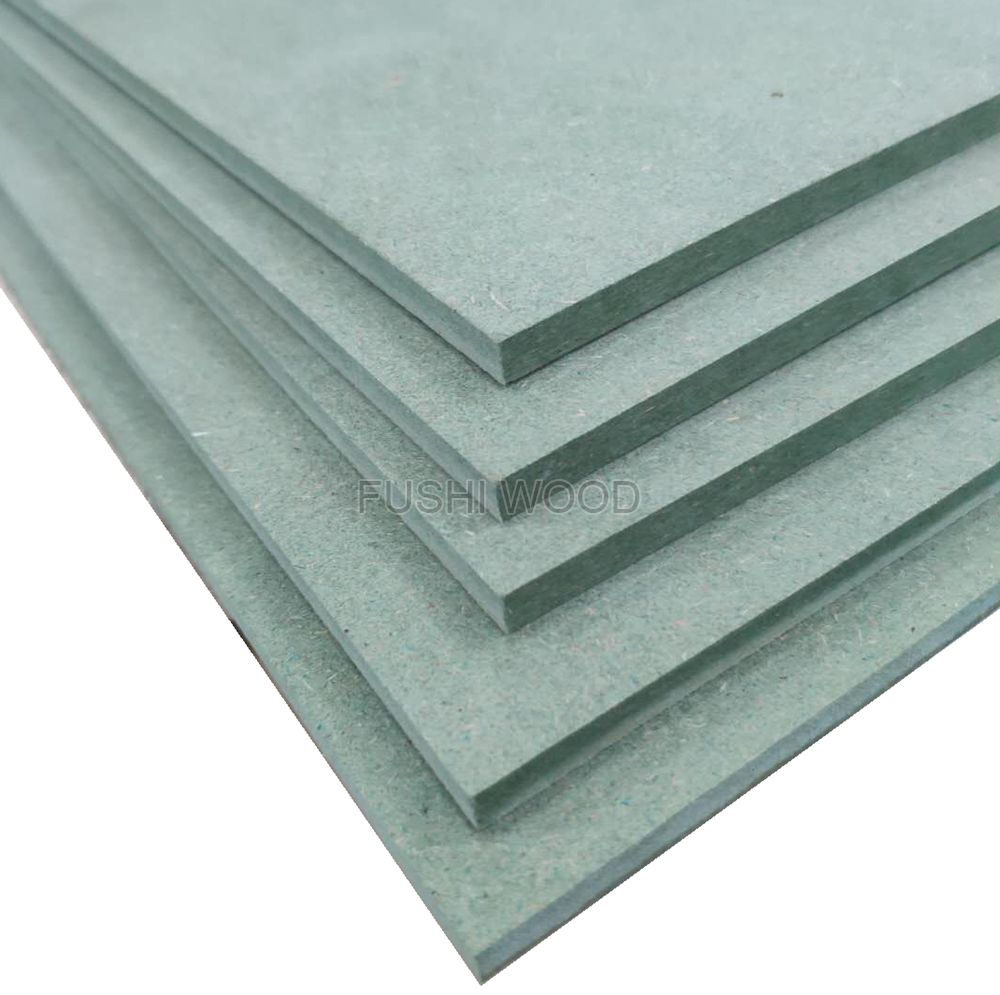

The global demand for water-resistant medium-density fiberboard (MDF) has surged in recent years, driven by increasing construction activity, rising demand for moisture-resistant interior materials, and expanding applications in humid environments such as kitchens and bathrooms. According to a 2023 report by Mordor Intelligence, the global MDF market is projected to grow at a CAGR of over 6.2% from 2023 to 2028, with water-resistant variants gaining significant traction due to their enhanced durability and performance. This growth is further supported by Grand View Research, which highlights a rising preference for engineered wood products in both residential and commercial sectors, particularly in regions with high humidity levels. As sustainability and performance standards evolve, manufacturers are innovating with advanced resins, wax treatments, and additives to improve moisture resistance. In this competitive landscape, eight key manufacturers have emerged as leaders, combining technological expertise, large-scale production capacity, and global distribution to meet the growing demand for reliable, water-resistant MDF solutions.

Top 8 Water Resistant Mdf Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 MDF Product Specifications

Domain Est. 1995

Website: weyerhaeuser.com

Key Highlights: Moisture Resistant, Used to achieve reduced-thickness swell relative to standard HDF when exposed to moisture. This product is for interior use only, not ……

#2 Medium Density Fiberboard (MDF)

Domain Est. 1996

Website: roseburg.com

Key Highlights: Whether moisture-resistant, flame retardant or no-added formaldehyde (NAF), Roseburg has an MDF panel to suit every setting. Made from recycled content, all of ……

#3 Trupan Moisture

Domain Est. 1996

Website: na.arauco.com

Key Highlights: Trupan Moisture Resistant is an interior, moisture resistant MDF panel that is ideally suited for kitchen, bath and laboratory cabinets….

#4 MDF

Domain Est. 1996

Website: uniboard.com

Key Highlights: NU Green MR50 NAF MDF, the latest addition to the NU Green® collection, is Uniboard’s most eco-friendly moisture resistant solution. This green, high ……

#5 MDF

Domain Est. 1997

Website: westfraser.com

Key Highlights: Moisture-resistant interior applications, well-suited to our UK-fabricated CaberMDF Trader MR and CaberMDF Pro MR products, as well as our North American ……

#6 MDF

Domain Est. 1997

Website: dixieply.com

Key Highlights: Medex MR is a moisture resistant panel manufactured with a synthetic resin, allowing the moisture resistant treatment to permeate the entire panel. It is ……

#7 Moisture Resistant MDF Boards

Domain Est. 2001

Website: madar.com

Key Highlights: High-performance HMR E2 MDF boards with ≤18.6% thickness swelling. Ideal for kitchens, bathrooms & humid areas. EN & CARB compliant. Shop now!…

#8 Moisture

Domain Est. 1997

Website: forestplywood.com

Key Highlights: Moisture-resistant MDF, sometimes called MR MDF, is engineered to withstand damp or humid conditions better than traditional MDF….

Expert Sourcing Insights for Water Resistant Mdf

H2: Emerging Market Trends for Water-Resistant MDF in 2026

By 2026, the global water-resistant medium-density fiberboard (MDF) market is poised for significant transformation driven by technological advancements, shifting consumer preferences, and evolving regulatory standards. Key trends shaping the industry include increased demand in humid and high-moisture environments, innovation in eco-friendly formulations, expansion in emerging markets, and growing adoption in architectural and interior design applications.

One of the most prominent drivers is the rising demand for durable building materials in regions with tropical or coastal climates. As urbanization accelerates in Southeast Asia, Latin America, and parts of Africa, water-resistant MDF is increasingly favored over traditional MDF for use in kitchens, bathrooms, and outdoor cabinetry due to its enhanced moisture tolerance and dimensional stability.

In parallel, sustainability is becoming a core differentiator. Manufacturers are investing heavily in formaldehyde-free resins and bio-based binders to improve the environmental profile of water-resistant MDF. The European Union’s Green Deal and similar initiatives worldwide are pressuring producers to reduce volatile organic compound (VOC) emissions, accelerating the adoption of low-emission and recyclable MDF variants.

Technological innovation is also playing a crucial role. By 2026, smart water-resistant MDF with embedded sensors for moisture detection or antimicrobial coatings is expected to enter commercial production, particularly for healthcare and hospitality sectors. Additionally, digital manufacturing techniques such as CNC precision cutting and seamless integration with BIM (Building Information Modeling) are streamlining construction workflows, further boosting demand.

Supply chain resilience and raw material availability remain challenges, especially with fluctuating wood fiber prices and logistics constraints. However, companies are responding by establishing regional production hubs and utilizing agricultural residues—such as bamboo and bagasse—as alternative fiber sources, reducing dependency on virgin timber.

Moreover, the DIY and modular furniture segments are expanding rapidly, fueled by e-commerce growth and demand for flat-pack, moisture-resistant furniture. This shift is encouraging manufacturers to develop lightweight, easy-to-assemble water-resistant MDF solutions tailored for home improvement retailers and online platforms.

In conclusion, the 2026 water-resistant MDF market is characterized by innovation, sustainability, and geographic diversification. Companies that prioritize R&D, environmental compliance, and market-specific customization are likely to gain a competitive edge in this dynamic landscape.

Common Pitfalls When Sourcing Water Resistant MDF

Sourcing water resistant Medium Density Fiberboard (MDF) requires careful consideration to ensure product performance and longevity, particularly in environments exposed to moisture. Overlooking key quality and Ingress Protection (IP) factors can lead to material failure, costly replacements, and safety hazards. Below are common pitfalls to avoid:

1. Confusing Water Resistant with Waterproof

A frequent misconception is equating “water resistant” with “waterproof.” Water resistant MDF is designed to withstand limited moisture exposure—such as humidity or occasional splashes—but is not suitable for prolonged submersion or continuous wet conditions. Sourcing materials without understanding this distinction may result in premature swelling, delamination, or structural failure in high-moisture areas like bathrooms or kitchens.

2. Overlooking Proper IP Ratings for Enclosure Applications

When using water resistant MDF in electrical or electronic enclosures, the Ingress Protection (IP) rating of the final assembly is critical. The MDF itself does not have an IP rating; rather, the entire enclosure’s design (including seals, gaskets, and joints) determines its protection level. Assuming the MDF provides sufficient moisture protection without proper enclosure engineering can compromise equipment safety and compliance with standards like IEC 60529.

3. Inadequate Quality Control from Suppliers

Not all water resistant MDF products are created equal. Some manufacturers may use substandard resins, inconsistent wax content, or poor fiber bonding, leading to reduced moisture resistance and mechanical strength. Sourcing from suppliers without verified quality certifications (e.g., CARB, FSC, or EN standards) increases the risk of receiving inconsistent or underperforming material.

4. Ignoring Edge Sealing and Finishing Requirements

Even high-quality water resistant MDF remains vulnerable at the edges, which are more porous than the face. Failure to properly seal edges with moisture-resistant primers, laminates, or edge banding can allow water ingress, leading to swelling and degradation. Sourcing material without a plan for appropriate finishing undermines the intended performance benefits.

5. Assuming All “Moisture-Resistant” MDF Meets Project Needs

Marketing terms like “moisture-resistant” or “humidity-resistant” are not standardized across suppliers. One manufacturer’s version may perform significantly better than another’s under real-world conditions. Relying solely on product names without reviewing test data (e.g., thickness swell after 24-hour immersion per EN 622-5) can result in unsuitable material selection.

6. Neglecting Environmental and Installation Conditions

Water resistant MDF performance depends heavily on the installation environment. Sourcing material without considering factors like temperature fluctuations, ventilation, and exposure to direct water (e.g., under sinks or outdoors) can lead to premature failure. Indoor-rated boards should never be used in exterior or high-condensation applications, even if labeled as water resistant.

By addressing these pitfalls early in the sourcing process—through clear specifications, supplier vetting, and proper design integration—buyers can ensure reliable performance of water resistant MDF in moisture-prone applications.

Logistics & Compliance Guide for Water Resistant MDF

Overview

Water Resistant Medium Density Fibreboard (WR MDF) is an engineered wood product designed to resist moisture and humidity better than standard MDF. It is commonly used in kitchens, bathrooms, and other high-moisture environments. Proper logistics and compliance procedures are essential to ensure product integrity, safety, and adherence to regulatory standards throughout the supply chain.

Storage Requirements

Proper storage is critical to preserve the water-resistant properties of WR MDF and prevent warping, swelling, or mold growth.

– Indoor Storage: Store WR MDF indoors in a dry, well-ventilated area. Avoid direct exposure to rain, snow, or high humidity.

– Elevation: Keep panels off the ground using pallets or skids to prevent moisture absorption from concrete or damp surfaces.

– Stacking: Stack panels flat and evenly supported. Use spacers between layers for airflow. Do not exceed recommended stack heights to avoid warping.

– Temperature: Store in environments between 10°C and 25°C (50°F to 77°F) with relative humidity below 65%.

Transportation Guidelines

Ensure WR MDF is protected during transit to maintain quality and performance.

– Weather Protection: Use waterproof tarps or enclosed trailers when transporting in exposed conditions. Prevent direct contact with rain or snow.

– Securement: Panels must be tightly strapped and braced to prevent shifting, chafing, or edge damage during transit.

– Loading/Unloading: Use forklifts or pallet jacks with smooth, clean forks to avoid surface damage. Avoid dragging panels.

– Cross-Contamination: Do not transport WR MDF with wet or leaking materials. Keep separated from raw lumber or materials that may leach moisture.

Handling Procedures

Safe and proper handling prevents damage and ensures worker safety.

– PPE: Operators should wear gloves, safety glasses, and dust masks when cutting or sanding WR MDF.

– Manual Handling: Use team lifting for large panels to avoid strain or dropping. Employ mechanical aids when possible.

– Cutting & Machining: Use sharp tools and appropriate machinery. Collect dust via local exhaust ventilation to minimize airborne particles.

– Edge Protection: Protect cut edges with sealants or edge banding to maintain water resistance.

Regulatory Compliance

WR MDF must comply with regional and international standards for formaldehyde emissions, safety, and environmental impact.

– Formaldehyde Emissions:

– CARB Phase 2 (USA): Must meet ≤ 0.05 ppm formaldehyde emission limit.

– EPA TSCA Title VI (USA): Complies with strict emission standards equivalent to CARB Phase 2.

– E1 (Europe): Emission ≤ 0.124 mg/m³ (chamber test), required for CE-marked products.

– F (Japan): Super low-emitting material; ≤ 0.3 mg/L (JIS standard).

– CE Marking (EU): WR MDF must comply with EN 622-5 and carry CE marking for construction use in the European Economic Area.

– REACH (EU): Ensure absence of SVHCs (Substances of Very High Concern) above threshold limits.

– FSC/PEFC Certification: If applicable, maintain chain-of-custody documentation for sustainably sourced wood fibers.

Labeling and Documentation

Clear labeling and accurate documentation support traceability and compliance.

– Product Labeling: Include product name, thickness, moisture resistance class (e.g., P20 or P30 per EN 622-5), formaldehyde class (e.g., E1), manufacturer, batch number, and CE mark (if applicable).

– Safety Data Sheet (SDS): Provide SDS compliant with GHS/CLP regulations detailing hazards, handling, storage, and disposal.

– Compliance Certificates: Supply test reports or certification documents for formaldehyde emissions, fire performance, and moisture resistance.

Environmental and Disposal Considerations

Sustainable end-of-life management is critical.

– Recycling: WR MDF can be recycled into new wood products or used for energy recovery in approved facilities.

– Disposal: Dispose of offcuts and waste in accordance with local regulations. Do not incinerate in open air due to potential formaldehyde release.

– Hazardous Waste: If treated with fire retardants or biocides, determine waste classification per local law (e.g., EPA or EWC codes).

Import/Export Requirements

International shipments must meet destination country regulations.

– Phytosanitary Certificates: Required in some regions to prevent pest spread; check destination requirements.

– Customs Documentation: Include commercial invoice, packing list, bill of lading, and compliance certificates.

– Tariff Codes: Use correct HS codes (e.g., 4411.13 for MDF in many jurisdictions).

Conclusion

Effective logistics and compliance practices are essential for the safe, legal, and sustainable distribution of Water Resistant MDF. Adherence to storage, handling, transport, and regulatory standards ensures product performance, worker safety, and environmental responsibility across the supply chain. Regular audits and staff training are recommended to maintain compliance and operational efficiency.

Conclusion for Sourcing Water-Resistant MDF

Sourcing water-resistant MDF (Medium Density Fiberboard) is a strategic decision that enhances durability, performance, and longevity in environments exposed to moisture. When selecting this material, it is essential to prioritize certified products specifically engineered for humid or damp conditions, such as moisture-resistant (MR) MDF or HMR (High Moisture Resistance) MDF, which offer improved resistance to swelling and degradation.

Key considerations in the sourcing process include product certification, compliance with environmental and safety standards (e.g., CARB, E0, or EN standards), reliable suppliers with consistent quality, and cost-effectiveness without compromising performance. Additionally, proper finishing and sealing methods during installation further enhance the board’s resistance to water.

Ultimately, investing in high-quality, water-resistant MDF from reputable suppliers not only reduces long-term maintenance and replacement costs but also ensures structural integrity and aesthetic consistency in applications such as bathrooms, kitchens, and outdoor cabinetry. A well-informed sourcing strategy supports sustainable building practices and meets the growing demand for resilient, high-performance materials in modern construction and furniture manufacturing.