The global water level switch market is experiencing robust growth, driven by increasing demand for automated water management systems across residential, industrial, and agricultural sectors. According to a report by Mordor Intelligence, the water level switch market is projected to grow at a CAGR of over 4.8% from 2023 to 2028, fueled by rising urbanization, infrastructure development, and the integration of smart technologies in fluid control systems. Similarly, Grand View Research highlights the expanding adoption of sensors in water treatment and HVAC applications as a key growth catalyst, with the global liquid level sensor market—encompassing water level switches—valued at USD 9.7 billion in 2022 and expected to expand at a CAGR of 5.6% through 2030. As reliability and precision become paramount in water monitoring, manufacturers are innovating to meet stringent quality standards and IoT-enabled automation demands. In this evolving landscape, identifying leading water level switch manufacturers is critical for engineers, procurement teams, and system integrators seeking performance-driven, scalable solutions.

Top 10 Water Level Switch Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 SMD Fluid Controls

Domain Est. 2003

Website: fluidswitch.com

Key Highlights: SMD Fluid Controls offers a wide variety of industrial float switches and liquid level sensors, with interactive custom design and OEM services available….

#2 Level Switch Manufacturers

Domain Est. 2007

Website: levelswitchmanufacturer.com

Key Highlights: Find top industrial level switch manufacturers and suppliers who offer high quality solutions and custom orders with fast delivery….

#3 Products

Domain Est. 1995

Website: emerson.com

Key Highlights: Level switch technology measures the level of liquid or solid material to detect the presence or absence of media at a point in a vessel….

#4 Level switches for point level measurement

Domain Est. 1994

Website: vega.com

Key Highlights: Level switches for point level measurement detect when a defined level is reached. » For liquids, pastes, powders or coarse bulk solids….

#5 Flowline Level Sensor, Transmitter, Switch & Control

Domain Est. 1996

Website: flowline.com

Key Highlights: We manufacture reliable level measurement, switch and control solutions for your chemical, water, wastewater, oil and dry solids applications….

#6 LiquidLevel.com

Domain Est. 1996

Website: liquidlevel.com

Key Highlights: Innovative Components offers high-quality float switches and liquid level solutions. With our extensive customization options and reliable delivery, you can ……

#7 Level Switches

Domain Est. 1997

Website: sorinc.com

Key Highlights: SOR level switches have earned a long-time reputation for their high quality, rugged construction and reliable performance under the most demanding applications ……

#8 Water Level Controls & Liquid Level Sensors by Waterline Controls®

Domain Est. 2007

Website: waterlinecontrols.com

Key Highlights: Solid state electronic water level controls and sensors. We provide the most precise and reliable controllers in the industry. Our automatic microprocessor ……

#9 Homepage

Domain Est. 2020

Website: rochestersensors.com

Key Highlights: Leader in design and manufacturing of liquid level gauges and sensors. Over 100 years in operation with nearly 200 patents issued. Select An Industry ……

#10 Thomas Products

Website: thomasproductsusa.com

Key Highlights: Thomas Products delivers reliable and precise Flow Switches, Level Switches, Pump Controls, Non-Electric Indicators and more, suited for every industry….

Expert Sourcing Insights for Water Level Switch

2026 Market Trends for Water Level Switch

The global water level switch market is poised for significant transformation by 2026, driven by advancements in automation, increasing demand for smart infrastructure, and growing concerns over water conservation. As industries and municipalities prioritize efficiency and sustainability, water level switches—critical components in fluid control systems—are evolving in design, functionality, and application scope.

Rising Demand Across Key Sectors

One of the most prominent trends shaping the 2026 landscape is the expanding adoption of water level switches in industrial automation, residential plumbing, wastewater management, and agricultural irrigation. The manufacturing and HVAC sectors are integrating advanced level sensing technologies to improve operational reliability and reduce maintenance costs. Simultaneously, smart home systems are incorporating compact and wireless water level switches to prevent flooding and optimize water usage, particularly in water heaters, sump pumps, and washing machines.

Technological Advancements and Smart Integration

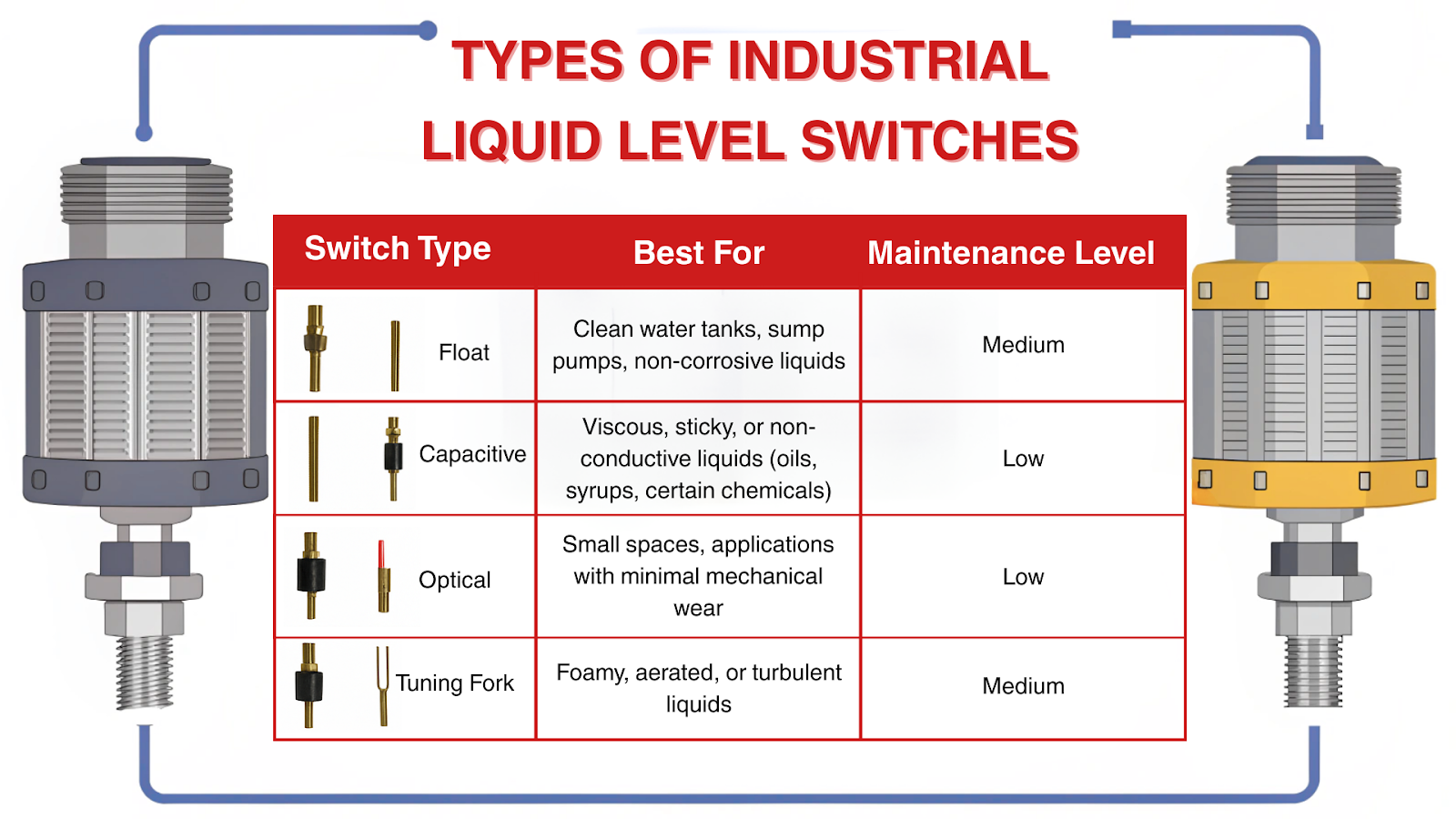

By 2026, the market will see a shift from conventional mechanical float switches to electronic and non-contact technologies such as ultrasonic, capacitive, and optical sensors. These next-generation switches offer higher accuracy, longer lifespan, and better resistance to harsh environments. Integration with IoT platforms allows real-time monitoring and remote control via mobile applications, enabling predictive maintenance and rapid response to anomalies. Such smart capabilities are becoming standard in industrial and municipal water management systems.

Sustainability and Regulatory Drivers

Environmental regulations and water scarcity concerns are compelling industries and governments to adopt efficient water management solutions. In regions facing drought or aging infrastructure, automated water level control systems help minimize waste and prevent overflow incidents. Regulatory standards in Europe and North America are increasingly mandating the use of reliable level detection in water treatment and distribution systems, further boosting market growth.

Regional Growth Dynamics

Asia-Pacific is expected to lead market expansion by 2026, fueled by rapid urbanization, industrial growth, and infrastructure development in countries like China, India, and Indonesia. Government initiatives promoting smart cities and water conservation will accelerate demand. Meanwhile, North America and Europe will focus on retrofitting legacy systems with intelligent sensing solutions, driven by sustainability goals and technological innovation.

Competitive Landscape and Market Opportunities

The market is becoming increasingly competitive, with established players and emerging startups investing in R&D for miniaturized, energy-efficient, and multi-functional switches. Strategic partnerships with IoT platform providers and system integrators are enabling faster deployment in smart building and industrial IoT applications. Opportunities also exist in after-market services, including calibration, monitoring, and cloud-based analytics.

In conclusion, the 2026 water level switch market will be defined by intelligence, connectivity, and sustainability. As digital transformation reshapes fluid management systems, water level switches will evolve from simple on/off devices into integral components of smart, data-driven ecosystems.

Common Pitfalls When Sourcing Water Level Switches (Quality and IP Rating)

Sourcing water level switches involves more than just matching basic specifications—overlooking critical quality and Ingress Protection (IP) rating factors can lead to premature failure, safety hazards, and costly downtime. Below are common pitfalls to avoid:

Inadequate IP Rating for the Environment

One of the most frequent mistakes is selecting a water level switch with an IP rating that doesn’t match the operating environment. For example:

– Using an IP65-rated switch in a submersible application (requiring IP68) leads to water ingress and sensor failure.

– Assuming “water-resistant” means waterproof without verifying the exact IP code.

– Overlooking external factors like high-pressure washdowns (common in food processing), which may require IP69K protection.

Solution: Always match the IP rating to the actual environmental conditions—consider submersion depth, exposure to jets of water, dust, and chemicals.

Poor Material Quality and Corrosion Resistance

Low-cost switches often use inferior materials such as:

– Brass or plastic housings that corrode in aggressive water (e.g., high salinity, acidic/alkaline pH).

– Seals and O-rings made from non-durable elastomers that degrade quickly.

This leads to leaks, mechanical failure, or inaccurate readings over time.

Solution: Specify switches with corrosion-resistant materials like 316 stainless steel, PVDF, or reinforced thermoplastics, especially for harsh chemical or marine environments.

Inaccurate or Inconsistent Level Detection

Some low-quality switches exhibit:

– Hysteresis or lag in response due to poor internal mechanisms.

– Float sticking caused by debris or low-tolerance design.

– False triggering due to electrical noise or weak contact integrity.

These issues result in pump cycling, overflow, or dry-run damage.

Solution: Choose switches with proven reliability, wide operating temperature ranges, and designs that minimize fouling (e.g., non-stick coatings, robust float guidance).

Lack of Certifications and Compliance

Purchasing switches without proper industry certifications (e.g., UL, CE, RoHS, WRAS for potable water) can pose safety and legal risks, especially in regulated industries like healthcare or drinking water systems.

Solution: Verify compliance with regional and application-specific standards before procurement.

Ignoring Long-Term Reliability and MTBF

Focusing only on upfront cost while ignoring Mean Time Between Failures (MTBF) leads to higher total cost of ownership. Cheap switches may fail within months, requiring frequent replacements and maintenance.

Solution: Evaluate long-term performance data and opt for suppliers with proven track records and warranties.

Poor Sealing and Internal Condensation

Even with a high IP rating, poor internal design can allow condensation to form inside the switch housing due to temperature cycling. This compromises electrical connections and causes short circuits.

Solution: Select switches with breathable membranes (if vented) or hermetically sealed enclosures designed to manage thermal expansion.

By addressing these common pitfalls—particularly around IP rating suitability and build quality—you can ensure reliable, safe, and cost-effective performance from water level switches across diverse applications.

Logistics & Compliance Guide for Water Level Switch

This guide provides essential information for the safe and compliant handling, transportation, storage, and regulatory compliance of water level switches across various markets.

Product Classification and HS Code

Water level switches are typically classified under Harmonized System (HS) codes related to electrical control equipment. A common classification is 8536.50 – “Electrical apparatus for switching or protecting electrical circuits, or for making connections to or in electrical circuits… for a voltage not exceeding 1,000 V: Other.” However, the exact code may vary based on design, function, and materials. Consult a customs expert or use a tariff classification tool to confirm the appropriate HS code for your specific product in the destination country.

Packaging and Labeling Requirements

Ensure water level switches are packaged to prevent damage during transit. Use anti-static materials where applicable and secure devices to prevent movement. Packaging must comply with international shipping standards (e.g., ISTA, ASTM). Labels must include:

– Product name and model number

– Manufacturer or brand name

– Voltage and current ratings

– RoHS and CE markings (if applicable)

– Country of origin

– Barcodes or SKUs for inventory tracking

– Handling symbols (e.g., “Fragile,” “This Side Up”)

Shipping and Transportation

Water level switches are generally non-hazardous and can be shipped via standard air, sea, or ground freight. Confirm with carriers that no special declarations are needed. For international shipments:

– Provide a commercial invoice, packing list, and bill of lading/air waybill

– Include a certificate of conformity if required by the destination country

– Declare accurate product value and description to avoid customs delays

Import and Export Regulations

Compliance with import/export regulations is critical. Key considerations include:

– Export Controls: Verify if the product contains technology subject to export control regimes (e.g., EAR in the U.S.). Most standard water level switches are not controlled, but dual-use components may require a license.

– Import Duties and Taxes: Duties vary by country and HS code. Use duty calculators or consult a customs broker to estimate costs.

– Documentation: Maintain records of export declarations, certificates of origin, and compliance documentation for at least five years.

Regulatory Compliance

Water level switches must meet safety and environmental standards in target markets:

– CE Marking (EU): Required under the Low Voltage Directive (LVD 2014/35/EU) and Electromagnetic Compatibility (EMC) Directive (2014/30/EU). RoHS compliance (2011/65/EU) is mandatory for restricted substances.

– UKCA Marking (UK): Required for products sold in Great Britain. Follows similar standards to CE.

– FCC Certification (USA): Required if the device emits radio frequency energy (e.g., electronic switching components). Compliance with Part 15 of FCC rules may apply.

– RoHS and REACH (EU): Ensure no banned substances (e.g., lead, cadmium) exceed limits. Provide substance declarations if requested.

– Other Regional Standards: Check requirements for markets such as Canada (CSA), Australia (RCM), and China (CCC mark if applicable).

Storage Conditions

Store water level switches in a dry, temperature-controlled environment (typically 5°C to 40°C). Avoid exposure to moisture, dust, and corrosive chemicals. Keep packaging sealed until ready for use to prevent contamination or damage.

End-of-Life and Recycling

Comply with WEEE (Waste Electrical and Electronic Equipment) Directive in the EU and similar e-waste laws elsewhere. Provide take-back information or partner with certified recyclers. Design products for disassembly and recycling where possible.

Documentation and Recordkeeping

Maintain the following for compliance audits and traceability:

– Technical files (including test reports and risk assessments)

– Declaration of Conformity (DoC)

– Bill of materials (BOM) with RoHS compliance status

– Shipping and customs documentation

– Supplier certifications (e.g., ISO 9001)

Adhering to this guide ensures smooth logistics operations and regulatory compliance for water level switch distribution worldwide.

Conclusion for Sourcing a Water Level Switch

After evaluating various options, the selection and sourcing of a suitable water level switch should be based on key factors such as application requirements, reliability, cost-effectiveness, compatibility with the liquid type and environment, and ease of installation and maintenance. Both mechanical and electronic (e.g., float, capacitive, ultrasonic) switches offer distinct advantages depending on the operational context—whether in residential, industrial, or commercial settings.

Sourcing from reputable suppliers ensures product quality, compliance with safety standards (such as IP ratings and certifications), and access to technical support. Additionally, considering long-term durability and after-sales service helps minimize downtime and maintenance costs.

In conclusion, a well-informed decision—balancing performance needs, environmental conditions, and budget—will ensure efficient and reliable water level control, contributing to enhanced system safety and operational efficiency. Conducting thorough market research and engaging with trusted vendors is essential for optimal sourcing outcomes.