The global water drive motors market is experiencing steady growth, driven by increasing demand for energy-efficient pumping systems in municipal water supply, wastewater treatment, and industrial applications. According to Mordor Intelligence, the water pump motor market is projected to grow at a CAGR of over 5.2% from 2023 to 2028, fueled by infrastructure modernization and rising water conservation initiatives worldwide. Additionally, Grand View Research reports that the global industrial electric motor market—of which water drive motors are a critical subset—is anticipated to expand at a CAGR of 5.5% from 2023 to 2030, underpinned by automation trends and regulatory push for high-efficiency motors. As industries prioritize reliability and sustainability, the prominence of advanced water drive motor manufacturers has never been greater. This list highlights the top 10 manufacturers leading innovation, performance, and market share in the water drive motor sector.

Top 10 Water Drive Motors Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 ABB Drives

Domain Est. 1990

Website: abb.com

Key Highlights: ABB Drives is a global technology leader serving industries, infrastructure and machine builders with world-class drives, drive systems and packages….

#2 Reliable Motors, Drives & Industrial Power Solutions

Domain Est. 1992

Website: toshiba.com

Key Highlights: Toshiba International Corporation provides reliable motors, drives, UPS, and industrial power solutions designed to reduce downtime, lower maintenance costs ……

#3 Baldor.com

Domain Est. 1995

Website: baldor.com

Key Highlights: ABB is the world’s number-one manufacturer of NEMA motors, and we’re proud to support you locally with the Baldor-Reliance product brand….

#4 Motors – great quality, efficient and reliable

Domain Est. 1995

Website: danfoss.com

Key Highlights: The Danfoss motor range is one of the broadest on the market – and your safest bet for quality, durability, efficiency and reliability….

#5 US Motors

Domain Est. 1997

Website: acim.nidec.com

Key Highlights: Residential Water System Pump Motors. For use on jet pumps, booster pumps, lawn sprinkler pumps, and other centrifugal pump applications. Variable Speed Motors ……

#6 Franklin Electric

Domain Est. 2000

Website: franklin-electric.com

Key Highlights: Every day, Franklin Electric manufactures approximately 20,000 pumps, motors, drives, and controls to move the 3 trillion gallons of fresh water used worldwide ……

#7 Electric Motors

Domain Est. 2004

Website: weg.net

Key Highlights: Solutions. WEG efficiency · Digital Solutions · WEG Motion Drives · Power Generation · Wind power · Thermal Energy · Farming and Agribusiness · Mining ……

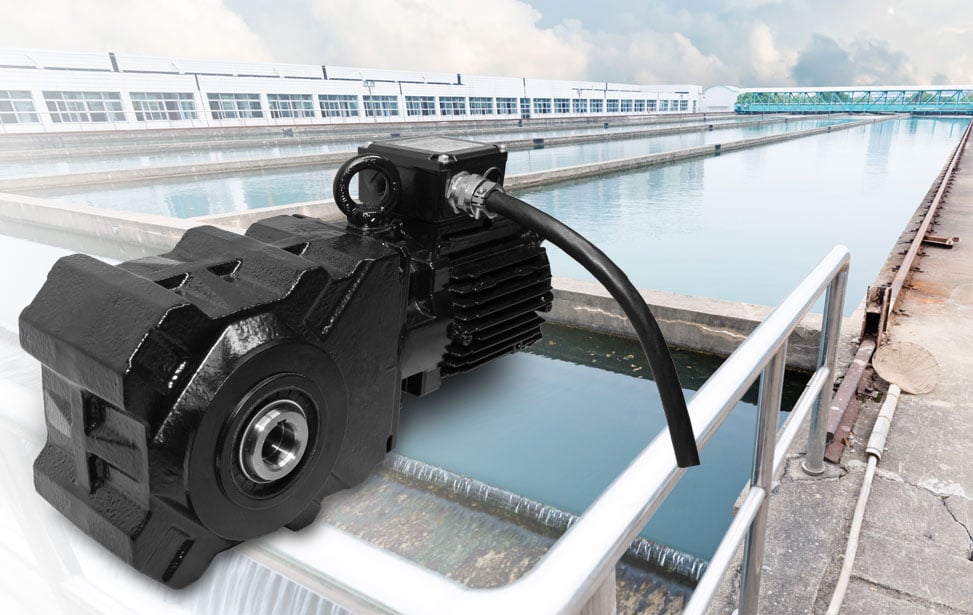

#8 Bauer Gear Motor

Domain Est. 2010

Website: bauergears.com

Key Highlights: Bauer Gear Motor has developed to become the preferred international provider of high-quality and extremely reliable geared motors….

#9 LEESON Brand

Domain Est. 2021

Website: regalrexnord.com

Key Highlights: The LEESON band spans thousands of alternating current (AC) and direct current (DC) motors, gearmotors, washdown and variable-speed control solutions….

#10 Wolong Electric America

Domain Est. 2023

Website: wolongamerica.com

Key Highlights: Wolong Electric America manufactures GE branded AC motors, DC motors, and NEMA low voltage and medium voltage electric motors. We serve heavy industries ……

Expert Sourcing Insights for Water Drive Motors

H2: Projected 2026 Market Trends for Water Drive Motors

As the global push for sustainable and energy-efficient technologies intensifies, water drive motors—also known as hydraulic motors powered by water rather than oil—are emerging as a transformative solution in various industrial and marine applications. The market for water drive motors is expected to experience significant growth and transformation by 2026, driven by technological advancements, environmental regulations, and increasing demand for clean power systems. Below is an analysis of key market trends shaping the water drive motor industry in 2026.

1. Rising Demand for Eco-Friendly Hydraulic Systems

Environmental concerns and stricter emissions regulations are accelerating the shift away from oil-based hydraulic systems. Water, as a non-toxic, biodegradable, and abundant fluid, is gaining traction as a sustainable alternative. By 2026, industries such as offshore drilling, wastewater treatment, and maritime transportation are projected to adopt water drive motors to comply with environmental standards like the EU’s Green Deal and IMO 2030/2050 emission targets.

2. Technological Innovations Enhancing Efficiency and Durability

Historically, water drive motors faced challenges related to corrosion, lubrication, and lower power density compared to oil-based systems. However, by 2026, advances in material science—such as corrosion-resistant coatings (e.g., ceramic composites and stainless steel alloys) and improved sealing technologies—are expected to overcome these limitations. Additionally, integrated digital monitoring systems and predictive maintenance algorithms will enhance reliability and reduce downtime, making water drive motors more viable for high-stakes applications.

3. Growth in Renewable Energy and Marine Applications

The offshore wind energy sector is poised to be a major growth driver for water drive motors. Hydraulic pitch and yaw systems powered by water-based fluids offer safer and cleaner operation in sensitive marine environments. With global offshore wind capacity projected to exceed 200 GW by 2030, demand for reliable and environmentally safe drive systems will increase significantly by 2026.

4. Expansion in Industrial Automation and Green Manufacturing

In manufacturing, particularly in food and beverage, pharmaceuticals, and cleanroom environments, the risk of oil contamination makes water-based hydraulic systems highly desirable. By 2026, automation trends and the rise of green manufacturing certifications are expected to boost adoption of water drive motors in precision machinery and robotic systems.

5. Regional Market Developments

Europe is anticipated to lead the market due to strong environmental regulations and early adoption of green technologies. North America will follow, driven by investments in offshore energy and defense applications. Meanwhile, Asia-Pacific—especially China and South Korea—is expected to emerge as a key manufacturing and deployment hub, supported by government incentives for clean tech innovation.

6. Competitive Landscape and Strategic Partnerships

By 2026, a more competitive landscape will emerge, with established hydraulic companies (e.g., Bosch Rexroth, Parker Hannifin) launching water-compatible motor lines and startups focusing on niche applications. Strategic collaborations between motor manufacturers, system integrators, and end-users will accelerate commercialization and standardization of water-based hydraulic components.

Conclusion

The 2026 outlook for water drive motors is highly promising, characterized by strong growth, technological maturation, and increasing alignment with global sustainability goals. As industries seek cleaner, safer, and more efficient alternatives to traditional hydraulics, water drive motors are set to transition from niche applications to mainstream adoption across multiple sectors. Companies investing in R&D, compliance, and ecosystem partnerships today will be well-positioned to capture market share in this evolving landscape.

Common Pitfalls Sourcing Water Drive Motors (Quality, IP)

Sourcing Water Drive Motors—typically referring to hydraulic motors powered by water or water-glycol solutions—presents unique challenges, especially in critical applications such as marine propulsion, underwater robotics, hydroelectric systems, or environmentally sensitive environments. While these motors offer benefits like fire resistance and environmental compatibility, several common pitfalls can compromise performance, safety, and longevity. Two major concerns are quality inconsistencies and incorrect Ingress Protection (IP) ratings.

Quality Inconsistencies

One of the most significant risks when sourcing water drive motors is encountering inconsistent or substandard product quality. Since these motors operate in harsh, wet environments, even minor defects can lead to rapid failure.

-

Material Compatibility Issues: Not all metals and seals are suitable for continuous exposure to water. Low-quality motors may use standard elastomers (like NBR) or metals prone to corrosion (e.g., non-stainless steel), leading to seal degradation, pitting, and internal leakage. High-quality motors should use materials like Viton seals, 316L stainless steel, or specialized coatings resistant to water-induced corrosion.

-

Poor Manufacturing Tolerances: Hydraulic motors depend on tight internal tolerances to maintain efficiency and prevent internal bypass. Inexpensive or poorly manufactured units may have inconsistent machining, leading to reduced torque output, overheating, or premature wear.

-

Lack of Testing and Certification: Reputable suppliers provide proof of performance testing under real-world conditions, including pressure, temperature, and endurance cycles. Sourcing from vendors without proper documentation or third-party certifications (e.g., ISO, DNV, ABS) increases the risk of receiving untested or non-compliant motors.

-

Counterfeit or Recycled Components: In competitive markets, some suppliers may offer “new” motors that incorporate refurbished or counterfeit parts. These components often fail prematurely and lack traceability or warranty support.

To mitigate quality risks, always:

– Request material specifications and test reports.

– Choose suppliers with proven experience in water-hydraulic applications.

– Conduct factory audits or request sample testing before bulk orders.

Incorrect Ingress Protection (IP) Ratings

The Ingress Protection (IP) rating is critical for water drive motors, as it defines the level of protection against solid particles and liquids. Selecting a motor with an inadequate IP rating is a common and costly mistake.

-

Underestimating Environmental Exposure: Many assume standard IP65 (dust-tight and protected against low-pressure water jets) is sufficient. However, motors used in submerged or high-pressure washdown environments require higher ratings such as IP67 (immersion up to 1m for 30 minutes) or IP68 (continuous submersion). Using an IP65 motor underwater will result in immediate water ingress and catastrophic failure.

-

Misunderstanding IP Code Structure: The IP code consists of two digits (e.g., IP68). The first digit indicates protection against solids, the second against liquids. Sourcing teams may focus only on dust protection (first digit) and overlook the need for robust water protection (second digit), especially in dynamic or variable conditions.

-

Lack of Real-World Validation: Some motors may claim high IP ratings based on lab conditions that don’t reflect actual operating environments—such as vibration, thermal cycling, or mechanical stress. Always verify that the IP rating has been tested under conditions mimicking your application.

-

Ignoring Cable Glands and Connectors: Even if the motor housing is IP68-rated, poor-quality or improperly installed cable entries can become failure points. Ensure the entire system, including connectors and junction boxes, meets the required IP standard.

To avoid IP-related failures:

– Clearly define the operational environment (e.g., depth, pressure, exposure duration).

– Require full IP certification documentation from the supplier.

– Inspect sealing mechanisms and ensure compatible accessories are supplied.

Conclusion

Sourcing reliable water drive motors demands careful attention to both quality and environmental protection. Prioritizing suppliers with proven expertise, rigorous testing, and accurate IP certification can prevent costly downtime, safety hazards, and maintenance issues. Always validate specifications against real-world conditions and avoid compromising on critical factors like material selection and ingress protection.

Logistics & Compliance Guide for Water Drive Motors

This guide outlines key logistics considerations and compliance requirements for the transportation, storage, and operation of Water Drive Motors. Adherence to these guidelines ensures safety, regulatory alignment, and operational efficiency.

Product Classification and Documentation

Water Drive Motors must be accurately classified for international and domestic shipping. Typically categorized under HS Code 8501.31 (Electric motors of an output not exceeding 37.5 W) or a similar motor classification depending on specifications. Ensure all shipments include a detailed commercial invoice, packing list, and, where applicable, a certificate of origin. Technical data sheets and user manuals compliant with destination market languages must accompany each unit.

Packaging and Handling Requirements

Use robust, waterproof packaging to protect Water Drive Motors from moisture, shock, and vibration during transit. Motors should be sealed in moisture-barrier bags with desiccants and placed in shock-absorbent materials within corrugated cartons or wooden crates for bulk shipments. Clearly label packages with orientation arrows, “Fragile,” and “Protect from Moisture” warnings. Avoid stacking excessive weight on packages containing motors.

Transportation Modes and Restrictions

Water Drive Motors are generally non-hazardous and can be shipped via air, sea, or ground freight. Confirm with carriers that no special restrictions apply due to embedded electronics or magnetic components. For air transport, comply with IATA Packing Instruction 967 for lithium batteries if integrated. Use temperature-controlled containers if shipping through extreme climates to prevent condensation or material degradation.

Import and Export Compliance

Verify export control classifications under the Export Administration Regulations (EAR) or equivalent national frameworks. Most Water Drive Motors fall under EAR99, but confirm based on technical performance (e.g., torque, speed, control systems). For exports to embargoed or restricted countries, obtain proper authorization. Importers must ensure compliance with local electrical safety and electromagnetic compatibility (EMC) standards such as CE (EU), UKCA (UK), or UL (USA).

Regulatory Certifications

Ensure all Water Drive Motors carry required certifications for target markets:

– CE Marking: Compliance with EU directives (e.g., Low Voltage Directive 2014/35/EU, EMC Directive 2014/30/EU).

– UKCA Marking: Required for sale in Great Britain.

– FCC Certification: Mandatory for EMC compliance in the United States.

– RoHS and REACH Compliance: Confirm restriction of hazardous substances and chemical registration.

Maintain up-to-date technical files and Declaration of Conformity for audit purposes.

Storage Conditions

Store Water Drive Motors in a dry, climate-controlled environment with temperatures between 5°C and 35°C and relative humidity below 70%. Avoid exposure to corrosive atmospheres, direct sunlight, or standing water. Keep motors in original packaging until installation to prevent dust accumulation and mechanical damage.

End-of-Life and Environmental Compliance

Dispose of Water Drive Motors in accordance with WEEE (Waste Electrical and Electronic Equipment) directives in applicable regions. Partner with certified e-waste recyclers to ensure proper dismantling and material recovery. Document recycling procedures to meet environmental reporting obligations.

Recordkeeping and Traceability

Maintain shipment logs, compliance certificates, and quality control records for a minimum of five years. Assign batch or serial numbers to motors to enable traceability in case of recalls or field failures. Implement a document control system to track revisions of manuals and compliance documentation.

Following this guide ensures safe, legal, and efficient handling of Water Drive Motors across the supply chain. Regularly review regulations as standards and trade policies evolve.

Conclusion for Sourcing Water-Drop Motors (Water-Cooled Motors or Water-Driven Motors)

In conclusion, sourcing water-driven or water-cooled motors requires a comprehensive evaluation of application needs, environmental conditions, technical specifications, and supplier reliability. These specialized motors are essential in industries where efficient heat dissipation, compact design, or operation in hazardous environments is critical—such as in marine applications, cooling systems, or sealed industrial units.

Key considerations in the sourcing process include motor efficiency, thermal management capabilities, corrosion resistance (especially when using water as a coolant or drive medium), and compliance with relevant industry standards (e.g., IP ratings, ISO certifications). Additionally, long-term maintenance requirements, availability of spare parts, and the technical support offered by suppliers play a significant role in ensuring operational reliability.

While water-driven systems may offer benefits such as quieter operation and improved thermal performance compared to air-cooled alternatives, they require careful integration and material selection to prevent degradation from moisture or water exposure. Therefore, partnering with reputable manufacturers experienced in fluid-compatible motor design and sealing technologies is vital.

Ultimately, a strategic sourcing approach—balancing performance, durability, cost, and lifecycle support—will ensure the successful implementation of water-driven motors in your application, enhancing system efficiency and longevity. Ongoing advancements in materials and motor technology continue to expand the viability of these systems, making them a compelling choice in specialized engineering environments.