The global plumbing fixtures market is experiencing steady expansion, fueled by rising urbanization, residential construction, and increasing demand for water-efficient systems. According to Mordor Intelligence, the global plumbing fixtures market was valued at USD 78.9 billion in 2023 and is projected to grow at a CAGR of 4.5% from 2024 to 2029. This growth trajectory underscores the increasing importance of specialized plumbing components, including washer boxes—critical elements in modern irrigation and plumbing systems that ensure leak-free connections and water conservation. With North America and Europe leading in infrastructure upgrades and smart water management adoption, manufacturers of washer box plumbing systems are innovating to meet stringent regulatory standards and performance expectations. As demand rises, seven key manufacturers have emerged at the forefront, combining engineering precision, durable materials, and compliance with industry certifications to dominate the competitive landscape.

Top 7 Washer Box Plumbing Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

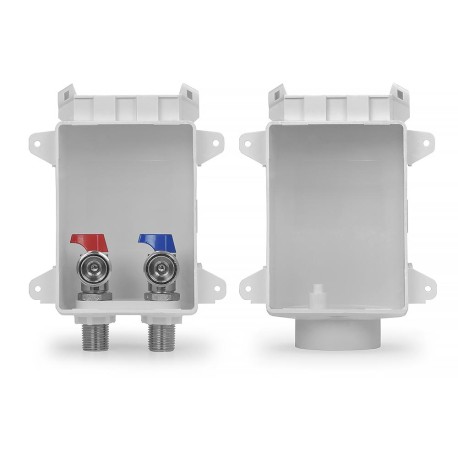

#1 Sioux Chief: Rough Plumbing Products

Domain Est. 1997

Website: siouxchief.com

Key Highlights: We are an American manufacturer. Sioux Chief believes in making our products right here in America. American manufacturing is important….

#2 Washing Machine Outlet Boxes

Domain Est. 1995

Website: plumbingsupply.com

Key Highlights: Free delivery over $98.99 30-day returnsThese washing machine outlet boxes provide quick, safe, water supply shut-off access. Complete with knockouts for waste or water lines….

#3 Oatey® Quadtro® 1/4

Domain Est. 1996

#4 LSP

Domain Est. 1996

Website: lspproducts.com

Key Highlights: LSP Products Group (LSP) was founded by plumbers over 45 years ago with a focus on designing and manufacturing innovative plumbing products….

#5 Acorn Engineering

Domain Est. 1996

Website: acorneng.com

Key Highlights: Acorn Engineering Company manufactures plumbing fixtures, products, and systems for institutional and commercial markets….

#6 Dual-Drain Washing Machine Outlet Box

Domain Est. 2001

Website: eastmanplumbing.com

Key Highlights: It is a one-piece box built with high-impact non-corrosive plastic. A right side or left side drain can be installed. It has a recessed design that accommodates ……

#7 Guy Gray

Domain Est. 2021 | Founded: 1958

Website: ipsplumbingproducts.com

Key Highlights: Established in 1958, Guy Gray is well known throughout the plumbing industry as the Original Washing Machine Outlet Box. Provided by IPS Corp Plumbing….

Expert Sourcing Insights for Washer Box Plumbing

H2: 2026 Market Trends for Washer Box Plumbing

The washer box plumbing market is poised for notable transformation by 2026, driven by advancements in building standards, sustainability demands, and evolving consumer preferences. Washer boxes—integral components that house water supply valves, drain connections, and sometimes vacuum breakers for laundry appliances—are increasingly being reimagined to meet modern efficiency, safety, and design requirements.

One of the dominant trends shaping the 2026 market is the integration of advanced leak prevention technologies. With water damage from faulty laundry connections ranking among the top causes of residential insurance claims, manufacturers are incorporating automatic shut-off valves, smart sensors, and water monitoring systems directly into washer box units. These innovations are expected to gain traction as smart home ecosystems expand, and consumers demand greater control over household water usage.

Another significant trend is the growing emphasis on compliance with plumbing codes and water conservation standards. Jurisdictions across North America and Europe are tightening regulations around backflow prevention and water efficiency. The International Plumbing Code (IPC) and Uniform Plumbing Code (UPC) now require accessible and code-compliant service outlets for washing machines, including proper air gaps and accessible shut-off valves—features that modern washer boxes are being engineered to support.

Sustainability is also influencing product development. By 2026, there is an increasing shift toward washer boxes made from recyclable or low-impact materials, such as lead-free brass and engineered polymers. Additionally, modular and retrofit-friendly designs are gaining popularity, allowing for easier installation in both new construction and renovation projects, reducing construction waste and labor time.

The demand for aesthetically integrated plumbing solutions is another driver. Homeowners and designers are favoring concealed or flush-mounted washer boxes that blend seamlessly into walls, aligning with minimalist interior trends. These units often feature durable finishes and customizable faceplates, catering to both residential and multi-family housing markets.

Lastly, the rise of prefabricated and modular construction is impacting the washer box market. As off-site building methods grow in popularity for their speed and quality control, standardized, pre-assembled plumbing chases that include integrated washer boxes are becoming commonplace. This shift is pushing manufacturers to standardize dimensions and connections for compatibility across modular systems.

In summary, the 2026 washer box plumbing market will be defined by smart technology integration, regulatory compliance, sustainable materials, design innovation, and alignment with modern construction practices. Companies that prioritize these trends are likely to lead in product adoption and market share.

Common Pitfalls Sourcing Washer Box Plumbing (Quality, IP)

Sourcing washer box plumbing components involves several critical considerations, particularly regarding product quality and intellectual property (IP). Overlooking these aspects can lead to performance issues, safety hazards, legal risks, and increased long-term costs. Below are key pitfalls to avoid:

Poor Material Quality and Durability

One of the most prevalent issues is selecting washer boxes made from substandard materials. Low-quality plastics or thin-gauge metals may crack, leak, or degrade prematurely when exposed to water, detergents, and temperature fluctuations. This compromises system integrity and can lead to water damage, mold growth, and costly repairs. Always verify material specifications—such as ABS or high-impact polystyrene—and look for certifications indicating compliance with plumbing standards (e.g., UPC, NSF).

Inadequate Ingress Protection (IP) Rating

Washer boxes in utility areas may be exposed to splashes or high humidity, especially in commercial or multi-residential settings. Sourcing units without appropriate IP ratings (e.g., IPX4 for splash resistance) risks water ingress into electrical components if the box integrates GFCI outlets or data ports. This creates serious safety hazards, including short circuits or electrocution. Ensure the IP rating matches the installation environment, particularly in damp or outdoor-adjacent locations.

Non-Compliance with Local Plumbing Codes

Many suppliers offer generic or internationally certified washer boxes that may not meet regional plumbing codes. Using non-compliant products can result in failed inspections, project delays, and liability issues. Always confirm that the washer box meets local requirements for backflow prevention, air gaps, and drain configurations. For example, U.S. installations often require specific anti-siphon features not mandated elsewhere.

Lack of Intellectual Property Due Diligence

Sourcing from manufacturers who replicate patented designs or use counterfeit trademarks exposes buyers to legal risks. Infringed products may be seized at customs or lead to litigation, especially in regulated markets. Conduct IP checks by verifying trademarks, design patents, and utility patents associated with leading brands. Work with reputable suppliers who provide IP indemnification and can prove legal manufacturing rights.

Inconsistent Quality Control from Overseas Suppliers

Importing washer boxes from low-cost regions often introduces variability in quality due to lax manufacturing oversight. Without proper auditing, you may receive inconsistent thread fittings, misaligned knockouts, or poor seals. Mitigate this by requiring third-party inspection reports (e.g., SGS, Intertek) and conducting sample testing before bulk orders.

Misleading Marketing Claims

Some suppliers exaggerate product capabilities, such as claiming “universal fit” or “code-compliant” without substantiation. These vague claims can mislead buyers into purchasing unsuitable products. Always request technical documentation, test reports, and reference installations to validate performance claims.

By proactively addressing these pitfalls—focusing on material quality, appropriate IP ratings, code compliance, IP legitimacy, and supply chain transparency—buyers can ensure reliable, safe, and legally sound washer box plumbing installations.

Logistics & Compliance Guide for Washer Box Plumbing

This guide outlines the essential logistics and compliance considerations when installing or working with washer box plumbing systems. Adhering to these standards ensures safety, functionality, and legal compliance.

Regulatory Compliance Standards

All washer box plumbing installations must comply with local, state, and national plumbing codes. Key regulatory frameworks include the International Plumbing Code (IPC), Uniform Plumbing Code (UPC), and any applicable amendments from local authorities having jurisdiction (AHJ). Installations must also meet requirements set by the Environmental Protection Agency (EPA) for water efficiency, particularly regarding water discharge and backflow prevention.

Required Permits and Inspections

Prior to installation, obtain necessary plumbing permits from the local building department. A pre-installation inspection may be required to verify system design compliance. After installation, a post-installation inspection must be scheduled to ensure all components—including water supply lines, drain connections, and ventilation—meet code requirements. Failure to secure permits or pass inspections can result in fines or mandated system modifications.

Material and Product Specifications

Only approved materials may be used for washer box plumbing. Supply lines must be made from code-compliant materials such as PEX, copper, or CSST, while drain piping must be constructed of ABS or PVC with a minimum diameter of 2 inches. The washer box unit itself must be listed by a recognized testing laboratory (e.g., IAPMO, UL) and include proper air gaps or vacuum breakers to prevent backflow contamination.

Installation Best Practices

Install the washer box at the recommended height (typically 36–42 inches above the floor) to accommodate standard washing machine hookups. Ensure hot and cold water supply valves are accessible and clearly labeled. The drain standpipe must be securely fastened, extend 18–42 inches above the trap, and include a proper P-trap to maintain water seal and prevent sewer gas intrusion. Slope drain lines at a minimum of ¼ inch per foot toward the main drainage system.

Backflow Prevention Requirements

A critical compliance measure is backflow prevention. Washer boxes must incorporate an air gap or hose connection vacuum breaker (HCVB) installed on both hot and cold supply lines. The air gap must be at least twice the diameter of the supply pipe and never submerged. This prevents contaminated laundry water from siphoning back into the potable water system.

Water Efficiency and Environmental Considerations

Comply with water conservation regulations by using washer boxes designed for high-efficiency (HE) washing machines. Verify that supply valves and hoses are rated for reduced water pressure and flow rates. Properly dispose of packaging and excess materials in accordance with local environmental guidelines. Recycle PVC and metal components whenever possible.

Documentation and Record Keeping

Maintain detailed records of all materials used, including manufacturer specifications, model numbers, and compliance certifications. Keep copies of permits, inspection reports, and as-built diagrams for at least five years. Provide the property owner with a compliance certificate and maintenance guidelines to ensure continued adherence to plumbing standards.

Maintenance and Compliance Audits

Schedule annual inspections to check for leaks, corrosion, and proper trap seal integrity. Replace worn supply hoses every five years or as recommended by the manufacturer. Conduct periodic compliance audits to verify that the system still meets current code requirements, especially after renovations or changes in local regulations.

In conclusion, sourcing a washer box plumbing system requires careful consideration of quality, compatibility, local plumbing codes, and installation requirements. It is essential to select a durable, code-compliant unit that fits the specific needs of the laundry area, including proper inlet and drain configurations. Whether opting for a basic model or one with added features like flood protection or recessed design, investing in a reliable washer box from a reputable supplier ensures long-term performance, leak prevention, and easier maintenance. Proper sourcing ultimately supports a safe, efficient, and code-compliant plumbing installation.