The global washing machine market is experiencing steady growth, driven by rising disposable incomes, urbanization, and increasing demand for energy-efficient appliances. According to a report by Mordor Intelligence, the washer market is projected to grow at a CAGR of over 4.5% from 2023 to 2028, fueled by technological advancements and a shift toward smart, water-efficient models. This expansion directly impacts the demand for high-quality washer components, including drain tubes—critical parts responsible for reliable water evacuation and system longevity. As manufacturers strive to meet stringent performance and durability standards, the need for specialized drain tube suppliers has intensified. Sourcing from reliable manufacturers ensures compatibility, resistance to wear and corrosion, and compliance with global regulations. To support procurement teams and OEMs in making informed decisions, we’ve identified the top 7 washer drain tube manufacturers leading in innovation, production capacity, and global supply chain integration.

Top 7 Washer Drain Tube Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

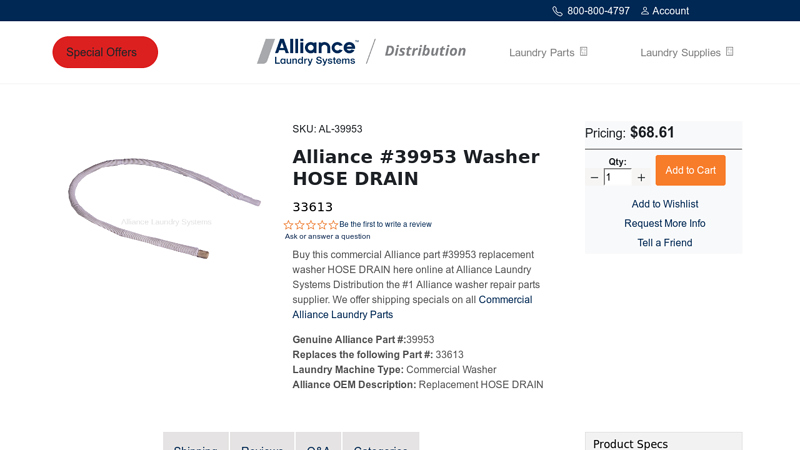

#1 Alliance #39953 Washer HOSE DRAIN

Domain Est. 1998

Website: parts.alliancelaundry.com

Key Highlights: In stock 4-day deliveryGenuine Alliance Part #:39953 · Replaces the following Part #: 33613 · Laundry Machine Type: Commercial Washer · Alliance OEM Description: Replacement HOSE D…

#2 Sioux Chief: Rough Plumbing Products

Domain Est. 1997

Website: siouxchief.com

Key Highlights: SiouxChief.com. American made rough plumbing products that save time and money on the job….

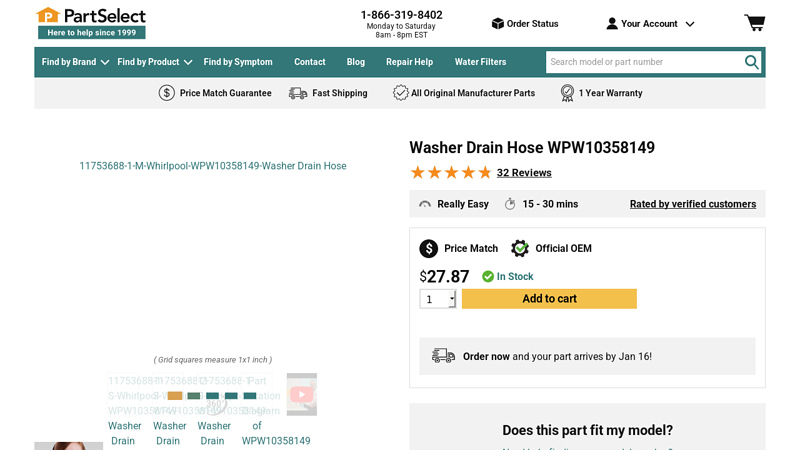

#3 Official Whirlpool WPW10358149 Washer Drain Hose

Domain Est. 1999

Website: partselect.com

Key Highlights: In stock Rating 4.8 (32) OEM WPW10358149 – Washer Drain Hose – replacement. We offer authentic parts, and the expert advice you need to complete the repair….

#4 Washer Drain Hose Assembly Aem AEM73732901

Domain Est. 2004

Website: ereplacementparts.com

Key Highlights: 1–2 day delivery 365-day returnsBuy the official LG Washer Drain Hose Assembly Aem AEM73732901 replacement – Use our model diagrams, repair help, and video tutorials to help get th…

#5 Flexible Drainage Pipe and Washing Machine Drain Hose

Domain Est. 1997

Website: crushproof.com

Key Highlights: Stretchable Drain Hoses & Tubes. Crushproof® Tubing provides drain hoses, tubes, and caps to some of the biggest names in the floor cleaning industry….

#6 Washing Machine Drain Rubber Hose

Domain Est. 2002

Website: thermoid.com

Key Highlights: The flexible, easy to use kink resistance Washing Machine Drain hose makes it ideal for curves and bends. This hose is designed to withstand the heat and ……

#7 Washing Machine Drain Hose

Domain Est. 1996

Website: doitbest.com

Key Highlights: 2-day delivery · Free 30-day returnsBest Washing Machine Drain Hose at a hardware store near you. Buy Do it, Abbott Rubber Washing Machine Hoses & Connectors at lowest prices….

Expert Sourcing Insights for Washer Drain Tube

H2: 2026 Market Trends for Washer Drain Tubes

The global market for washer drain tubes is poised for steady growth and transformation by 2026, driven by advancements in appliance technology, increasing demand for energy-efficient washing machines, and evolving consumer preferences. Here are key trends shaping the washer drain tube market in 2026:

1. Rising Demand for High-Efficiency Washing Machines

As consumers and governments prioritize water and energy conservation, high-efficiency (HE) washing machines are gaining popularity. These machines require optimized drainage systems, including durable and flexible drain tubes capable of handling variable water flow and debris. This trend is fueling innovation in drain tube materials and design to ensure reliability and prevent clogging.

2. Growth in Smart and Connected Appliances

By 2026, the integration of IoT in home appliances is expanding. Smart washing machines equipped with self-diagnostic features can detect drainage issues early. This shift is influencing drain tube manufacturers to focus on compatibility with sensor-based systems and develop tubes that minimize maintenance alerts by enhancing flow efficiency and resistance to blockages.

3. Shift Toward Sustainable and Recyclable Materials

Environmental regulations and consumer awareness are pushing manufacturers to adopt eco-friendly materials. In 2026, washer drain tubes are increasingly being made from recyclable thermoplastics and bio-based polymers. Companies are investing in sustainable production methods to reduce carbon footprints and meet global environmental standards.

4. Expansion in Emerging Markets

Urbanization and rising disposable incomes in regions such as Asia-Pacific, Latin America, and Africa are driving demand for home appliances, including washing machines. This growth is directly increasing the need for replacement and OEM washer drain tubes, creating new market opportunities for manufacturers and suppliers.

5. Focus on Durability and Anti-Microbial Properties

With increasing concerns over mold, mildew, and bacterial buildup in drain systems, manufacturers are incorporating anti-microbial additives into drain tube materials. In 2026, premium drain tubes feature enhanced resistance to degradation and biofilm formation, improving hygiene and extending product lifespan.

6. Aftermarket and Replacement Segment Growth

As the installed base of washing machines grows, so does the need for replacement parts. The aftermarket for washer drain tubes is expanding, supported by e-commerce platforms and DIY repair trends. By 2026, easy-to-install, universal-fit drain tubes are gaining traction among consumers and service technicians.

7. Supply Chain Resilience and Localization

Post-pandemic supply chain disruptions have prompted manufacturers to localize production and diversify sourcing. In 2026, regional manufacturing hubs for washer components, including drain tubes, are emerging to reduce dependency on single geographies and ensure timely delivery.

In conclusion, the washer drain tube market in 2026 reflects broader trends in sustainability, smart technology integration, and global market expansion. Manufacturers who innovate in materials, design, and supply chain efficiency will be best positioned to capitalize on these evolving dynamics.

Common Pitfalls Sourcing Washer Drain Tube (Quality, IP)

Sourcing a reliable washer drain tube involves navigating several potential pitfalls, especially concerning quality and Ingress Protection (IP) ratings. Overlooking these can lead to premature failures, safety hazards, and costly replacements. Key issues include:

Inadequate Material Quality

Many low-cost drain tubes use substandard rubber or PVC that degrades quickly when exposed to hot water, detergents, or UV light. This can result in cracking, swelling, or brittleness, leading to leaks or ruptures. Always verify material specifications (e.g., EPDM rubber) that resist chemical and thermal stress.

Misleading or Missing IP Ratings

Some suppliers claim IP67 or similar ratings without certification. Drain tubes in washing machines must prevent water ingress into electrical compartments. Without a verified IP rating, there’s a risk of moisture penetration causing short circuits or corrosion. Ensure third-party test reports accompany IP claims.

Poor Dimensional Accuracy

Tubes with inconsistent inner/outer diameters or lengths may not fit standard pumps or housings, leading to leaks or installation challenges. Tolerance deviations can also affect flow efficiency and increase backpressure.

Insufficient Pressure and Temperature Resistance

Not all tubes are rated for the pressure surges or temperature extremes (e.g., 70–90°C) common in modern wash cycles. Using a tube outside its operational range can cause bursting or deformation during use.

Lack of Compliance Documentation

Reputable suppliers should provide material safety data sheets (MSDS), RoHS, and REACH compliance. Missing documentation raises red flags about traceability and regulatory adherence, especially for international markets.

Inconsistent Batch-to-Batch Quality

Without strict quality control, performance can vary between production runs. Implement incoming inspections or audit supplier quality management systems (e.g., ISO 9001) to mitigate this risk.

Avoiding these pitfalls requires thorough vetting of suppliers, demanding certified test data, and conducting sample validation under real-world conditions.

Logistics & Compliance Guide for Washer Drain Tube

Product Classification and Tariff Information

The washer drain tube, typically made of rubber or flexible plastic, is used in laundry appliances to channel wastewater from the washing machine to the drainage system. For international shipping and customs compliance, proper classification is essential.

- Harmonized System (HS) Code: 8481.80 or 4008.21 (depends on material—rubber vs. plastic)

- If primarily rubber: HS 4008.21.00 (Tubes, of vulcanized rubber)

- If thermoplastic: HS 3917.33.00 (Plastic tubes, pipes, and hoses)

- If classified as a washing machine part: HS 8451.21.00 (Parts of washing machines)

- Duty Rates: Vary by country; confirm based on destination and trade agreements (e.g., USMCA, EU preferences).

- Country of Origin Labeling: Required per destination regulations (e.g., “Made in China” must be clearly marked).

Packaging and Shipping Requirements

Proper packaging ensures product integrity during transit and compliance with carrier and regulatory standards.

- Packaging Standards:

- Use moisture-resistant, durable packaging (e.g., polyethylene bags inside corrugated cardboard boxes).

- Clearly label with product name, part number, quantity, and handling instructions (e.g., “Fragile,” “Do Not Stack”).

- Shipping Documentation:

- Commercial Invoice (with HS code, value, weight, and origin)

- Packing List (itemized per shipment)

- Bill of Lading (for ocean freight) or Air Waybill (for air freight)

- Hazard Classification: Non-hazardous; no special handling required under IATA/IMDG.

Import/Export Compliance

Adherence to international trade laws and regional regulations ensures smooth customs clearance.

- Export Controls:

- Generally not subject to ITAR or EAR restrictions.

- Confirm no dual-use applications (e.g., industrial or military use).

- Import Requirements by Region:

- United States: CBP clearance; possible FDA review if rubber contains food-grade materials (unlikely).

- European Union: CE marking not required unless part of an integrated appliance. However, REACH and RoHS compliance is mandatory.

- Canada: Complies with CBSA tariff regulations; ensure accurate NMF (Non-Manufactured in Canada) marking if applicable.

- Australia/New Zealand: Complies with ABF import standards; check ACIC product safety requirements if bundled with appliances.

Environmental and Safety Regulations

Compliance with chemical and environmental standards is critical, especially for polymer-based components.

- RoHS (EU): Restricts use of lead, cadmium, mercury, and other hazardous substances. Ensure rubber/plastic compounds are RoHS-compliant.

- REACH (EU): Requires declaration of Substances of Very High Concern (SVHC). Confirm no banned phthalates or carcinogens in materials.

- California Proposition 65: If sold in California, assess for chemicals known to cause cancer or reproductive harm (e.g., certain plasticizers). Label if required.

- WEEE (EU): Not applicable to individual spare parts unless marketed as standalone electrical equipment.

Labeling and Traceability

Accurate labeling supports compliance, inventory management, and end-user safety.

- Required Labels:

- Manufacturer name and address

- Part number and model compatibility (e.g., “Fits Model X, Y, Z”)

- Material composition (e.g., “PVC-Free,” “Recycled Content”)

- Batch/lot number for traceability

- Barcoding: UPC (North America) or EAN (global) for retail distribution.

Storage and Handling

Maintain product integrity through appropriate warehousing practices.

- Temperature Range: Store between 10°C and 35°C; avoid direct sunlight and extreme heat to prevent warping or cracking.

- Shelf Life: Rubber tubes may degrade over time; recommend rotation within 3–5 years.

- Stacking Limits: Follow packaging guidelines to prevent deformation (typically no more than 5–6 cartons high).

Returns and Reverse Logistics

Establish clear procedures for defective or excess inventory returns.

- Return Authorization (RA): Require RA number for all returns.

- Inspection Protocol: Check for damage, contamination, or tampering before restocking.

- Recycling/Disposal: Partner with certified e-waste or plastic recyclers for non-reusable tubes.

Summary

The washer drain tube, while a simple component, requires attention to classification, material compliance, and logistical best practices. By following this guide, businesses can ensure regulatory adherence, reduce customs delays, and maintain supply chain efficiency across global markets.

Conclusion for Sourcing Washer Drain Tube:

After evaluating various sourcing options for a washer drain tube, it is clear that a balanced approach considering quality, cost, availability, and compatibility is essential. Original Equipment Manufacturer (OEM) parts offer guaranteed compatibility and durability but often come at a higher price point. Aftermarket alternatives provide cost savings and broader availability, though quality can vary between suppliers. Online marketplaces and home improvement retailers offer convenience and competitive pricing, while local appliance stores may provide immediate access and technical support.

For optimal results, sourcing should prioritize OEM or reputable aftermarket brands that meet industry standards to ensure long-term performance and avoid leaks or damage. Additionally, verifying the correct part number and specifications for the specific washer model is critical to ensure proper fit and function. Establishing relationships with reliable suppliers and maintaining a small inventory of commonly needed parts can also enhance operational efficiency, particularly in repair and maintenance settings.

In conclusion, a strategic sourcing approach that balances cost-effectiveness with reliability and compatibility will ensure dependable performance of the washer drain tube while minimizing downtime and repair costs.