The global washing machine market is undergoing significant transformation, driven by rising consumer demand for smart, energy-efficient appliances and the integration of advanced electronics in home laundry systems. A critical component at the heart of modern washing machines is the control board—the central processor that regulates operations such as wash cycles, motor control, water temperature, and fault diagnostics. As automation and IoT-enabled appliances gain traction, the demand for reliable and intelligent control boards has surged. According to Grand View Research, the global washing machine market size was valued at USD 66.8 billion in 2022 and is expected to expand at a compound annual growth rate (CAGR) of 6.1% from 2023 to 2030. This growth trajectory is mirrored in the downstream component supply chain, particularly in the control board segment, where precision engineering, durability, and compatibility with smart home ecosystems are becoming key differentiators. As manufacturers scale production to meet demand across both developed and emerging markets, a select group of control board suppliers has emerged as leaders in innovation, quality, and market reach. Here are the top five washing machine control board manufacturers shaping the future of laundry technology.

Top 5 Washing Machine Control Board Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

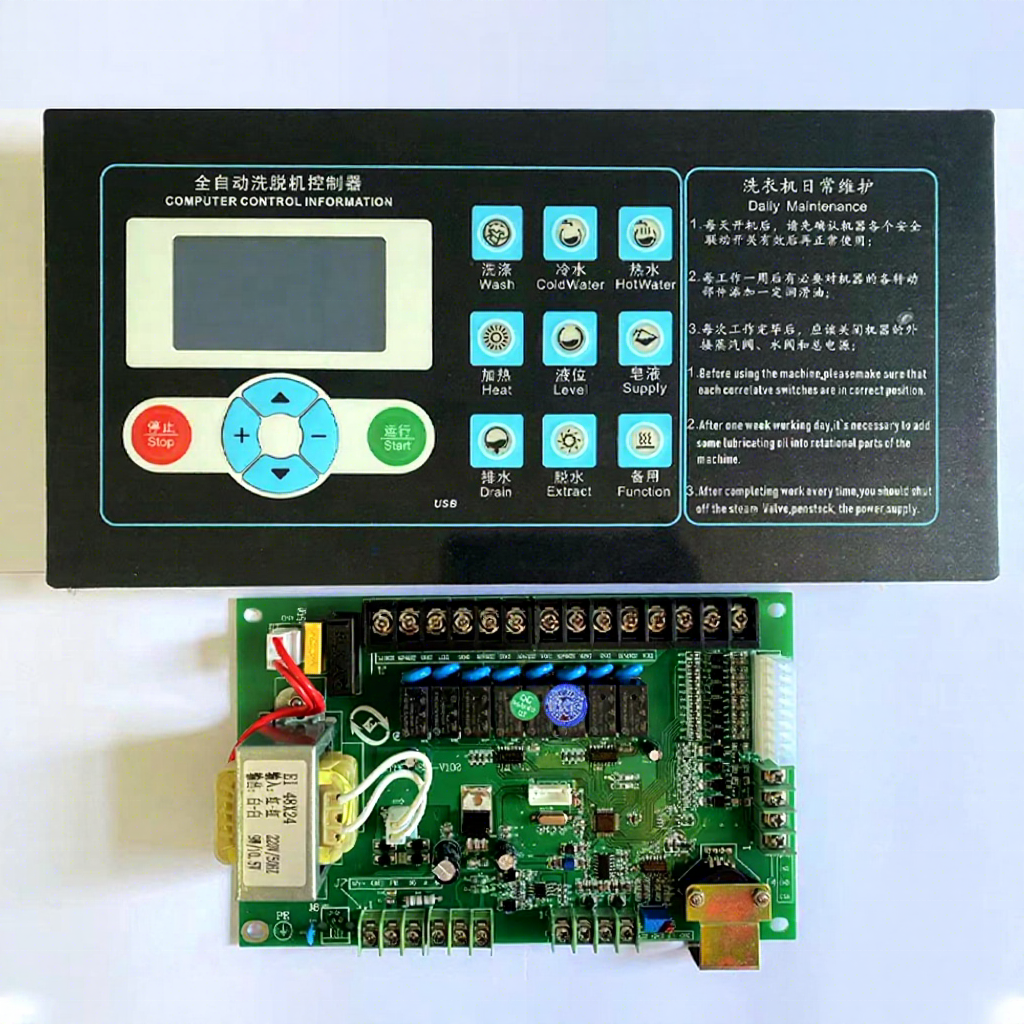

#1 Washing machine controller manufacturer

Domain Est. 2020

Website: elecontro.com

Key Highlights: We specialize in designing and manufacturing state-of-the-art control panels for various types of washing machines, ensuring reliability, efficiency, and ……

#2 Washing Machine Control Board

Domain Est. 1999

Website: geapplianceparts.com

Key Highlights: $7.95 delivery 30-day returnsWashing Machine Control Board · About this Product · Features · Claims & Certifications · Manuals & Downloads · Specs & Details · Ratings and Q&A · Acc…

#3 Washing Machine Control Board

Domain Est. 2002

Website: en.szhittech.com

Key Highlights: The intelligent control system for washing machines consists of an integrated main control board with variable frequency motor control, a display interface ……

#4 Washing Machine Control Boards

Domain Est. 2008

#5 Washing Machine

Domain Est. 2010

Website: circuitboardmedics.com

Key Highlights: 1–6 day deliveryThis is a repair service for an Alliance Laundry Systems washing machine control board, part number 202392, that is experiencing issues. Our repairs are ……

Expert Sourcing Insights for Washing Machine Control Board

H2: 2026 Market Trends for Washing Machine Control Boards

The global market for washing machine control boards is poised for significant transformation by 2026, driven by technological innovation, increasing demand for smart appliances, and evolving consumer preferences. Control boards—central to modern washing machine functionality—serve as the “brain” of the appliance, managing operations such as cycle selection, motor control, water intake, and fault diagnostics. Several key trends are expected to shape the industry landscape in 2026:

-

Growth in Smart and IoT-Enabled Appliances

The integration of Internet of Things (IoT) technology into home appliances is a major driver for the control board market. By 2026, smart washing machines with Wi-Fi connectivity, remote monitoring, and predictive maintenance capabilities are expected to dominate. Control boards will need to support advanced communication protocols (e.g., Wi-Fi, Bluetooth, Zigbee), cloud integration, and mobile app interoperability. This shift is fueled by rising consumer demand for convenience and energy efficiency. -

Increased Adoption of AI and Machine Learning

Artificial intelligence (AI) is enhancing washing machine performance by enabling load sensing, water optimization, and adaptive wash cycles. Control boards in 2026 will likely incorporate microprocessors capable of running lightweight AI algorithms to improve washing efficiency and reduce wear and tear. For example, AI-powered control systems can detect fabric types and adjust settings automatically, requiring more sophisticated control board designs. -

Focus on Energy Efficiency and Sustainability

With global emphasis on reducing carbon emissions and energy consumption, regulatory standards (such as ENERGY STAR and EU Ecodesign Directive) are pushing manufacturers to produce more efficient washing machines. Control boards will play a crucial role in optimizing motor speed, water heating, and cycle duration. In 2026, expect wider use of inverter-compatible control boards that work with variable-speed motors to minimize energy use. -

Rising Demand in Emerging Markets

Asia-Pacific, particularly countries like India, Indonesia, and Vietnam, will see robust growth in washing machine ownership due to urbanization and rising disposable incomes. This will increase demand for cost-effective yet reliable control boards. Manufacturers may develop region-specific variants with simplified features to cater to price-sensitive markets while maintaining durability and performance. -

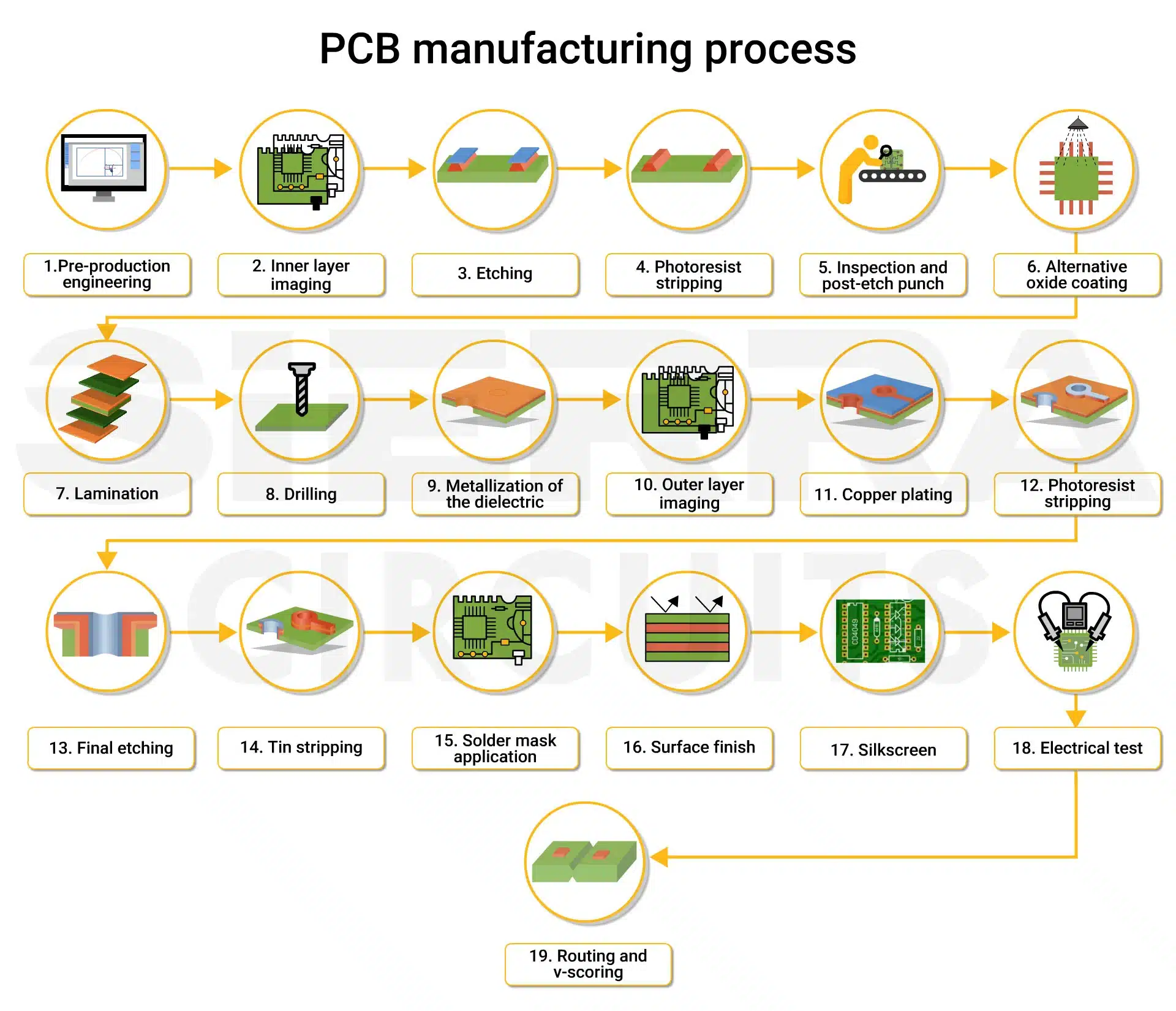

Component Miniaturization and Integration

Control boards are becoming smaller and more integrated, combining multiple functions (e.g., motor control, user interface, diagnostics) into a single printed circuit board (PCB). By 2026, advancements in semiconductor technology and surface-mount device (SMD) manufacturing will enable higher component density, improving reliability and reducing production costs. -

Supply Chain Resilience and Localization

Ongoing global supply chain disruptions have prompted appliance manufacturers to localize production. In 2026, we can expect an increase in regional manufacturing of control boards, especially in Southeast Asia and Eastern Europe, to reduce dependency on single-source suppliers and mitigate risks. -

Growth in Aftermarket and Repair Services

As washing machines become more complex, demand for replacement control boards in the aftermarket is rising. Online retail platforms and third-party repair services will drive growth in this segment. By 2026, universal or programmable control boards may gain traction, allowing easier replacements across different machine models. -

Cybersecurity Considerations

With increased connectivity, control boards in smart washing machines may become vulnerable to cyber threats. In 2026, manufacturers will need to embed security features such as firmware encryption, secure boot processes, and over-the-air (OTA) update capabilities to protect user data and device integrity.

In conclusion, the 2026 washing machine control board market will be defined by intelligence, connectivity, efficiency, and resilience. Companies that invest in R&D, embrace modular designs, and align with global sustainability goals will be best positioned to capture growth in this dynamic sector.

Common Pitfalls When Sourcing Washing Machine Control Boards (Quality and IP)

Sourcing washing machine control boards involves several risks, particularly concerning product quality and intellectual property (IP) rights. Being aware of these pitfalls can help avoid costly mistakes and legal complications.

Quality-Related Pitfalls

Inconsistent Component Standards

Many suppliers, especially in unregulated markets, use substandard or counterfeit electronic components. This includes using recycled ICs or resistors with incorrect tolerances, which can lead to premature failure, unreliable performance, or safety hazards.

Lack of Compliance with Safety Standards

Control boards must meet international safety standards such as IEC 60335 (safety of household appliances). Sourcing from non-certified manufacturers may result in boards that do not comply, increasing liability and risk of product recalls.

Poor Manufacturing Processes

Without proper quality control—such as automated optical inspection (AOI), in-circuit testing (ICT), or functional testing—defective boards may pass visual inspection but fail in real-world operation. Poor soldering, incorrect firmware programming, or missing components are common issues.

Inadequate Environmental Protection

Control boards in washing machines are exposed to moisture, heat, and vibration. Boards without proper conformal coating or robust PCB design may degrade quickly in humid environments, leading to corrosion and short circuits.

Insufficient Testing and Burn-In Procedures

Reputable manufacturers conduct burn-in tests and functional validation under simulated operating conditions. Sourcing from suppliers who skip these steps increases the risk of early field failures.

Intellectual Property (IP) Risks

Unauthorized Cloning or Copying of Designs

Many generic control boards are reverse-engineered copies of original equipment manufacturer (OEM) designs. Using these may infringe on patents, copyrights, or design rights, exposing the buyer to legal action, especially in markets with strong IP enforcement.

Use of Unlicensed Firmware or Software

Control boards often include proprietary firmware. Suppliers may use illegally copied or modified firmware without proper licensing, which can lead to software instability and expose the buyer to intellectual property litigation.

Lack of Documentation and Traceability

Legitimate suppliers provide full technical documentation, including schematics, BOMs, and firmware versions. Unscrupulous suppliers often withhold this information, making it difficult to verify IP ownership or ensure long-term support.

Hidden Dependencies on Proprietary Protocols

Some control boards rely on proprietary communication protocols (e.g., for diagnostics or smart features). Using cloned boards may violate licensing agreements or result in non-interoperability with original systems.

Mitigation Strategies

- Source from reputable suppliers with verifiable certifications (e.g., ISO 9001, UL, CE).

- Require full compliance documentation including RoHS, REACH, and safety certifications.

- Conduct independent quality audits or third-party testing before mass procurement.

- Verify IP ownership through legal review of design rights and firmware licenses.

- Use contractual safeguards such as indemnity clauses for IP infringement.

Avoiding these pitfalls ensures reliable product performance and reduces legal and operational risks in the supply chain.

Logistics & Compliance Guide for Washing Machine Control Board

This guide outlines the essential logistics and compliance considerations for the international shipment, handling, and regulatory adherence of Washing Machine Control Boards.

Product Classification & Documentation

Ensure accurate classification of the Washing Machine Control Board under the Harmonized System (HS) Code. Typical classifications fall under 8537 (boards for electrical control or regulation) or 8504 (power supply units), depending on primary function. Confirm the correct tariff code with local customs authorities. Required documentation includes a detailed commercial invoice, packing list, bill of lading/air waybill, and Certificate of Origin. Include technical specifications and a bill of materials (BOM) for customs verification.

Packaging & Handling Requirements

Package control boards in anti-static materials to prevent electrostatic discharge (ESD) damage. Use rigid inner packaging (e.g., molded foam or clamshells) within sturdy outer cartons with sufficient cushioning. Clearly label packages with ESD-sensitive warnings, handling instructions (e.g., “Fragile,” “This Side Up”), and product identifiers (model number, batch/lot code). Avoid moisture exposure by using desiccant packs and moisture barrier bags if necessary.

Transportation & Storage Conditions

Transport control boards under controlled environmental conditions. Maintain temperatures between 0°C and 40°C and relative humidity below 75% to prevent condensation and component degradation. Avoid exposure to direct sunlight, dust, and corrosive atmospheres. Store in a clean, dry warehouse with shelves elevated off the floor. Implement a first-in, first-out (FIFO) inventory system to minimize aging of electronic components.

Regulatory Compliance

Ensure compliance with international and destination-country regulations. Key standards include:

- RoHS (EU): Restriction of Hazardous Substances. Confirm lead, mercury, cadmium, and other restricted substances are below allowable limits.

- REACH (EU): Registration, Evaluation, Authorization, and Restriction of Chemicals. Declare substances of very high concern (SVHC) if present above thresholds.

- WEEE (EU): Waste Electrical and Electronic Equipment. Provide take-back and recycling information.

- CE Marking: Required for EU market access, indicating conformity with health, safety, and environmental protection standards.

- FCC (USA): Electromagnetic interference (EMI) compliance for digital devices.

- KC (South Korea), PSE (Japan), CCC (China): Country-specific safety and electromagnetic compatibility certifications as applicable.

Provide a Declaration of Conformity (DoC) for each market.

Import/Export Controls

Verify if the control board contains encryption or dual-use components that may require export licenses (e.g., under EAR in the U.S. or EU Dual-Use Regulation). Screen all parties (suppliers, customers, intermediaries) against government sanctions lists. Maintain records of compliance screenings and export authorizations for audit purposes.

After-Sales & Warranty Logistics

Establish a reverse logistics process for defective or returned units. Include clear return authorization (RMA) procedures, secure packaging for return shipments, and data capture for failure analysis. Retain compliance documentation for the product’s lifecycle to support warranty and regulatory audits.

Environmental & Sustainability Considerations

Design packaging using recyclable materials and minimize excess volume/weight to reduce carbon footprint. Comply with local producer responsibility schemes for electronics. Provide end-of-life disposal guidance in user documentation or on the manufacturer’s website.

Conclusion for Sourcing Washing Machine Control Boards

In conclusion, sourcing washing machine control boards requires a strategic approach that balances cost, quality, reliability, and supply chain efficiency. After evaluating various suppliers, manufacturing locations, and technical specifications, it is evident that partnering with reputable manufacturers—whether established OEMs or qualified third-party suppliers—is essential to ensure compatibility, durability, and compliance with industry standards.

Key considerations such as board specifications (voltage, compatibility with washing machine models), certification standards (e.g., CE, RoHS), production capacity, lead times, and after-sales support play a critical role in making an informed sourcing decision. Additionally, conducting supplier audits, sample testing, and ongoing quality control checks can significantly reduce the risk of defects and field failures.

For long-term success, it is recommended to develop strong relationships with a diversified supplier base to mitigate risks related to geopolitical issues, supply chain disruptions, or component shortages. Investing in quality upfront not only enhances product performance and customer satisfaction but also reduces warranty claims and service costs over time.

Ultimately, a well-structured sourcing strategy for washing machine control boards will contribute to improved operational efficiency, product reliability, and competitive advantage in the home appliance market.