The global washing machine market is experiencing steady growth, driven by rising urbanization, increasing disposable incomes, and growing demand for energy-efficient home appliances. According to Grand View Research, the global home appliances market was valued at USD 541.6 billion in 2022 and is expected to expand at a compound annual growth rate (CAGR) of 4.8% from 2023 to 2030, with washing machines representing a significant share of this expansion. As demand for reliable and safe electrical components grows in tandem, the need for high-quality electrical plugs—critical for performance, safety, and compliance—has become paramount. Mordor Intelligence further projects that the home appliances market will grow at a CAGR of over 5.5% during the forecast period 2023–2028, underscoring the escalating demand for durable and certified electrical connectivity solutions. In this evolving landscape, a select group of manufacturers have emerged as leaders in producing washing machine electrical plugs, combining innovation, stringent safety standards, and scalable production capabilities to meet global industry needs. The following list highlights the top nine manufacturers shaping this essential niche within the appliance supply chain.

Top 9 Washing Machine Electrical Plug Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Official Washer Parts

Domain Est. 1999

Website: partselect.com

Key Highlights: $12.99 deliveryShop for genuine OEM Washer Parts at PartSelect. Official parts that fit your Washer, same–day shipping, video tutorials, and expert repair help….

#2 LSP

Domain Est. 1996

Website: lspproducts.com

Key Highlights: LSP Products Group (LSP) was founded by plumbers over 45 years ago with a focus on designing and manufacturing innovative plumbing products….

#3 Oatey® Quadtro® 1/4

Domain Est. 1996

Website: oatey.com

Key Highlights: Rating 4.8 (24) The Oatey Quadtro Washing Machine Outlet Box is made for commercial or residential applications where supply valves and waste drains are recessed into the wall….

#4 Viking Electric

Domain Est. 1997

Website: vikingelectric.com

Key Highlights: Visit Viking Electric for quality electrical supplies, services & solutions. Shop online for your materials, tools & equipment – plus free delivery or ……

#5 Equator Advanced Appliances

Domain Est. 1999

Website: equatorappliances.com

Key Highlights: Equator Advanced Appliances provides all types of Home Appliances. Equator has the best Combo Washer Dryer, Stackable Washer Dryer, Best Refrigerator, ……

#6 Bosch Spare Parts for Appliances

Domain Est. 2008

Website: bosch-home.com

Key Highlights: Get original spare parts for your Bosch appliances. Every spare part is manufactured for Bosch and is generally available up to 15 years….

#7 The Appliance Plug

Domain Est. 2018

Website: theapplianceplug.com

Key Highlights: The Appliance Plug specializing in Appliances. Serving Tampa, Riverview, Valrico, Apollo Beach, Lutz, Wesley Chapel, Clearwater, St Petersburg, ……

#8 Types of Electrical Plugs

Domain Est. 2004

Website: iqsdirectory.com

Key Highlights: Explore the many uses and types of electrical plugs. Learn about plug adapters, replacement plugs, two-pronged and three-pronged plugs….

#9 Washer Electrical Plug

Domain Est. 2013

Website: paclights.com

Key Highlights: This guide delves into the various aspects of washer electrical plugs, including their types, specifications, safety standards, and installation practices….

Expert Sourcing Insights for Washing Machine Electrical Plug

H2: 2026 Market Trends for Washing Machine Electrical Plugs

The global market for washing machine electrical plugs is poised for significant evolution by 2026, driven by technological advancements, regulatory changes, and shifting consumer demands. As home appliances become smarter and more energy-efficient, the components that power them—including electrical plugs—are undergoing transformation to meet new performance, safety, and sustainability standards.

-

Increased Demand for Smart and Energy-Efficient Plugs

By 2026, the integration of smart technology into household appliances is expected to extend to associated components like electrical plugs. Smart plugs capable of monitoring energy consumption, enabling remote control via mobile apps, and providing overload protection are gaining traction. With washing machines increasingly connected to home automation systems (e.g., via IoT), electrical plugs are evolving to support data communication and real-time diagnostics. This trend is particularly strong in North America and Western Europe, where smart home adoption is accelerating. -

Emphasis on Safety and Compliance Standards

Regulatory bodies worldwide are tightening safety requirements for electrical components. By 2026, washing machine plugs will need to comply with updated standards such as IEC 60320 (appliance couplers) and regional certifications (e.g., UL in the U.S., CE in Europe, and CCC in China). Enhanced features like child-safe shutters, temperature monitoring, and arc-fault detection are expected to become standard, reducing fire and electrocution risks. -

Growth in Emerging Markets

Asia-Pacific, Latin America, and Africa are witnessing rapid urbanization and rising disposable incomes, fueling demand for home appliances—including washing machines. This growth is directly increasing the need for reliable and affordable electrical plugs. Manufacturers are responding by producing cost-effective, durable plug solutions tailored to local voltage standards (e.g., 220–240V in India and Southeast Asia) and environmental conditions. -

Sustainability and Eco-Friendly Materials

Environmental regulations and consumer preferences are pushing manufacturers toward sustainable materials. By 2026, there will be a noticeable shift toward electrical plugs made from recycled plastics, biodegradable polymers, and halogen-free compounds. Companies are also reducing packaging waste and improving energy efficiency in production processes to align with ESG (Environmental, Social, and Governance) goals. -

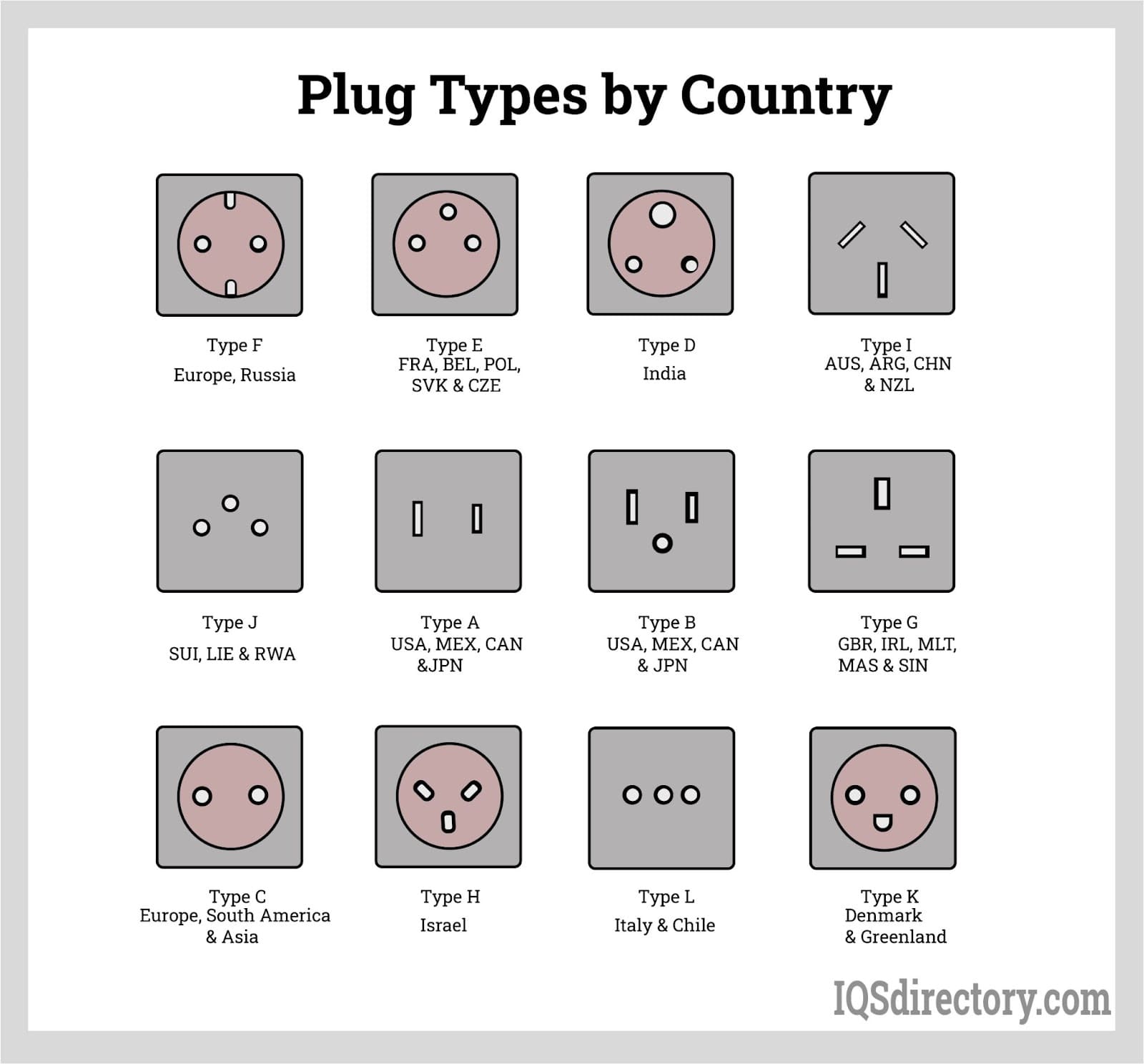

Standardization vs. Regional Variations

Despite global efforts toward standardization, regional plug types (e.g., Type C, D, F, G, I) remain a challenge. Manufacturers are focusing on adaptable or modular plug designs that can be easily customized for different markets. Additionally, dual-voltage plugs and universal socket compatibility are emerging as competitive advantages in export-oriented markets. -

Impact of Electrification and Renewable Energy Integration

As households adopt solar power and battery storage systems, there is growing interest in appliances and components that support energy optimization. By 2026, washing machine plugs may feature compatibility with low-voltage DC systems or energy feedback mechanisms that work in tandem with home energy management systems (HEMS), supporting greener energy usage.

Conclusion

The 2026 market for washing machine electrical plugs will be shaped by innovation in smart functionality, heightened safety standards, regional market growth, and sustainability imperatives. Stakeholders—including manufacturers, regulators, and retailers—must adapt to these trends to remain competitive in an increasingly connected and eco-conscious global marketplace.

Common Pitfalls When Sourcing Washing Machine Electrical Plugs (Quality and IP Rating)

Sourcing the correct electrical plug for a washing machine involves more than just matching the shape and voltage. Critical factors like quality and ingress protection (IP) rating must be carefully evaluated to ensure safety, compliance, and long-term reliability. Overlooking these aspects can lead to serious hazards. Here are the most common pitfalls:

Inadequate IP Rating for Wet Environments

Washing machines operate in high-moisture environments, making the IP (Ingress Protection) rating of the plug critical. A common mistake is selecting plugs with insufficient protection against water and dust. Using a plug with a low IP rating (e.g., IP20) can result in short circuits, electric shocks, or fire. The plug must typically have at least an IP44 rating (protected against splashing water from any direction) to safely withstand typical laundry room conditions.

Poor Material Quality and Durability

Low-quality plugs often use substandard plastics and conductive materials that degrade quickly when exposed to humidity, temperature fluctuations, and mechanical stress. This can lead to brittle casings, loose connections, or overheating. Sourcing from suppliers without proper material certifications (e.g., UL, VDE, or CE) increases the risk of receiving plugs that fail prematurely or pose safety hazards.

Non-Compliance with Regional Electrical Standards

Electrical plugs must comply with regional safety and performance standards (e.g., BS 1363 in the UK, NEMA in North America, or IEC standards internationally). A frequent pitfall is sourcing plugs that visually resemble the correct type but do not meet local certification requirements. Non-compliant plugs may not withstand required current loads or incorporate essential safety features like shutters or proper earthing.

Inconsistent Manufacturing and Lack of Quality Control

When sourcing from low-cost manufacturers, especially without on-site audits, there’s a risk of inconsistent production quality. Batches may vary in dimensions, contact resistance, or insulation thickness. Without rigorous quality control (QC) procedures and third-party testing, defective units can slip through, increasing field failure rates and potential liability.

Misjudging Current and Temperature Ratings

Washing machines can draw high inrush currents during startup and operate under sustained loads. Using a plug rated below the machine’s electrical requirements can cause overheating and melting. A common error is assuming all standard-looking plugs handle the same load. Always verify that the plug is rated for the washing machine’s maximum current (typically 10A to 16A) and operating temperature range.

Overlooking Strain Relief and Cable Gland Quality

Poor strain relief mechanisms can lead to wire detachment inside the plug due to repeated movement or tension. Low-quality cable glands may not seal properly, allowing moisture ingress even if the plug body has a high IP rating. This undermines the entire protection system and poses a significant safety risk.

Insufficient Supplier Verification and Traceability

Sourcing from unknown or unverified suppliers increases the risk of counterfeit or non-genuine parts. Lack of traceability makes it difficult to address quality issues, conduct recalls, or prove compliance during audits. Always verify supplier credentials, request test reports, and ensure batch traceability for electrical components.

Avoiding these pitfalls requires due diligence in supplier selection, clear technical specifications, and ongoing quality assurance. Prioritizing certified, high-IP-rated plugs from reputable manufacturers ensures safe and reliable operation of washing machines in demanding environments.

Logistics & Compliance Guide for Washing Machine Electrical Plug

This guide outlines the essential logistics considerations and compliance requirements for the electrical plug used with washing machines, ensuring safe, efficient, and legally compliant distribution and use.

Regulatory Compliance

Ensure the electrical plug adheres to the specific safety and performance standards of the target market. Key regulations include:

- IEC 60320: International standard for appliance couplers, including connectors for household and similar general purposes.

- UL 60745 (North America): Underwriters Laboratories standard for appliance inlets and connectors.

- BS 1363 (UK): Specifies requirements for 13A fused plugs used in the United Kingdom.

- AS/NZS 3112 (Australia/New Zealand): Standard for plugs and socket outlets, including requirements for earthed and fused plugs.

- CEE 7/7 (Europe): Common plug standard used in many European countries (e.g., Schuko and French variants).

- Country-Specific Certification: Obtain mandatory certifications such as CE (EU), UKCA (UK), CCC (China), PSE (Japan), and INMETRO (Brazil) as applicable.

Non-compliant plugs may result in product recalls, legal liability, or market entry denial.

Voltage and Frequency Compatibility

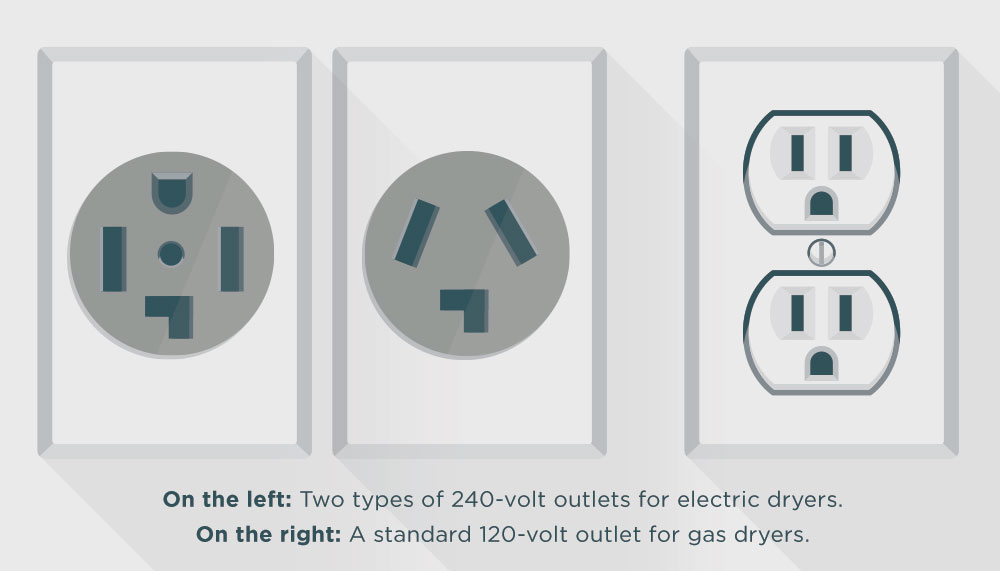

Verify plug compatibility with local electrical systems:

- Match plug design to regional voltage (e.g., 120V in North America, 230V in Europe) and frequency (50Hz or 60Hz).

- Ensure washing machine power requirements align with the plug and local grid specifications.

- Avoid using adapters or converters that may compromise safety or performance.

Plug Type and Configuration

Select the appropriate plug type based on destination:

- Use region-specific plug types (e.g., Type A/B for North America, Type G for UK, Type F for Germany).

- Ensure correct pin configuration, grounding, and fuse rating (e.g., 13A fuse in UK plugs).

- Avoid universal or multi-standard plugs unless explicitly certified for use in all target markets.

Packaging and Labeling

Implement proper packaging and labeling practices:

- Clearly label plugs with voltage, current rating, safety certifications, and manufacturer details.

- Include multilingual instructions and safety warnings where necessary.

- Use tamper-evident packaging to prevent substitution or damage during transit.

Supply Chain and Inventory Management

Optimize logistics for plug variants:

- Maintain regional inventory of correct plug types to avoid last-minute modifications.

- Coordinate with manufacturers for region-specific cable and plug assembly.

- Track compliance documentation (test reports, certificates) for each batch.

Transportation and Handling

Ensure safe handling during shipping:

- Protect plugs from moisture, extreme temperatures, and physical damage.

- Use anti-static packaging if components are sensitive.

- Comply with international transport regulations for electrical components (e.g., IATA for air freight).

End-of-Life and Environmental Compliance

Adhere to environmental regulations:

- Follow WEEE (Waste Electrical and Electronic Equipment) directives in the EU and similar laws elsewhere.

- Use recyclable materials and minimize hazardous substances (RoHS compliance).

- Provide take-back or recycling instructions to consumers.

Quality Assurance and Testing

Implement rigorous quality control:

- Conduct routine electrical safety, durability, and temperature rise testing.

- Perform batch sampling and third-party verification.

- Maintain traceability of components and compliance records.

Adhering to this guide ensures safe, reliable operation of washing machines and smooth global market access.

In conclusion, sourcing a washing machine electrical plug requires careful consideration of electrical specifications, regional standards, and safety certifications. It is essential to match the plug type to the local voltage, frequency, and grounding requirements to ensure safe and efficient operation. Using a plug that is certified (such as UL, CE, or other regional standards) and compatible with the washing machine’s power needs helps prevent electrical hazards and ensures compliance with safety regulations. Whether replacing a damaged plug or installing a new one, consulting manufacturer guidelines and, if necessary, a qualified electrician will ensure a reliable and code-compliant connection. Proper sourcing not only protects the appliance but also enhances user safety and longevity of the equipment.